In the realm of mechanical engineering, comprehending the intricate assembly of specialized devices is essential for optimal performance and maintenance. This exploration delves into the structure and functionality of a particular model, highlighting its essential elements and their interrelationships. Gaining insight into these components not only enhances operational efficiency but also aids in troubleshooting and repairs.

By examining the configuration of this specific apparatus, users can familiarize themselves with the various functionalities and roles each element plays within the whole. Whether you are a seasoned technician or a curious enthusiast, understanding these connections is vital for effective management of the machine. Knowledge of its construction leads to better decision-making during both routine maintenance and unexpected malfunctions.

As we break down the intricacies of this device, we will provide a clear representation of its architecture. This will serve as a valuable resource for anyone looking to deepen their understanding of the mechanics at play. Ultimately, mastering the layout and function of each segment empowers individuals to utilize the machine to its fullest potential.

Overview of Strikemaster MAG 2000

The subject of this section highlights a notable aircraft renowned for its design and operational capabilities. This model has garnered attention for its effectiveness in various roles, particularly in training and light attack missions. Its performance and reliability have made it a preferred choice among military and civilian operators alike.

Key Features

This aircraft is equipped with advanced avionics and a robust airframe, allowing it to execute a range of tasks efficiently. The powerful engine contributes to impressive speed and maneuverability, making it suitable for both combat and instructional purposes. Additionally, the design emphasizes ease of maintenance, ensuring that it remains operational even in challenging conditions.

Operational Versatility

The versatility of this model is evident in its ability to adapt to various mission profiles. From close air support to reconnaissance, it can be configured with an array of equipment and armaments, enhancing its tactical flexibility. This adaptability has solidified its position in numerous air forces around the world.

Conclusion

In summary, this aircraft represents a significant advancement in the realm of military aviation, combining modern technology with user-friendly features. Its enduring legacy is a testament to its design and operational prowess, making it a vital asset in the aviation community.

Understanding Parts and Functionality

This section delves into the intricate components and their roles within the system. By comprehending the various elements, users can better appreciate how each part contributes to the overall operation and efficiency.

The assembly consists of several key elements, each serving a distinct purpose. Below is an overview of these critical components:

- Engine: The powerhouse that drives performance, converting fuel into mechanical energy.

- Fuel System: Responsible for delivering the necessary energy source, ensuring optimal combustion.

- Control Mechanism: Allows the user to manage speed and direction, enhancing maneuverability.

- Cooling System: Maintains an appropriate temperature, preventing overheating and ensuring longevity.

- Transmission: Facilitates the transfer of power from the engine to the drive mechanism.

Understanding how these elements interact can significantly improve the user experience. Each component’s functionality is interconnected, and recognizing this synergy can lead to more effective maintenance and operation.

- Regularly inspect the engine for wear and tear.

- Ensure the fuel system is clean and free from contaminants.

- Familiarize yourself with the control mechanism for better handling.

- Monitor the cooling system to avoid performance issues.

- Check the transmission for smooth operation and efficiency.

In summary, a thorough grasp of these components and their functionalities not only enhances performance but also contributes to the reliability and safety of the entire assembly.

Essential Components of the MAG 2000

Understanding the fundamental elements that contribute to the functionality of an aircraft is crucial for both enthusiasts and professionals. Each part plays a vital role in ensuring optimal performance, safety, and efficiency. This section will explore the key components that make up this particular model, highlighting their significance and interrelationships.

Key Structural Elements

- Fuselage: The main body that houses the cockpit, passengers, and cargo.

- Wings: Provide lift and stability during flight.

- Empennage: The tail structure that aids in stability and control.

- Landing Gear: Supports the aircraft during takeoff, landing, and taxiing.

Critical Operational Systems

- Engine: The powerhouse that propels the aircraft through the air.

- Control Surfaces: Ailerons, elevators, and rudders that help maneuver the aircraft.

- Fuel System: Manages the storage and delivery of fuel to the engine.

- Electrical System: Powers essential instruments and systems.

Each of these components not only serves its individual purpose but also works in harmony with others to ensure a seamless flying experience. Familiarity with these elements is essential for maintenance, troubleshooting, and enhancing overall aircraft performance.

