The intricacies of agricultural machinery play a crucial role in enhancing efficiency and productivity on the field. Familiarizing oneself with the various elements that constitute these machines is essential for optimal performance and maintenance.

In this section, we will explore the essential components of a specific type of agricultural implement, providing clarity on their functions and interrelationships. Recognizing how each piece contributes to the overall operation can lead to better troubleshooting and informed decision-making.

Through a detailed examination of the mechanical layout, users can gain insights into the assembly and functionality of the device. This understanding empowers operators to make adjustments and repairs, ensuring longevity and effectiveness in their agricultural practices.

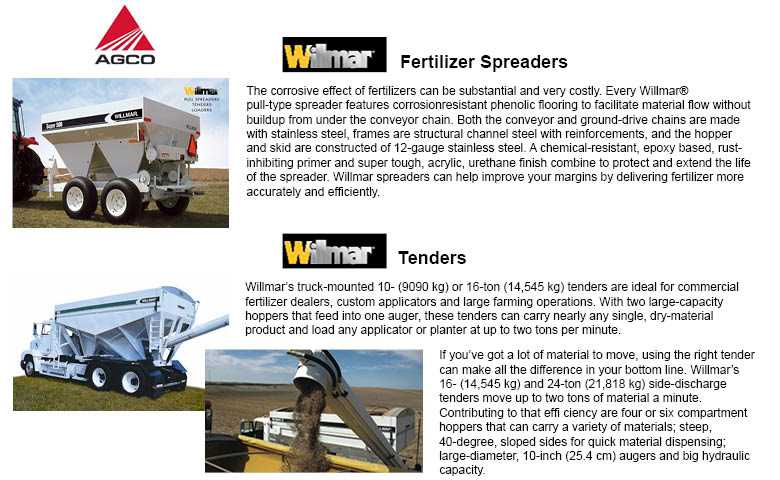

Understanding Willmar 500 Fertilizer Spreaders

This section delves into the essential components and functioning of a specific type of agricultural equipment designed for efficient distribution of nutrients across various terrains. These machines play a crucial role in modern farming practices, ensuring even application and maximizing crop yield.

Key elements include the mechanism responsible for distributing materials, the structure that supports overall operation, and various controls that enhance usability. A thorough comprehension of these components aids operators in maintaining optimal performance and troubleshooting issues that may arise during usage.

Furthermore, familiarity with the assembly and interaction of individual elements contributes to improved efficiency and productivity. Understanding the relationships between the different sections of the machine allows users to operate it with greater confidence and effectiveness.

Key Components of the Spreader

Understanding the essential elements of a distribution machine is crucial for effective operation and maintenance. Each component plays a vital role in ensuring that materials are evenly distributed across various terrains, contributing to optimal performance and efficiency.

1. Hopper: This is the primary container where the material is stored before being spread. Its design and capacity significantly influence the amount of material that can be handled at one time.

2. Agitator: An integral part of the system, the agitator ensures that the material flows smoothly and evenly from the hopper. It prevents clumping and ensures consistent distribution during operation.

3. Distribution Mechanism: This component is responsible for controlling how the material is released from the hopper. Different types of mechanisms can be used, each offering various spreading patterns and distances.

4. Drive System: The drive system powers the machine, allowing it to operate efficiently. It can be hydraulic, mechanical, or electric, depending on the design and intended use.

5. Wheels and Chassis: The wheels and supporting structure are crucial for mobility and stability. They enable the machine to traverse different types of terrain while maintaining balance and control.

6. Calibration System: This system allows operators to adjust the rate of material application, ensuring that the desired amount is distributed accurately over the intended area.

By familiarizing oneself with these fundamental components, users can enhance their understanding of the machine’s functionality and improve their operational strategies.

Importance of Maintenance for Longevity

Proper upkeep is crucial for ensuring the extended lifespan of any machinery. Regular attention not only enhances performance but also prevents unforeseen breakdowns that can lead to costly repairs. By adhering to a consistent maintenance schedule, operators can safeguard their investment and optimize functionality.

Timely inspections play a pivotal role in identifying wear and tear before it escalates into a significant issue. This proactive approach can reduce downtime and ensure that the equipment operates efficiently, delivering consistent results.

Moreover, routine maintenance fosters safety by ensuring that all components function correctly. Neglecting these practices may result in accidents or malfunctions that jeopardize both the user and the surrounding environment. Investing time in maintenance ultimately pays off through enhanced reliability and productivity.

How to Interpret Component Schematics

In understanding a visual breakdown of machine components, clarity hinges on your ability to decipher symbols, shapes, and relationships depicted. These graphics delineate intricate assemblies into discrete units, enabling precise identification and replacement of constituent parts.

Key Elements in Schematic Understanding

At the core of schematic comprehension lies a structured depiction where abstract symbols convey concrete components. Each symbol embodies a particular element or function, serving as a gateway to comprehensive part recognition.

| Symbol | Function | Description |

|---|---|---|

| ○ | Connector | Represents junctions linking different parts or systems. |

| ▢ | Switch | Indicates an on-off mechanism affecting operational states. |

| Δ | Motor | Denotes a power-driven component for mechanical operation. |

Through this structured approach, schematic analysis becomes an intuitive process, fostering effective troubleshooting and systematic part replacement.

