The efficient operation of your trimming tool relies on a well-coordinated assembly of its various elements. Each component plays a crucial role in ensuring that the machine performs optimally, providing you with the precision and effectiveness needed for your gardening tasks. Familiarity with these elements can significantly enhance your maintenance routine and overall performance.

In this section, we will explore the intricate layout of these components, highlighting their functions and relationships. By understanding how each part contributes to the tool’s performance, you will be better equipped to troubleshoot issues and carry out repairs, ensuring that your equipment remains in top condition.

Whether you are a seasoned gardener or a novice, knowing the intricacies of your trimming tool’s assembly can lead to improved efficiency and a better gardening experience. Let’s delve into the various elements and discover how they work together to help you achieve a well-maintained landscape.

Understanding Weed Eater Components

Exploring the various elements that contribute to the functionality of a trimming device is essential for effective maintenance and operation. Each component plays a vital role in ensuring the machine performs optimally, enhancing the user’s experience while ensuring safety and efficiency.

Main Elements of the Trimming Device

- Motor: The power source that drives the machine, available in gas or electric options.

- Shaft: The long rod that connects the motor to the cutting head, available in straight or curved designs.

- Cutting Head: The part that houses the cutting mechanism, which can be either a line or blade.

- Handle: Provides the user with control and maneuverability while operating the equipment.

Additional Features

- Throttle Control: Allows the user to adjust the speed and power according to the task at hand.

- Guard: A protective shield that prevents debris from flying toward the user.

- Shoulder Strap: An accessory that aids in balancing the weight during prolonged use.

Understanding these components not only helps in choosing the right device but also aids in troubleshooting and maintenance, ensuring longevity and performance efficiency.

Importance of Weed Eater Maintenance

Regular upkeep of garden trimming equipment is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to decreased efficiency, higher costs, and premature failure. A well-maintained tool not only enhances productivity but also contributes to a safer working environment.

Benefits of Regular Maintenance

- Improved Performance: Consistent care ensures that the equipment operates at peak efficiency.

- Increased Lifespan: Routine checks and repairs can extend the life of the tool.

- Cost Savings: Investing time in maintenance can prevent expensive repairs or replacements.

- Safety: Properly maintained equipment reduces the risk of accidents and injuries.

Key Maintenance Tasks

- Cleaning: Regularly remove debris and residue from the device.

- Inspection: Check for wear and tear on components to identify potential issues.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction.

- Sharpening: Keep cutting tools sharp for efficient trimming.

Prioritizing the maintenance of garden tools ensures that they remain reliable and effective, ultimately leading to a more enjoyable and productive gardening experience.

Identifying Essential Parts of a Weed Eater

Understanding the key components of a trimming tool is vital for effective maintenance and operation. Each section plays a crucial role in ensuring optimal performance, enabling users to tackle overgrown areas with ease. Familiarity with these elements can enhance the lifespan of the device and improve its functionality.

Core Components

The central elements of the trimming apparatus include the motor, which powers the unit, and the cutting mechanism, designed to handle various types of vegetation. Additionally, the handle and shaft provide control and maneuverability, making it easier to reach tight spots.

Supporting Features

Supporting elements such as the guard and harness are essential for safety and comfort during operation. Understanding these features helps users make informed decisions regarding maintenance and potential upgrades, ultimately leading to a more efficient trimming experience.

Common Issues with Weed Eater Components

Many users encounter various challenges when maintaining their trimming equipment. Understanding these common problems can enhance performance and extend the lifespan of the device.

- Engine Troubles: Frequent starting issues or stalling can arise from fuel or air supply problems.

- Cutting Mechanism Failures: Dull blades or improper alignment often lead to ineffective cutting.

- Line Feed Problems: Jamming or breaking of the line can occur due to wear or incorrect installation.

- Vibration and Noise: Excessive vibrations may signal loose components or unbalanced parts.

- Overheating: Insufficient cooling or clogged vents can cause the motor to overheat, leading to potential damage.

Addressing these issues promptly can ensure optimal functionality and durability of the equipment.

How to Replace Weed Eater Parts

Maintaining garden tools is essential for their longevity and optimal performance. Knowing how to swap out components can ensure your device runs smoothly and effectively. This guide outlines the steps to efficiently replace various elements of your gardening tool, helping you to restore its functionality with ease.

