In the realm of automotive engineering, the intricate systems responsible for delivering fuel play a crucial role in engine performance. A comprehensive exploration of these mechanisms reveals the complexity and precision required to ensure optimal functionality. By breaking down each component, enthusiasts and professionals alike can appreciate the artistry involved in these designs.

Identifying key elements within these systems is essential for maintenance and troubleshooting. Knowledge of the various components enables one to effectively manage performance issues and enhance overall efficiency. Diagrams serve as valuable tools, providing a visual representation that simplifies the understanding of how these elements interact.

Furthermore, delving into the specifics of each piece can lead to the ultimate enhancement of engine reliability and longevity. Whether for repair or modification, understanding these crucial systems is invaluable for anyone engaged in automotive technology.

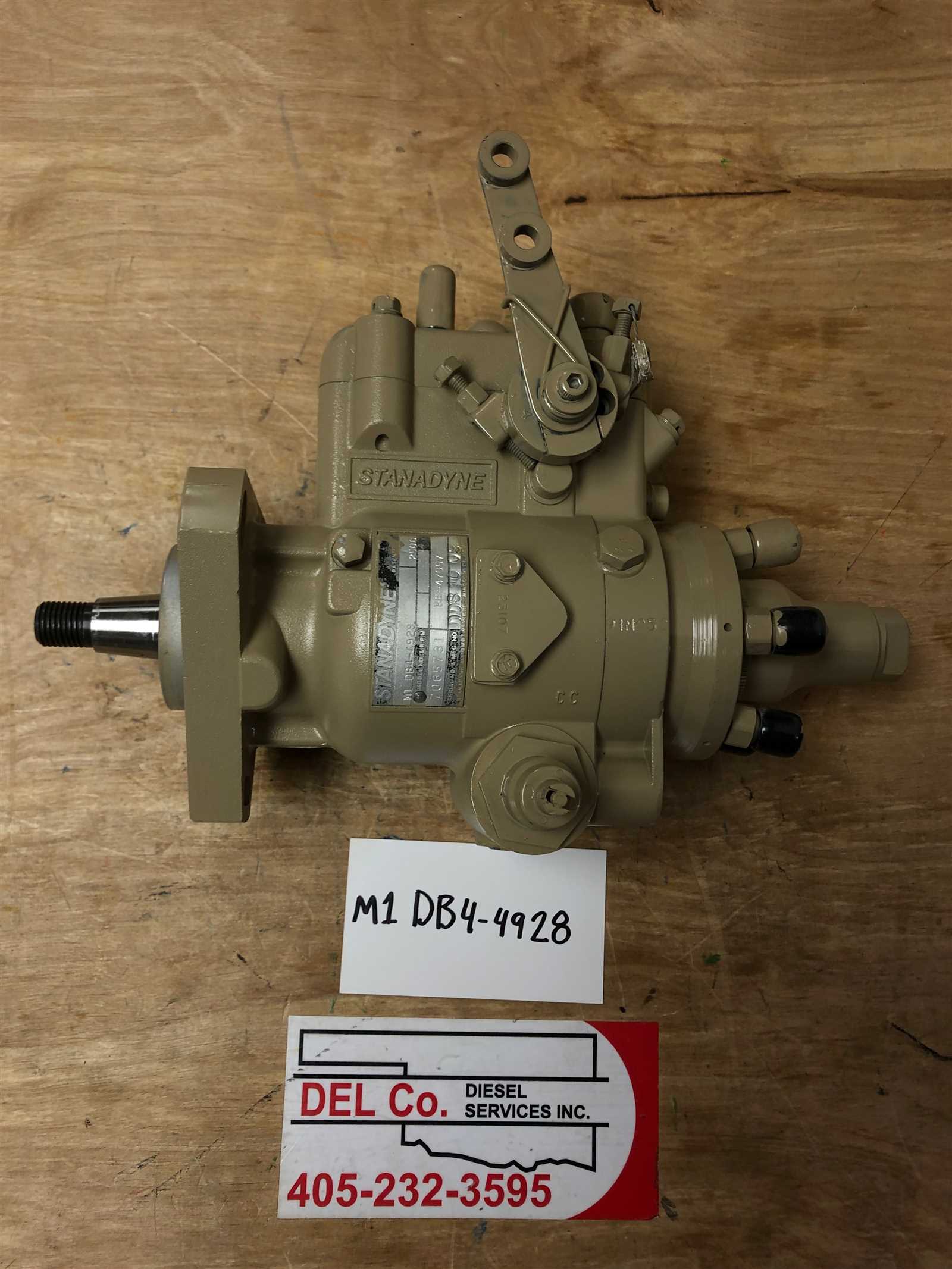

Understanding the Stanadyne DB4 Pump

This section explores a crucial component of diesel engine systems, emphasizing its role in delivering fuel efficiently. A deeper comprehension of this mechanism reveals its intricate design and functionality, which are essential for optimal engine performance.

