In the realm of winter maintenance, efficient machinery plays a crucial role in ensuring safe and accessible roadways. The intricate design of these tools requires a clear understanding of their individual elements, allowing operators to effectively manage snow and ice challenges.

Recognizing the various sections of this machinery not only enhances operational efficiency but also simplifies maintenance tasks. By exploring the structure and functionality of each component, users can ultimately improve their experience and outcomes during harsh weather conditions.

This guide aims to delve into the essential components involved in snow clearing systems, providing insights that can aid both seasoned professionals and new enthusiasts. Whether for repair, upgrade, or general knowledge, understanding these mechanisms is vital for optimal performance.

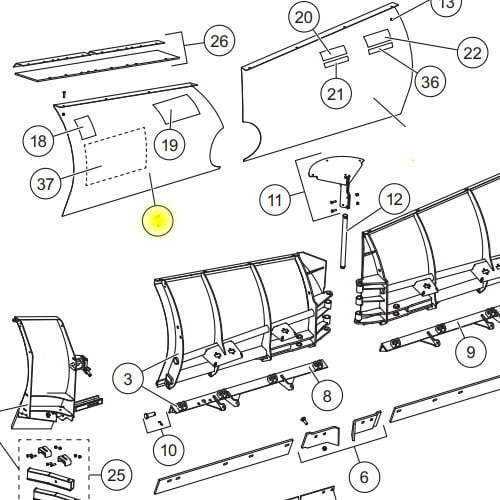

Understanding Western Unimount Plows

This section aims to provide insight into a specific type of snow removal equipment known for its versatility and efficiency. By exploring its structure and functionalities, users can gain a deeper appreciation for how it operates and the essential components involved in its design.

Key Features: The equipment is characterized by its robust build and adaptable mechanisms, making it suitable for various terrains and conditions. Understanding these features is crucial for optimal performance.

Maintenance and Care: Regular upkeep is vital for ensuring longevity and effectiveness. Familiarity with the necessary components can help users identify potential issues before they become problematic.

In summary, delving into the intricacies of this equipment not only enhances user experience but also maximizes its ultimate potential in winter operations.