Before beginning the replacement process, ensure you have the necessary tools and new components ready. Common items needed include screwdrivers, wrenches, and safety gloves. Always consult the user manual for specific instructions related to your model to avoid any mishaps.

Start by disconnecting the power source to prevent accidents during the procedure. Carefully examine the device to identify which components need to be replaced. Once identified, use the appropriate tools to remove the old parts, taking care to keep any screws or fasteners in a safe place for reinstallation.

Next, align the new components properly and secure them as per the manufacturer’s guidelines. Double-check your work to ensure everything is fitted correctly and firmly in place. Finally, reconnect the power source and conduct a test run to verify that the changes have restored the tool’s performance.

Regular maintenance and timely replacements can greatly extend the lifespan of your gardening equipment, making it a worthwhile endeavor for any garden enthusiast.

Safety Precautions When Repairing Equipment

When engaging in the maintenance and repair of machinery, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can significantly mitigate risks associated with handling tools and equipment. Understanding these precautions ensures a safer working environment for everyone involved.

Before starting any repair work, familiarize yourself with the equipment and its components. Proper preparation can help avoid unexpected hazards. Below are some essential safety measures to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment such as goggles, gloves, and sturdy footwear to protect against injuries. |

| Disconnect Power Sources | Ensure all power sources are disconnected before beginning repairs to prevent accidental starts. |

| Keep Workspace Organized | A tidy workspace reduces the risk of tripping or misplacing tools, leading to safer repairs. |

| Use Proper Tools | Utilize the correct tools for the job to avoid damage to the equipment and reduce the chance of injury. |

| Read Manuals | Consult the manufacturer’s instructions to understand the specific safety recommendations for the equipment. |

By implementing these safety measures, individuals can enhance their protection while performing repairs and ensure a more efficient workflow. Safety should always be the top priority in any maintenance task.

Tools Needed for Weed Eater Repairs

When it comes to maintaining and fixing your outdoor trimming device, having the right tools is essential for efficient and effective repairs. A well-equipped toolkit not only saves time but also ensures that you can tackle various issues that may arise during operation. Familiarity with the necessary instruments will empower you to perform repairs confidently and extend the life of your equipment.

Essential Hand Tools

A solid selection of hand tools is crucial for any repair job. Basic items such as screwdrivers, wrenches, and pliers will allow you to address common issues like loose screws or damaged components. Additionally, having a utility knife can help with cutting through any debris or old parts that need to be replaced. It’s advisable to invest in quality tools that will stand the test of time and provide reliable performance during maintenance tasks.

Specialized Equipment

In addition to standard hand tools, certain specialized equipment can greatly facilitate repairs. A torque wrench is vital for ensuring that all fittings are tightened to the manufacturer’s specifications, which can prevent further damage. Moreover, a multimeter can assist in diagnosing electrical issues, while a replacement line spool can be a lifesaver for quickly restoring functionality. Having these specialized tools on hand will enable you to address a wider range of repair challenges efficiently.

