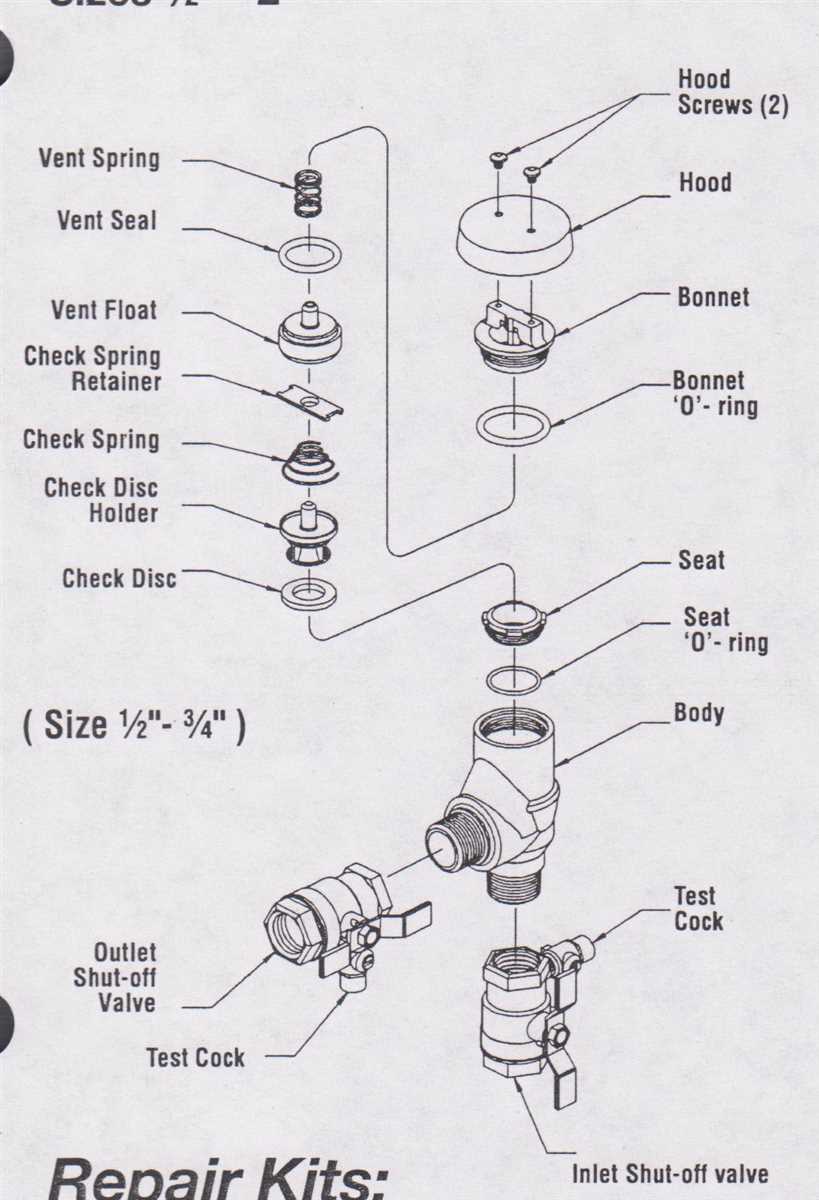

In the realm of mechanical systems, a comprehensive understanding of each element’s role and interconnection is essential for effective upkeep and troubleshooting. When engaging with intricate devices, having a visual representation that outlines the arrangement of various components can significantly enhance one’s ability to address issues and optimize performance.

Such illustrations serve not only as a guide for maintenance tasks but also as an educational resource for those seeking to familiarize themselves with the machinery. By dissecting these arrangements, one can gain insights into the functionality and dependencies of individual elements, leading to more informed decisions during repairs or upgrades.

Moreover, these visual tools foster a deeper appreciation for the engineering behind the equipment. Understanding how each piece contributes to the overall operation allows users to anticipate potential failures and implement preventative measures, ultimately ensuring longevity and reliability in their systems.

Understanding Watts 800m4 Overview

This section provides an essential overview of a specific model that plays a significant role in its category. Its design and functionality cater to various applications, making it a versatile choice for both professionals and enthusiasts. Analyzing the components and their interactions allows users to appreciate the efficiency and reliability of the system.

Key Features

The model showcases several standout attributes that enhance its performance. Notably, its innovative structure promotes optimal functionality while ensuring ease of use. Users can benefit from the robust construction, which guarantees longevity and durability in demanding environments.

