Efficient snow removal is crucial for maintaining safe and accessible roads during winter months. A clear understanding of the various components that contribute to the functionality of snow-clearing machinery can enhance performance and reliability. This section aims to provide insights into the intricate elements that ensure effective operation in challenging conditions.

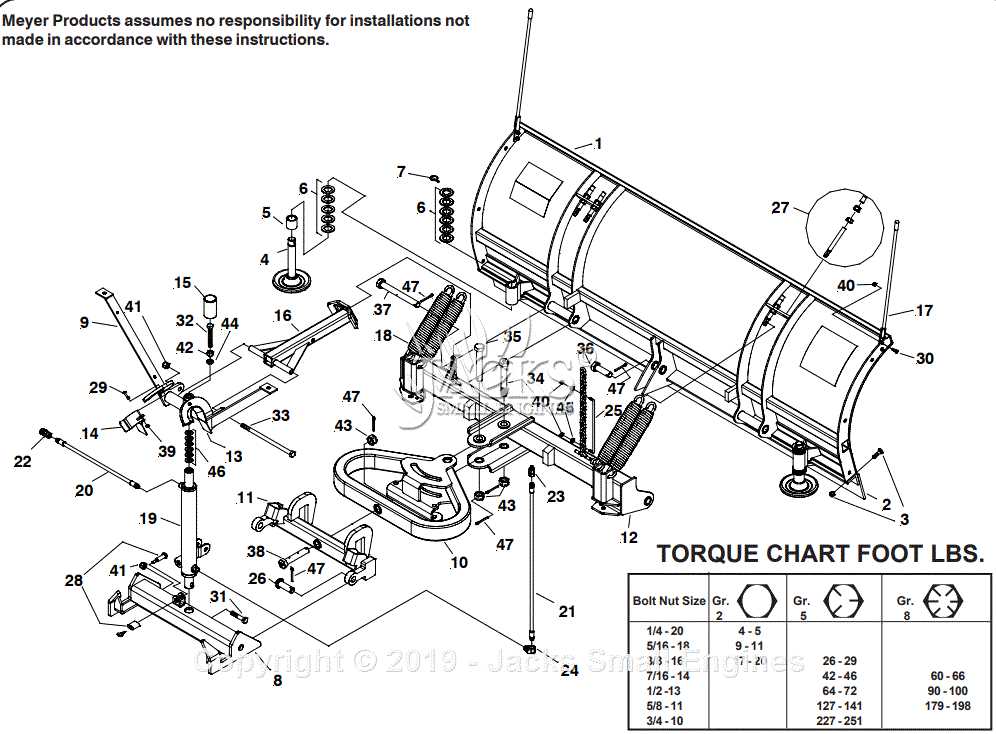

From hydraulic systems to cutting edges, each component plays a vital role in the overall mechanism. Familiarity with these elements enables operators to identify potential issues quickly and carry out necessary maintenance. By exploring the arrangement and interconnections of these critical elements, users can improve their knowledge and application of snow-clearing equipment.

Grasping the layout of these tools not only facilitates better handling but also enhances safety during operation. Proper awareness of the various elements involved allows users to make informed decisions regarding repairs and upgrades. Ultimately, this understanding contributes to the longevity and efficiency of the equipment, ensuring reliable performance when it is needed the most.

Understanding Western Plow Components

The efficiency of snow removal equipment relies heavily on its various components working in harmony. Each element plays a significant role in ensuring optimal functionality, enabling operators to tackle winter weather challenges effectively. A thorough understanding of these components allows for better maintenance and improved performance.

