In the world of machinery, comprehending the layout and organization of essential components is crucial for effective operation and maintenance. A thorough grasp of how different elements interconnect can significantly enhance both performance and longevity. This knowledge not only facilitates repairs but also improves overall functionality.

Machine enthusiasts and professionals alike benefit from visual representations that elucidate the intricate relationships between various parts. By studying these layouts, users can identify each component’s role, contributing to more efficient troubleshooting and enhancement. Whether you’re a seasoned technician or a novice user, familiarizing yourself with these schematics can empower you to work confidently and competently.

Ultimately, recognizing how each segment fits into the larger framework fosters a deeper appreciation of mechanical craftsmanship. This understanding serves as a foundation for successful operation and innovative advancements, making it an invaluable asset for anyone involved in machinery maintenance and repair.

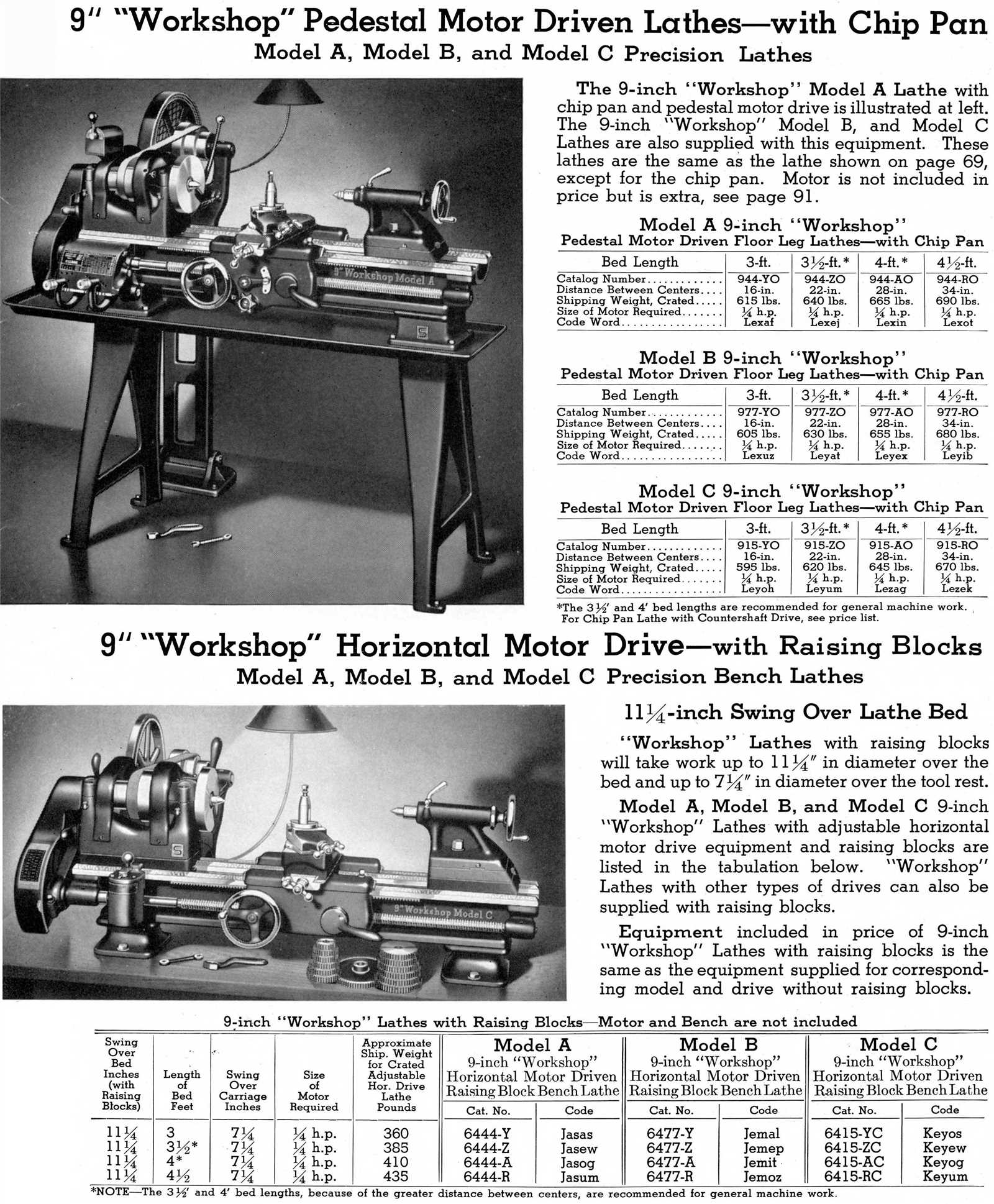

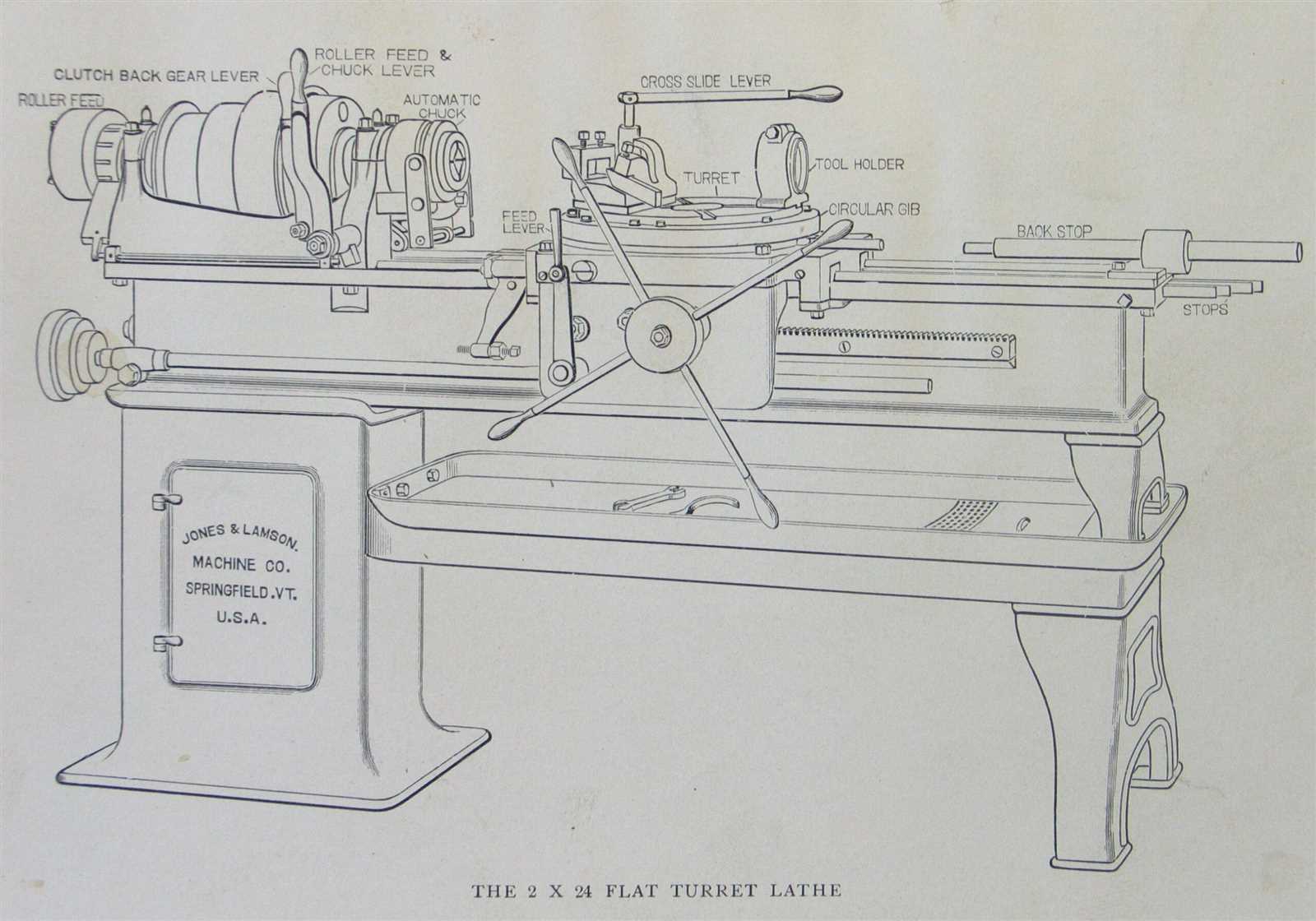

Understanding the fundamental components of a machining tool is crucial for both operation and maintenance. These key elements work together to facilitate precision in shaping and cutting various materials. Each segment plays a specific role, ensuring the overall functionality and effectiveness of the device.

