Exploring the intricacies of a cutting machine reveals a world of engineering precision and efficiency. Each element plays a crucial role in the overall functionality, contributing to the smooth operation and performance of the device. This section aims to illuminate the essential components that make up this sophisticated tool.

Comprehending the structure involves recognizing how various mechanisms interact harmoniously to achieve optimal cutting results. From the guiding systems to the drive mechanisms, every segment is meticulously designed to ensure durability and reliability.

As we delve into the specific elements, it becomes evident how their interdependence fosters superior outcomes in material processing. By understanding these components, one can appreciate the ultimate craftsmanship behind such machines.

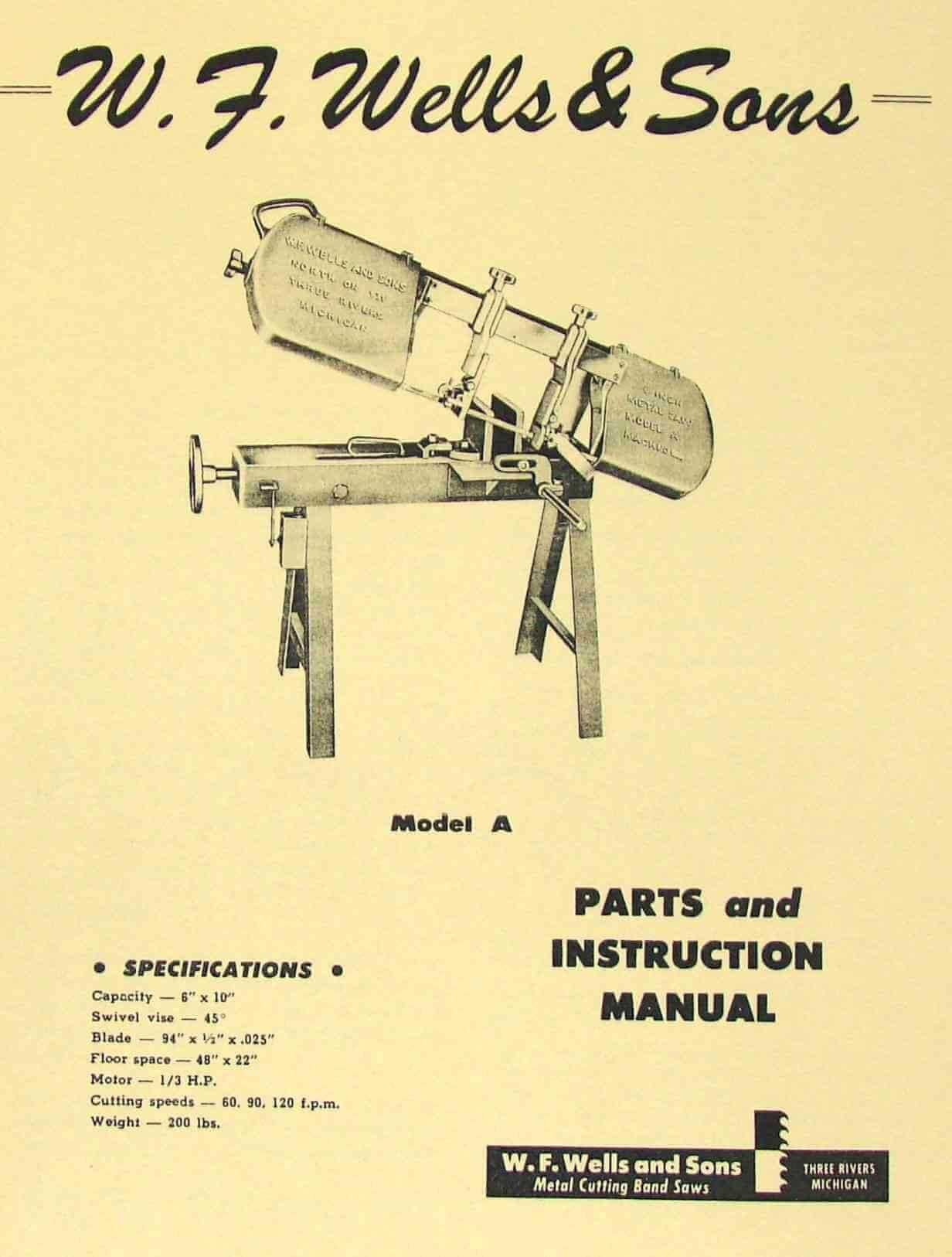

Understanding Horizontal Band Saw Components

In this section, we will explore the essential elements that make up a cutting machine, focusing on their functions and how they contribute to the overall operation. Grasping the significance of each component enhances your ability to maintain and utilize the equipment effectively.

