The efficiency and effectiveness of snow-clearing equipment largely depend on its individual elements. Each component plays a vital role in the overall functionality, ensuring optimal performance during harsh winter conditions. This exploration delves into the intricate parts that comprise such machinery, highlighting their importance and interconnections.

By examining the structure and arrangement of these vital elements, one can gain valuable insights into the operational capabilities of the equipment. Understanding how each piece fits into the larger system can enhance maintenance practices and improve overall performance. This knowledge is essential for operators seeking to maximize productivity and extend the lifespan of their tools.

In this section, we will break down the various components, emphasizing their specific functions and contributions to the snow management process. Through a detailed overview, users will learn how to identify, maintain, and optimize each part, ensuring that their equipment remains in peak condition for effective winter operations.

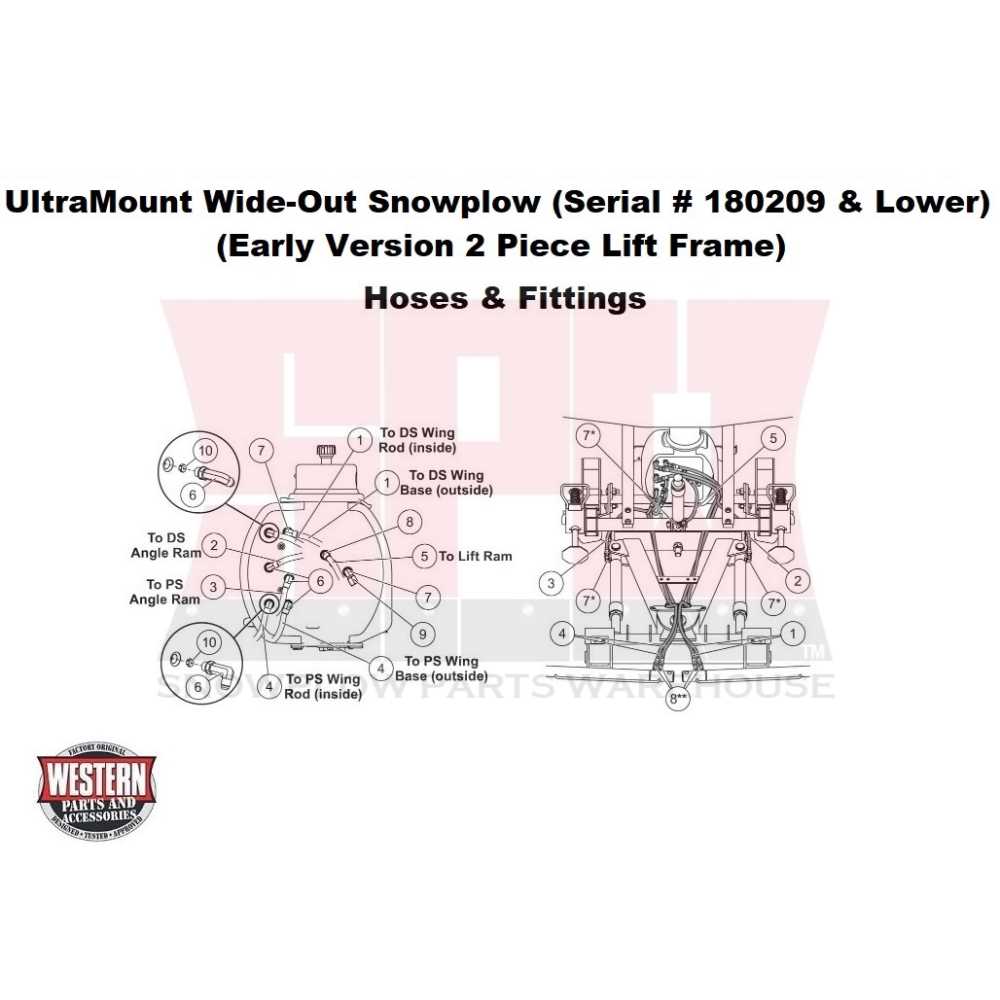

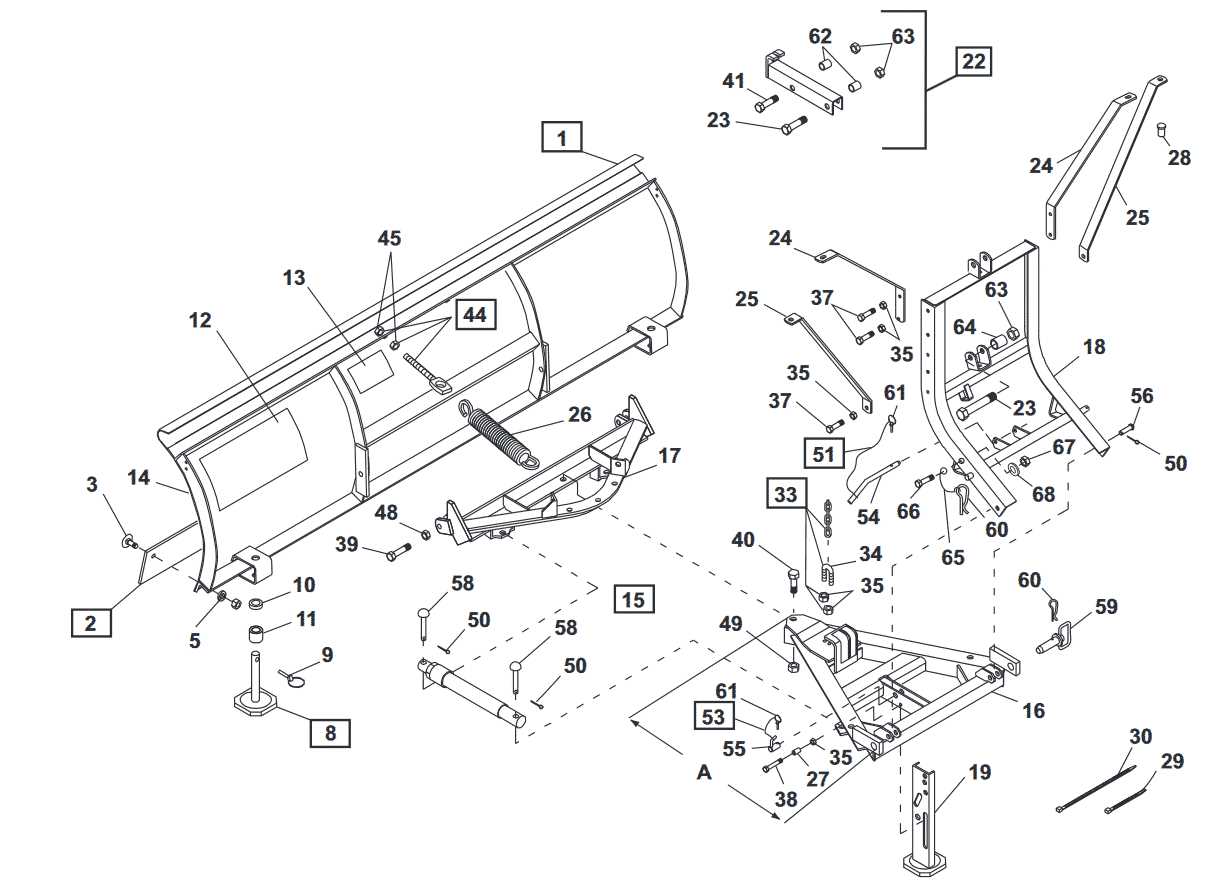

Understanding Western Wideout Components

This section explores the essential elements that contribute to the functionality and efficiency of the snow removal system. Each component plays a vital role in ensuring optimal performance and ease of operation.

Key Elements: The system is composed of various mechanisms, each designed for specific tasks. These components work harmoniously to enhance the overall effectiveness, making snow clearing more efficient.

Operational Mechanics: Understanding the intricate relationships between these elements can lead to better maintenance practices and improved performance during usage. By delving into their functions, operators can maximize the system’s capabilities and ensure longevity.