| Component | Description |

|---|---|

| Headstock | The main section that houses the motor and drive system, allowing rotation of the workpiece. |

| Tailstock | Provides support for the other end of the workpiece and can hold tools for drilling. |

| Bed | The foundation that supports all other components, ensuring stability during operation. |

| Carriage | A movable assembly that enables the tool holder to traverse along the workpiece. |

| Tool Post | The fixture that holds the cutting tool in place during the machining process. |

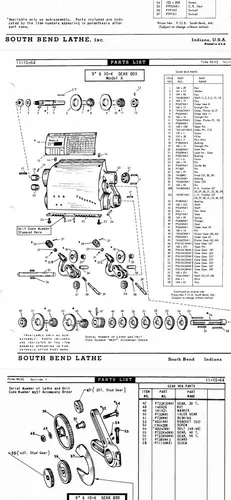

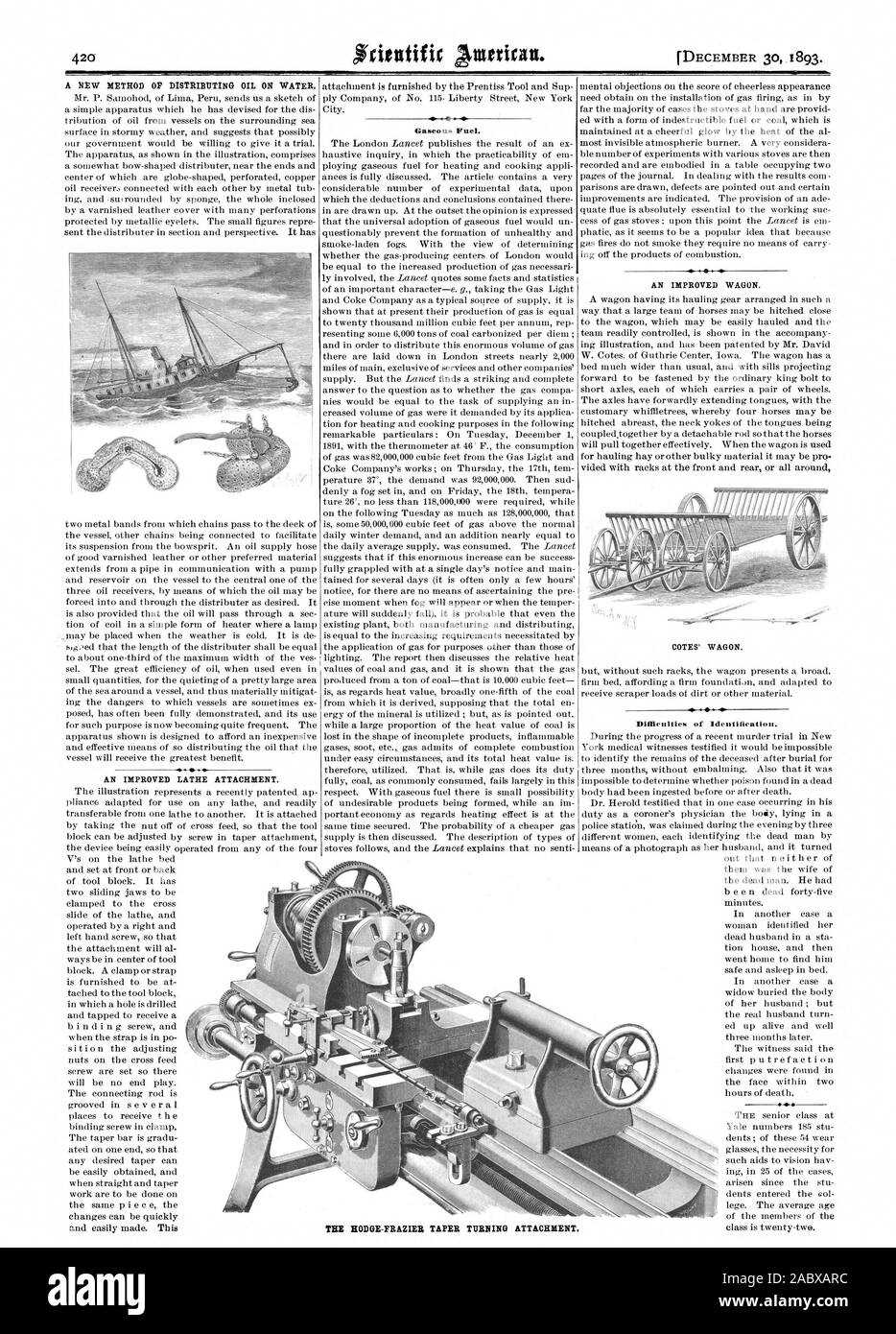

Diagram Overview and Explanation

This section aims to provide a comprehensive understanding of the visual representation and its significance in the context of machinery assembly and functionality. Such illustrations are invaluable for users, as they convey intricate details about the components and their interconnections, facilitating a clearer grasp of how each part contributes to the overall operation.

Key Components and Their Functions

Within the visual representation, each element plays a crucial role in the machine’s performance. Recognizing the function of each section allows for better maintenance and troubleshooting. For instance, the primary mechanism is responsible for driving the entire unit, while auxiliary components support various operations, enhancing efficiency.

Utilizing the Illustration for Maintenance

By referring to this representation, users can effectively identify parts that require attention during routine checks or repairs. Familiarity with the layout enables quicker diagnostics, ensuring that any issues can be addressed promptly, thereby extending the lifespan of the machinery.