The device operates by regulating fuel flow and maintaining pressure, ensuring a steady supply for combustion. Its construction typically involves multiple elements working in harmony, contributing to reliable operation and longevity.

Maintenance is vital for preserving its efficiency, with regular checks and timely replacements of worn-out components. Understanding the various elements and their interactions can lead to improved performance and a reduction in mechanical failures.

Ultimately, knowledge of this system enhances one’s ability to troubleshoot issues and perform necessary repairs, ensuring the longevity of the engine it serves.

Key Components of the DB4 System

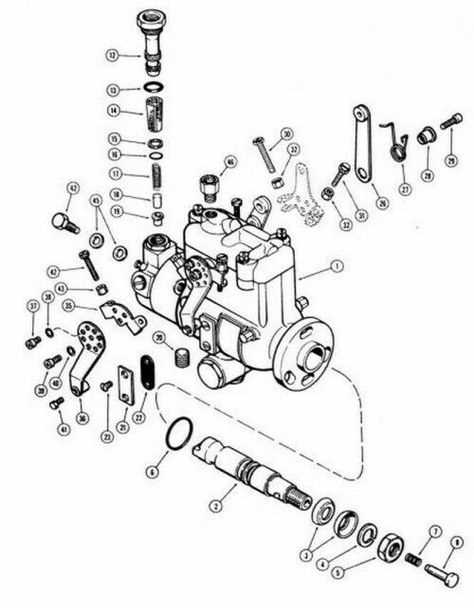

The effective functioning of a fuel delivery mechanism relies on several critical elements that work together to ensure optimal performance and reliability. Understanding these key components is essential for anyone looking to grasp the intricacies of the system and maintain it properly.

At the core of the mechanism lies the rotor, which plays a vital role in the distribution of fuel. This component rotates to generate pressure, facilitating the efficient transfer of fuel to the engine. Complementing the rotor is the cam, which controls the timing and sequence of fuel delivery, ensuring that each cylinder receives the appropriate amount at the right moment.

Another significant part is the governor, responsible for regulating engine speed and load. By adjusting the fuel flow based on engine demands, it helps maintain performance while optimizing fuel efficiency. Additionally, the delivery valves play a crucial role in managing the release of fuel, ensuring that it is injected precisely when needed.

Lastly, the housing encases these components, providing structural integrity and protecting them from external elements. Proper maintenance of each of these parts is essential for the longevity and efficiency of the overall system, making it crucial for operators to be familiar with their functions and interactions.