Main Components

- Frame: The robust structure that supports all other elements.

- Motor: Powers the cutting action, providing the necessary energy.

- Blade: The primary tool for cutting through various materials.

- Table: Holds the workpiece in place during the operation.

Supporting Features

- Guide System: Ensures the blade remains aligned for precise cuts.

- Feed Mechanism: Controls the speed and depth of the cut.

- Cooling System: Reduces heat buildup, prolonging the life of the blade.

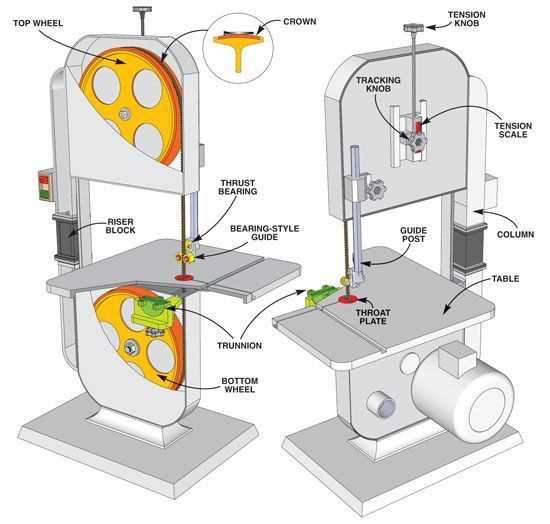

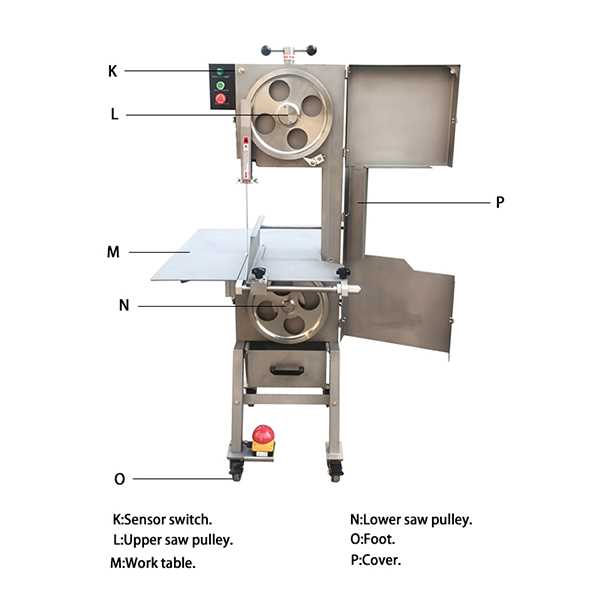

Essential Parts of Band Saws

Understanding the fundamental components of cutting machines is crucial for effective operation and maintenance. Each element plays a significant role in ensuring precision and efficiency during the cutting process. From the drive mechanism to the guiding systems, every part contributes to the overall performance.

Main Components Overview

These machines consist of several key elements that work in harmony. The primary features include the frame, motor, and blade support systems, each serving a distinct function in the cutting process.

Detailed Component Breakdown

| Component | Description |

|---|---|

| Frame | The structural base that supports all other elements and provides stability during operation. |

| Motor | Drives the blade, supplying the necessary power for cutting through materials. |

| Blade | The cutting element designed to slice through various materials with precision. |

| Guides | Assist in maintaining blade alignment and reducing vibration during the cutting process. |

| Tensioning System | Ensures the blade is securely held in place and maintained under appropriate tension for optimal performance. |

| Table | The surface where materials are placed for cutting, often adjustable for different thicknesses. |