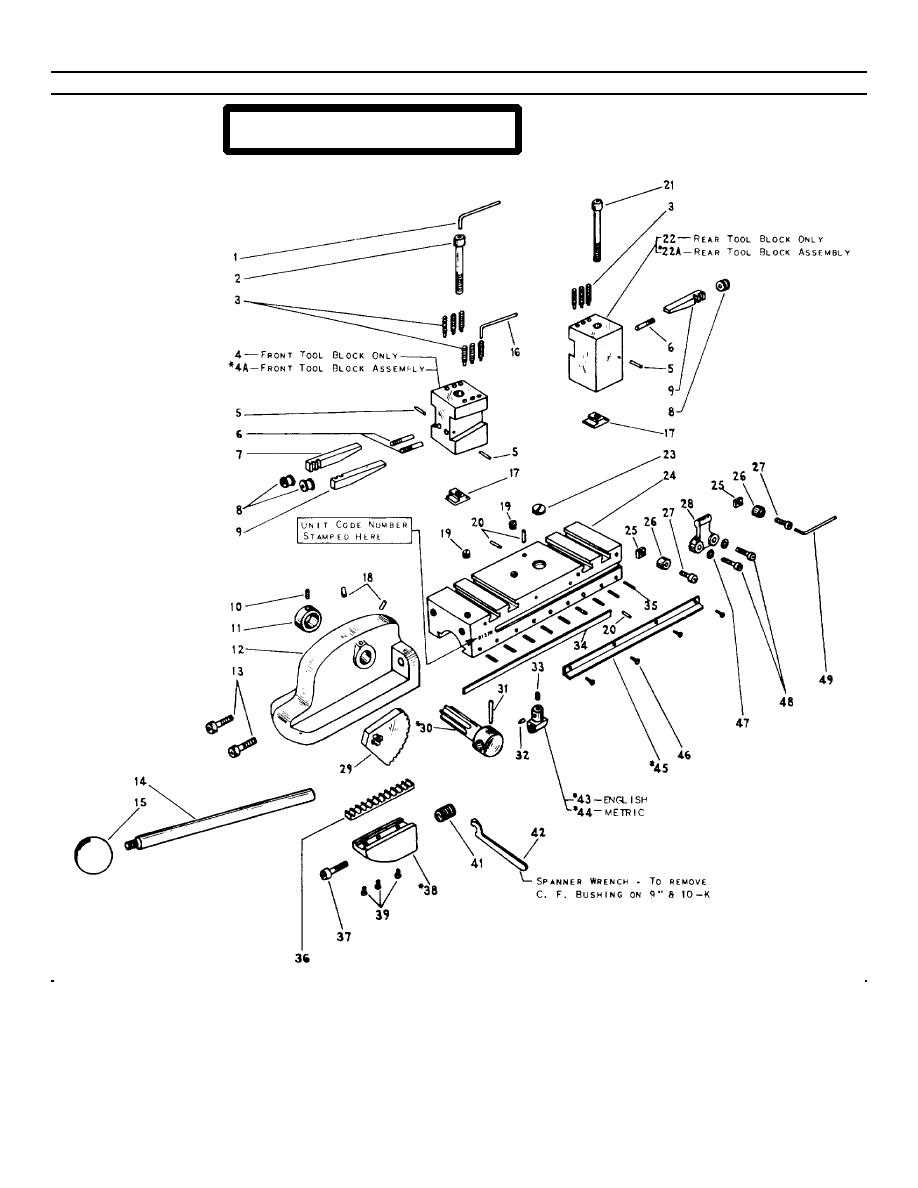

How to Identify Each Part

Understanding the various components of a machine is essential for effective operation and maintenance. Each element plays a crucial role, and recognizing them can greatly enhance your proficiency in working with the equipment. This section will provide insights into identifying individual components, helping you to familiarize yourself with their functions and characteristics.

Key Components Overview

To effectively identify the elements, it’s important to know their primary functions and physical attributes. Each component serves a unique purpose, and understanding these roles will aid in distinguishing between them. Below is a table that outlines common components, their descriptions, and functions.

| Component Name | Description | Function |

|---|---|---|

| Headstock | Located at the machine’s front, housing the main motor. | Drives the spindle, providing power to the cutting tool. |

| Tailstock | Situated opposite the headstock, it can be adjusted along the bed. | Supports the workpiece and can hold tools for drilling. |

| Carriage | Moves along the bed and holds the cutting tool. | Facilitates tool movement in relation to the workpiece. |

| Bed | The main base of the machine, providing support and stability. | Holds all other components in alignment and stability. |

Visual Inspection Tips

When examining the equipment, pay close attention to the shape, size, and location of each component. Familiarizing yourself with the overall layout will assist in quicker identification during operation or maintenance. Consider using a reference guide or diagram as a visual aid to reinforce your understanding of each part.

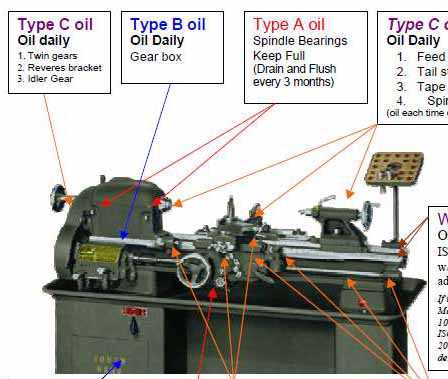

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves regular upkeep and attention to detail. Implementing effective maintenance practices can significantly extend the life of your machinery, enhancing performance and reliability. By adopting a proactive approach, you can prevent common issues and ensure smooth operation over time.