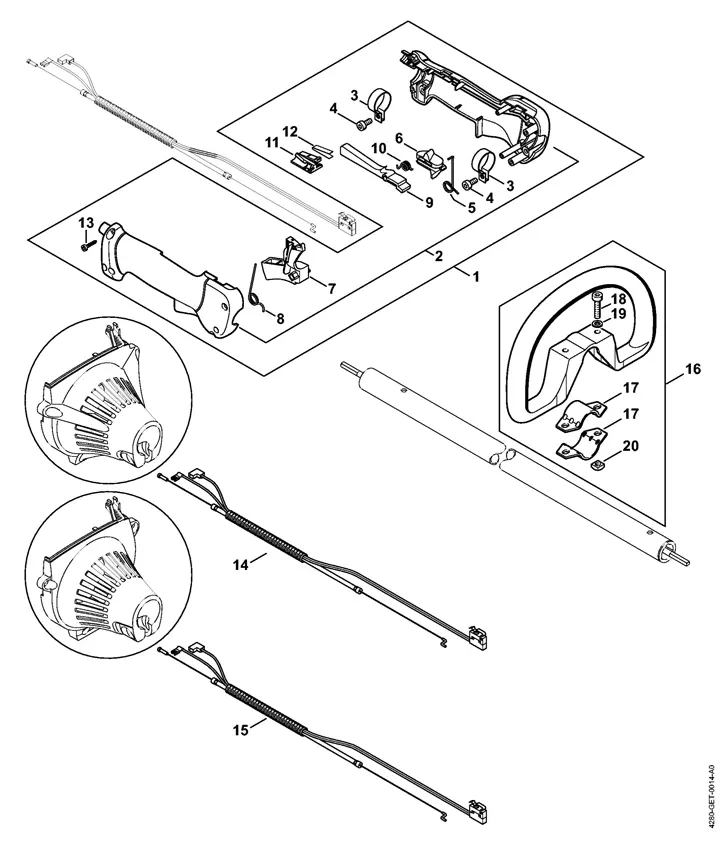

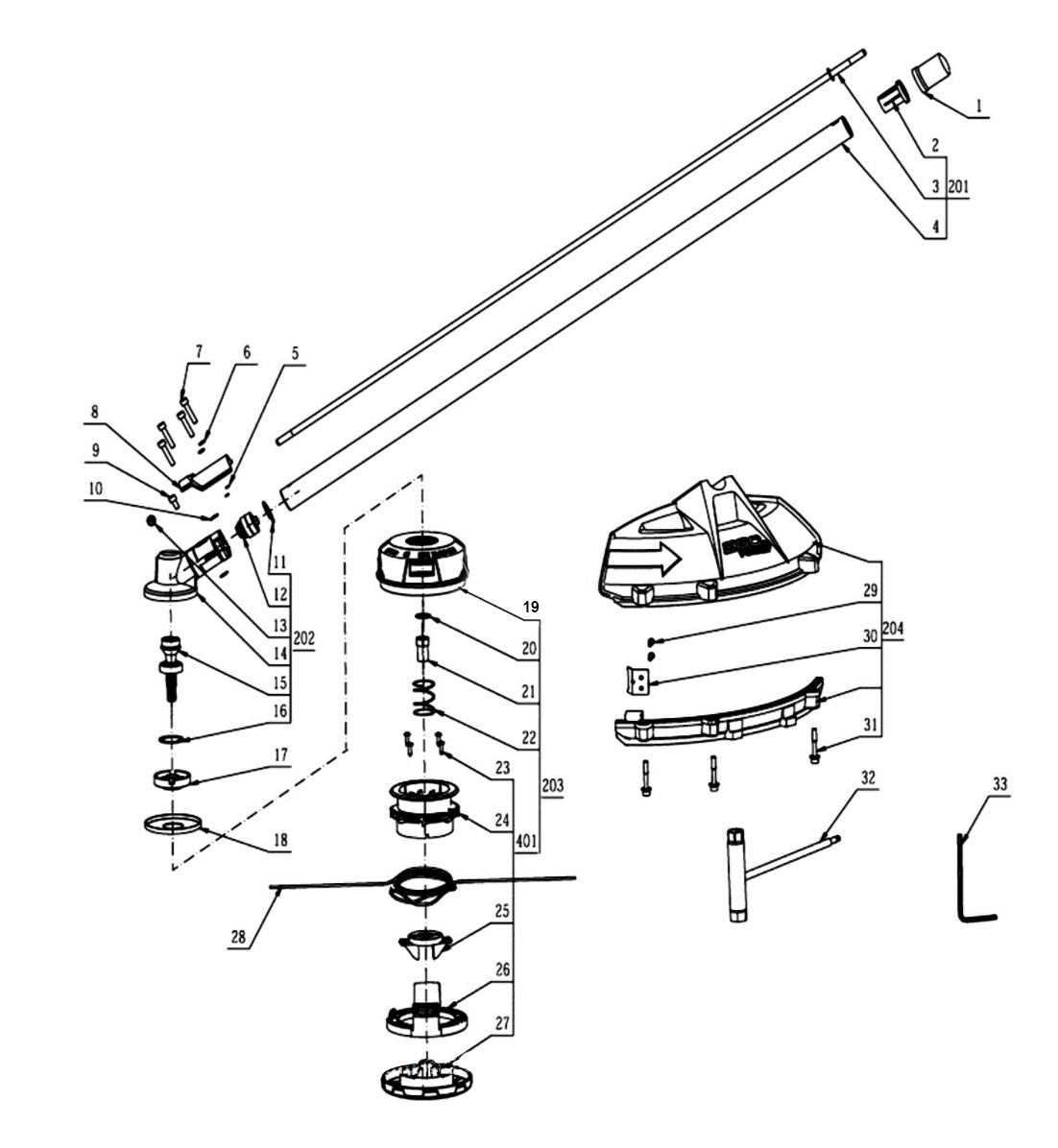

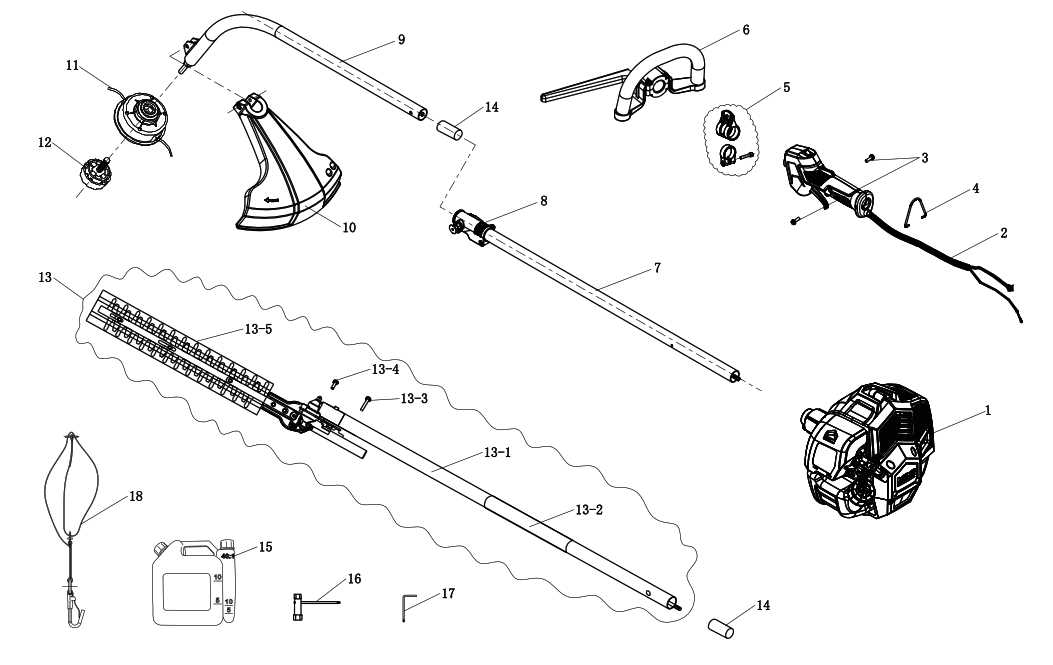

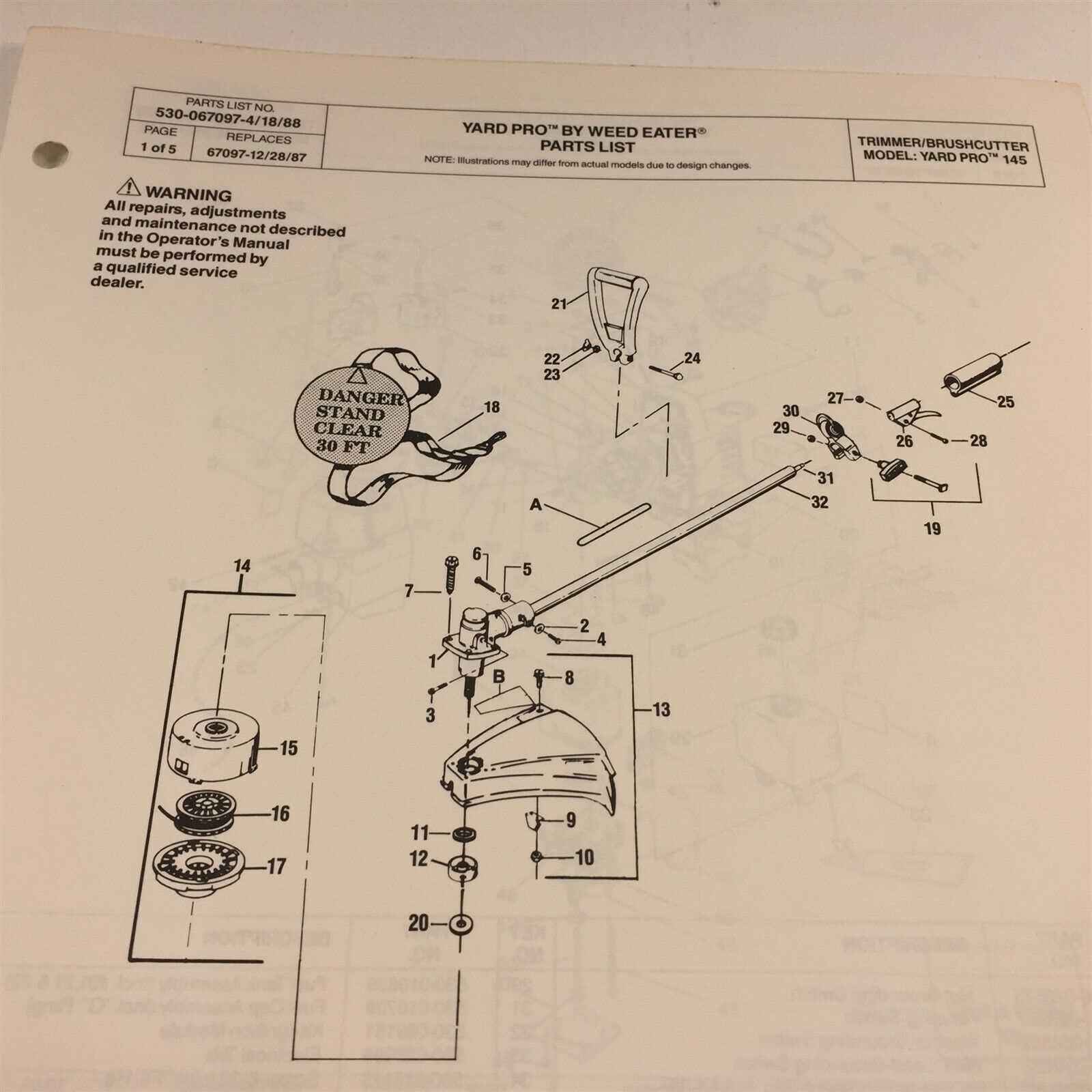

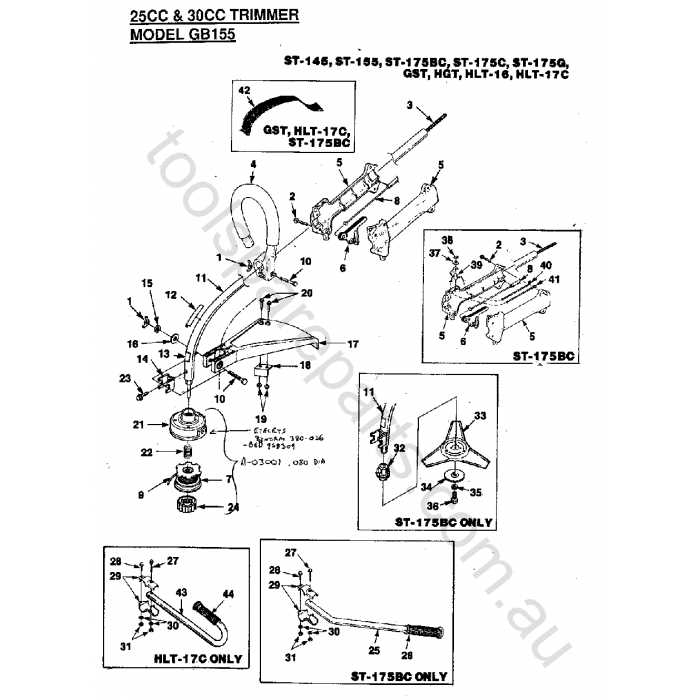

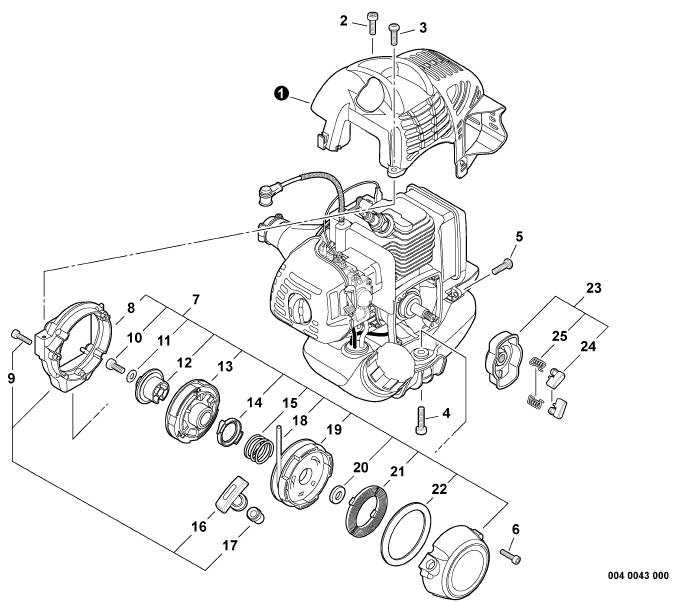

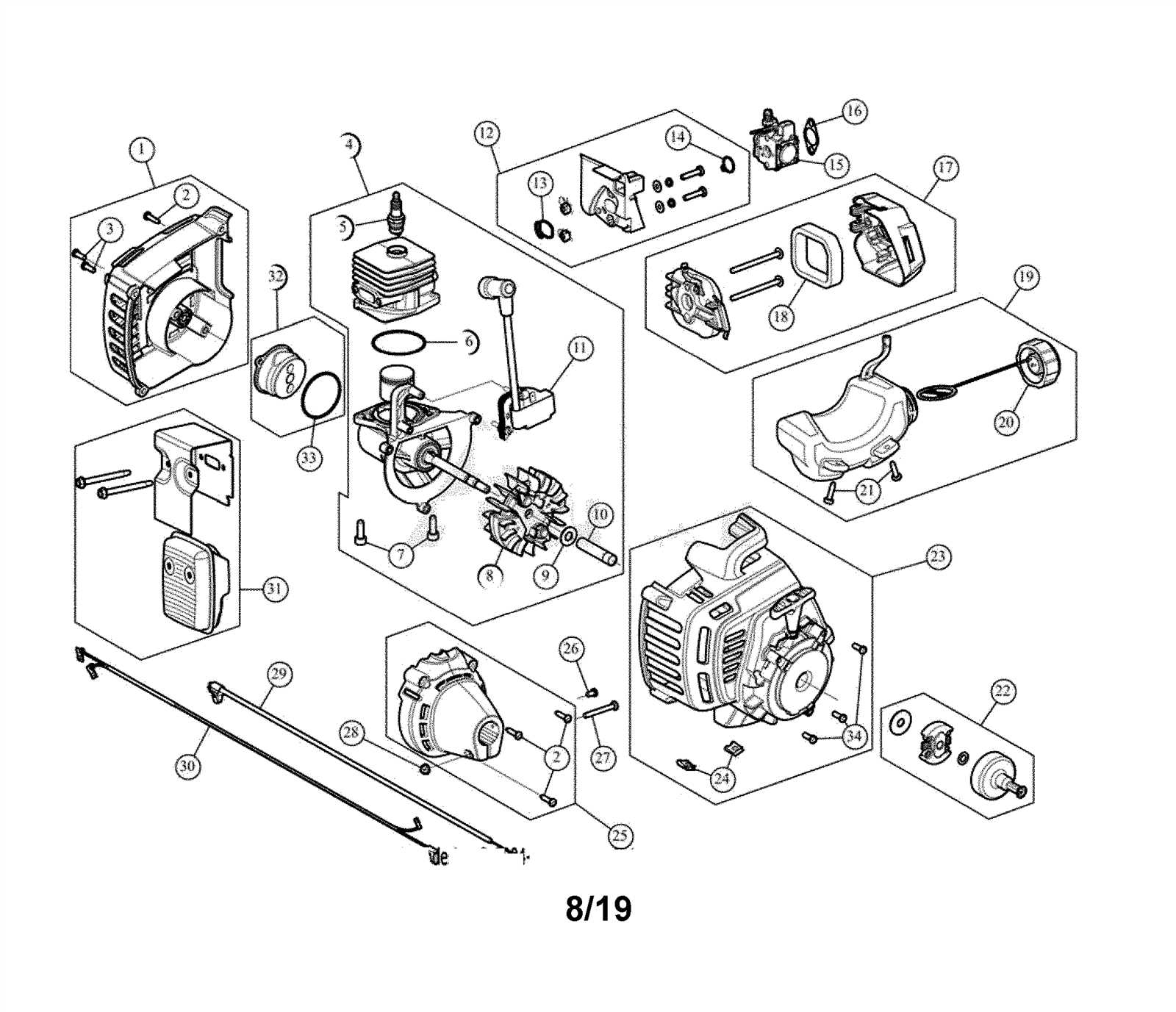

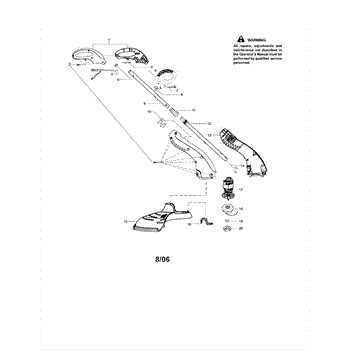

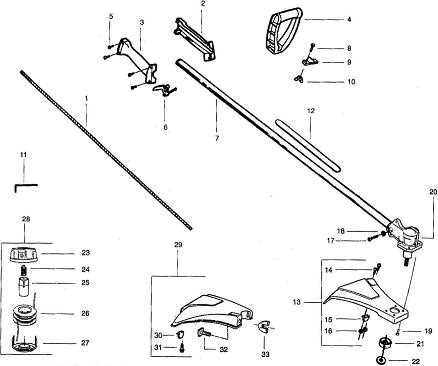

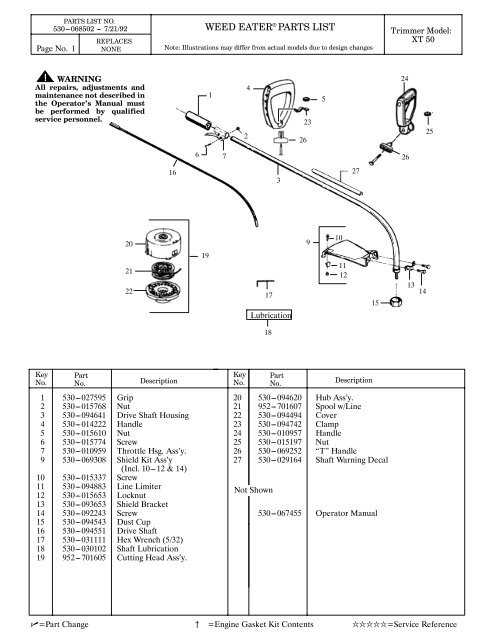