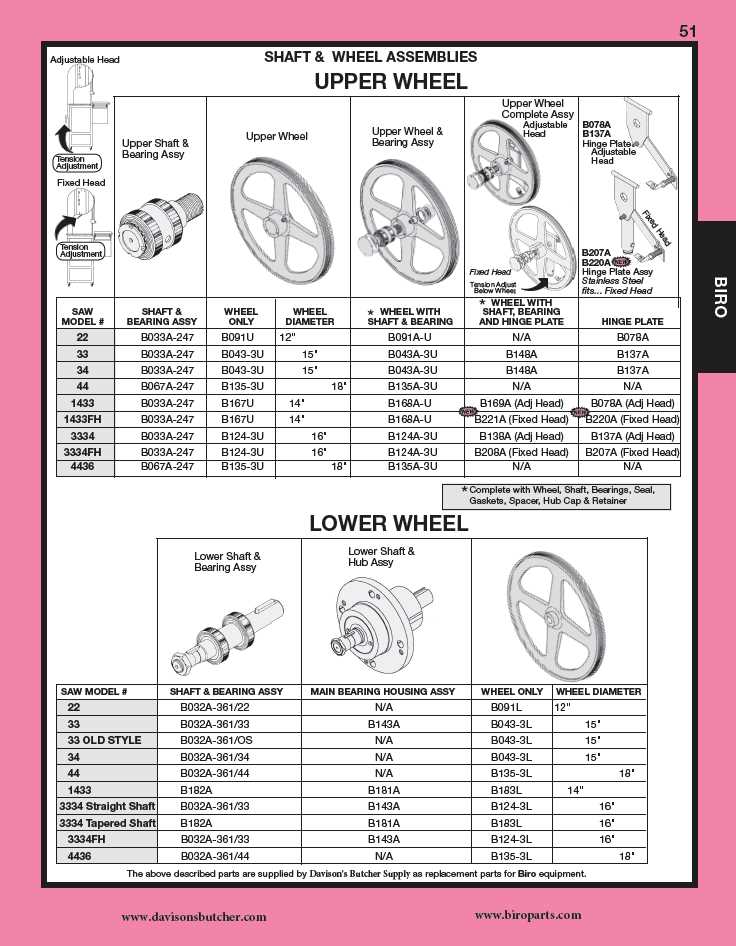

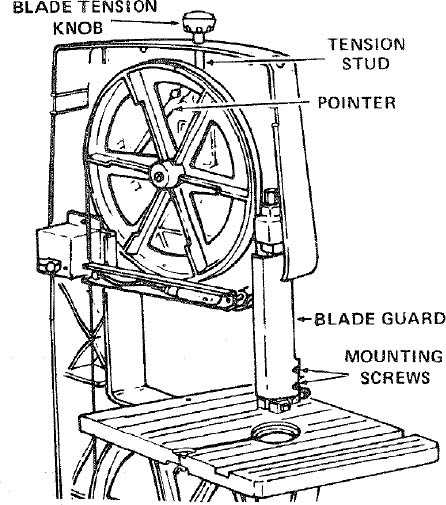

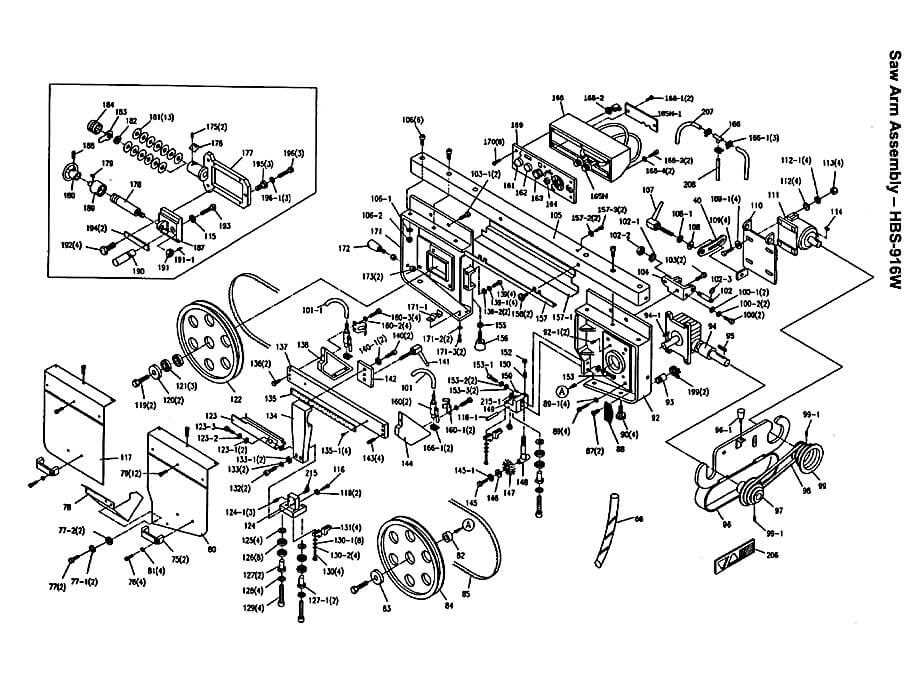

Diagram Overview of Band Saw Design

This section provides a comprehensive look at the components that make up the mechanism used for cutting materials. Understanding the arrangement and function of each element is crucial for optimizing performance and ensuring safety during operation.

Key Components

The essential elements include a frame, a power source, and a cutting blade, among others. Each part plays a significant role in the overall functionality and efficiency of the tool. Below is a table summarizing these components and their functions:

| Component | Description |

|---|---|

| Frame | Provides structural support and stability during cutting operations. |

| Power Source | Drives the blade, facilitating the cutting action through various materials. |

| Blade | The cutting tool that performs the actual material removal. |

| Guide Rollers | Ensure proper alignment and tension of the cutting tool for consistent performance. |

| Table | Provides a stable surface to support the material being cut. |

Understanding the Layout

A clear understanding of the arrangement of these elements helps users operate the machinery more effectively. Familiarity with how each component interacts contributes to better maintenance practices and enhances overall safety while using the equipment.

Functionality of Each Band Saw Part

This section explores the essential components of a cutting machine and their specific roles in ensuring efficient operation. Understanding the function of each element contributes to the overall performance and reliability of the equipment.

Primary Components

The main structure of the equipment provides stability and support, enabling precise cuts. The motor drives the movement, allowing the blade to engage with the material seamlessly. The tensioning mechanism ensures the blade remains taut, preventing slippage during operation.

Support Systems

Guide systems play a critical role in maintaining blade alignment, minimizing wear, and enhancing accuracy. Additionally, the feed system regulates the material’s movement, ensuring a consistent and controlled cutting process. Lastly, safety features protect the user and the machine from potential hazards, emphasizing the importance of well-designed elements.

