In the world of heavy machinery, the intricacies of equipment design play a crucial role in ensuring optimal performance. A comprehensive grasp of how various elements interconnect is essential for both maintenance and efficiency. By exploring the layout of key components, operators can enhance their understanding of functionality and troubleshoot issues effectively.

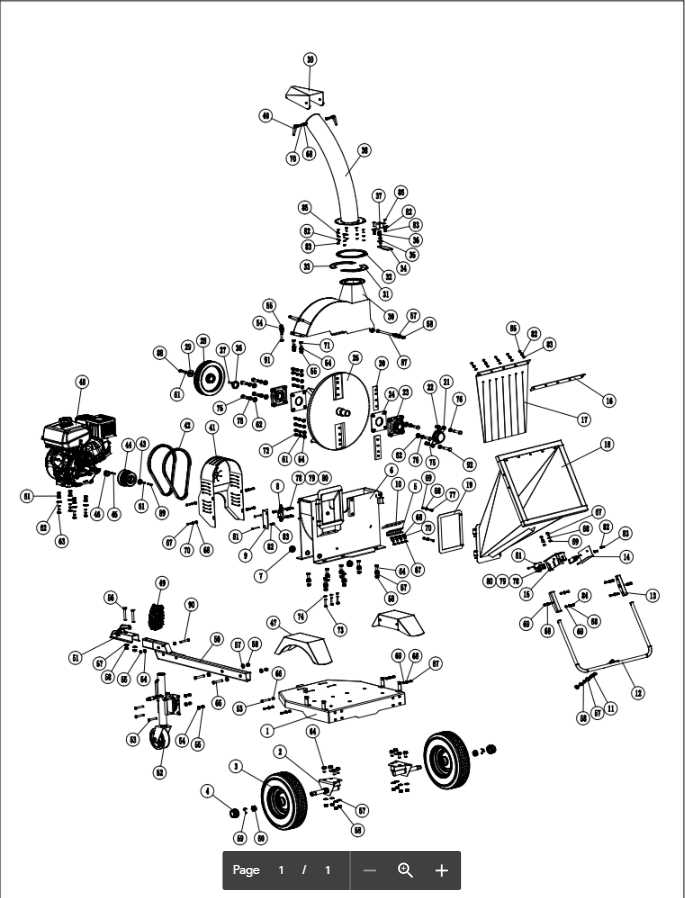

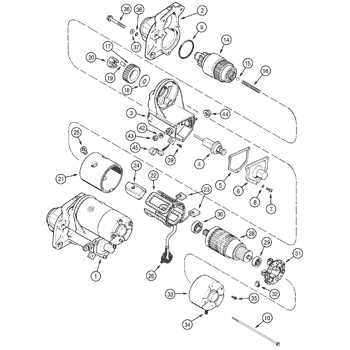

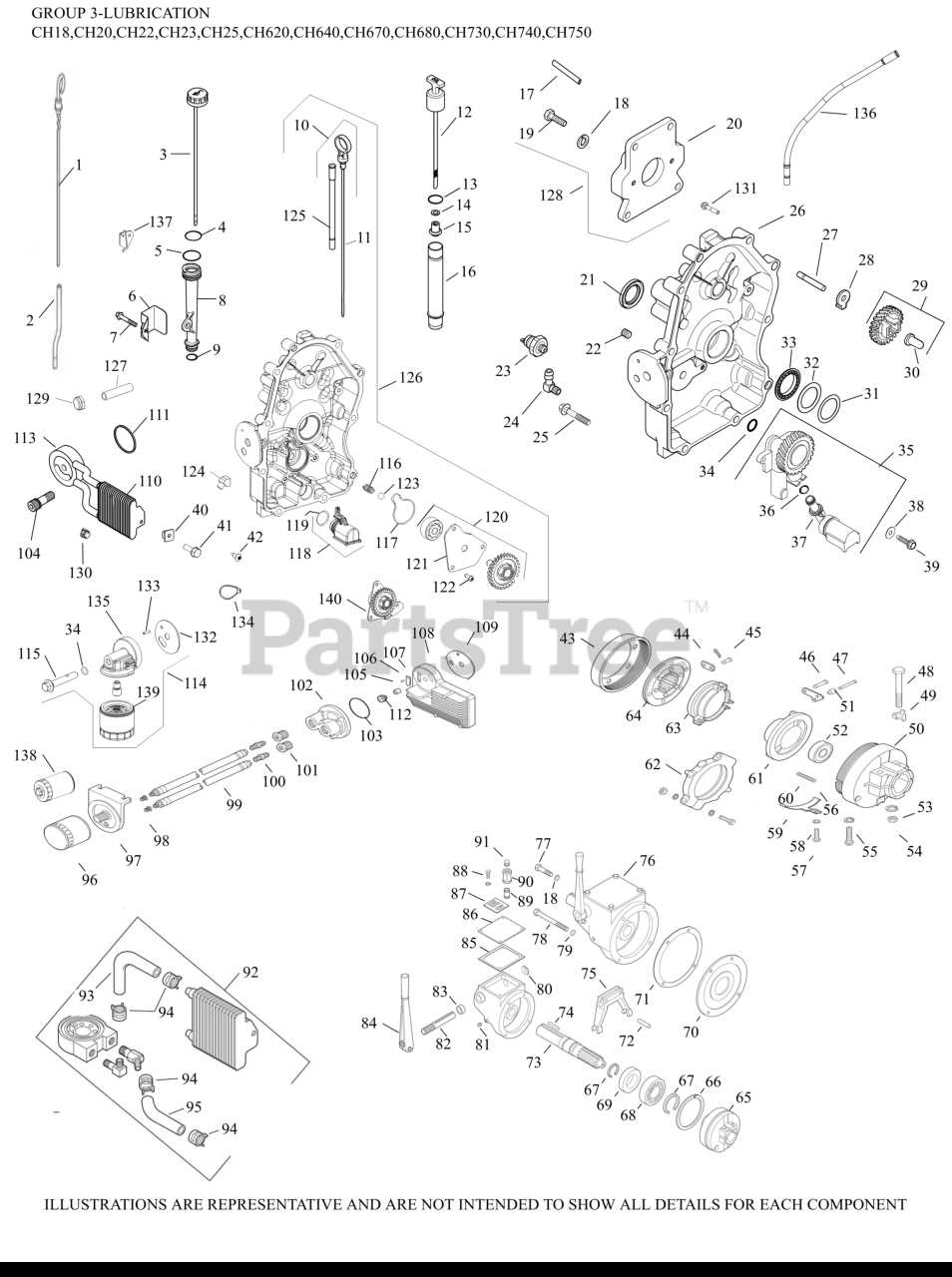

Detailed illustrations serve as invaluable resources for anyone working with complex machinery. These visuals break down the relationships between individual pieces, providing clarity on how they contribute to overall operation. Engaging with these representations allows for a deeper insight into mechanical interactions and potential improvements.

Furthermore, becoming familiar with these schematics empowers users to identify parts that may require attention or replacement. This knowledge not only aids in maintaining peak operational standards but also fosters a proactive approach to equipment care. Ultimately, a thorough examination of these layouts can lead to enhanced productivity and longevity.

Understanding Vermeer Trenchers

This section delves into the essential machinery used for underground excavation and utility installation. These machines are designed to create narrow, precise channels in the ground, facilitating various construction and maintenance projects. Their efficiency and precision make them indispensable in modern civil engineering and landscaping.

Key Features and Benefits

Modern excavation machines come equipped with advanced technology that enhances their performance. Features such as variable depth control, powerful cutting capabilities, and user-friendly controls allow operators to perform tasks with greater accuracy and speed. Additionally, these machines are designed for durability, ensuring they withstand the rigors of heavy use in challenging environments.

Maintenance and Care

Regular maintenance is crucial for ensuring optimal performance and longevity of these excavation machines. Routine checks, such as inspecting cutting edges, monitoring fluid levels, and cleaning filters, help prevent breakdowns and enhance efficiency. Understanding the maintenance requirements is vital for operators to ensure their machinery remains in top working condition throughout its lifespan.

