When exploring the structure of any sophisticated cooling system, understanding how different elements work together is key. Each section plays an integral role in ensuring the equipment functions efficiently and reliably. This guide provides a clear overview of the internal setup and how various elements are interconnected.

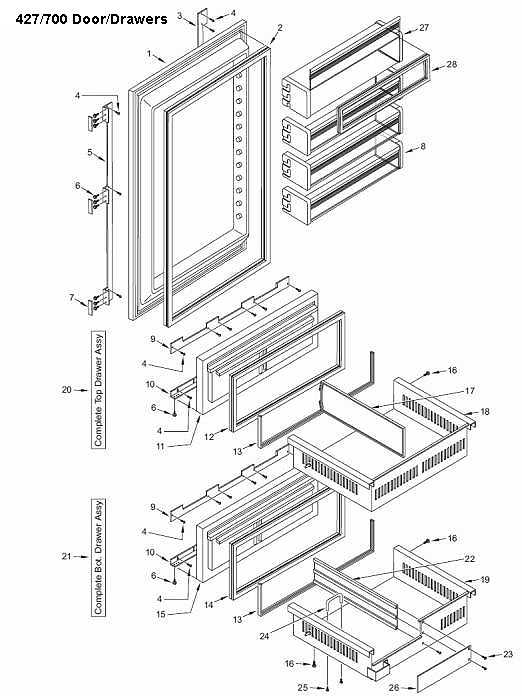

With a deeper dive into the construction, it’s important to focus on individual sections of the system. By understanding the layout and placement of each crucial element, you’ll gain a more thorough grasp of how the system maintains its overall stability and efficiency.

Exploring the essential components can help you pinpoint specific areas of interest, making repairs or upgrades smoother. Having a clear understanding of the internal layout allows for more efficient troubleshooting and maintenance when necessary.