Maintenance Tips for Band Saw Parts

Proper upkeep of your cutting tool components ensures longevity and optimal performance. Regular attention to each element can prevent issues and enhance efficiency.

- Cleaning: Regularly remove debris and dust from surfaces to avoid wear and tear.

- Lubrication: Apply appropriate lubricants to moving elements to reduce friction and prevent rust.

- Inspection: Frequently check for signs of damage or wear, focusing on key areas that experience the most stress.

- Tension Adjustment: Ensure that the tension is correctly set to maintain precision and prolong component life.

- Blade Replacement: Change blades when dull to maintain cutting efficiency and reduce strain on other elements.

Implementing these practices will significantly enhance the overall functionality and durability of your equipment.

Common Issues with Band Saw Components

When working with cutting machinery, understanding the frequent problems associated with its various elements is crucial for maintaining optimal performance. Identifying these issues early can prevent costly repairs and improve efficiency in operations.

Several components may experience wear and tear over time, leading to malfunctions. Here are some common challenges encountered with these machines:

| Component | Common Issues | Possible Solutions |

|---|---|---|

| Blade | Dulling, misalignment, and breakage | Regular inspection and timely replacement |

| Motor | Overheating and loss of power | Ensure proper cooling and check electrical connections |

| Guides | Worn out or incorrectly adjusted | Frequent adjustments and replacement as needed |

| Frame | Vibration and instability | Check for tightness and reinforce as necessary |

By addressing these common concerns, operators can extend the lifespan of their equipment and ensure consistent, high-quality results in their cutting tasks.

Choosing Quality Parts for Durability

When selecting components for your machinery, the emphasis on quality significantly impacts longevity and performance. Investing in superior materials ensures reliability and minimizes maintenance costs, which ultimately enhances operational efficiency.

Key Factors to Consider

Several aspects must be taken into account when evaluating options. Materials, manufacturing processes, and compatibility all play crucial roles in determining the overall durability of your equipment.

