In regions where winter weather can be severe, maintaining efficient operations for clearing pathways and roadways is crucial. A comprehensive understanding of the critical elements involved in these mechanisms is key to ensuring optimal performance. Each component plays a vital role in the overall functionality, and familiarity with their arrangement and interconnections can lead to enhanced efficiency and reduced downtime.

Identifying the key features of these systems allows operators to troubleshoot issues more effectively and plan for maintenance. By examining the various elements, users can gain insights into how each part contributes to the machine’s overall operation. This knowledge is essential for anyone involved in the upkeep or utilization of such equipment, ensuring a smoother experience during harsh weather conditions.

Additionally, recognizing how these components fit together can empower operators to make informed decisions when repairs are necessary. A detailed exploration of the layout and function of each element facilitates a deeper appreciation of the technology behind winter management tools. This understanding not only aids in maintenance but also enhances operational readiness, allowing for swift responses to snow-laden challenges.

Understanding Snow Plow Components

This section explores the essential elements that contribute to the efficiency of winter equipment, highlighting their functions and importance in maintaining safe roadways. A comprehensive grasp of these components ensures optimal performance and longevity of the machinery during challenging weather conditions.

Key Elements of the Equipment

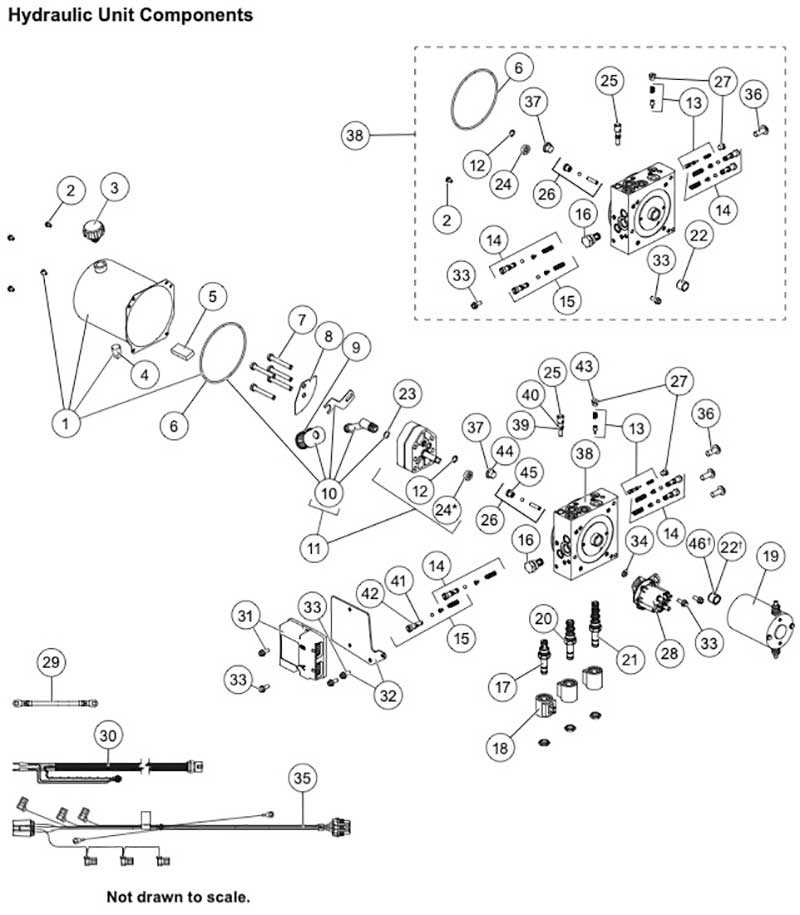

Each unit consists of several critical components, including the frame, blade, hydraulic systems, and control mechanisms. These parts work in harmony to enable smooth operation and effective management of accumulated precipitation, providing a reliable solution for ice and snow removal.

Maintenance and Functionality

Regular upkeep of these crucial elements is vital for peak performance. Understanding how each component interacts can help operators identify potential issues early, ensuring that the machinery remains effective and ready for use throughout the winter season.

Types of Western Snow Plows

This section explores various categories of equipment designed for clearing surfaces during winter conditions. Understanding the different models available can help in selecting the right machinery for specific needs and environments.

- Standard Models

- Designed for general use on roads and parking lots.

- Typically feature a straight blade for efficient removal of accumulated ice and snow.

- V-Shaped Units

- Equipped with a blade that can be adjusted to a V configuration.