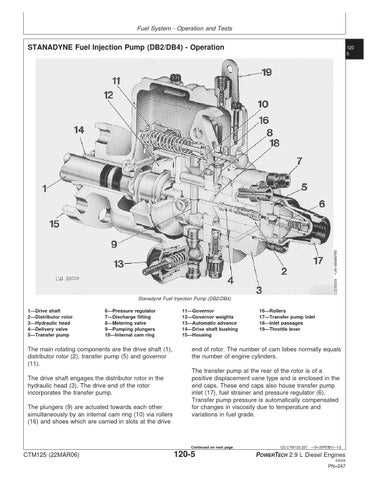

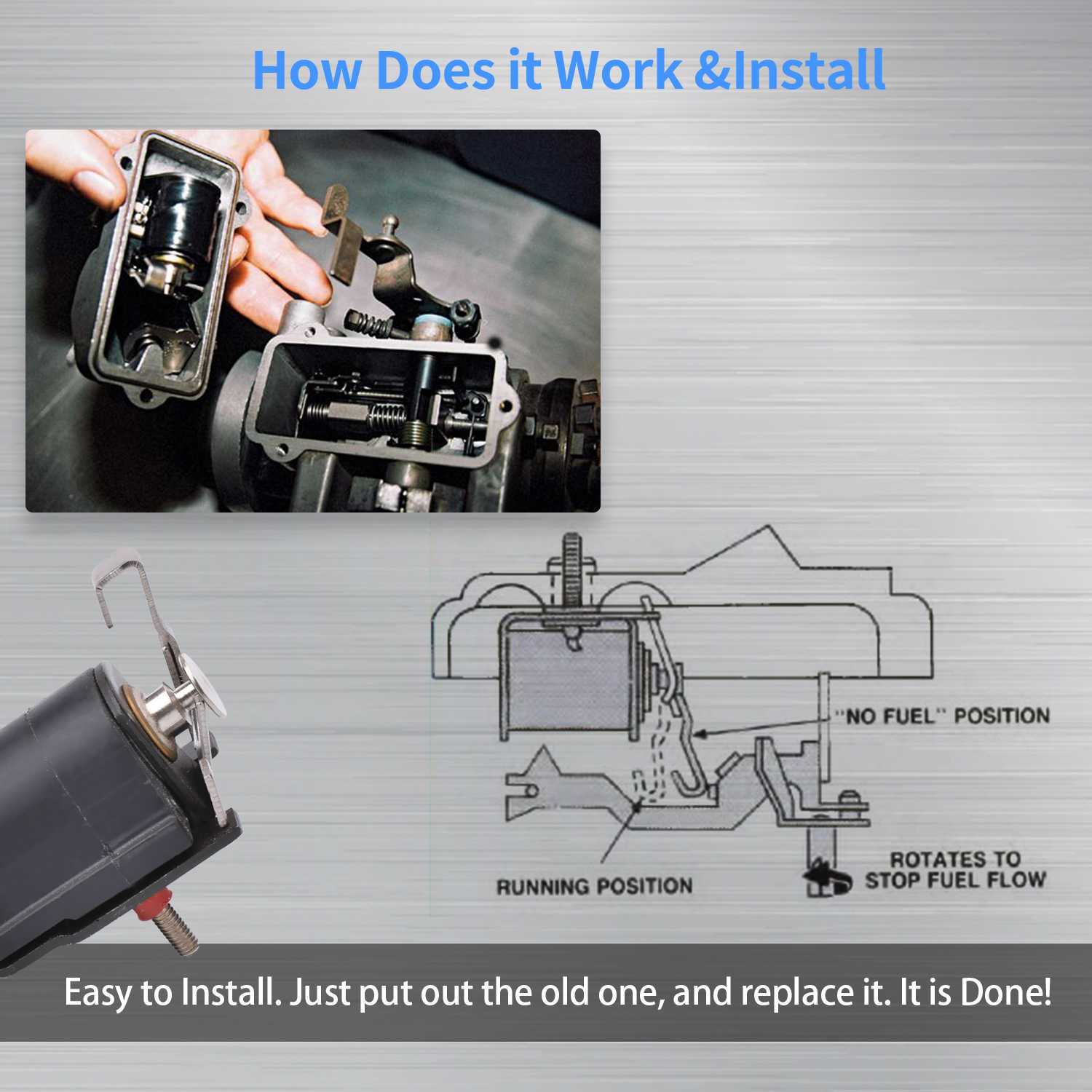

How the Injection Pump Functions

This section explores the essential mechanisms behind a fuel delivery system, focusing on how it effectively manages fuel flow and pressure to optimize engine performance. Understanding these processes is crucial for ensuring proper functionality and enhancing overall efficiency.

Operation Mechanism

The device operates through a series of precise movements that regulate fuel distribution. By utilizing a combination of rotational and linear motions, it creates the necessary pressure to deliver fuel to the combustion chamber at the right moment, thus facilitating efficient combustion.

Key Components

Several critical elements work together within this system. A rotor plays a vital role in transferring energy, while valves control the flow of fuel. Additionally, the camshaft coordinates the timing of these movements, ensuring that each cycle is executed flawlessly for optimal engine performance.

Common Issues with DB4 Pumps

In the world of fuel delivery systems, certain challenges can arise that affect performance and reliability. Understanding these typical problems is essential for maintaining efficiency and prolonging the lifespan of the equipment. From wear and tear to improper adjustments, several factors can contribute to complications in operation.