Key elements of this type of machinery include:

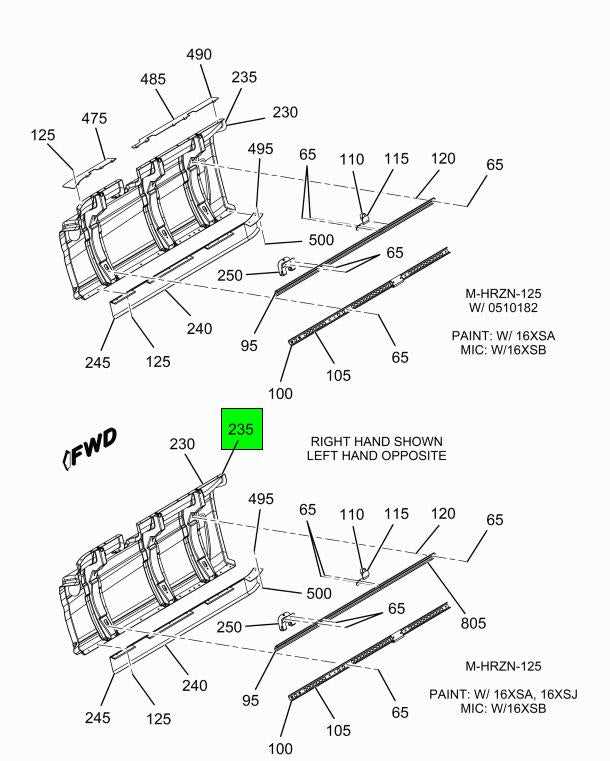

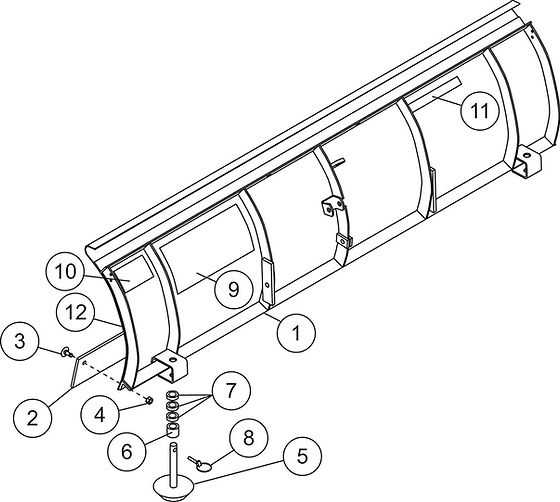

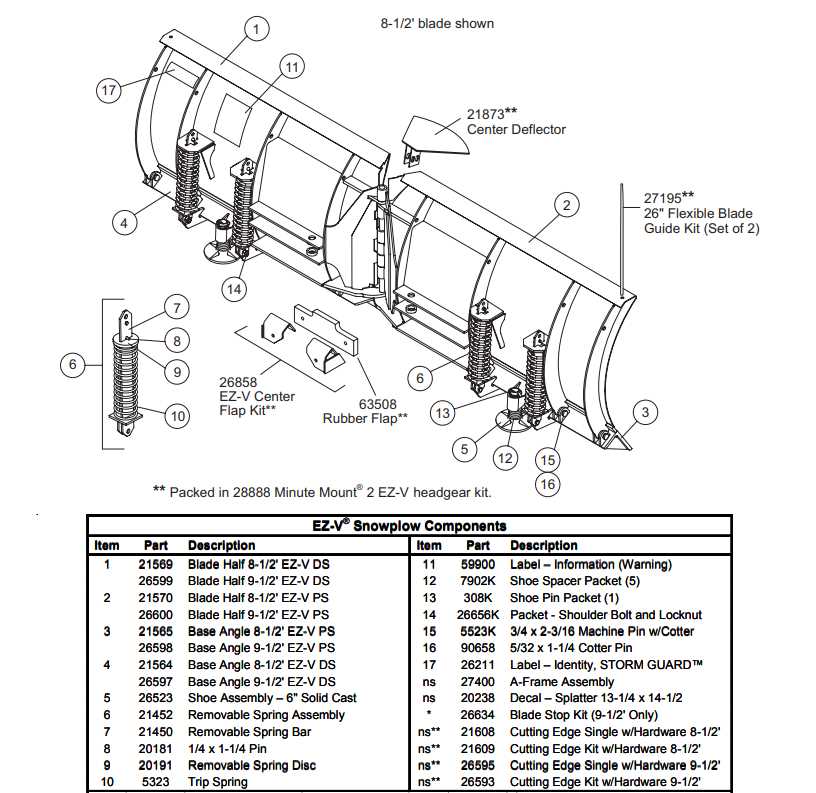

- Blade: The primary surface that interacts with snow, designed to withstand harsh conditions.