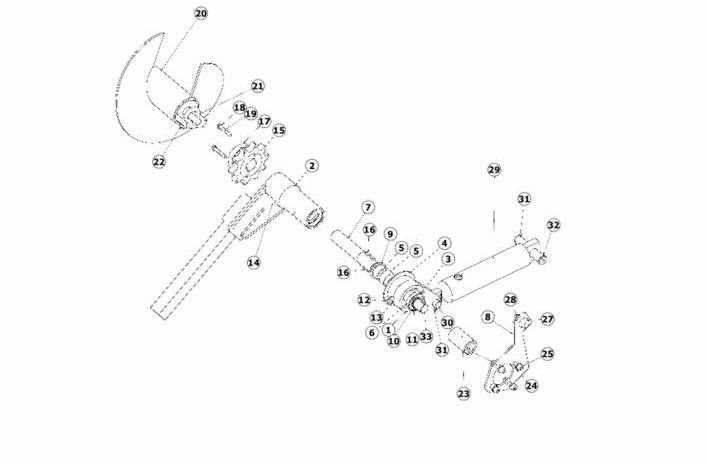

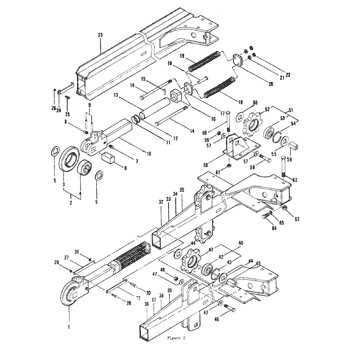

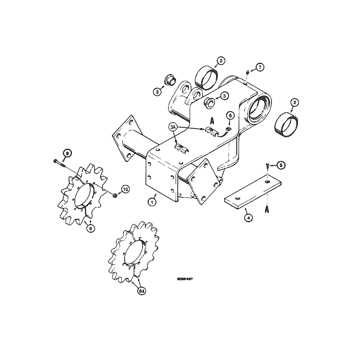

Components of Vermeer Trencher Models

This section explores the essential elements that contribute to the functionality and efficiency of specific machinery used for underground excavation. Understanding these components helps in recognizing their roles and importance in the overall operation.

1. Cutting Mechanism: The cutting apparatus is vital for effectively breaking through various soil types. It ensures precise and efficient excavation.

2. Drive System: The propulsion system is responsible for the movement of the equipment. Its design influences speed and maneuverability in different terrains.

3. Hydraulic Components: These elements facilitate the operation of various attachments and enhance the machine’s overall performance. Proper maintenance is crucial for their longevity.

4. Frame and Chassis: The structural foundation provides stability and support, ensuring that all other components function together seamlessly.

5. Control Systems: These allow operators to manage various functions intuitively, enhancing precision during operation and improving safety standards.

By delving into each component, users can better appreciate the engineering behind this machinery and its applications in various projects.