Understanding the Sub Zero 650 System Layout

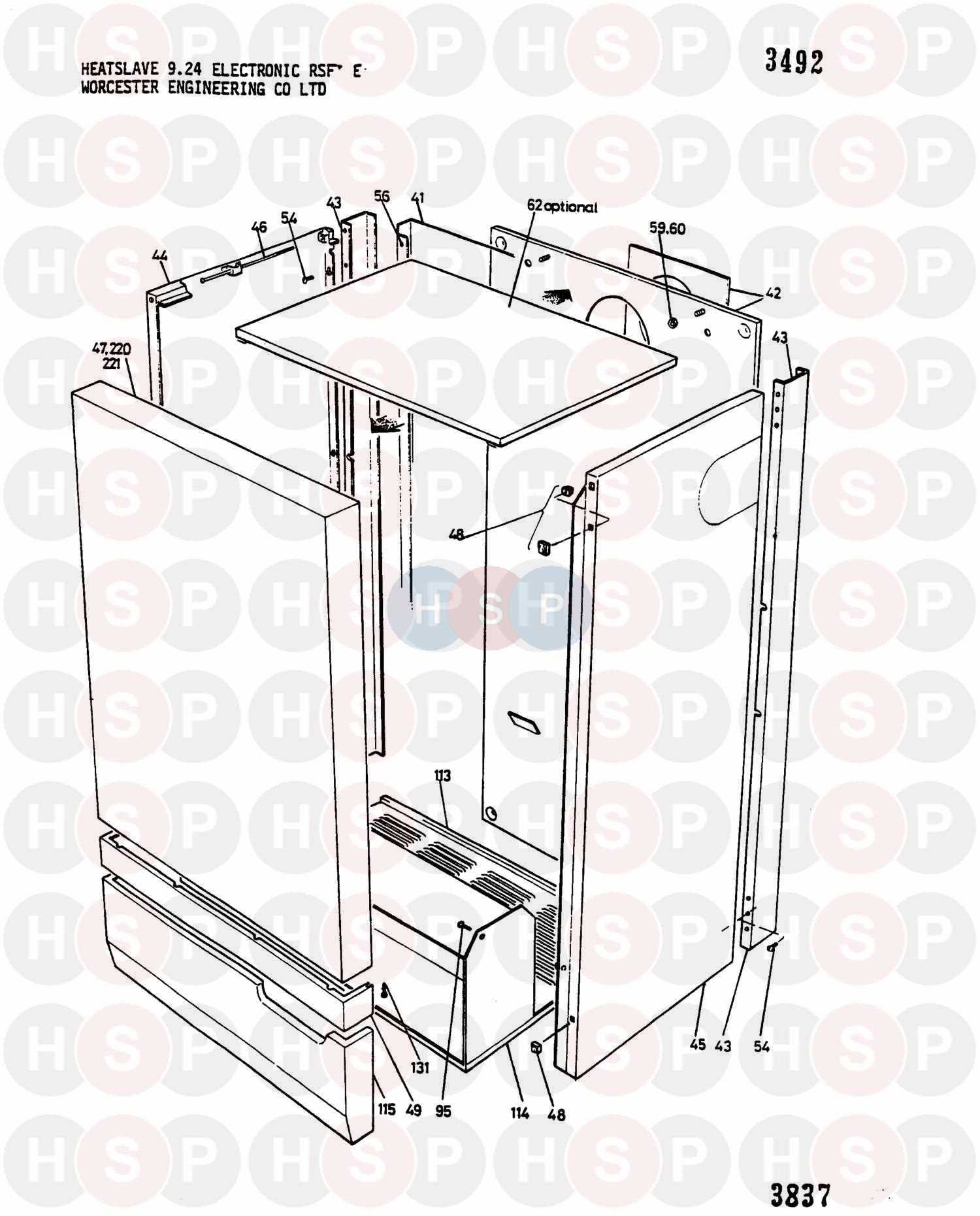

Comprehending the structure and organization of this cooling system is essential for efficient maintenance and repair. The internal framework consists of various interconnected elements, each playing a critical role in ensuring optimal temperature control and energy efficiency. By gaining insight into how these components interact, you can better identify potential issues and enhance the system’s performance.

At the core of this refrigeration unit are several key mechanisms designed to regulate airflow, control humidity, and maintain consistent cooling. These systems work together to create an environment that preserves freshness and extends the lifespan of stored items. Understanding the arrangement of these components can help you troubleshoot problems and optimize functionality.

It is important to familiarize yourself with the individual functions of these mechanisms. By doing so, you can ensure that all parts work in harmony, maintaining