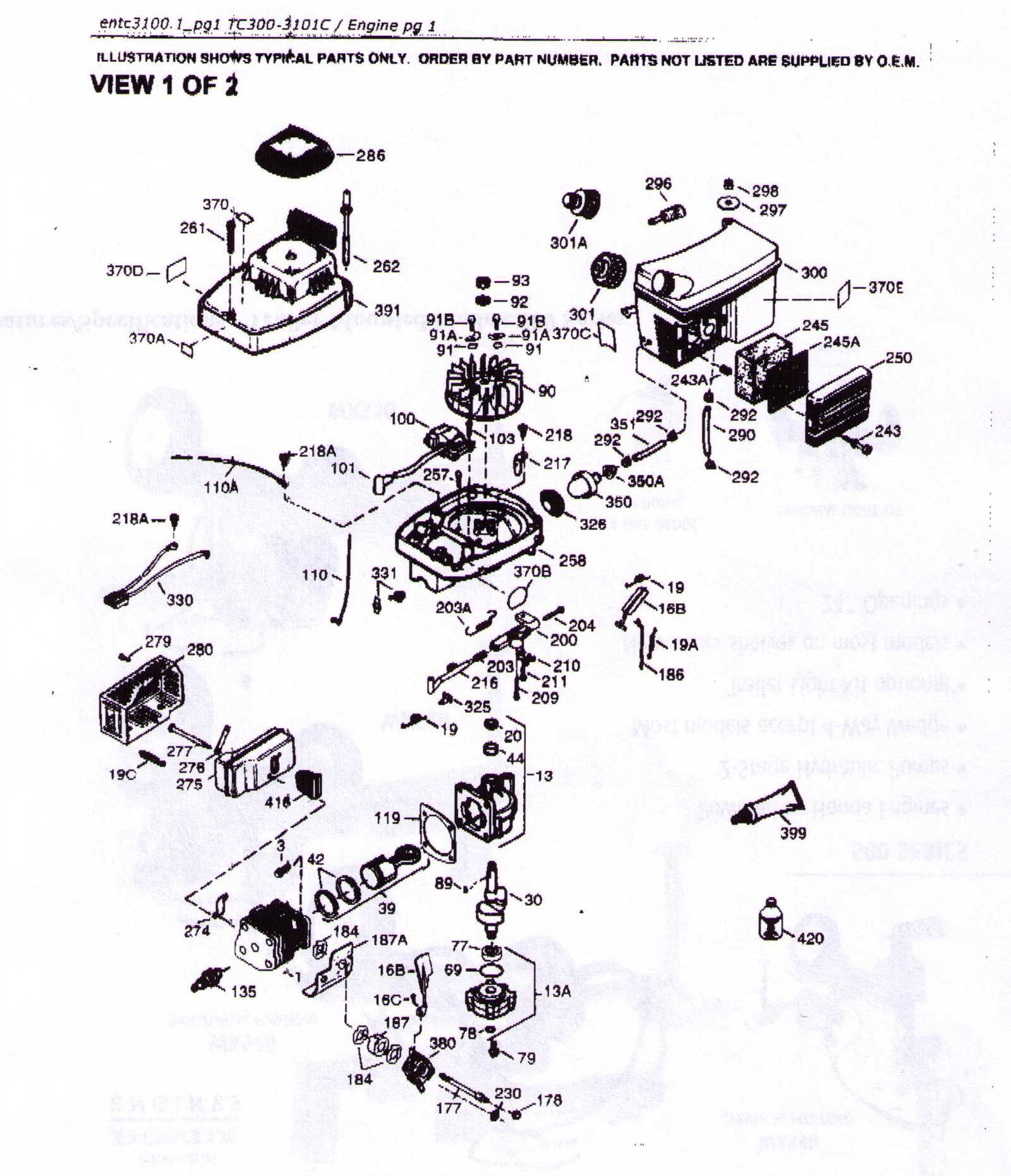

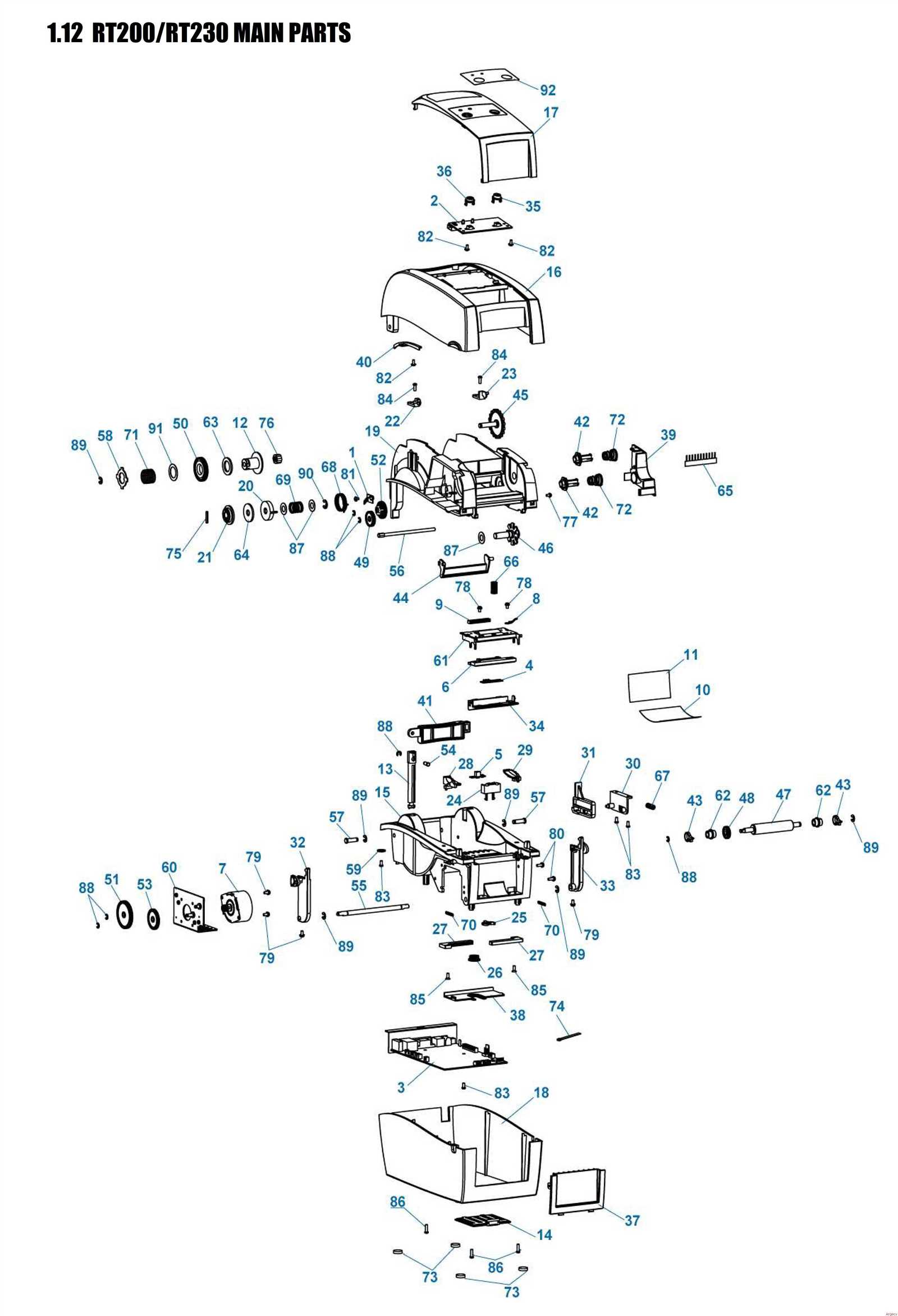

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide crucial insights into the structure and assembly of various elements, enabling users to identify, locate, and understand the function of each item in a system.