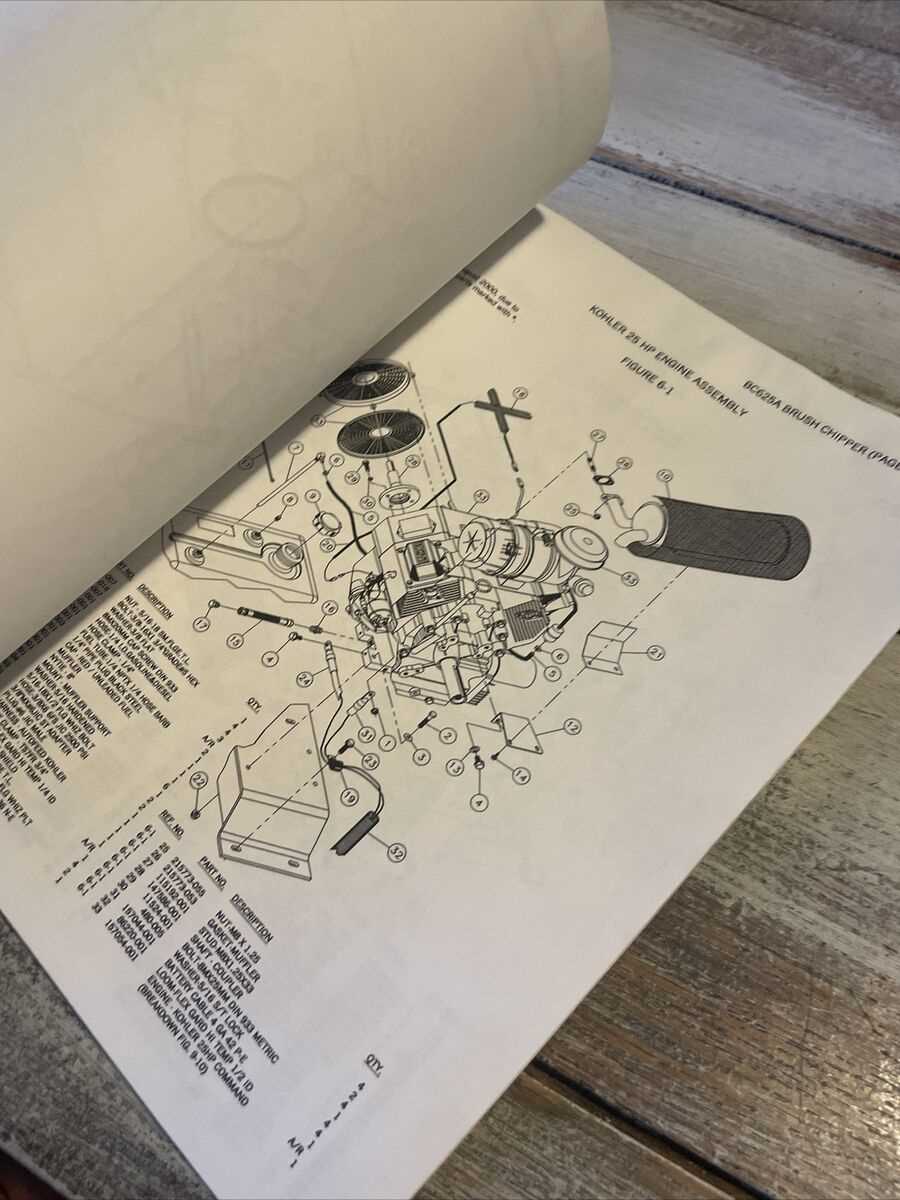

Importance of Accurate Parts Diagrams

Clear and precise illustrations of components play a crucial role in the maintenance and repair of machinery. These visual aids serve as a reference that simplifies the understanding of complex systems, allowing users to identify and locate each individual element effectively. Without accurate representations, the risk of errors during assembly or disassembly increases significantly.

Benefits of Detailed Illustrations

- Facilitates Efficient Repairs: Users can quickly identify faulty components and understand their functions, leading to faster repair times.

- Enhances Safety: Accurate visuals help ensure that each part is handled correctly, reducing the risk of accidents or damage.

- Promotes Proper Maintenance: Users can follow maintenance schedules more effectively when they have a clear view of all necessary elements.

- Supports Training: New technicians can learn the layout and functions of machinery more rapidly through detailed visual guides.

Consequences of Inaccurate Representations

- Increased Downtime: Errors in identifying components can lead to extended repair periods, impacting productivity.

- Higher Costs: Mistakes during repairs may result in further damage, necessitating additional repairs and expenses.

- Frustration: Confusion over unclear illustrations can lead to dissatisfaction and a lack of confidence in handling equipment.

- Compromised Performance: Misunderstanding of component functions can lead to improper use, affecting the overall efficiency of the machinery.