- Frame: The robust structure that supports all components and absorbs impact during operation.

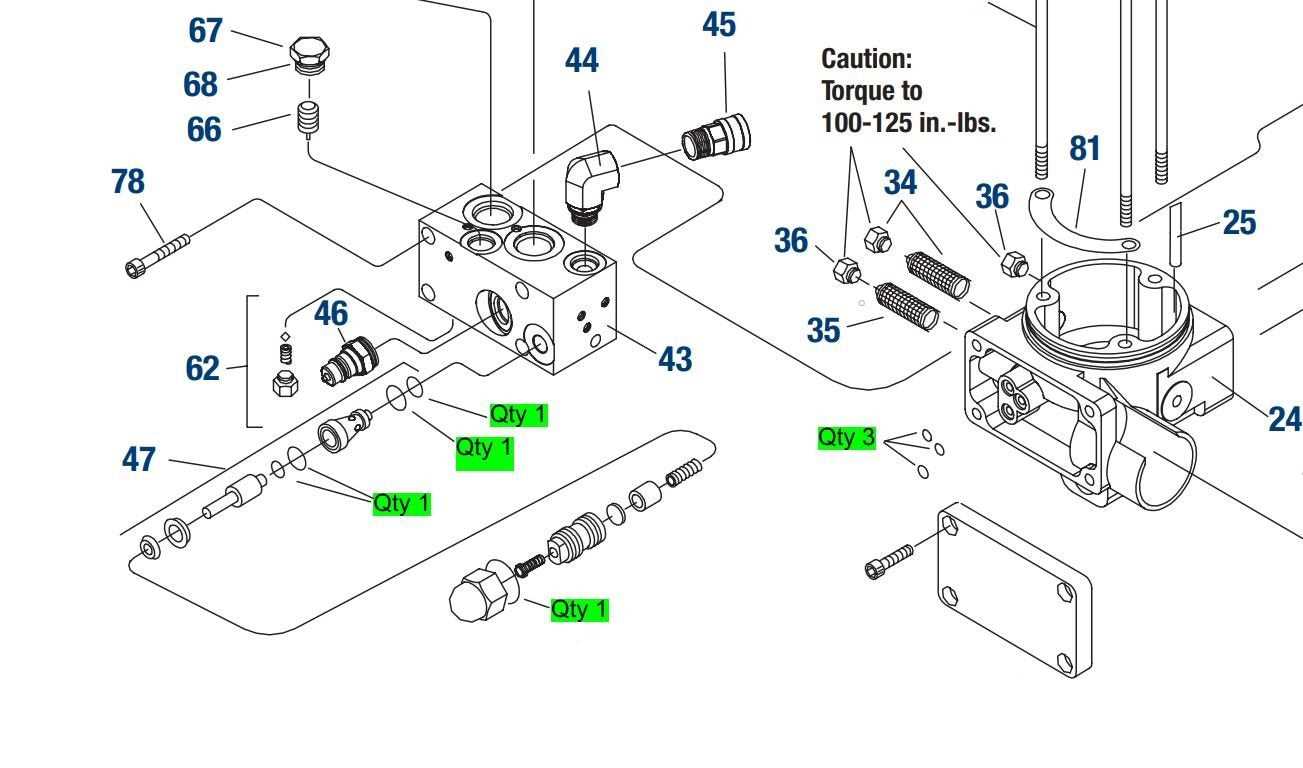

- Hydraulic System: Responsible for adjusting the angle and height of the blade, allowing for precise control.

