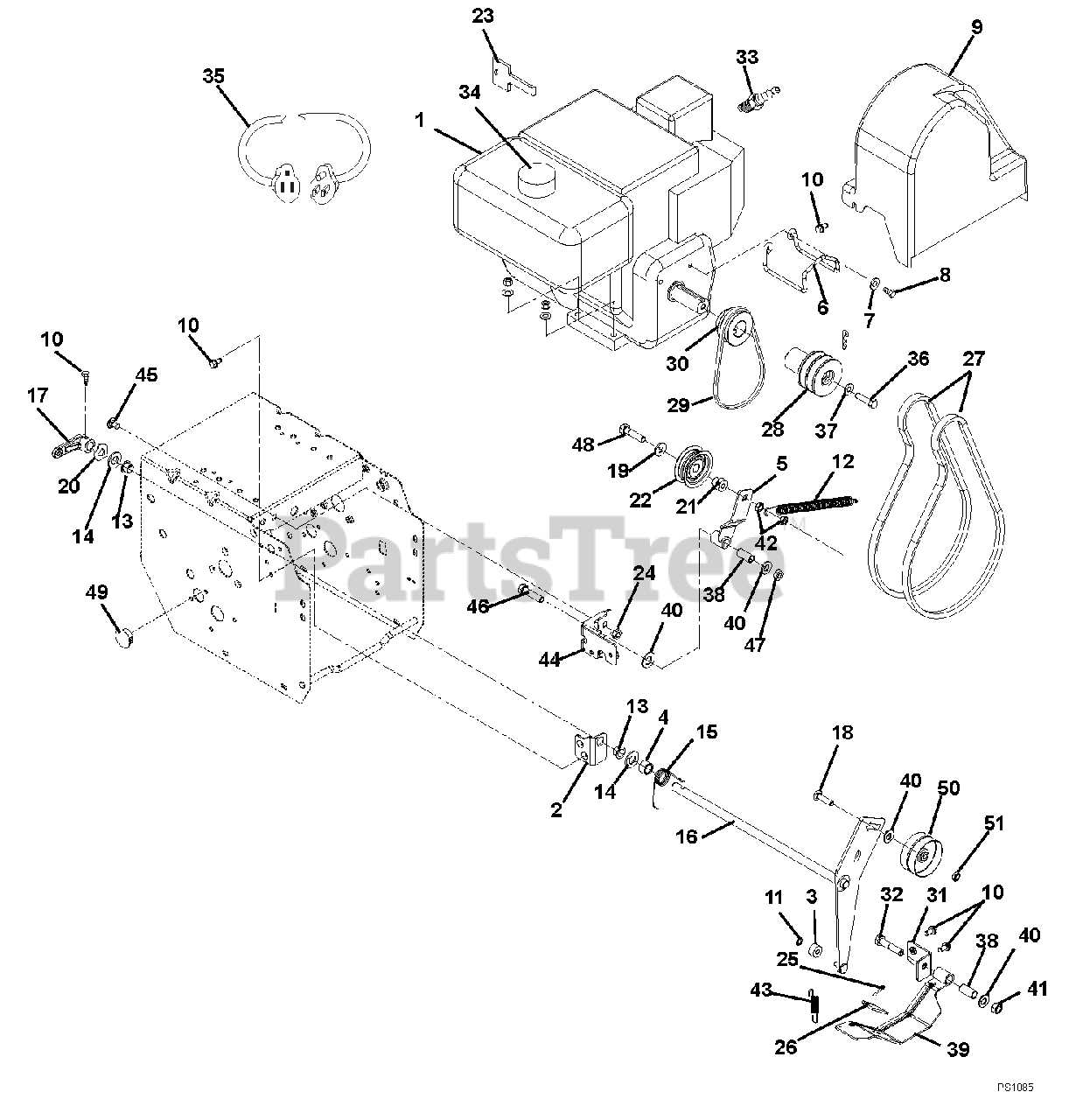

Understanding the structure and arrangement of key elements in an engine is essential for maintaining and repairing the system effectively. This section provides a clear and detailed overview, helping you identify and locate the necessary components that ensure smooth operation.

The layout and connectivity of various mechanical parts within an engine can be complex. Whether you’re focusing on troubleshooting or simply maintaining performance, having a visual representation of how these elements interact is crucial for anyone involved in the upkeep or repair process.