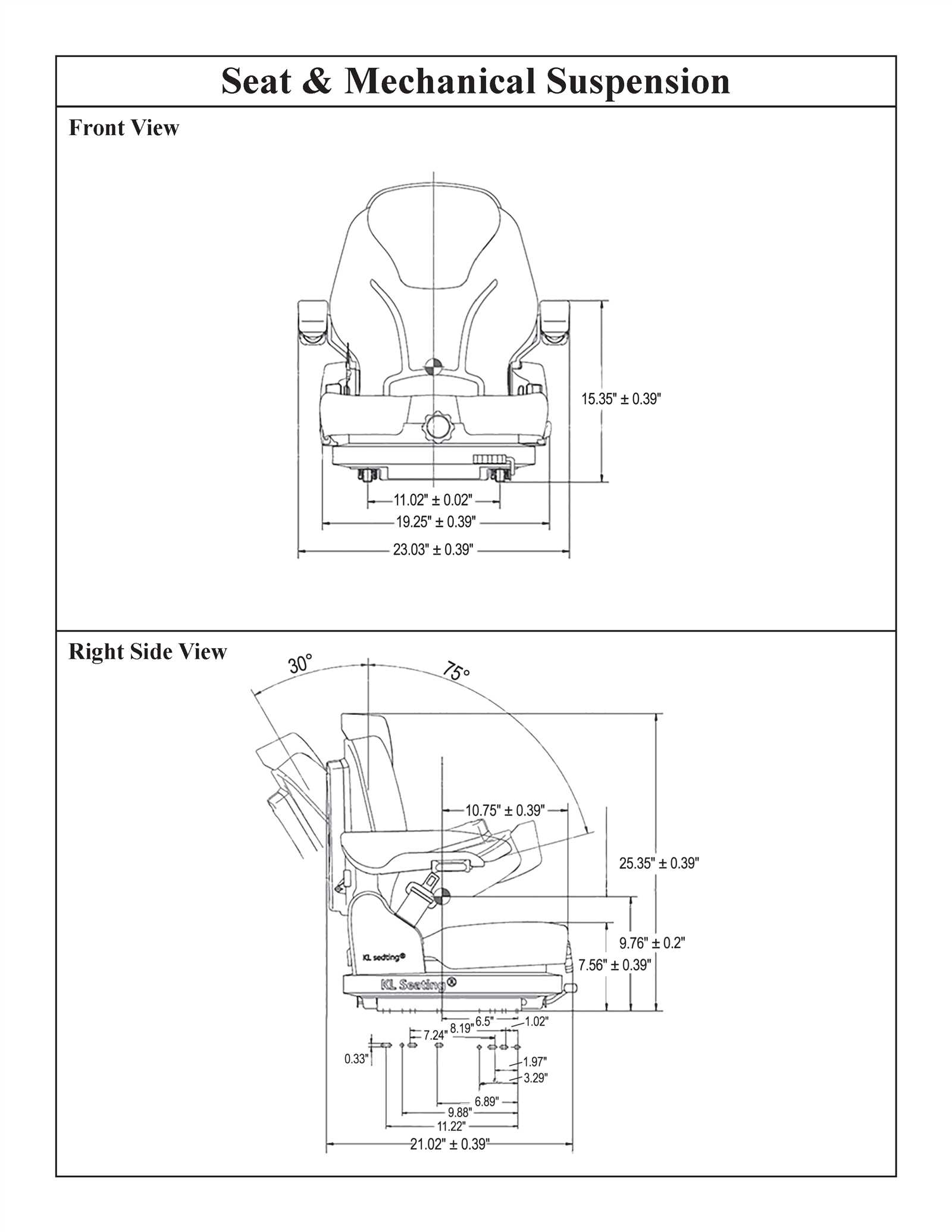

How to Read Trench Diagram

Understanding the layout and components of an excavation tool is essential for effective operation and maintenance. A visual representation provides valuable insights into the machine’s structure, highlighting key elements that contribute to its functionality. By familiarizing yourself with this illustration, you can ensure proper usage and address any issues that may arise during work.

Identifying Key Elements

Begin by examining the main sections of the illustration. Each part is typically labeled, allowing you to easily pinpoint the various components. Pay attention to the symbols and color codes used, as they often indicate specific functions or characteristics. Familiarity with these symbols enhances your ability to interpret the visual effectively.

Understanding Relationships Between Components

Next, focus on how different elements interact with one another. Lines or arrows may denote connections, indicating how power or materials flow through the system. Recognizing these relationships is crucial for troubleshooting and optimizing performance. Consider creating notes or a legend that summarizes the meaning of various elements for quick reference in the future.

Common Issues with Trencher Parts

When operating specialized excavation equipment, users often encounter various complications that can impede performance and efficiency. Understanding these common challenges is crucial for maintaining optimal functionality and extending the lifespan of the machinery. Regular maintenance and prompt attention to issues can mitigate significant downtime and repair costs.

Wear and Tear

One of the most frequent problems arises from the natural degradation of components due to continuous use. As tools engage with hard materials, they can suffer from abrasion and fatigue, leading to diminished effectiveness. Routine inspections can help identify worn-out elements before they cause further damage.

Hydraulic System Failures

Hydraulic mechanisms play a vital role in the operation of these machines. Issues such as leaks or pressure drops can severely hinder performance. Regularly checking hydraulic fluid levels and inspecting hoses and connections for integrity is essential to avoid unexpected breakdowns.