- Effective for tackling heavy accumulations and for maneuvering around obstacles.

- Expandable Blades

- Features adjustable width for versatile operation.

- Ideal for varying conditions and can enhance efficiency on wider surfaces.

- Angle Blades

- Can be tilted to either side to direct debris more effectively.

- Useful for clearing sidewalks and driveways where precision is essential.

- Heavy-Duty Options

- Built for rugged conditions and larger vehicles.

- Designed to handle extreme weather and heavy snowfall.

Choosing the right type of equipment can significantly impact the efficiency of winter maintenance efforts. Each category offers unique advantages tailored to specific operational needs.

Common Parts and Their Functions

Understanding the key components of a vehicle’s snow management system is crucial for efficient operation and maintenance. Each element plays a specific role, contributing to the overall effectiveness of the equipment during winter conditions. Below are some essential elements and their respective functions.

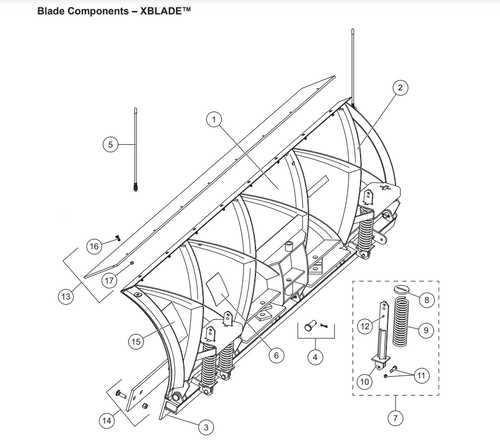

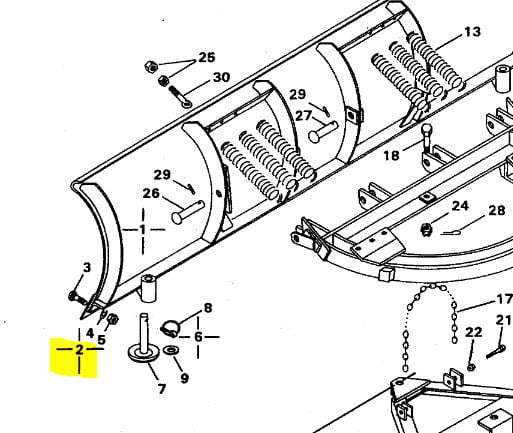

Blade Assembly

The blade assembly is the primary component responsible for clearing the surface. It is designed to efficiently push away accumulated material, allowing for smooth and safe travel. The angle and height of the blade can often be adjusted to accommodate various conditions, enhancing its versatility.

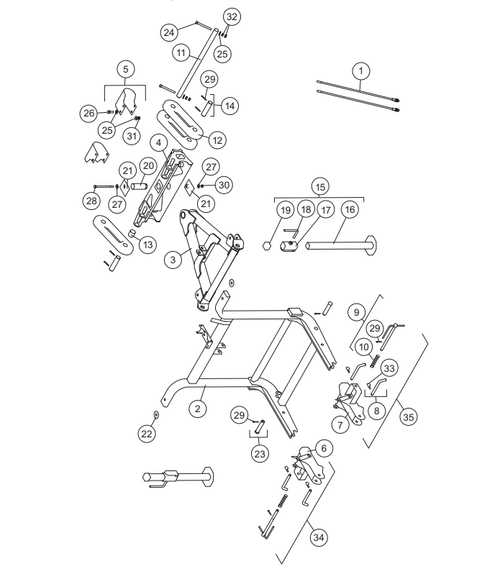

Mounting System

The mounting system connects the clearing apparatus to the vehicle, ensuring stability and control. This mechanism allows for easy attachment and detachment, facilitating quick transitions between tasks. A robust mounting system is essential for maintaining performance and safety during operation.

Control Mechanisms are crucial for managing the operation of the system. They enable the operator to adjust the settings of the blade and other components with ease, ensuring optimal performance in changing conditions. Regular maintenance of these controls is vital for preventing malfunctions and ensuring smooth operation.

Maintenance Tips for Snow Plow Parts

Regular upkeep of your equipment is crucial for optimal performance and longevity. By adhering to a few essential practices, you can ensure that your machinery operates smoothly throughout the winter season. This section provides key insights into how to maintain your essential tools effectively.

Routine Inspections

Conduct frequent checks on all components to identify wear and tear early. Look for signs of rust, cracks, or any unusual wear on surfaces. Addressing these issues promptly can prevent costly repairs and ensure efficiency.