Recommended Materials

| Material Type | Benefits |

|---|---|

| High-Carbon Steel | Excellent strength and wear resistance. |

| Tool Steel | Superior toughness and hardness for high-performance use. |

| Aluminum Alloys | Lightweight with good corrosion resistance. |

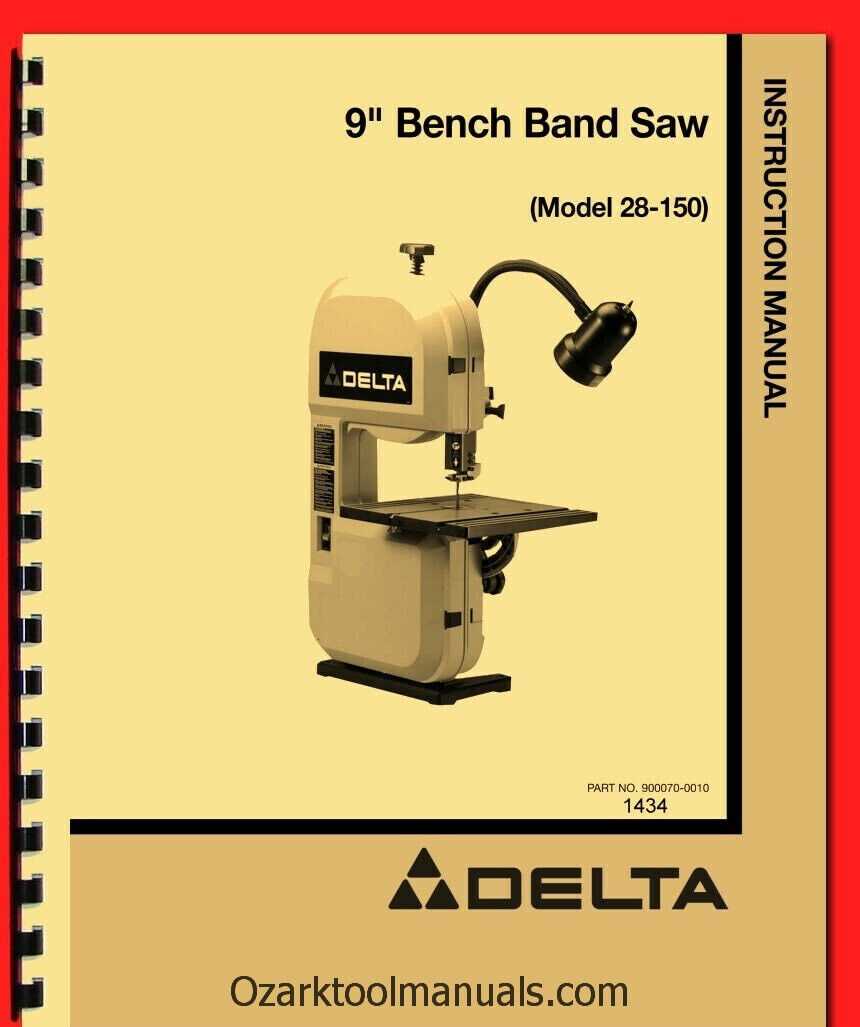

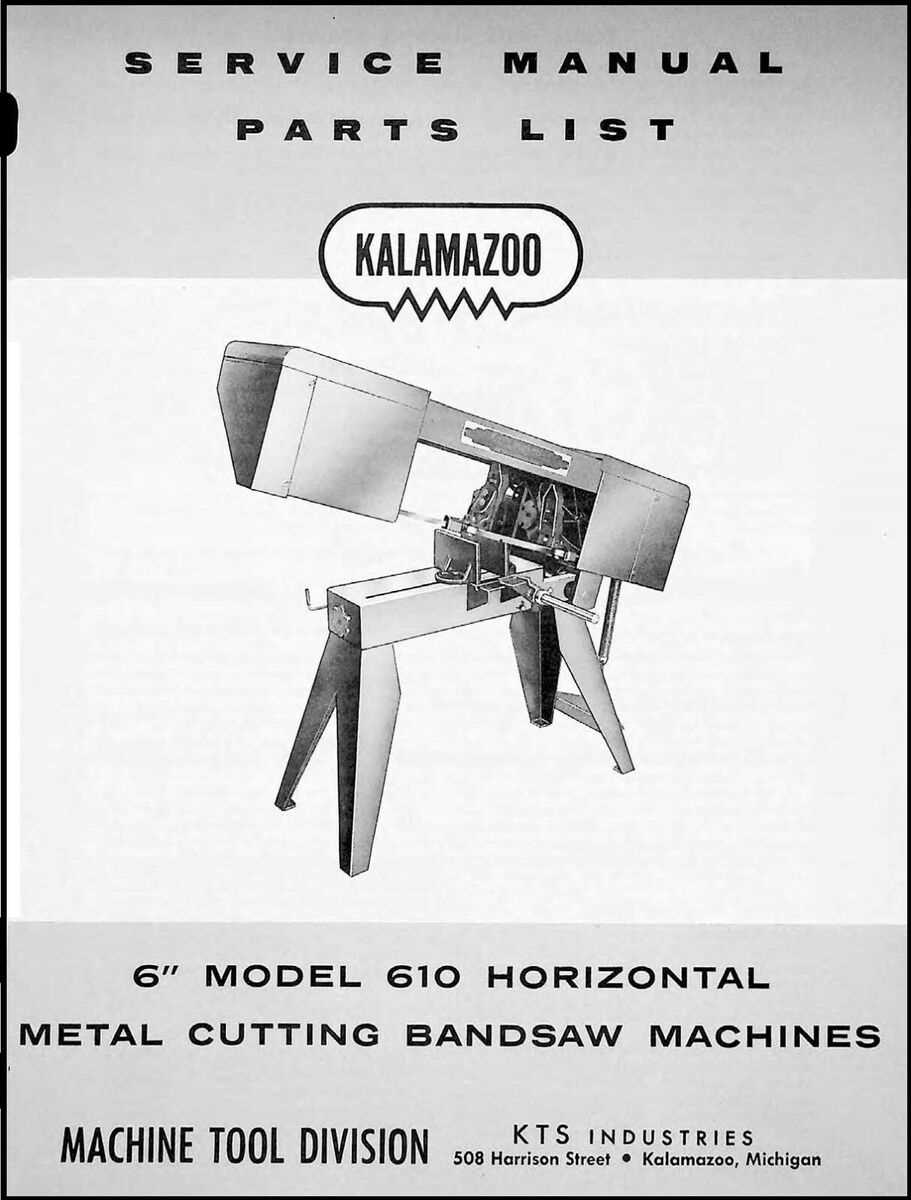

Comparing Band Saw Models and Features

When selecting a cutting tool, understanding the various models and their distinct characteristics is essential for making an informed choice. Each type of equipment offers unique functionalities tailored to specific tasks, which can significantly affect performance and efficiency in various applications. Analyzing the strengths and limitations of different options helps users align their needs with the right machinery.

Key Features to Consider

Several critical attributes should be examined when comparing models. Power and speed capabilities play a vital role in determining how effectively the tool can handle various materials. Additionally, the design and build quality influence durability and user experience. Features such as adjustable blade tension, ease of maintenance, and safety mechanisms also contribute to the overall functionality of the equipment.

Model Variations and Their Applications

Different variations are available, each suited for specific tasks. For instance, some designs are optimized for precision cutting, making them ideal for intricate work, while others prioritize speed and efficiency for larger projects. Understanding these variations allows users to select the model that best meets their operational requirements, ensuring optimal results in their cutting endeavors.

Safety Precautions When Using Band Saws

Ensuring safety in the workshop is crucial when operating machinery designed for cutting. By adhering to proper protocols, operators can significantly reduce the risk of accidents and injuries. Awareness and preparation are key components in maintaining a secure working environment.

- Always wear appropriate personal protective equipment (PPE), including goggles, gloves, and ear protection.

- Keep the workspace clean and free of obstacles to prevent tripping hazards.

- Ensure all safety guards and devices are in place and functioning correctly.

- Maintain a safe distance from the cutting area while the equipment is in operation.

- Stay focused and avoid distractions when using the machine.

In addition to these precautions, it is essential to familiarize yourself with the machine’s operating manual and guidelines. Regular maintenance checks will also help in identifying any potential issues before they become serious hazards.