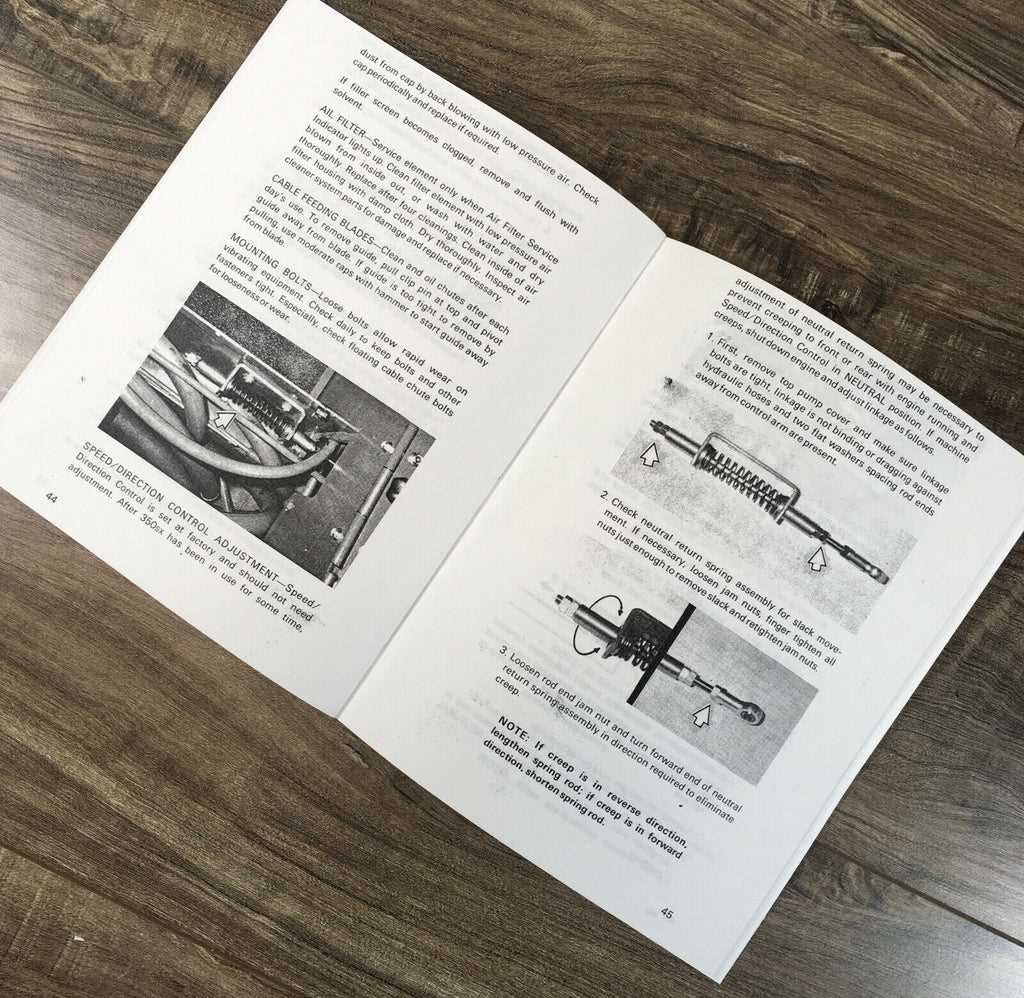

Maintaining Your Vermeer Trencher

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a structured maintenance routine, you can prevent potential issues and enhance efficiency during operations. This guide outlines key practices to keep your machinery in top shape.

Routine Inspections

Conducting frequent evaluations is crucial. Examine the machine for any signs of wear or damage. Check the hydraulic systems, belts, and cutting tools for proper functioning. Addressing minor issues promptly can prevent them from escalating into significant problems.

Lubrication and Cleaning

Proper lubrication is vital to minimize friction and wear. Ensure all moving components are adequately greased according to the manufacturer’s specifications. Additionally, cleaning the equipment after use helps remove dirt and debris, which can interfere with performance and lead to corrosion over time.