By examining the specific arrangement of these elements, you can gain deeper insights into how each piece plays a role in overall functionality. This guide aims to simplify that process, offering a practical reference to keep your equipment running efficiently.

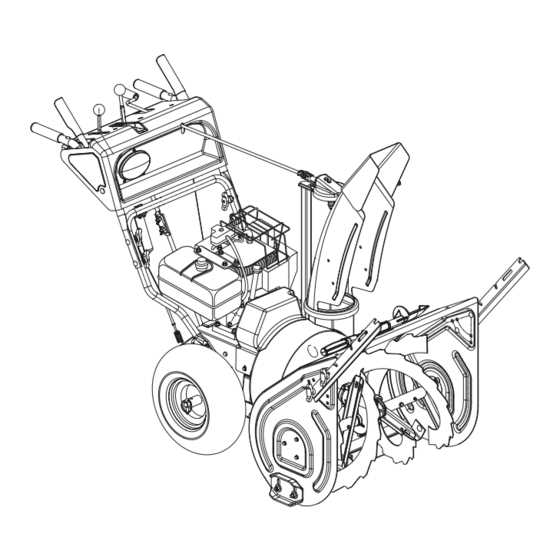

Engine Overview

The engine in question is a compact, air-cooled model commonly used in outdoor power equipment. It is designed for efficiency, durability, and ease of maintenance, making it a reliable choice for various applications. This engine offers a balance between power output and fuel economy, providing sufficient torque to handle challenging tasks.

Built with robust materials and featuring an overhead valve design, the motor operates with reduced emissions and improved performance. Its lightweight construction also allows for easier handling, while still maintaining the reliability needed for long-term use. Regular care ensures it continues to operate smoothly under various conditions.