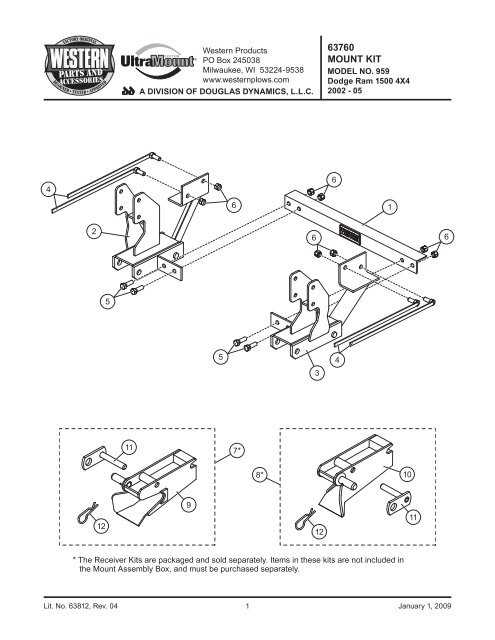

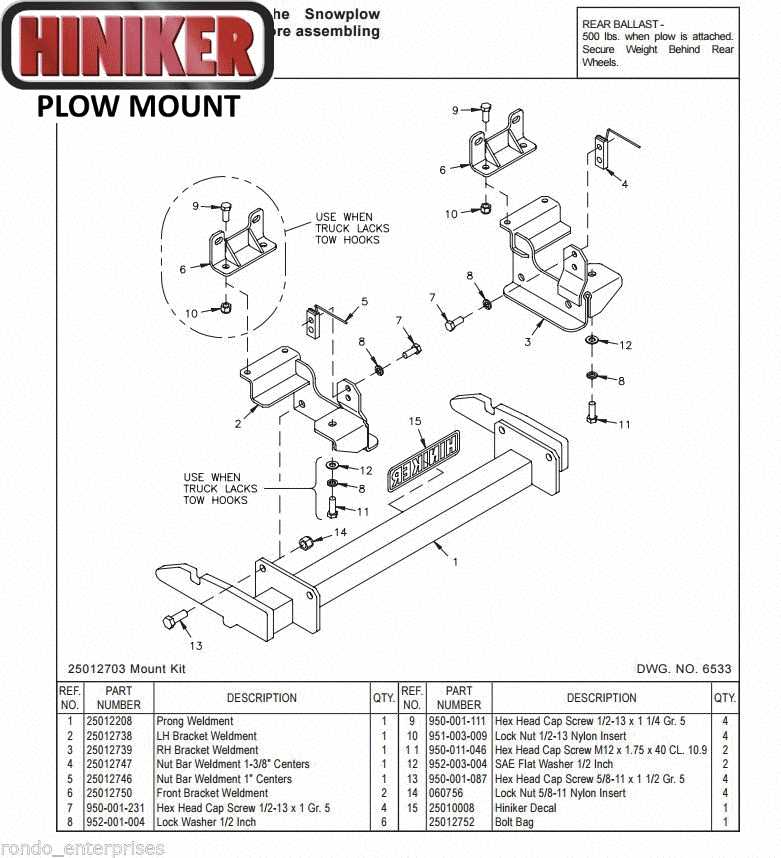

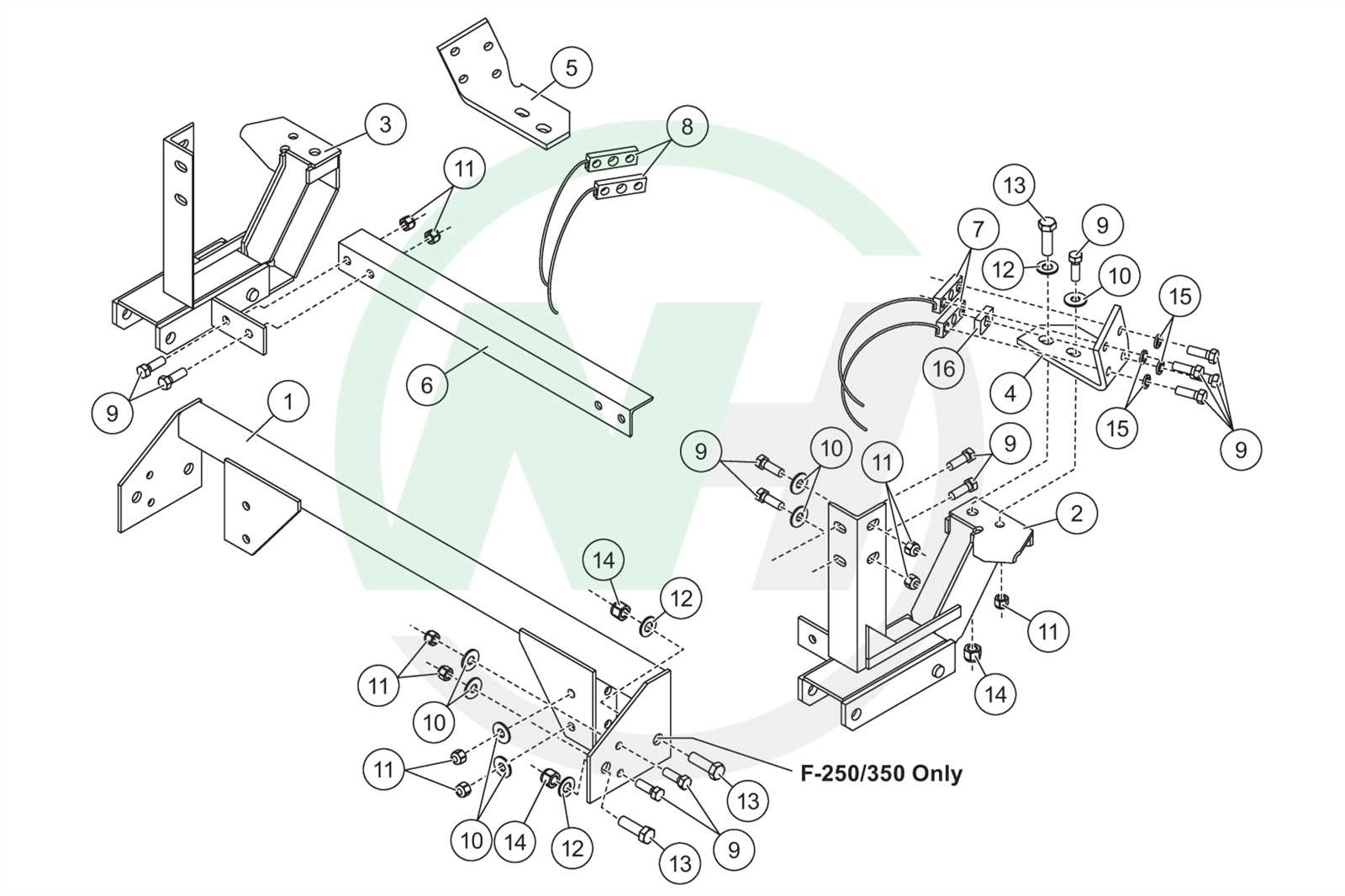

- Mounting Brackets: Connect the equipment securely to the vehicle, ensuring stability during use.

- Electrical System: Powers the hydraulic components and any additional features, such as lights or controls.

Maintenance of these components is crucial for longevity and efficiency:

- Regularly inspect the blade for wear and tear.

- Check the hydraulic fluid levels and ensure there are no leaks.

- Ensure all electrical connections are secure and functional.

- Lubricate moving parts to reduce friction and wear.

- Review the mounting brackets for any signs of corrosion or damage.

By familiarizing oneself with these essential components, operators can ensure their equipment remains in peak condition, ready to tackle any snow-covered terrain.

Key Features of Western Snow Plows

Snow removal equipment is essential for maintaining safe and accessible roadways during winter months. These systems offer a variety of capabilities to enhance efficiency and effectiveness in clearing snow. Understanding the core characteristics can help users maximize performance and achieve optimal results.

- Durable Construction: Built from high-quality materials, ensuring longevity and resistance to wear from harsh weather conditions.