Applications and Use Cases

Widely utilized in various fields, this system excels in scenarios requiring precision and dependability. Whether employed in residential, commercial, or industrial settings, it demonstrates adaptability and effectiveness, meeting diverse operational needs. Understanding its applications helps potential users make informed decisions regarding its implementation.

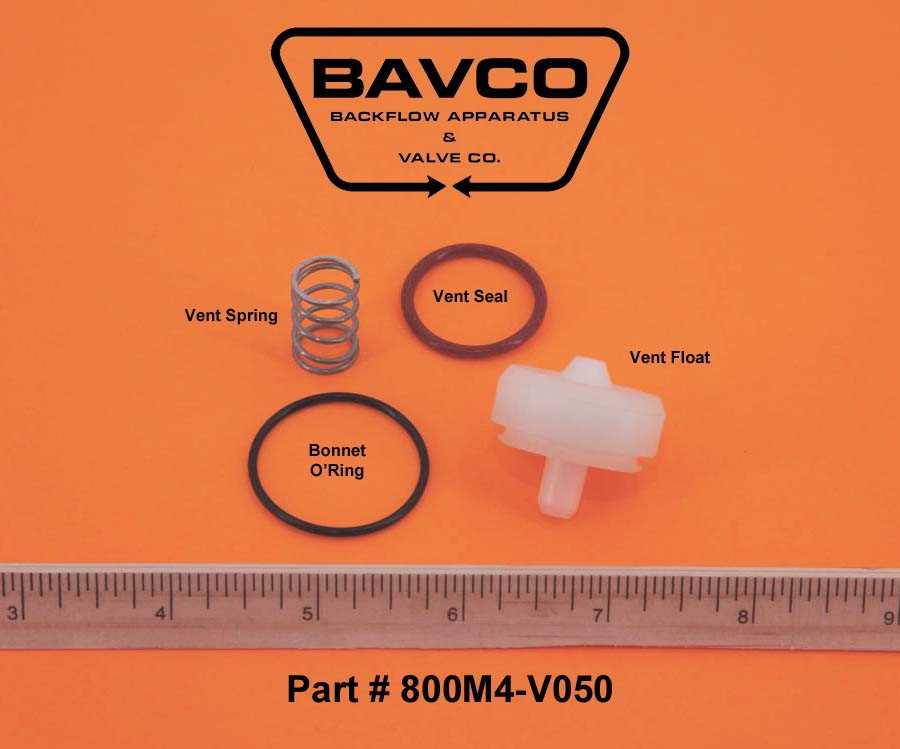

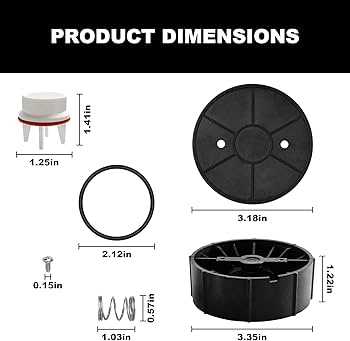

Key Components of Watts 800m4

This section delves into the essential elements that contribute to the functionality and efficiency of this particular model. Understanding these components is crucial for users looking to maximize performance and ensure longevity.

One of the primary elements is the actuator, which plays a pivotal role in regulating flow and maintaining optimal pressure levels. This device ensures smooth operation by adjusting to varying system demands.

Another significant part is the control mechanism, which allows for precise adjustments and monitoring of the system’s performance. This feature enhances user experience by providing real-time feedback and control over the device’s operations.

Additionally, the housing structure is designed for durability and resistance to environmental factors. Its robust construction safeguards internal components, ensuring reliable operation even under challenging conditions.

Lastly, seals and gaskets are critical for preventing leaks and maintaining system integrity. Their quality and design directly influence the overall efficiency and safety of the unit.

Functionality of Each Part Explained

This section delves into the essential roles played by various components in a specific system. Understanding how each element operates not only enhances overall comprehension but also facilitates effective maintenance and troubleshooting.

Here is a breakdown of the main components and their functions:

-

Element A:

This component serves as the primary regulator, ensuring optimal performance by controlling flow and pressure.

-

Element B:

Acting as a filter, this part is crucial for maintaining the integrity of the system by removing impurities and preventing clogs.

-

Element C:

This section functions as a connector, linking various parts together for seamless operation and efficient energy transfer.