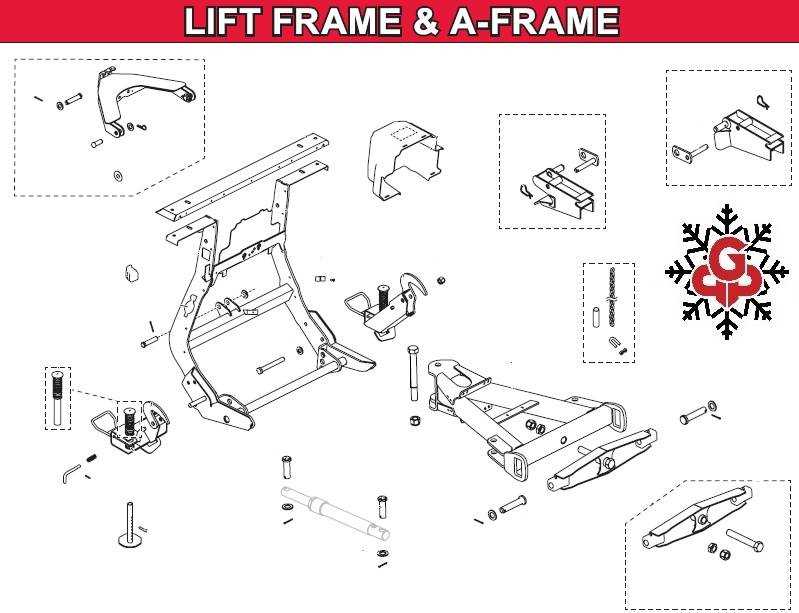

Key Parts of the Diagram

This section explores essential components that contribute to the overall functionality and efficiency of the system. Understanding these crucial elements helps in grasping the intricate relationships and roles each plays in achieving optimal performance.

Main Components

Each integral segment serves a unique purpose, enhancing the overall effectiveness of the setup. From connectors to supports, recognizing these parts allows for better troubleshooting and maintenance, ensuring longevity and reliability.

Examining how each element interacts reveals deeper insights into operational dynamics. A thorough understanding of these relationships can lead to improved strategies for implementation and innovation.