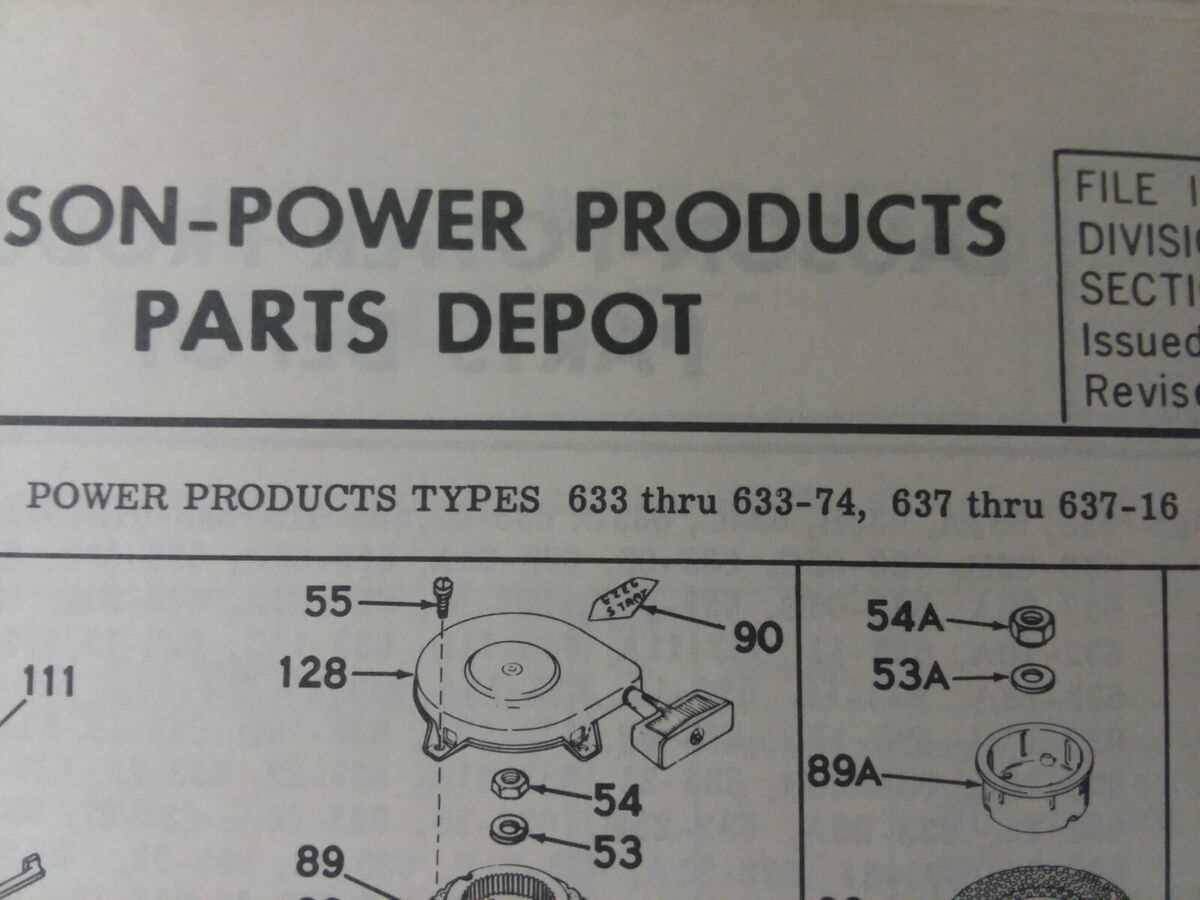

Key Components of the LH318SA Model

This engine configuration features several crucial elements that contribute to its efficiency and performance. Each component is designed to work harmoniously to ensure reliable operation under various conditions. In this section, we will explore the primary elements that play a significant role in its functionality.

Engine Block and Cooling System

The core structure includes a robust engine block that houses all internal mechanisms. The cooling system is integral to maintaining optimal operating temperatures, ensuring longevity and preventing overheating during extended use. This system includes both air and liquid cooling methods, depending on the specific model configuration.

Fuel and Ignition System

The fuel delivery system ensures proper combustion by mixing the right amount of fuel with air. An efficient ignition system, featuring high-quality spark plugs and a reliable ignition coil, ensures that the engine starts promptly and runs smoothly. Together, these systems are vital for the consistent and effective operation of the engine.

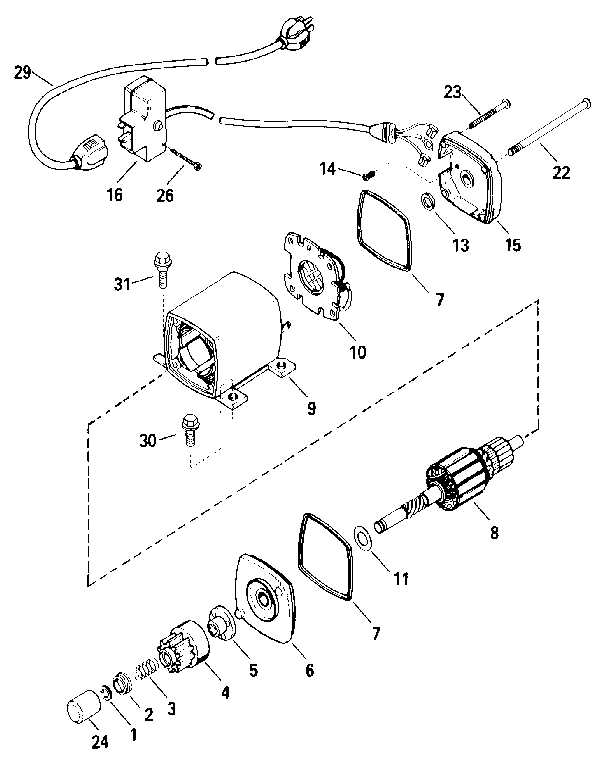

Detailed View of Carburetor Assembly

The carburetor is an essential component responsible for regulating the air-fuel mixture in small engines. Understanding its structure and the arrangement of its components is crucial for maintenance and troubleshooting. Below is an overview of the carburetor’s key parts and how they work together to ensure efficient engine performance.

| Component | Function |

|---|---|

| Throttle Valve | Controls the amount of air entering the engine, affecting speed and power output. |

| Float Chamber | Maintains the fuel level, allowing a steady flow to the mixing chamber. |

| Choke Valve | Restricts air intake during cold starts, enriching the fuel mixture for easier ignition. |

| Needle Valve | Regulates fuel flow into the carburetor, ensuring the correct fuel-to-air ratio. |

| Jet | Meters the amount of fuel delivered to the engine based on airflow. |