When it comes to the functionality of lifting mechanisms, a clear understanding of their essential components is crucial. These devices play a significant role in various applications, ensuring stability and ease of movement. By familiarizing oneself with the intricate elements that contribute to their operation, users can enhance their efficiency and maintenance practices.

Visual representation of these components serves as a valuable tool for both novices and experienced individuals. It helps in identifying the relationships between different elements, thereby facilitating better comprehension of how each piece interacts within the entire system. This knowledge empowers users to address potential issues proactively.

Furthermore, an in-depth look at the mechanics involved can lead to improved safety measures and operational performance. Whether one is involved in routine maintenance or seeking to troubleshoot, understanding the makeup of these mechanisms is essential. The following sections will provide a detailed exploration of the various components and their functions.

Understanding Trailer Jack Components

When dealing with towing mechanisms, it’s crucial to grasp the various elements that ensure stability and functionality. Each component plays a specific role, contributing to the overall efficiency of the system. Recognizing how these pieces interact can significantly enhance your experience and safety during transport.

Key Elements and Their Functions

Among the essential components are the lifting mechanisms, which facilitate raising and lowering. Additionally, the base provides stability, allowing for secure placement on different surfaces. The handle serves as the primary control, enabling easy adjustment while ensuring proper alignment during use.

Maintenance and Best Practices

Regular inspection of each component is vital for longevity and performance. Lubrication of moving parts can prevent wear and tear, while checking for any signs of rust or damage ensures safety. Understanding the specific functions of each element can lead to more informed decisions regarding upkeep and repair.

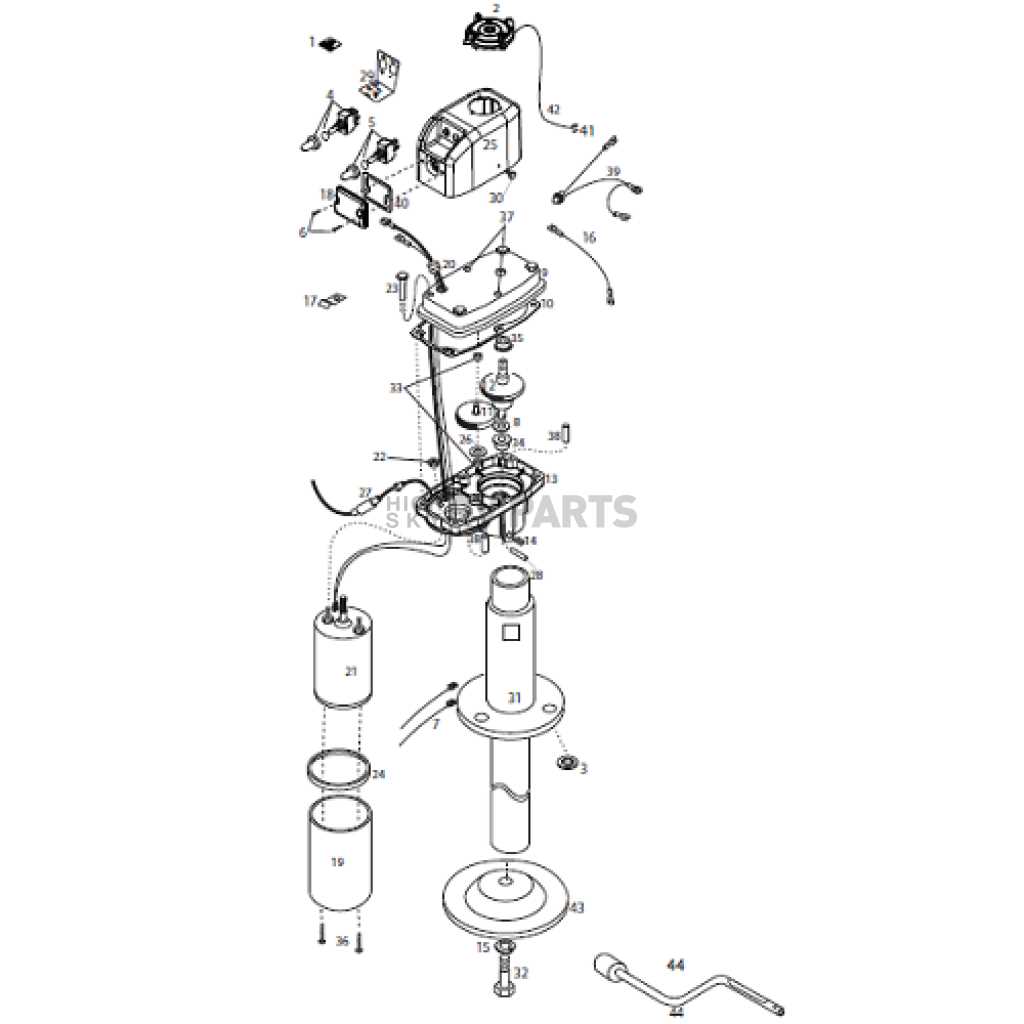

Essential Parts of a Trailer Jack

Understanding the fundamental components of a lifting mechanism is crucial for effective operation and maintenance. Each element plays a specific role, contributing to the overall functionality and safety of the equipment. Below are the key elements that make up this essential tool.