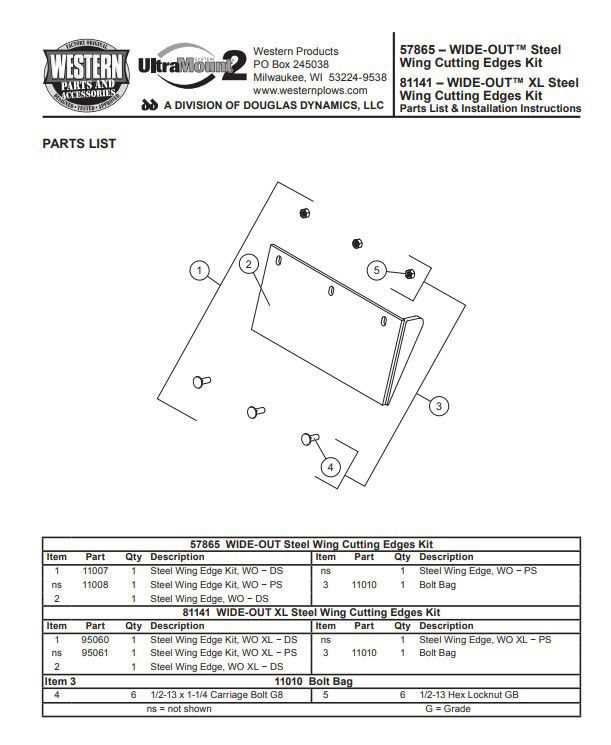

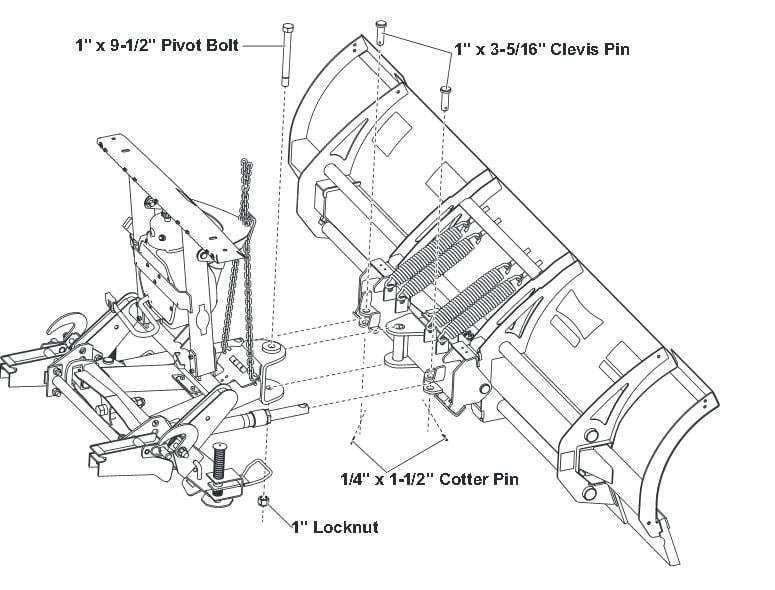

Functionality of Each Component

This section explores the specific roles that various elements play within the overall assembly, highlighting their contributions to the system’s performance. Understanding these functions is crucial for optimizing efficiency and ensuring reliability in operation.

Key Elements

The primary constituents of the assembly work in harmony to achieve the desired outcomes. Each piece is designed with a unique purpose that enhances the functionality of the entire system.

| Component | Function |

|---|---|

| Element A | Responsible for initiating the process, ensuring smooth operation. |

| Element B | Facilitates communication between components, optimizing performance. |

| Element C | Provides stability and support, maintaining structural integrity. |

| Element D | Enhances efficiency by regulating the flow of resources. |

Impact on Overall System

The interplay among these elements is critical for achieving the ultimate functionality. By ensuring each component performs its designated role effectively, the entire system operates at peak efficiency.

Common Issues with Wideout Parts

When dealing with snow removal equipment, various challenges can arise that affect performance and efficiency. Understanding these common concerns is crucial for maintaining optimal functionality and ensuring longevity. Many users encounter similar problems that, if addressed promptly, can prevent more significant complications down the line.

Wear and Tear

One of the primary issues faced by operators is the natural deterioration of components due to constant use. Factors such as abrasive surfaces and harsh weather conditions can lead to significant wear. Regular inspection and timely replacement of worn-out elements are essential to avoid operational disruptions and ensure effective snow clearance.

Misalignment and Adjustment

Another frequent challenge involves the alignment of equipment, which can impact its performance. Improper setup can lead to uneven distribution of force and reduced effectiveness. Ensuring that all components are correctly adjusted and calibrated can enhance efficiency and extend the lifespan of the machinery.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of equipment requires consistent care and attention. By implementing effective maintenance practices, users can prolong the lifespan of their machinery and minimize the likelihood of unexpected failures. Below are several key strategies to enhance longevity and performance.

Regular Inspections

Frequent assessments of your equipment are crucial. Here are some steps to follow:

- Check for signs of wear and tear.

- Examine all components for proper functionality.

- Look for leaks or unusual noises during operation.

Proper Cleaning

Keeping your machinery clean is essential for optimal performance. Consider these cleaning tips:

- Remove debris and dirt regularly to prevent clogs.

- Use appropriate cleaning agents that won’t damage surfaces.

- Ensure that all moving parts are free from buildup.

By adhering to these maintenance guidelines, users can significantly extend the life of their equipment and enhance overall productivity.

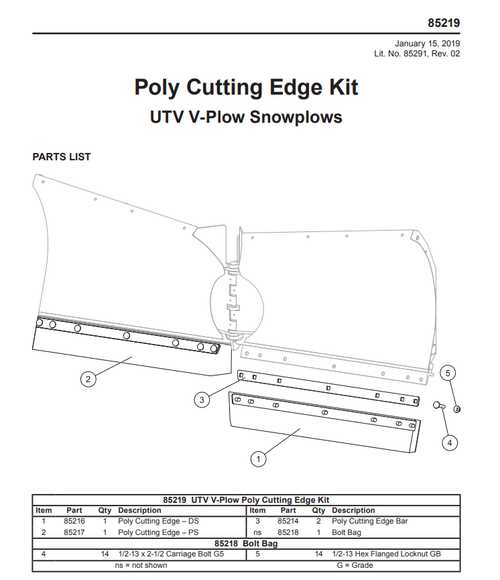

Upgrades and Modifications Explained

Enhancements and adjustments play a crucial role in optimizing performance and functionality. Understanding how these changes impact overall efficiency can help users make informed decisions. This section delves into various improvements that can be implemented to elevate the operational capacity of equipment.