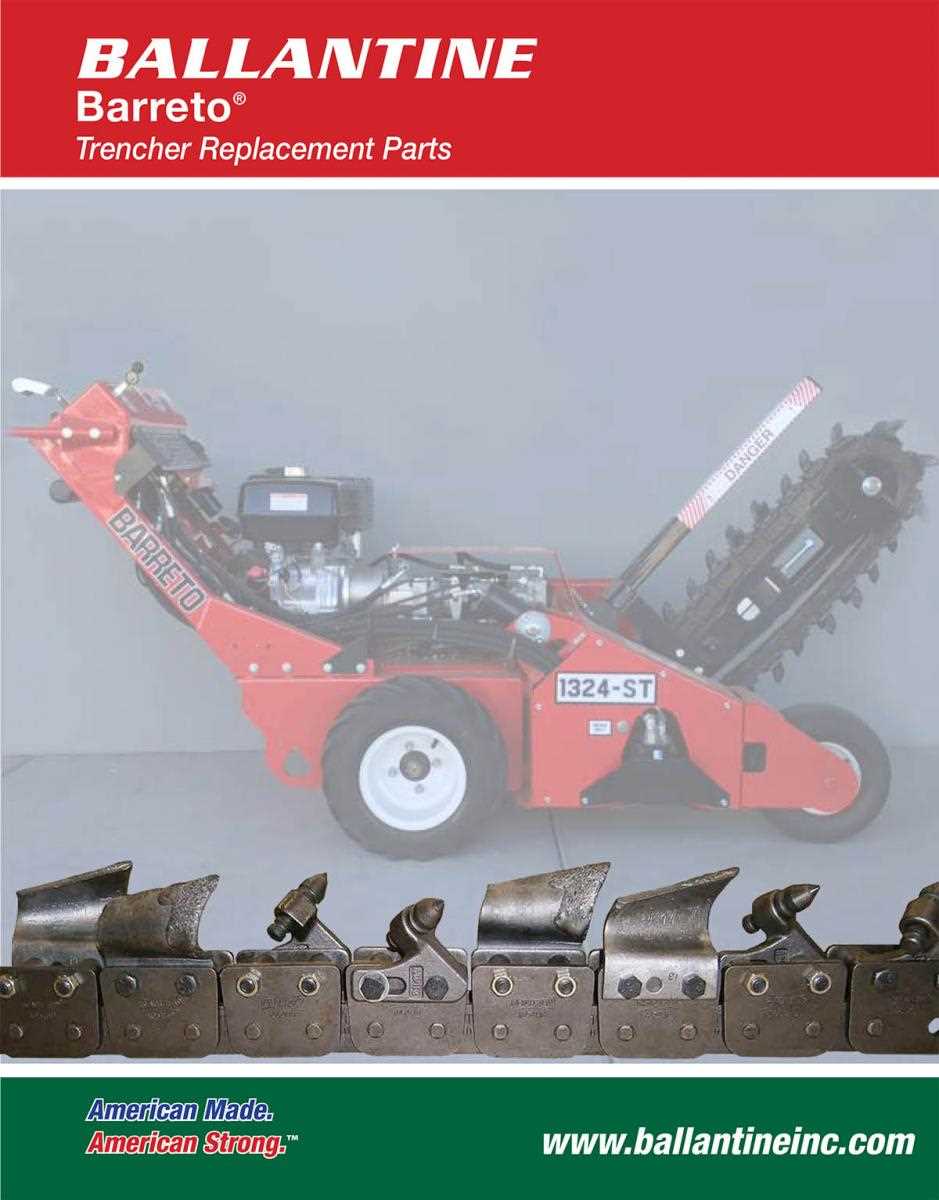

Where to Find Replacement Parts

Locating components for machinery maintenance can often be a daunting task. However, several reliable sources can streamline this process, ensuring that you have access to high-quality replacements. Understanding where to search will not only save time but also enhance the performance of your equipment.

Here are some recommended avenues to explore:

| Source | Description |

|---|---|

| Manufacturer’s Website | Check the official site for authentic components, specifications, and ordering options. |

| Authorized Dealers | Local dealers often stock genuine items and can offer advice on compatibility. |

| Online Marketplaces | Websites such as eBay and Amazon provide a variety of options, but verify the seller’s reputation. |

| Specialty Stores | Stores focusing on industrial equipment may have a diverse inventory of necessary items. |

| Salvage Yards | These locations can be treasure troves for used components at reduced prices. |

By exploring these resources, you can efficiently acquire the necessary components to keep your machinery in optimal condition.