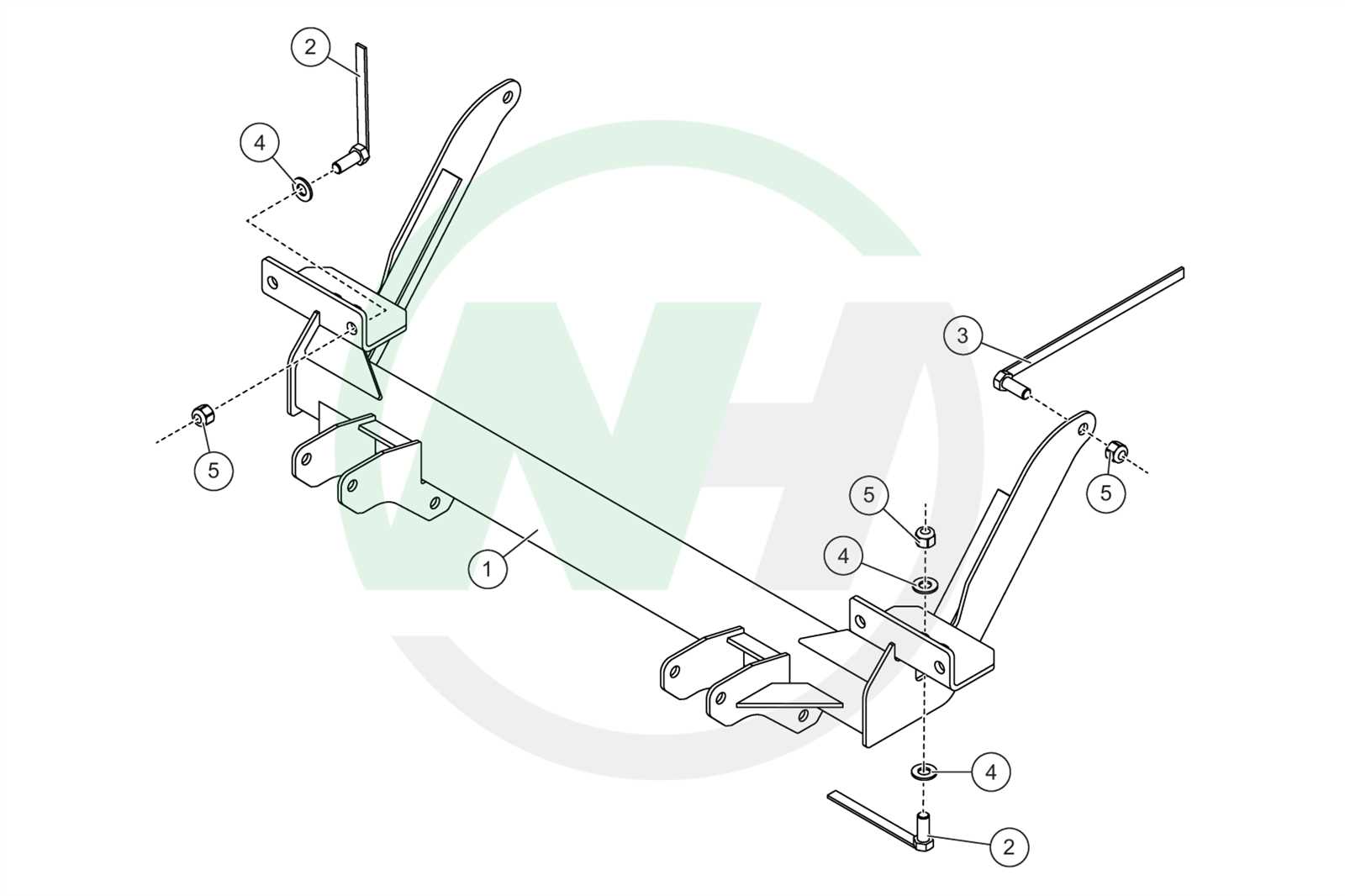

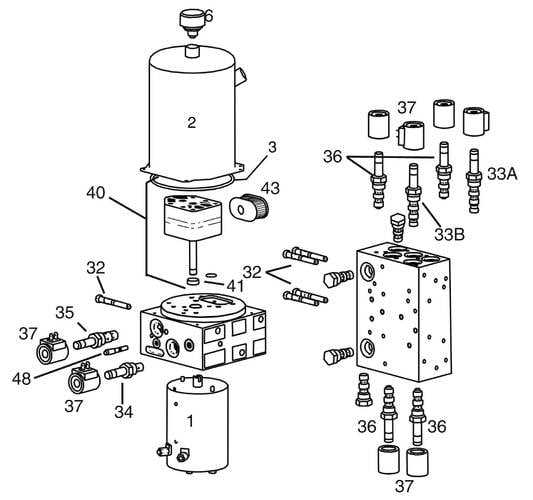

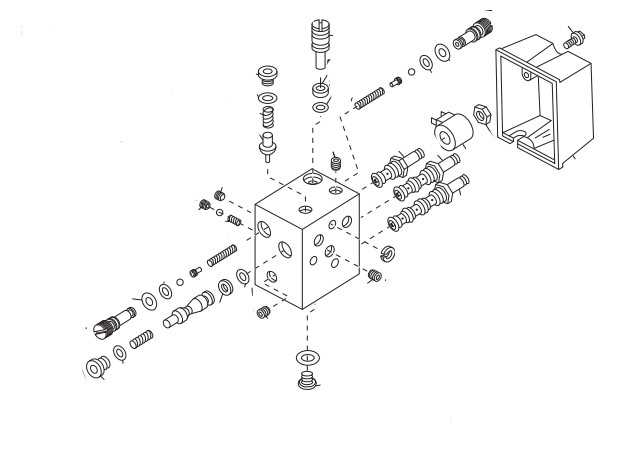

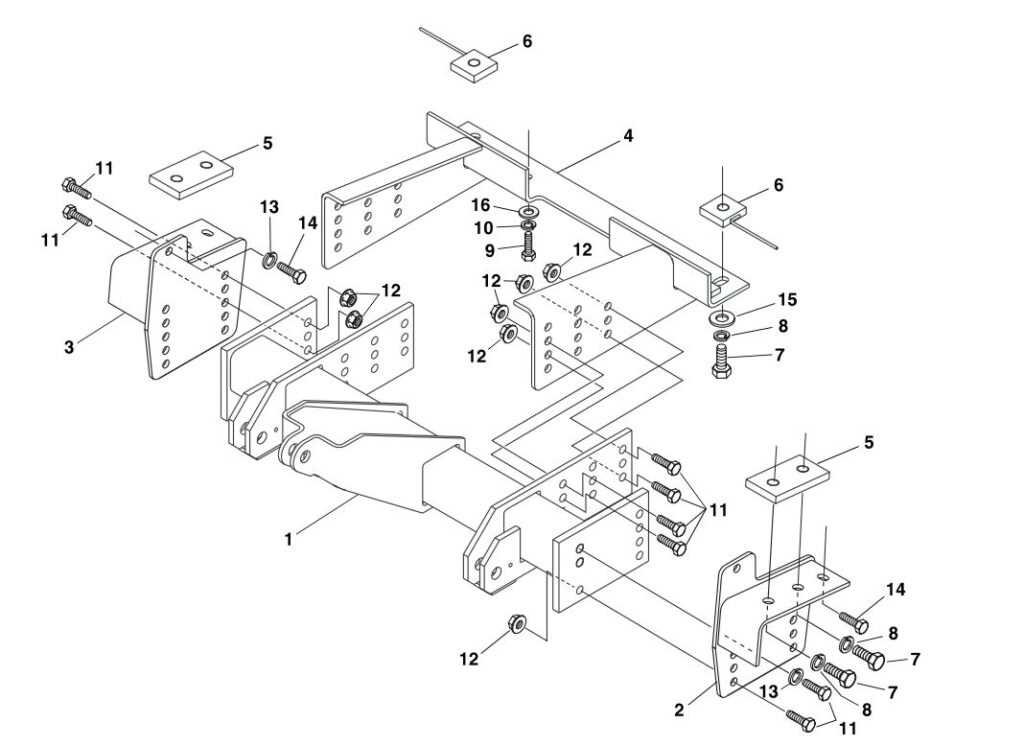

Key Components of Unimount Systems

Understanding the fundamental elements of these attachment systems is essential for effective operation and maintenance. Each component plays a crucial role in ensuring optimal performance and reliability.

Essential Elements

- Mounting Bracket: Provides a secure connection to the vehicle.

- Frame: Supports the entire assembly and distributes weight evenly.

- Lift Mechanism: Allows for raising and lowering the device as needed.

- Control System: Facilitates operation and adjustment from inside the cab.

Maintenance Considerations

- Regularly inspect all components for wear and damage.

- Ensure proper lubrication of moving parts.

- Check electrical connections for reliability.

- Clean any debris that may hinder functionality.