Lubrication and Cleaning

Keep all moving elements well-lubricated to reduce friction and prevent breakdowns. Regularly clean your equipment to remove debris and ice buildup. This not only enhances functionality but also extends the lifespan of your machinery.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair tasks. These visual aids serve as valuable tools, providing insight into the organization and functionality of different elements within a system. By mastering the interpretation of these illustrations, you can ensure efficient assembly, disassembly, and troubleshooting.

Key Elements to Identify

- Legend or Key: This section explains the symbols used in the illustration, making it easier to understand what each icon represents.

- Numbering System: Often, components are numbered for quick reference. Familiarize yourself with this system to locate parts efficiently.

- Component Labels: Labels provide descriptive names for each item, aiding in the identification of specific parts.

- Connections: Arrows or lines may indicate how different components are linked or interact with each other.

Steps to Follow

- Start by examining the legend to familiarize yourself with the symbols and terminology.

- Identify the components you need by cross-referencing the labels with the numerical system.

- Trace connections to understand how components relate to one another, which is crucial for assembly.

- Use the diagram as a reference during your maintenance tasks, ensuring you follow the structure laid out in the illustration.

Identifying Replacement Parts Easily

Finding the right components for your equipment can be a daunting task, especially when you need to maintain optimal performance. Understanding how to identify the correct elements is crucial for ensuring longevity and reliability. This section will guide you through the process of pinpointing what you need with confidence.

Utilizing Reference Guides

One of the most effective methods to locate necessary components is by using comprehensive reference guides. These resources often include detailed illustrations and descriptions, allowing you to match your requirements precisely. Familiarizing yourself with these guides can significantly reduce the time spent searching.

Consulting Online Resources

In the digital age, numerous online platforms offer valuable information regarding various components. Forums, manufacturer websites, and parts catalogs provide insights that can help you identify what you need quickly. Engaging with these resources can also connect you with a community of users who share similar experiences, further aiding in your search.

By leveraging reference materials and online platforms, you can streamline the process of finding replacement components and ensure your equipment remains in peak condition.

Troubleshooting Common Issues

When operating heavy equipment for winter maintenance, encountering difficulties can be a common occurrence. Identifying and resolving these problems promptly is essential for ensuring efficiency and safety. This section focuses on typical challenges operators might face, along with practical solutions.

| Issue | Possible Cause | Solution |

|---|---|---|

| Equipment not responding | Electrical failure | Check connections and replace any blown fuses. |

| Uneven clearing | Misalignment | Adjust the angle of the blade to ensure uniform contact with the surface. |

| Excessive wear | Poor maintenance | Regularly inspect and lubricate components as per the maintenance schedule. |

| Hydraulic issues | Fluid leakage | Locate and seal leaks, and ensure fluid levels are adequate. |

Upgrading Your Snow Plow System

Enhancing your winter equipment can significantly improve efficiency and performance. By focusing on various components, you can ensure a smoother operation during harsh weather conditions.

Consider the following upgrades:

- Blade Material: Switching to a more durable material can enhance longevity and effectiveness.

- Hydraulic System: Upgrading to a more advanced hydraulic system can increase response time and control.

- Lighting: Installing brighter, energy-efficient lights improves visibility during nighttime operations.

- Control Systems: Modernizing the control system allows for better precision and user experience.

Evaluating these areas can lead to the ultimate enhancement of your setup, ensuring you are prepared for whatever winter throws your way.

Resources for Parts and Repairs

Accessing quality components and reliable services is essential for maintaining the functionality and longevity of your equipment. This section aims to provide valuable information on where to find the necessary items and assistance for effective repairs. Whether you are looking for replacements or specialized services, a variety of options are available to meet your needs.

Authorized Dealers and Distributors

Working with certified dealers ensures that you receive authentic components that meet the manufacturer’s specifications. These establishments often provide a comprehensive range of products and expert advice. They can also assist in sourcing hard-to-find items, ensuring that your machinery operates smoothly and efficiently.

Online Marketplaces and Forums

The internet is a treasure trove of resources for both purchasing components and seeking guidance. Online platforms offer numerous listings for various components, often at competitive prices. Additionally, community forums provide an excellent opportunity to connect with fellow users who can share insights, troubleshooting tips, and recommendations for repair services.

When exploring these resources, it is crucial to verify the credibility of sellers and to ensure that the parts meet quality standards. Investing time in research will pay off in the long run, leading to improved performance and durability of your equipment.