Common Issues and Troubleshooting Tips

When operating agricultural application equipment, users may encounter various challenges that affect performance and efficiency. Identifying these issues promptly can save time and ensure optimal functioning of the machinery. Below are some typical problems and effective solutions to enhance operational reliability.

| Issue | Possible Causes | Troubleshooting Tips |

|---|---|---|

| Uneven Distribution | Blocked outlets or incorrect settings | Check for clogs and adjust the calibration settings. |

| Mechanical Noises | Lack of lubrication or worn components | Inspect moving parts for wear and apply appropriate grease. |

| Inconsistent Flow | Damaged hoses or filters | Examine and replace any damaged hoses and clean filters. |

| Difficulty in Starting | Battery issues or electrical faults | Check the battery connections and test for any electrical faults. |

| Overheating | Blocked air vents or low fluid levels | Ensure air vents are clear and check fluid levels regularly. |

Addressing these common issues with the recommended troubleshooting tips can significantly enhance the longevity and performance of the equipment, allowing for more efficient and effective agricultural practices.

Upgrading Parts for Better Performance

Enhancing the efficiency of your equipment can significantly impact productivity and longevity. By investing in superior components, you can achieve more reliable operation and improved results in your agricultural practices.

When considering upgrades, it’s essential to focus on several key areas:

- Durability: Choose materials that withstand wear and tear, ensuring longevity and reducing maintenance costs.

- Precision: Upgrading to components that offer better calibration can lead to more accurate distribution, enhancing overall effectiveness.

- Compatibility: Ensure that new elements are compatible with existing systems to avoid installation issues.

- Efficiency: Look for innovations that promote fuel efficiency and reduced environmental impact.

Investing in quality upgrades not only improves functionality but also contributes to achieving optimal performance in various agricultural applications. Consider evaluating your current setup and exploring available options to enhance your operations effectively.

Where to Find Replacement Parts

Locating suitable components for your equipment can often be a challenging task. Understanding where to seek these crucial elements is essential for ensuring the longevity and functionality of your machinery. Several avenues exist for sourcing these items, ranging from online marketplaces to specialized retailers.

Online Resources

- Manufacturer Websites: Many manufacturers provide a comprehensive list of components directly on their official sites, often including detailed specifications and ordering options.

- Third-Party Vendors: Websites like eBay and Amazon often have a wide range of components available, both new and used, allowing for cost-effective solutions.

- Forums and Community Groups: Engaging with online communities can provide valuable recommendations for where to find specific items and insights from other users’ experiences.

Local Options

- Equipment Dealers: Local dealers often stock original components or can order them for you, ensuring compatibility with your machinery.

- Repair Shops: Specialized repair facilities might have spare components available or can suggest reliable sources.

- Salvage Yards: Visiting salvage yards can yield unexpected finds, often at a fraction of the original cost.

Comparing Models: Willmar 500 vs Others

When assessing various machinery options, it is crucial to understand the unique features and performance metrics that distinguish one model from another. This comparison delves into the strengths and weaknesses of a popular choice and its competitors, offering insights for potential buyers. By examining key characteristics such as capacity, durability, and efficiency, users can make informed decisions based on their specific needs.

Performance and Capacity

One of the primary factors to consider is the overall performance and load capacity of each model. The leading option excels in handling larger volumes with minimal downtime, making it suitable for extensive agricultural operations. In contrast, alternative models may cater to smaller tasks but can offer enhanced maneuverability in tighter spaces. Understanding these differences can greatly impact operational efficiency.

Durability and Maintenance

Durability is another critical aspect, as users need equipment that can withstand rigorous use and various environmental conditions. The examined model often features robust materials and construction, leading to lower maintenance needs over time. On the other hand, some alternatives might require more frequent servicing, which can increase overall operational costs. Assessing these maintenance requirements ensures long-term satisfaction and reliability.

Customer Experiences and Reviews

This section delves into the insights and evaluations shared by users regarding their experiences with the equipment. Understanding the opinions of fellow customers can provide valuable guidance for those considering a purchase or seeking maintenance advice.

Positive Feedback

- Users frequently commend the reliability and durability of the machinery, highlighting its consistent performance over time.

- Many appreciate the ease of use, noting that even novice operators can quickly adapt and achieve optimal results.

- Customers often express satisfaction with the customer support, mentioning timely responses and effective solutions to their queries.

Areas for Improvement

- Some users have reported challenges with assembly, suggesting clearer instructions could enhance the experience.

- A few customers noted that replacement components can be hard to find, which can delay maintenance efforts.

- Occasional feedback points to the need for additional features that would improve efficiency during operation.

Overall, user reviews provide a balanced perspective, showcasing both strengths and potential improvements, helping future buyers make informed decisions.