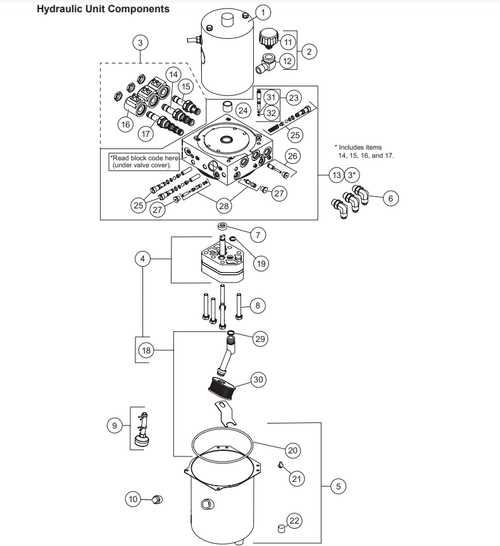

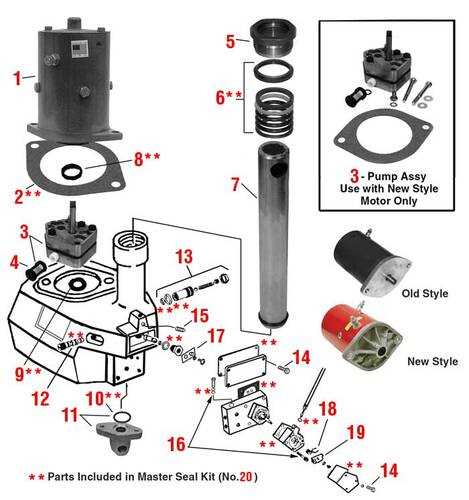

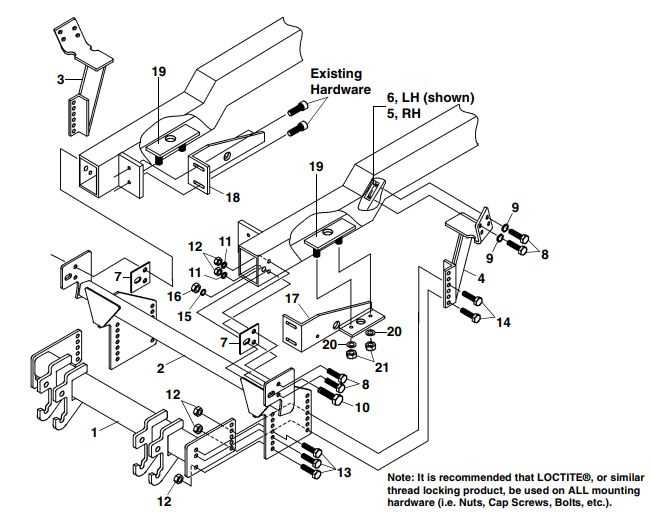

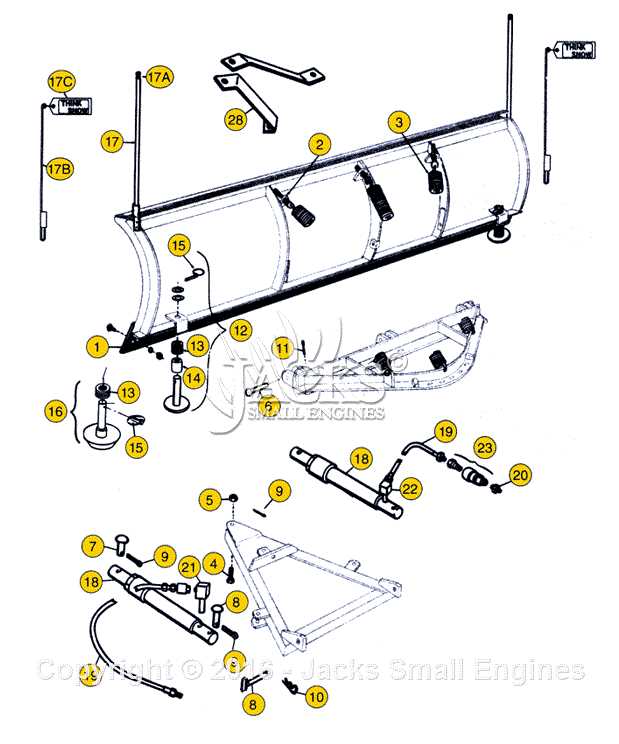

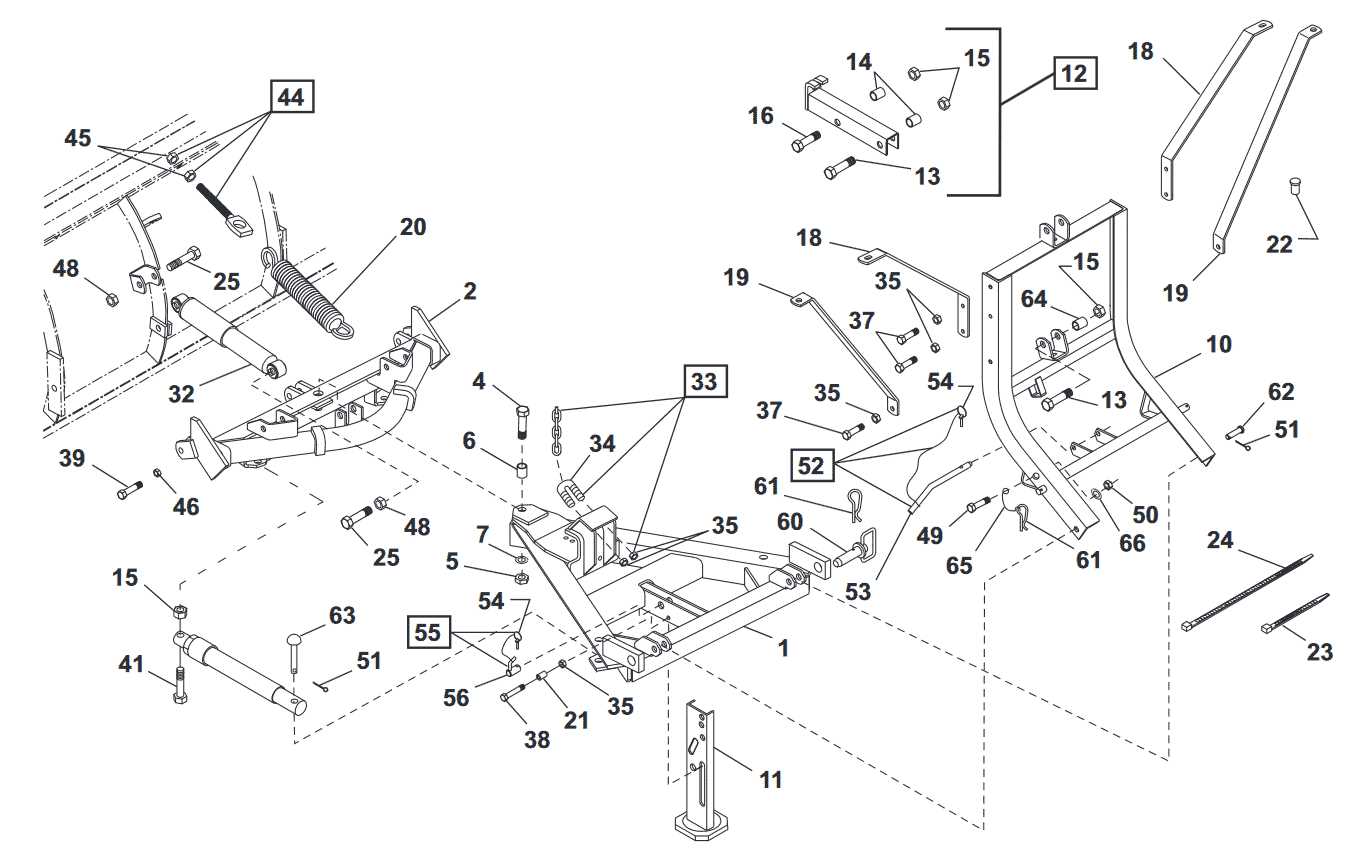

How to Read Parts Diagrams

Understanding technical illustrations is crucial for efficient repairs and maintenance. These visual guides provide a clear representation of components and their relationships, allowing users to identify specific items and their functions within a system.

First, familiarize yourself with the layout. Typically, the diagram will categorize elements based on their location or purpose, making it easier to locate what you need. Pay attention to any labels or legends that offer explanations for symbols used.

Next, take note of the reference numbers often assigned to each piece. These numbers correlate with lists detailing specifications and part numbers, streamlining the ordering process. Understanding this connection can save time and reduce errors.

Finally, practice is key. The more you engage with these illustrations, the more proficient you’ll become at quickly locating and identifying components. With patience and attention to detail, you’ll enhance your ability to work effectively with these valuable resources.

Common Issues with Plow Parts

When it comes to snow removal equipment, several common challenges can arise that affect performance and reliability. Understanding these issues is crucial for effective maintenance and optimal operation during winter conditions.

- Wear and Tear: Components often experience significant wear due to constant exposure to harsh elements.

- Corrosion: Moisture and road salts can lead to rust and deterioration, compromising the integrity of various elements.

- Alignment Problems: Misalignment can occur, affecting the functionality and efficiency of the entire setup.

- Hydraulic Failures: Leaks and pressure loss in hydraulic systems can lead to reduced performance.

- Electrical Issues: Faulty wiring or connections can cause operational failures, particularly in lighting and controls.