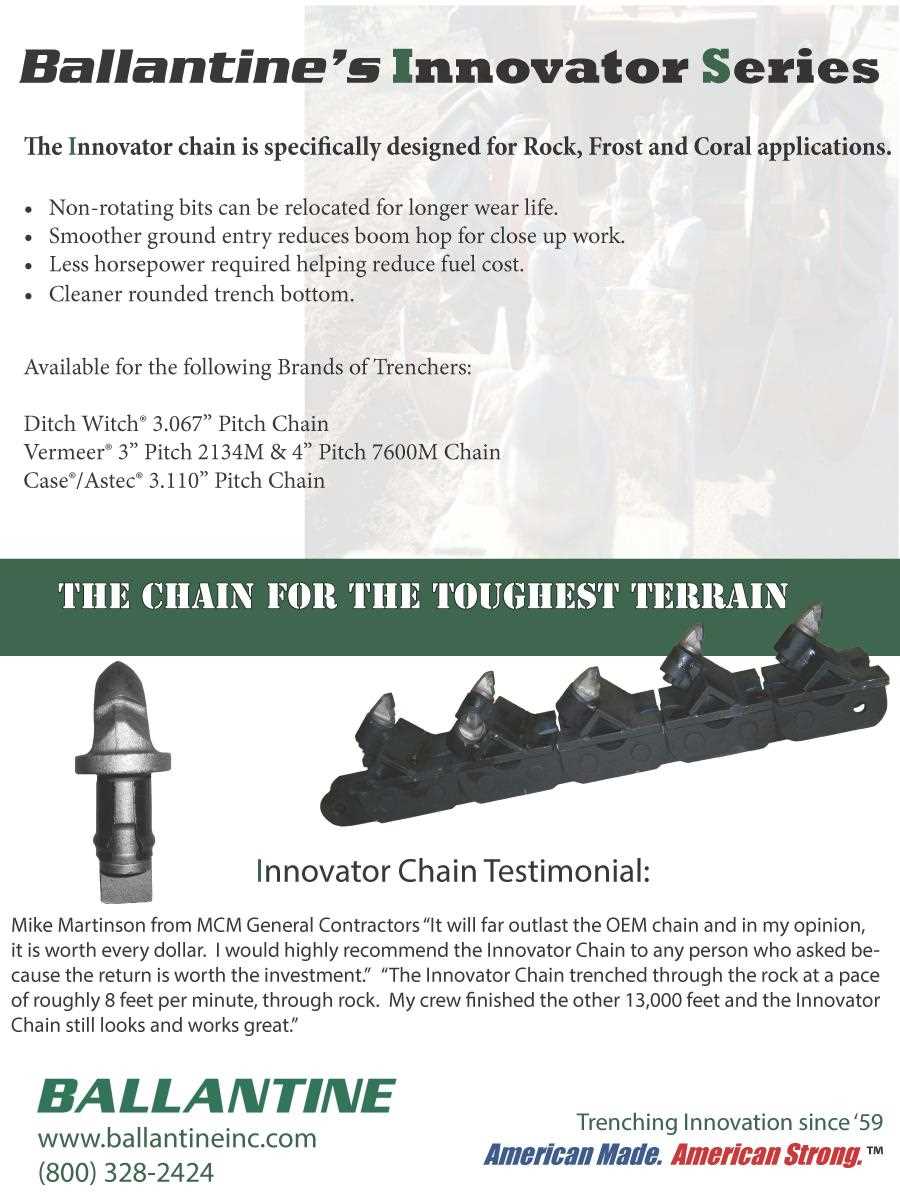

Upgrading Vermeer Trencher Components

Enhancing the functionality and efficiency of your machinery can significantly impact overall performance. This section explores various methods to improve essential elements, ensuring a smoother operation and extended lifespan. Investing in superior components not only boosts productivity but also reduces maintenance costs in the long run.

Choosing Quality Components

Selecting high-quality replacements is crucial. Prioritize durable materials that can withstand demanding conditions, which ultimately leads to fewer breakdowns and better reliability. Consider options that enhance compatibility and performance with existing systems.

Implementing Technological Advances

Tips for Troubleshooting Trenchers

When working with complex machinery, encountering issues is not uncommon. Understanding how to identify and resolve problems can significantly enhance performance and longevity. This section provides practical insights for effectively diagnosing and addressing common challenges faced during operation.

Begin by performing a thorough inspection of the equipment. Look for any visible signs of wear or damage, such as cracks or loose components. Regular maintenance can prevent many issues, so ensure all parts are properly lubricated and secured.

Next, check the operational settings. Ensure that all controls are functioning as intended and that the machine is set to the correct parameters for the task at hand. Misconfigurations can lead to inefficient operation and potential breakdowns.

If the machinery exhibits unusual noises or vibrations, this may indicate an underlying issue. Investigate these symptoms promptly, as they could signify misalignment or failing components. Listening carefully can provide valuable clues to the source of the problem.

In cases where the equipment fails to operate as expected, consult the user manual for troubleshooting guidelines specific to the model. Documentation often includes common issues and recommended solutions that can save time and effort.

Finally, don’t hesitate to seek assistance from experienced professionals. Engaging with knowledgeable technicians can provide insights that may not be immediately apparent, ensuring that any repairs are carried out efficiently and correctly.