When considering upgrades, it’s essential to evaluate both the benefits and potential drawbacks. Customizing components can lead to increased power, efficiency, and adaptability, allowing for better handling of diverse conditions. However, it is vital to ensure compatibility and avoid compromising reliability.

Modification options can vary widely, from simple replacements to complex overhauls. Selecting the right upgrades requires careful assessment of individual needs and the intended use of the equipment. Whether for enhanced speed, durability, or ease of use, each modification should align with the overall goals of performance improvement.

Additionally, staying informed about the latest technologies and trends can provide valuable insights. Engaging with expert opinions and user experiences can aid in identifying the most effective enhancements. The journey towards better performance is continuous, and each upgrade is a step toward achieving optimal results.

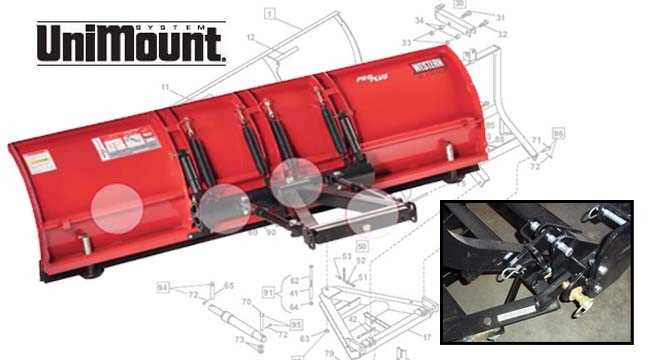

Comparing Different Wideout Models

This section explores the diverse variations of a popular type of equipment, focusing on their unique characteristics and applications. Understanding these differences can enhance performance and inform better choices for specific needs.

Performance Features

Each model presents distinct performance features that cater to varying requirements. Some designs emphasize speed and agility, while others prioritize durability and load capacity. Analyzing these attributes allows users to align their selections with desired outcomes.

Material and Construction

The materials used in manufacturing significantly impact both functionality and longevity. From lightweight composites to robust metals, the choice of construction can influence the overall efficiency. Evaluating the advantages and disadvantages of each material helps in making an informed decision based on intended use.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for efficiency and effectiveness. A well-equipped toolkit enables individuals to address issues swiftly and ensures that each component is handled properly. Understanding which instruments are necessary can greatly influence the outcome of any repair project.

Key items typically include wrenches, screwdrivers, pliers, and specialized tools tailored to specific tasks. Additionally, a reliable torque wrench and measuring instruments play crucial roles in ensuring precision. It is also advisable to have safety gear on hand to protect against potential hazards during the repair process.

Best Practices for Safe Operation

Ensuring the secure and efficient functioning of machinery requires a comprehensive understanding of operational protocols. Following established guidelines minimizes risks and enhances productivity, fostering a safer working environment for all personnel involved.

Key Safety Measures

Implementing specific safety measures is crucial for optimal operation. Here are some essential practices to consider:

| Practice | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify potential issues before they escalate. |

| Proper Training | Ensure all operators are thoroughly trained in the equipment’s use and safety protocols. |

| Personal Protective Equipment | Mandate the use of appropriate protective gear to minimize injury risks. |

| Clear Signage | Install visible warning signs and labels to guide safe operation. |

Emergency Preparedness

Having a robust emergency response plan is vital. Ensure all team members are familiar with emergency procedures, and conduct regular drills to reinforce this knowledge. A well-prepared team can effectively mitigate potential hazards and respond swiftly to unforeseen situations.