Wear and Tear

Over time, components can degrade due to constant use and exposure to harsh conditions. Seal deterioration is a frequent issue, often leading to fuel leaks and reduced efficiency. Regular inspections can help identify signs of wear early, preventing more significant failures.

Calibration and Adjustment Issues

Improper calibration can lead to inconsistent performance. Timing errors and incorrect settings may result in poor fuel atomization, which directly impacts engine performance. Ensuring that adjustments are made according to manufacturer specifications is crucial for optimal functionality.

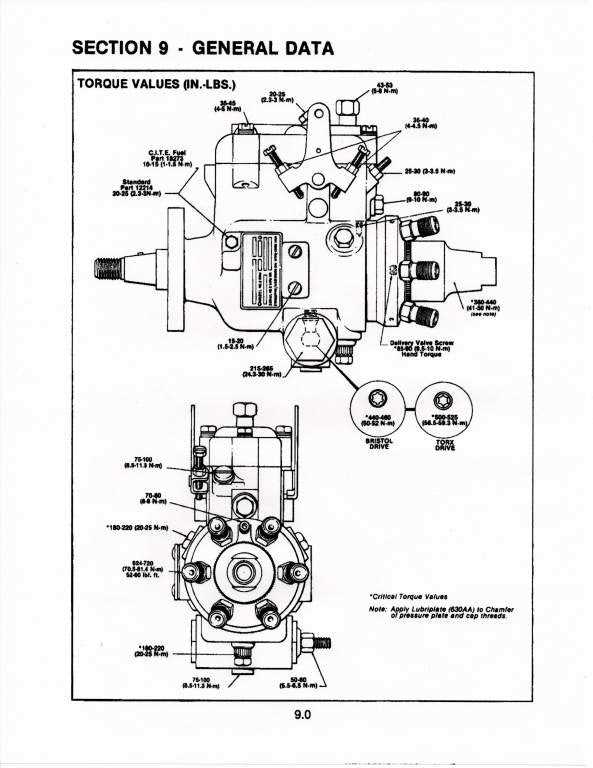

Maintenance Tips for Longevity

Ensuring the extended life of any mechanical device requires careful attention to its upkeep and regular servicing. Proper maintenance not only enhances performance but also minimizes the risk of unexpected failures. By adopting a proactive approach, you can significantly extend the operational lifespan of your equipment.

Regular Inspections: Conduct routine checks to identify any signs of wear or damage. Early detection can prevent more significant issues from arising and reduce repair costs.

Quality Lubrication: Use high-quality lubricants as recommended by the manufacturer. Adequate lubrication reduces friction, which is essential for optimal functioning and longevity.

Clean Components: Keep all elements free from dirt and contaminants. Regular cleaning helps maintain efficiency and prevents premature deterioration.

Temperature Monitoring: Ensure that the device operates within the recommended temperature range. Overheating can cause severe damage and lead to costly repairs.

Timely Replacements: Replace worn or damaged components promptly. Ignoring minor issues can lead to more significant problems that affect the entire system.

Follow Manufacturer Guidelines: Adhere to the maintenance schedule and guidelines provided by the manufacturer. This ensures that all necessary procedures are followed, promoting optimal performance.

By implementing these practices, you can ensure the reliability and longevity of your mechanical system, avoiding unnecessary downtime and enhancing overall efficiency.

Replacement Parts Overview

When maintaining and repairing fuel delivery systems, understanding the various components that may require substitution is essential for optimal performance. Ensuring that each element is in good working condition not only enhances efficiency but also prolongs the lifespan of the entire assembly.

Common Components for Replacement

- Seals and Gaskets

- Fuel Delivery Mechanisms

- Control Valves

- Spring Assemblies

- Drive Shafts

Factors to Consider When Choosing Components

- Quality: Always opt for high-grade materials to ensure durability.

- Compatibility: Verify that the new component fits with existing elements.

- Cost: Balance between price and quality to avoid frequent replacements.

- Supplier Reputation: Choose reliable vendors with good reviews.

By focusing on these aspects, one can effectively maintain the integrity and functionality of the fuel system, ensuring smooth operation over time.