Regular inspection and timely repairs can mitigate these challenges, ensuring that your equipment remains in top condition throughout the winter season.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires regular upkeep and attention. By following a systematic maintenance routine, you can enhance the lifespan and reliability of your machinery. Here are some essential practices to consider.

Regular Inspections

- Conduct routine visual checks for wear and tear.

- Inspect all moving components for proper alignment and function.

- Look for signs of rust or corrosion, and address them promptly.

Routine Cleaning

- Clean the surfaces regularly to remove debris and dirt.

- Use appropriate cleaning solutions to avoid damage to components.

- Pay special attention to areas that may trap moisture, leading to rust.

By implementing these tips, you can significantly prolong the life of your equipment, ensuring it remains functional and reliable for many years to come.

Finding Replacement Parts Online

Locating the necessary components for your equipment can be a straightforward process when you know where to look. The internet offers a vast array of resources that simplify the search for suitable items, ensuring that you can get back to work quickly and efficiently.

Here are some effective strategies for sourcing what you need:

- Online Retailers: Numerous e-commerce platforms specialize in offering a wide range of components. Check their catalogs for specific items.

- Manufacturer Websites: Visit the official sites of producers for detailed information and direct purchases. They often have a dedicated section for replacements.

- Forums and Community Groups: Engage with online communities related to your equipment. Members often share links, recommendations, and advice on where to find hard-to-get items.

- Local Dealerships: Some local businesses maintain online inventories. It’s worth checking their websites or contacting them directly.

- Comparison Sites: Utilize platforms that aggregate various retailers, allowing you to compare prices and availability in one place.

When searching online, remember to use specific terminology relevant to your equipment to yield the best results. Additionally, ensure you check customer reviews and ratings to assess the reliability of the source before making a purchase.

Upgrading Your Plow System

Enhancing your snow management equipment can significantly improve efficiency and performance. By investing in advanced components, you can optimize your setup for various conditions and increase your overall productivity.

- Evaluate current components for wear and functionality.

- Research the latest innovations in snow removal technology.

- Consider upgrading to a more efficient hydraulic system.

- Explore advanced cutting edges for better snow handling.

- Invest in improved mounting systems for easier attachment and detachment.

Implementing these upgrades will ensure your equipment meets the demands of any winter storm.

Safety Precautions During Operation

Ensuring safety during the use of snow removal equipment is crucial for both the operator and the surrounding environment. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Awareness and preparation are key components in achieving a safe working environment.

- Always wear appropriate personal protective equipment, including gloves, boots, and high-visibility clothing.

- Conduct a thorough inspection of the machinery before operation to identify any potential hazards or maintenance needs.

- Be aware of your surroundings and maintain a safe distance from pedestrians, vehicles, and obstacles.

- Follow the manufacturer’s instructions for safe operation and maintenance of the equipment.

- Never exceed the recommended weight limits or operational capabilities of the machinery.

Regular training and refreshers for operators can enhance safety awareness and ensure that everyone is familiar with emergency procedures. It is also advisable to have a first aid kit readily available in case of any incidents.

- Communicate effectively with team members during operation to ensure coordinated movements.

- Be cautious of changing weather conditions that may affect visibility and traction.

- Park machinery on a flat surface and engage safety mechanisms when not in use.

By following these precautions, operators can help create a safer environment, thereby minimizing the likelihood of accidents and ensuring efficient performance.

FAQs About Unimount Equipment

This section aims to address common inquiries regarding specific equipment systems designed for snow removal and similar tasks. Understanding these elements can help users make informed decisions and maintain their gear effectively.

What types of equipment are available?

There is a variety of machinery suited for different applications, including residential and commercial snow clearing. Options range from compact units for smaller areas to larger models designed for extensive operations.

How can I ensure optimal performance?

Regular maintenance is crucial for peak functionality. This includes checking hydraulic systems, ensuring all components are well-lubricated, and replacing any worn-out elements promptly. Consulting the manufacturer’s guidelines can provide valuable insights into maintaining your equipment.

Understanding your equipment’s specifications and adhering to proper care routines can greatly enhance its longevity and effectiveness.