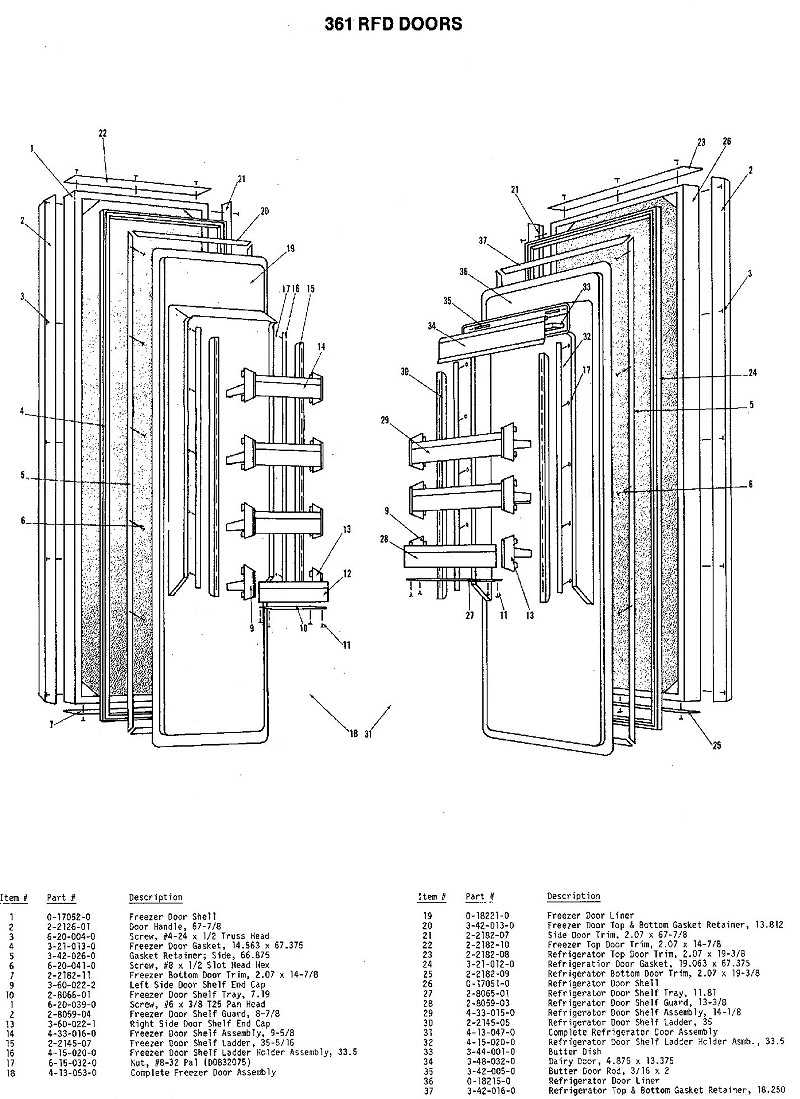

Key Components of the Sub Zero 650 Model

The cooling system under discussion is built from a variety of essential elements, each playing a critical role in maintaining performance and efficiency. These components ensure effective temperature control, energy consumption optimization, and long-term reliability. Understanding the key elements of this model allows for a better grasp of its operation and maintenance.

| Component | Function | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressor | Regulates the cooling process by compressing refrigerant and controlling its flow throughout the system. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Evaporator Coil | Responsible for absorbing heat from the refrigerator’s interior, aiding in the cooling cycle. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Condenser Coil | Dissipates heat collected from inside the unit to the external environment, ensuring efficient cooling. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermostat | Mon

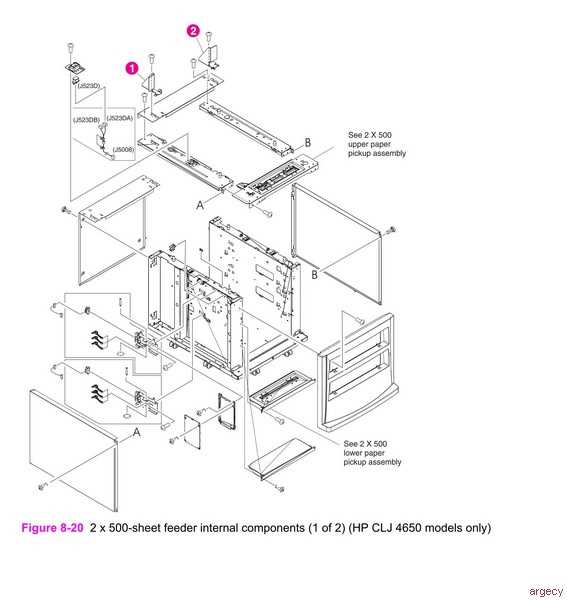

Detailed Overview of Internal MechanismsThe intricate inner workings of cooling systems rely on a variety of interconnected components that work in unison to regulate temperature and ensure efficient performance. Understanding the core mechanisms provides valuable insights into how each element contributes to maintaining optimal conditions. Main Components and Their FunctionsThe internal structure consists of several key elements that play distinct roles. From compressors to evaporators, each part has a specific purpose in controlling airflow, condensation, and energy consumption. These mechanisms are designed for durability and to ensure a long-lasting operation. Core Mechanism Breakdown

|