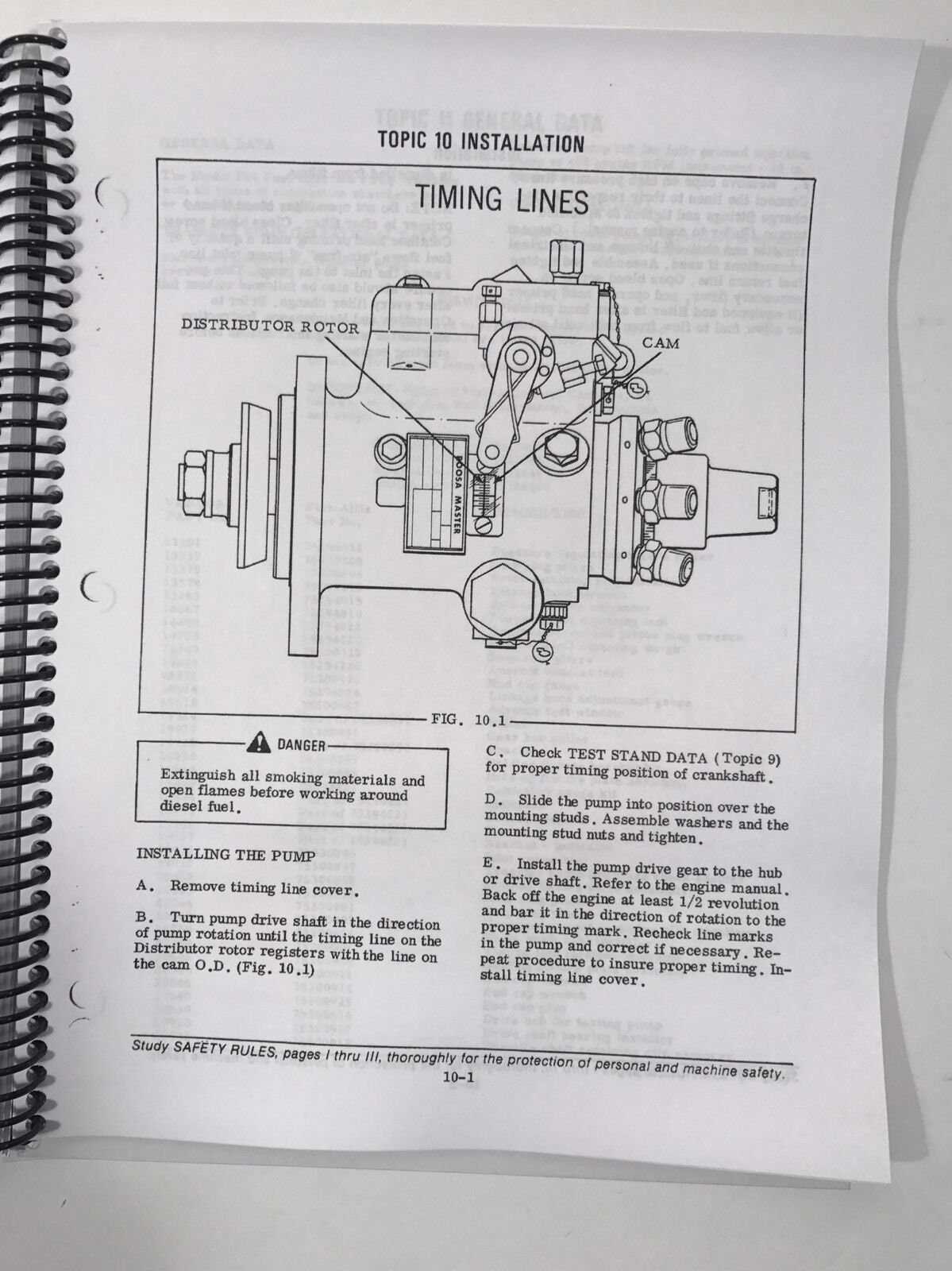

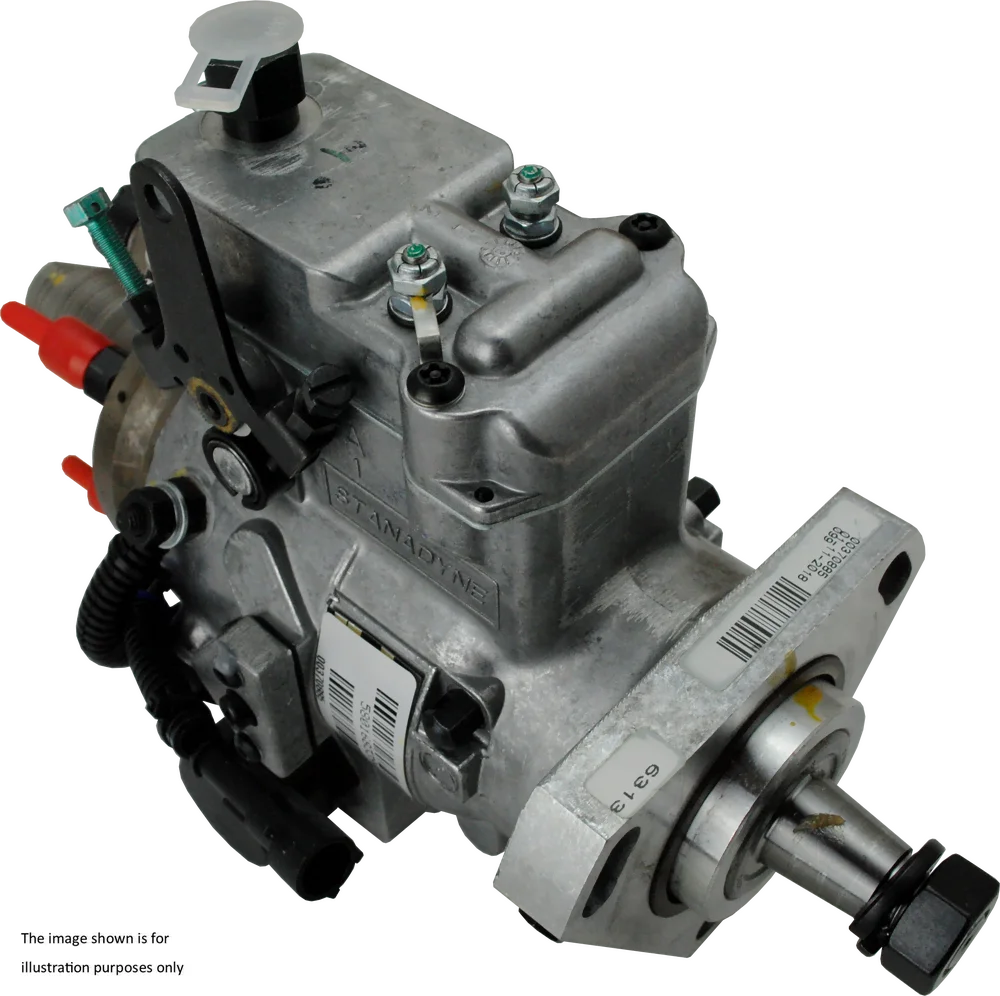

Visual Guide to DB4 Diagram

This section aims to provide a comprehensive overview of a specific schematic representation, which is essential for understanding the intricacies of a particular mechanical system. A well-structured visual guide can enhance clarity and facilitate easier troubleshooting and maintenance, making it invaluable for enthusiasts and professionals alike.

Understanding the Components

To fully grasp the functionality depicted in the schematic, it’s important to familiarize oneself with the key elements involved. Below are some critical components you may encounter:

- Control Mechanism

- Fuel Delivery System

- Timing Devices

- Valves and Regulators

- Seals and Gaskets

Interpreting the Visual Representation

When analyzing the visual layout, consider the following tips for effective interpretation:

- Start from the power source and trace the flow through the system.

- Pay attention to connection points and their respective functions.

- Identify any symbols or notations that may indicate specific operations.

- Cross-reference with service manuals for detailed explanations of each part.

By breaking down the schematic into manageable sections, users can develop a clearer understanding of the overall system and improve their ability to perform maintenance and repairs efficiently.

Performance Enhancements and Modifications

Optimizing fuel delivery systems is essential for improving engine efficiency, power output, and overall vehicle performance. By making strategic modifications, you can achieve smoother operation, increased longevity, and better responsiveness. This section explores key upgrades and adjustments to fine-tune the system for enhanced performance.

- Upgraded Components: Replacing certain elements with high-performance alternatives can significantly enhance the flow, ensuring a more precise and efficient operation.

- Calibration Adjustments: Fine-tuning specific settings allows for more accurate control over fuel delivery, optimizing power and fuel efficiency under different conditions.

- Increased Flow Capacity