Visual Guide to Weed Eater Assembly

This section provides a comprehensive visual reference for assembling a trimming tool. Understanding the various components and their arrangement is essential for efficient operation and maintenance. With clear illustrations and descriptions, users will be able to easily navigate through the assembly process.

Key Components Overview

The assembly consists of several crucial elements, each serving a specific function. Familiarizing yourself with these components will facilitate a smoother assembly experience. From the handle to the cutting mechanism, each part plays an integral role in the tool’s performance.

Step-by-Step Assembly Process

Follow this straightforward process to ensure proper setup. Start by securing the handle to the main body, making sure all connections are tight. Next, attach the cutting assembly, aligning it precisely for optimal efficiency. Finally, review each connection to ensure everything is in place. Regular checks will help maintain the tool’s functionality and extend its lifespan.

Upgrading Your Weed Eater Efficiency

Enhancing the performance of your trimming device can lead to significant improvements in both speed and effectiveness. By focusing on various components and maintenance strategies, you can ensure a smoother operation and greater longevity.

Key Areas to Focus On

- Regular Maintenance

- High-Quality Accessories

- Optimized Cutting Techniques

Maintenance Tips

- Clean the cutting mechanism regularly to prevent buildup.

- Check and replace worn-out components promptly.

- Ensure fuel and lubrication are adequate for optimal function.