Main Components

- Base: The sturdy foundation that provides stability during use.

- Post: The vertical structure that supports the lifting mechanism.

- Handle: The lever used to operate the lifting mechanism, often designed for ease of use.

- Gear System: The mechanism that enables lifting by multiplying force applied to the handle.

Support Features

- Wheels: Optional features that enhance mobility, allowing for easy repositioning.

- Foot Pad: The component that makes contact with the ground, offering additional stability.

- Locking Mechanism: A safety feature that ensures the unit remains securely in place during use.

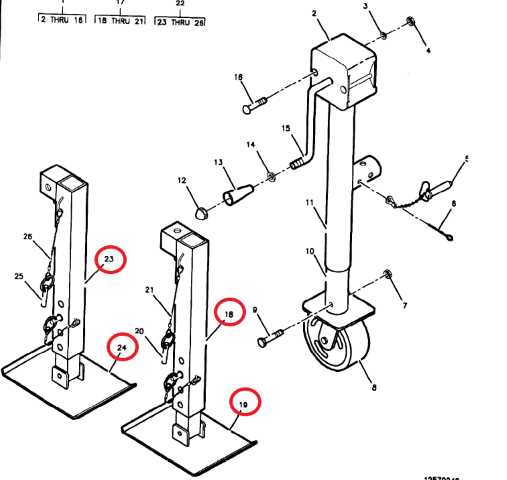

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and assembly. These visual aids provide clarity on how individual elements interconnect and function together, allowing users to troubleshoot issues or replace specific items efficiently.

Key Elements to Note

When examining a visual representation of components, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Indicate the names or functions of components, making it easier to identify each part. |

| Numbers | Often used to reference specific components in a corresponding list, ensuring precise identification. |

| Lines | Show connections and relationships between various elements, highlighting how they interact. |

| Symbols | Represent specific functions or types of components, aiding in quick recognition. |

Steps for Effective Interpretation

To successfully interpret a schematic:

1. Start by familiarizing yourself with the overall layout.

2. Identify and understand the labels and numbers used for reference.

3. Follow the lines to see how each element connects and operates within the system.

4. Cross-reference with any accompanying documentation to clarify details.

Common Issues with Trailer Jacks

When it comes to towing equipment, several challenges can arise that impact functionality and safety. These obstacles can stem from mechanical wear, environmental factors, or improper maintenance. Understanding these common concerns is essential for ensuring reliable operation and longevity of your equipment.

Wear and Tear

Over time, components can degrade due to frequent use and exposure to the elements. Rust, corrosion, and physical damage are prevalent issues that can hinder performance. Regular inspections and prompt repairs can mitigate these effects and extend the lifespan of your equipment.

Improper Handling

Inadequate operation techniques can lead to malfunctioning. Users may struggle with securing loads or adjusting height correctly, resulting in stability problems. Training on proper usage can significantly reduce the likelihood of these issues and enhance overall safety.

Tools for Trailer Jack Maintenance

Regular upkeep of lifting equipment is essential for ensuring smooth operation and longevity. Utilizing the right instruments can simplify the process, making it more efficient and effective. This section explores various tools that are instrumental in maintaining these vital components.

Wrenches are crucial for adjusting and securing various fittings. Having a set of different sizes allows for versatility in handling different types of hardware. A socket wrench can provide added torque, making it easier to tighten or loosen bolts.

Screwdrivers are equally important, especially when dealing with smaller screws that secure protective covers or components. A magnetic tip can be particularly useful for retrieving screws in hard-to-reach areas.

Lubricants play a significant role in maintenance. Applying the appropriate grease can reduce friction and prevent wear, ensuring smooth operation over time. Regular lubrication checks can help in identifying potential issues before they escalate.

Cleaning supplies such as brushes and cloths are essential for keeping equipment free from dirt and debris. A clean surface not only looks better but also enhances functionality, reducing the risk of rust and other damages.

Finally, a reliable torque wrench is necessary for ensuring that all connections are tightened to the manufacturer’s specifications, promoting safety and performance. Investing in these essential tools will enhance the longevity and reliability of your equipment.