Key Elements of Visual Representations

Each illustration typically includes several important features that aid in comprehension:

| Element | Description |

|---|---|

| Labels | Numerical or alphanumeric indicators that reference specific items within the representation. |

| Legend | A guide that explains the symbols and colors used, clarifying the meaning of various components. |

| Connections | Lines or arrows that show how components interact or fit together, highlighting the relationships between them. |

| Views | Different perspectives of the assembly, such as top, side, or exploded views, which provide comprehensive understanding. |

Steps to Interpret Illustrations

To effectively utilize these visual tools, follow these steps:

- Familiarize yourself with the legend to understand symbols and references.

- Identify the labels and cross-reference them with the accompanying list or manual.

- Pay attention to connection lines to grasp how items are assembled and interact.

- Use multiple views for a complete understanding of complex assemblies.

By mastering these techniques, users can enhance their ability to troubleshoot and repair systems efficiently.

Common Issues with Strikemaster Parts

In the realm of equipment maintenance, certain components frequently present challenges that can affect performance and longevity. Understanding these common pitfalls is essential for efficient troubleshooting and repair.

| Issue | Description |

|---|---|

| Worn Components | Regular use can lead to wear and tear, impacting functionality. |

| Corrosion | Exposure to moisture may cause rust, weakening structural integrity. |

| Improper Assembly | Incorrect installation can result in operational failures or damage. |

| Fuel System Blockage | Debris accumulation can hinder fuel flow, causing performance issues. |

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the extended lifespan of your equipment. By implementing a consistent maintenance routine, you can prevent issues that might arise over time and enhance overall performance.

1. Cleanliness is Key: Keep the device free from dirt and debris. Regularly wipe down surfaces and ensure all components are clean to prevent wear and tear.

2. Lubrication: Use appropriate lubricants on moving parts to reduce friction. This will not only improve efficiency but also minimize the risk of damage.

3. Regular Inspections: Conduct routine checks for any signs of wear or malfunction. Early detection can save time and money on repairs.

4. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. This ensures that you address all necessary tasks in a timely manner.

5. Store Properly: When not in use, store the equipment in a dry, protected environment to prevent corrosion and deterioration.

By following these simple yet effective tips, you can significantly enhance the longevity and reliability of your equipment.

Where to Find Replacement Parts

Finding components for maintenance or repairs can be challenging, but there are several reliable sources to explore. Whether you are looking for specific items or a complete assembly, understanding where to search is crucial for ensuring your equipment remains functional.

Consider the following options when searching for the necessary components:

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides the most accurate listings and specifications, along with direct purchase options. |

| Authorized Dealers | Local or online retailers authorized by the manufacturer typically stock a wide range of items and can assist with finding the right fit. |

| Aftermarket Suppliers | Third-party vendors may offer alternative options that are compatible and often more cost-effective. |

| Online Marketplaces | Platforms like eBay or Amazon provide a vast selection from various sellers, often including new and used items. |

| Forums and Community Groups | Joining specialized forums can connect you with enthusiasts who may have spare components or know where to find them. |

By exploring these avenues, you can increase your chances of successfully locating the required items to keep your equipment in top condition.

Upgrading Your Strikemaster Equipment

Enhancing your equipment can significantly improve performance and efficiency. By investing in quality components, you can ensure that your machine operates at its best, meeting the demands of various tasks while prolonging its lifespan. Understanding the available upgrades is crucial to making informed decisions that align with your specific needs.

Identifying Key Areas for Improvement

Start by assessing the current capabilities of your device. Look for areas where enhancements can make a noticeable difference, such as the engine, cutting systems, or handling features. Prioritizing upgrades based on usage and environment will lead to better overall functionality.

Quality Over Quantity

When selecting new components, focus on high-quality materials that offer durability and reliability. Investing in reputable brands ensures that the upgrades will withstand wear and tear, providing a solid return on your investment. Remember, the goal is to create a harmonious synergy between the upgraded parts and the existing structure.

Regular Maintenance

Upgrading is only part of the equation; regular maintenance is essential to keep everything running smoothly. Create a maintenance schedule that includes routine checks and servicing of all new parts. This proactive approach will help prevent potential issues and keep your equipment in optimal condition.

Consulting Experts

If you’re uncertain about which upgrades are best for your needs, consider seeking advice from professionals. They can provide insights based on experience and knowledge of the latest advancements in technology. Collaborating with experts will help you make well-informed choices and maximize your equipment’s performance.