- Advanced Design: Streamlined shapes that minimize drag and enhance maneuverability, allowing for easier navigation in tight spaces.

- Adjustable Angles: Flexibility in blade positioning enables operators to customize snow displacement according to specific needs and environments.

- Enhanced Visibility: Integrated lighting systems improve safety and visibility during nighttime or low-light operations.

- Quick Attachment System: Simplifies the process of connecting and disconnecting equipment, saving valuable time during setup and breakdown.

- Variable Height Options: Allows users to select the ideal height for different snow depths, optimizing performance for various conditions.

These features collectively contribute to an effective approach to snow management, ensuring reliable performance even in the most challenging conditions. Selecting equipment with these attributes can significantly enhance productivity and safety on the job.

Common Issues with Plow Parts

Various challenges can arise with snow removal equipment components, impacting their performance and longevity. Understanding these issues is essential for maintaining optimal functionality and ensuring efficient operation during winter conditions.

- Worn Components: Regular use can lead to significant wear on essential elements, resulting in decreased effectiveness. Inspecting for signs of wear is crucial.

- Corrosion: Exposure to moisture and road salt can cause rust and deterioration, compromising the integrity of metal parts.

- Improper Alignment: Misalignment of attachments can lead to uneven wear and operational difficulties. Regular checks can help maintain correct positioning.

- Hydraulic Issues: Leaks or malfunctions in the hydraulic system can lead to power loss, affecting the ability to raise and lower the equipment smoothly.

- Fastener Failures: Loose or broken fasteners can cause components to detach, leading to potential hazards and operational failures.

Addressing these common challenges through routine maintenance and timely repairs can significantly enhance the performance and reliability of your snow removal equipment.

Maintenance Tips for Plow Systems

Regular upkeep of snow removal equipment is crucial for optimal performance and longevity. By following a systematic maintenance routine, operators can ensure that their machinery operates efficiently and safely, minimizing the risk of breakdowns during critical snow events.

Here are some essential maintenance practices:

- Inspect Before Use: Always conduct a thorough inspection before the first use of the season. Check for any signs of wear or damage that may need addressing.

- Lubrication: Regularly lubricate moving parts to prevent friction and wear. This includes hinges, pivot points, and any other areas where metal meets metal.

- Check Hydraulic Fluids: Ensure that hydraulic fluids are at proper levels and free from contamination. Replace fluids as recommended by the manufacturer.

- Blade Maintenance: Regularly sharpen the cutting edge to ensure effective snow removal. Replace blades that show significant wear or damage.

- Electrical Systems: Inspect all wiring and connections for signs of corrosion or damage. Ensure all lights and indicators function properly for safe operation.

- Fasteners: Regularly check and tighten all bolts and fasteners to prevent them from loosening during operation.

Implementing these practices will help maintain the effectiveness of your snow management machinery and extend its operational life, ensuring you are prepared for winter challenges.

How to Identify Plow Models

Understanding the various models of snow-clearing equipment is essential for ensuring optimal performance and compatibility with your vehicle. Recognizing specific features and configurations can help users select the appropriate model for their needs. This section will guide you through key aspects to consider when determining the model of your snow-removal apparatus.

Key Features to Look For

Start by examining the physical characteristics of the apparatus. Look for the overall size, shape, and any unique design elements that differentiate one model from another. Notable features such as blade width, lift mechanisms, and attachment points can provide significant clues. Additionally, consider the materials used in construction, as this can vary across different series.

Model Identification Resources

Utilize available resources such as manuals, online databases, or manufacturer websites to cross-reference the observed features with known specifications. Serial numbers often provide a definitive means of identification, allowing for accurate model retrieval. Online forums and communities can also be invaluable for connecting with other users who may have encountered similar equipment.

Upgrades for Enhanced Plow Performance

Improving the efficiency and effectiveness of snow management equipment can significantly impact performance during winter operations. Various enhancements are available that optimize functionality, extend durability, and boost overall productivity. These modifications can range from simple additions to more comprehensive overhauls, each designed to tackle unique challenges faced during snow removal tasks.

