When working with complex machinery, a thorough comprehension of its individual components is essential for efficient maintenance and operation. Each element plays a crucial role in the overall functionality, and knowing how they fit together can significantly enhance performance and longevity.

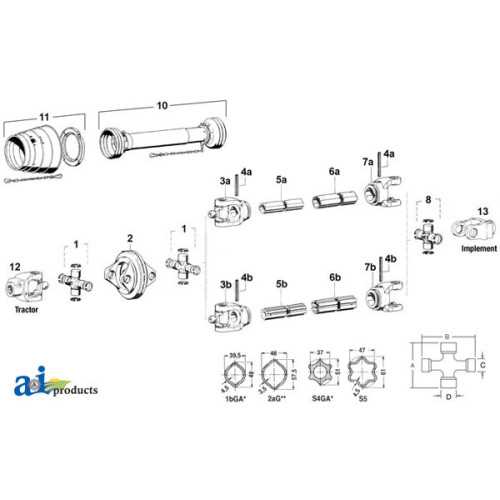

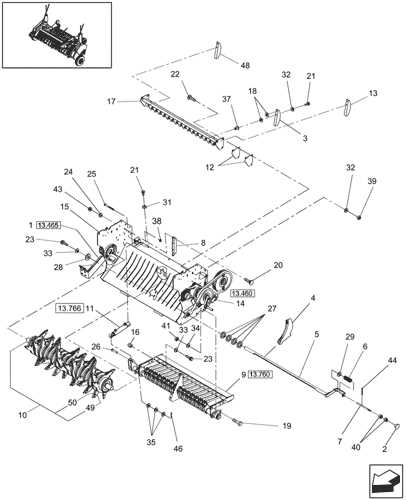

Visual representations of these elements can greatly aid in this understanding, providing clarity on how each section interacts with others. These layouts serve as valuable tools for technicians and operators alike, streamlining repair processes and enabling informed decisions during upgrades or troubleshooting.

Moreover, familiarity with the configuration of these components fosters a deeper appreciation for the engineering behind the equipment. Whether for routine checks or major overhauls, grasping the intricacies of the system empowers users to maintain optimal operational standards.

Understanding Vermeer 5410 Rebel Parts

Familiarizing oneself with the components of specialized machinery is crucial for optimal operation and maintenance. Each element plays a vital role in the overall functionality, and knowing how they interact can significantly enhance performance and longevity. A detailed examination of these components reveals their significance in ensuring smooth and efficient processes.

Each section of the equipment is designed to fulfill a specific purpose, from power transmission to material handling. Recognizing the different functions allows operators to troubleshoot issues effectively and perform necessary upkeep. Whether it’s the drive mechanism, control systems, or structural frameworks, a comprehensive grasp of each segment contributes to a more productive workflow.

Moreover, understanding the arrangement and relationship between various components aids in making informed decisions regarding repairs and upgrades. This knowledge empowers users to maintain their machinery in peak condition, ultimately leading to better results and reduced downtime. A well-rounded understanding of all elements is essential for anyone involved in the operation and care of such advanced equipment.

Importance of Parts Diagrams

Understanding the layout and composition of machinery components is crucial for effective maintenance and repair. Visual representations that outline individual elements provide invaluable insights for technicians and operators alike, enabling them to identify, locate, and replace components efficiently. These illustrations facilitate communication and comprehension, ensuring that everyone involved has a clear understanding of the equipment’s structure.

Enhanced Maintenance Efficiency

By utilizing detailed visuals, professionals can streamline the maintenance process. Clear depictions help in quickly pinpointing issues and accessing the necessary components, reducing downtime and enhancing productivity. Additionally, these illustrations serve as a reference guide, making it easier for both experienced technicians and novices to navigate complex machinery.

Facilitating Training and Support

Visual aids are essential tools in training programs. They allow new employees to familiarize themselves with the equipment without the need for hands-on experience initially. Furthermore, these resources assist in troubleshooting by providing a common point of reference for discussions and inquiries, fostering better understanding among team members.

| Benefits | Description |

|---|---|

| Efficiency | Quick identification and replacement of components. |

| Clarity | Clear visual representation of complex machinery. |

| Training | Assists in the onboarding process for new employees. |

| Collaboration | Improves communication and understanding among team members. |

Common Issues with Vermeer Equipment

Every piece of machinery faces challenges over time, and understanding these common problems can significantly enhance performance and longevity. Identifying typical issues helps operators maintain equipment effectively, ensuring smooth operation in various conditions.

Mechanical Failures

Mechanical breakdowns often occur due to wear and tear. Regular maintenance and timely inspections can mitigate risks. Hydraulic leaks are a frequent concern, affecting efficiency and leading to costly repairs if not addressed promptly.

Electrical Malfunctions

Electrical issues can disrupt functionality. Faulty wiring or damaged sensors may result in erratic performance. Implementing routine checks and proper troubleshooting techniques can prevent these complications from escalating.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a comprehensive overview of various elements and their relationships, enabling users to identify parts quickly and accurately. Mastering this skill can enhance troubleshooting efficiency and facilitate seamless assembly processes.