-

Element D:

Responsible for measurement, this element provides vital data that helps in monitoring performance and diagnosing issues.

-

Element E:

This part is integral to the activation mechanism, enabling the system to start and operate as intended.

By familiarizing yourself with these components, you can better appreciate their interdependence and the overall efficiency of the mechanism.

Maintenance Tips for Watts 800m4

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular checks and maintenance routines can prevent potential issues and enhance efficiency, allowing for smoother operation over time.

Here are some key maintenance practices to consider:

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for leaks, cracks, or signs of wear. |

| Cleaning | Quarterly | Remove dust and debris to ensure proper airflow. |

| Lubrication | Biannually | Apply appropriate lubricant to moving parts. |

| Functional Testing | Annually | Verify operational efficiency and safety features. |

Following these guidelines can help maintain peak performance and extend the lifespan of your unit.

Common Issues and Troubleshooting

This section addresses frequent problems that users may encounter with their equipment and provides practical solutions for effective resolution. Understanding these challenges can significantly enhance performance and longevity.

Here are some common issues:

- Leaks: Often caused by worn seals or improper fittings.

- Noisy Operation: This can indicate mechanical wear or insufficient lubrication.

- Inconsistent Performance: Usually linked to blockages or irregular pressure levels.

- Temperature Fluctuations: May result from sensor malfunctions or inadequate insulation.

To troubleshoot these problems, consider the following steps:

- Check for visible signs of wear or damage.

- Ensure all connections are secure and free from debris.

- Verify that all settings are correctly adjusted according to specifications.

- Consult the user manual for specific guidelines related to your model.

If issues persist after these checks, it may be necessary to consult a professional technician for further diagnosis and repair.

Replacement Parts Availability and Sources

Ensuring the longevity and efficiency of any equipment often hinges on the accessibility of its components. When repairs or upgrades are necessary, it’s crucial to know where to find reliable replacements. This section explores various avenues for obtaining essential elements to maintain optimal functionality.

| Source Type | Description | Advantages |

|---|---|---|

| Manufacturer’s Website | Direct access to original components and documentation. | Authenticity and quality assurance. |

| Authorized Distributors | Partners recognized by the manufacturer for resale. | Expertise and reliable customer support. |

| Aftermarket Suppliers | Third-party vendors offering alternative options. | Potential cost savings and wider availability. |

| Online Marketplaces | Platforms where various sellers list their inventory. | Convenience and competitive pricing. |

| Local Repair Shops | Nearby facilities specializing in repairs and parts. | Personalized service and immediate assistance. |

By exploring these different sources, users can ensure they find the right replacements, enabling the continued effectiveness of their systems and reducing downtime.

Benefits of Using Watts 800m4

The implementation of advanced systems in fluid management offers numerous advantages that can significantly enhance operational efficiency. These benefits stem from the design and functionality of components that ensure optimal performance, reliability, and longevity in various applications.

Efficiency: Utilizing modern equipment allows for improved energy consumption, reducing overall operational costs. The innovative design ensures that resources are used effectively, leading to better performance under varying conditions.

Durability: High-quality materials and construction techniques contribute to a longer lifespan. This resilience minimizes the need for frequent replacements, providing cost savings over time.

Ease of Maintenance: Components designed with user-friendly features simplify maintenance tasks. Quick access to key areas allows for faster service, ensuring systems remain operational without extensive downtime.

Versatility: The adaptability of these systems makes them suitable for a wide range of applications, from residential to industrial settings. This flexibility enables users to tailor solutions that meet specific needs efficiently.

Safety: Incorporating advanced safety features reduces the risk of accidents and enhances overall operational security. Users can work with confidence, knowing that their systems are designed to prevent failures.

In summary, the benefits associated with the use of innovative fluid management solutions significantly impact productivity and safety, making them an essential choice for modern applications.

Comparative Analysis with Other Models

This section explores the differences and similarities among various devices within the same category, highlighting key features that set them apart. By examining performance, efficiency, and design, we can better understand their unique attributes and how they cater to different user needs.

In comparison to its peers, this particular model demonstrates superior durability and reliability, making it a favored choice for demanding environments. Other models may excel in specific functionalities, but often at the expense of overall robustness. Such distinctions are crucial for users looking to make informed decisions based on their specific requirements.

Furthermore, the user interface and ease of maintenance are significant factors in this comparative study. While some alternatives offer advanced features, they can complicate user experience. The balance between complexity and usability is essential when evaluating different options in the market.