Performance Enhancements

- Improved Blade Material: Upgrading to high-strength steel or composite materials can enhance wear resistance and reduce maintenance needs.

- Adjustable Blade Angle: Implementing a system for variable blade angles allows for better adaptability to different snow conditions and terrain types.

- Wear Bars: Adding reinforced wear bars can help minimize blade wear, prolonging the life of the equipment and maintaining optimal cutting efficiency.

Operational Features

- Hydraulic Assist: Introducing hydraulic mechanisms for lifting and angling can increase operational ease and responsiveness.

- LED Lighting: Installing high-intensity LED lights improves visibility during nighttime or low-light conditions, enhancing safety and performance.

- Control Systems: Upgrading to advanced electronic control systems allows for more precise handling and monitoring of equipment performance.

These enhancements not only contribute to better performance but also ensure that winter operations are carried out with greater efficiency and safety. By investing in such upgrades, operators can maximize their equipment’s potential and tackle winter challenges with confidence.

Safety Considerations for Plow Usage

When engaging in snow removal tasks, ensuring the well-being of both the operator and bystanders is paramount. Proper precautions and adherence to safety protocols can significantly reduce the risk of accidents and injuries. A thorough understanding of equipment functionality and environmental factors contributes to safer operations.

Before commencing any snow-clearing activity, operators should conduct a meticulous inspection of their equipment. This includes checking for any signs of wear and tear, ensuring all components are secure, and verifying that safety features are operational. Familiarity with the equipment’s manual and operational guidelines further enhances safety awareness.

Additionally, operators must be aware of their surroundings. Monitoring the terrain and visibility conditions is crucial, as uneven surfaces or poor visibility can lead to mishaps. Keeping a safe distance from pedestrians and vehicles is essential to prevent collisions or accidental contact.

Proper attire is also a critical element of safety. Operators should wear appropriate clothing that offers protection against cold weather while ensuring visibility to others. Utilizing high-visibility gear can help in being seen, especially during low-light conditions.

Lastly, it is advisable to remain vigilant and focused during operations. Avoiding distractions and remaining alert to changing conditions will help in managing risks effectively. In case of an emergency, having a plan in place can assist in responding quickly and efficiently, thereby safeguarding everyone involved.

Where to Find Replacement Parts

When the need arises to restore your equipment to optimal condition, finding the correct components is essential. Whether you are performing routine maintenance or addressing a specific issue, sourcing reliable replacements can make all the difference in keeping your system running smoothly. Understanding where to acquire these items ensures efficiency and durability in your machinery.

Authorized Dealers and Distributors

One of the most reliable sources for obtaining compatible components is through official dealers. These businesses work directly with manufacturers, providing access to original items that meet the required specifications. Additionally, authorized distributors often offer warranties and customer support, ensuring you get quality service along with your purchase.

Online Marketplaces and Specialized Stores

Another option is browsing online platforms where both new and used components are available. Many websites specialize in hard-to-find items and offer a variety of options, including aftermarket alternatives. These stores often provide customer reviews, helping you assess the reliability and compatibility of the components before making a purchase.

- Official dealer

Benefits of Original Equipment Parts

When maintaining or repairing complex systems, using genuine components is essential to ensure reliability and longevity. These components are specifically designed to match the original specifications, which guarantees optimal performance and a seamless fit.

- Enhanced Durability: Authentic replacements are built to last, providing better resistance to wear and tear compared to alternatives.

- Perfect Compatibility: Genuine items are engineered to match the exact measurements and requirements of the original design, reducing the risk of malfunctions.

- Reliable Performance: Using original components ensures that the system continues to function as intended, maintaining efficiency and safety.

- Warranty Protection: Many manufacturers offer extended warranties for systems maintained with authentic components, offering added peace of mind.

- Safety Assurance: High-quality original equipment undergoes rigorous testing to meet safety standards, which is crucial for heavy-duty applications.