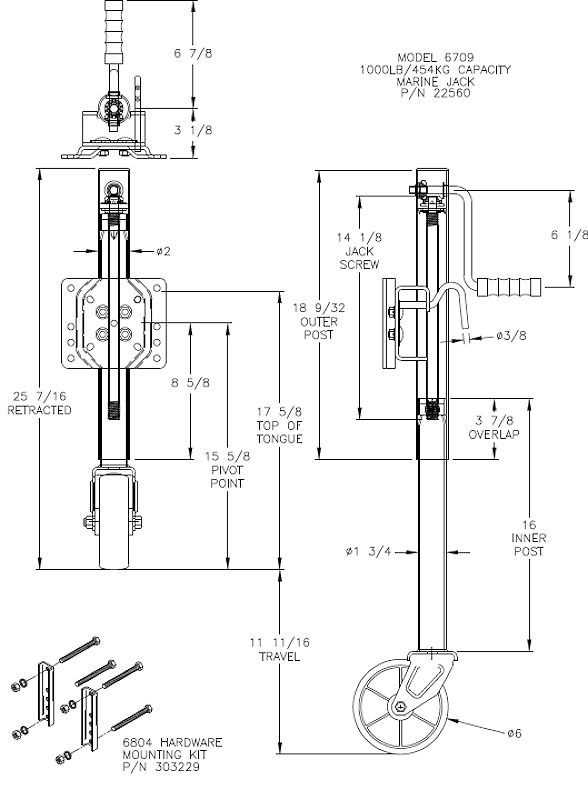

Choosing the Right Trailer Jack

Selecting the appropriate lifting device for your hauling needs is crucial for ensuring safety and efficiency during loading and unloading. Understanding the various options available and their specific functionalities can greatly enhance your overall experience.

First, consider the weight capacity required for your equipment. It’s essential to choose a model that can comfortably handle the load, providing stability and reliability. Additionally, the height range is another key factor; different designs offer varying lift heights, which may be necessary depending on the vehicle type.

Ease of use is also important. Look for features such as quick-release mechanisms or ergonomic handles that simplify operation. Material durability should not be overlooked, as robust construction will ensure longevity and reduce the risk of malfunction.

Finally, evaluate the mounting options available. Some lifting devices are designed for specific setups, while others offer more versatility. Taking the time to assess these aspects will help you make an informed decision that best suits your requirements.

DIY Repair Tips for Trailer Jacks

Maintaining and fixing essential equipment is crucial for safe and efficient operation. With a little know-how and the right tools, you can tackle common issues that arise with these mechanisms. Here are some practical suggestions to help you make effective repairs on your own.

- Inspect Regularly: Frequent checks can prevent minor problems from escalating. Look for signs of wear, rust, or damage.

- Lubricate Moving Parts: Ensure all movable components are properly lubricated to avoid friction and potential breakdowns.

- Check Connections: Loose or damaged connections can compromise performance. Tighten bolts and replace any faulty fasteners.

- Replace Worn Components: Identify parts that show significant wear. Replace them promptly to maintain functionality.

- Use Quality Replacement Items: Always opt for high-quality parts to ensure durability and reliability in your repairs.

By following these tips, you can keep your equipment in top condition and prolong its lifespan. Don’t hesitate to seek assistance if you’re unsure about any repair process.

Safety Precautions When Using Jacks

Ensuring safety while handling lifting devices is crucial to prevent accidents and injuries. Proper knowledge and adherence to safety measures can significantly reduce risks associated with these tools. Awareness of the correct usage procedures and potential hazards is essential for anyone working in environments where lifting equipment is employed.

1. Inspect Equipment Regularly: Always examine the lifting mechanism for any signs of wear or damage before use. Check for cracks, rust, or any malfunctioning components that may compromise its integrity.

2. Use on Stable Ground: Ensure that the lifting device is positioned on a flat, stable surface. Avoid soft or uneven ground, as this can lead to instability and potential tipping.

3. Follow Weight Limits: Adhere strictly to the manufacturer’s specified weight limits. Overloading can cause equipment failure and endanger everyone nearby.

4. Keep Area Clear: Maintain a clear workspace around the lifting area. Remove any obstacles and ensure that bystanders are at a safe distance to avoid accidents.

5. Use Safety Features: Utilize any built-in safety mechanisms, such as locking pins or supports, to enhance stability during use.

6. Wear Protective Gear: Always wear appropriate personal protective equipment (PPE), including gloves and safety goggles, to minimize injury risk.

7. Training and Awareness: Ensure that all operators are properly trained in the use of lifting devices. Understanding the equipment’s functionality and risks is vital for safe operation.

By following these precautions, users can significantly mitigate risks associated with lifting tasks, ensuring a safer working environment for everyone involved.