Familiarize Yourself with the Layout: Begin by examining the overall structure of the illustration. Typically, components are arranged in a logical manner, often following the order of assembly. Identify sections or clusters that group related items together, as this can simplify navigation.

Decode the Symbols: Each component is usually represented by a specific symbol or number. Familiarize yourself with the legend or key provided, which explains what each symbol denotes. This understanding will enable you to pinpoint the exact item needed for your task.

Pay Attention to Annotations: Notes and annotations often accompany illustrations, offering crucial information such as part numbers, specifications, or assembly instructions. These details can significantly aid in ensuring you select the correct components.

Cross-Reference with Manuals: For optimal accuracy, refer to any accompanying documentation. Manuals often provide additional context that may not be immediately obvious from the illustration alone. This combination of resources can enhance your understanding and guide you in making informed decisions.

Essential Components of the Rebel 5410

Understanding the critical elements of a specific machinery model is vital for effective operation and maintenance. Each component plays a unique role in ensuring that the equipment functions smoothly and efficiently. This section delves into the fundamental parts that make up this machine, highlighting their importance and interconnections.

Main Functional Elements

At the heart of the machinery lies the engine, which provides the necessary power for all operations. Coupled with the transmission system, it ensures that energy is effectively transferred to the working components. Additionally, the hydraulic system is crucial for performing tasks that require significant force, enabling the equipment to handle various materials with ease.

Support and Control Systems

Equally important are the control systems, which allow operators to monitor and adjust the machine’s performance. This includes the dashboard interface, where key metrics are displayed for real-time decision-making. Furthermore, the frame and suspension systems provide structural integrity and stability, ensuring that the equipment can operate effectively across diverse terrains.

Where to Find Replacement Parts

Locating suitable components for machinery can be a challenging endeavor. Whether you’re in need of specific items for maintenance or repairs, understanding where to search is crucial for efficiency and cost-effectiveness.

Begin your quest by exploring authorized dealers who specialize in machinery supplies. They often maintain a comprehensive inventory and can provide expert advice on compatibility and availability.

Online marketplaces also offer a vast selection of components, allowing you to compare prices and read reviews from other users. Make sure to check for reliable sellers to ensure quality.

Additionally, salvage yards and equipment resellers can be treasure troves for hard-to-find items at lower prices. Networking with industry professionals may also lead to valuable recommendations and insights.

Lastly, consider joining forums or groups dedicated to your machinery type. Engaging with the community can yield tips on sourcing components and possibly connect you with sellers directly.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your machinery requires a commitment to regular upkeep and care. Proper maintenance not only extends the lifespan of equipment but also enhances efficiency and safety. Here are essential practices to follow for keeping your machines in top shape.

Regular Inspection

- Conduct routine checks to identify wear and tear.

- Look for any signs of leakage or damage.

- Ensure that all components are securely fastened and in good condition.

Proper Lubrication

- Use the recommended lubricants for different parts.

- Check oil levels frequently and top up as needed.

- Clean any excess lubricant to prevent buildup.

By adhering to these guidelines, you can significantly enhance the reliability and lifespan of your equipment.

Upgrading vs. Replacing Parts

When it comes to enhancing the performance and longevity of machinery, the decision between upgrading components or replacing them entirely is crucial. Each option carries its own set of benefits and challenges, and understanding these can help in making a more informed choice. Upgrades can often provide a cost-effective way to improve functionality, while replacements may ensure optimal performance and reliability.

Benefits of Upgrading

Opting for enhancements allows users to retain existing systems while improving efficiency and capabilities. This approach often involves integrating newer technologies or improved materials, which can lead to significant performance gains without the need for a complete overhaul. Additionally, upgrades can be less time-consuming and may require fewer resources compared to full replacements.

Advantages of Replacing

In contrast, complete substitutions can guarantee that all components meet the latest standards for safety and efficiency. This method eliminates the risk of compatibility issues that may arise from integrating older elements with new technologies. Furthermore, starting fresh with new components can provide peace of mind regarding reliability and maintenance, ensuring that the equipment operates at its best from day one.

Resources for Technical Support

Accessing reliable assistance is crucial for maintaining equipment efficiency and resolving issues promptly. Various platforms provide valuable resources, including manuals, troubleshooting guides, and community forums where users can exchange experiences and solutions. These channels not only enhance understanding but also ensure that any operational challenges are addressed effectively.

Official websites often host comprehensive documentation, including schematics and maintenance instructions. Additionally, many manufacturers offer customer service hotlines for direct support, allowing users to connect with experts for personalized guidance. Online video tutorials can also be beneficial, providing visual demonstrations for complex repairs and adjustments.

Engaging with online communities, such as social media groups or dedicated forums, enables users to delve into discussions and share insights. This collaborative approach fosters a deeper understanding of potential issues and innovative solutions. Overall, leveraging these resources can lead to enhanced performance and longevity of the machinery.