Regular Cleaning and Inspection

Maintaining a clean environment is crucial for optimal functionality. Periodically inspect components for signs of wear or damage. Remove debris and dust, especially from moving parts, to prevent unnecessary friction and deterioration. Regular assessments will help identify potential problems before they escalate.

Lubrication and Adjustments

Proper lubrication is essential to minimize wear and tear. Use appropriate oils or greases as recommended by the manufacturer to keep moving parts functioning smoothly. Frequent adjustments to settings and alignments can also enhance performance, ensuring that all components operate harmoniously. Establish a routine to check these aspects regularly.

Common Issues and Solutions

In the world of machinery, various complications can arise that affect performance and efficiency. Understanding these common challenges and their corresponding remedies is essential for maintaining optimal functionality. This section highlights frequent problems encountered with mechanical tools and offers practical solutions to address them.

| Issue | Description | Solution |

|---|---|---|

| Inaccurate Cuts | Imprecise dimensions can lead to poor outcomes in projects. | Ensure proper calibration of the tool and inspect the cutting edges for wear. |

| Excessive Vibration | Unwanted shaking can affect both the quality of work and operator comfort. | Check for proper installation and secure all components; consider adding dampening materials. |

| Overheating | Heat buildup can damage components and reduce performance. | Regularly clean the machine and use appropriate lubricants to minimize friction. |

| Tool Wear | Cutting tools may degrade over time, impacting efficiency. | Implement a routine maintenance schedule to replace or sharpen tools as necessary. |

| Power Fluctuations | Inconsistent energy supply can disrupt operation. | Check the power source and connections for stability; consider using a voltage stabilizer. |

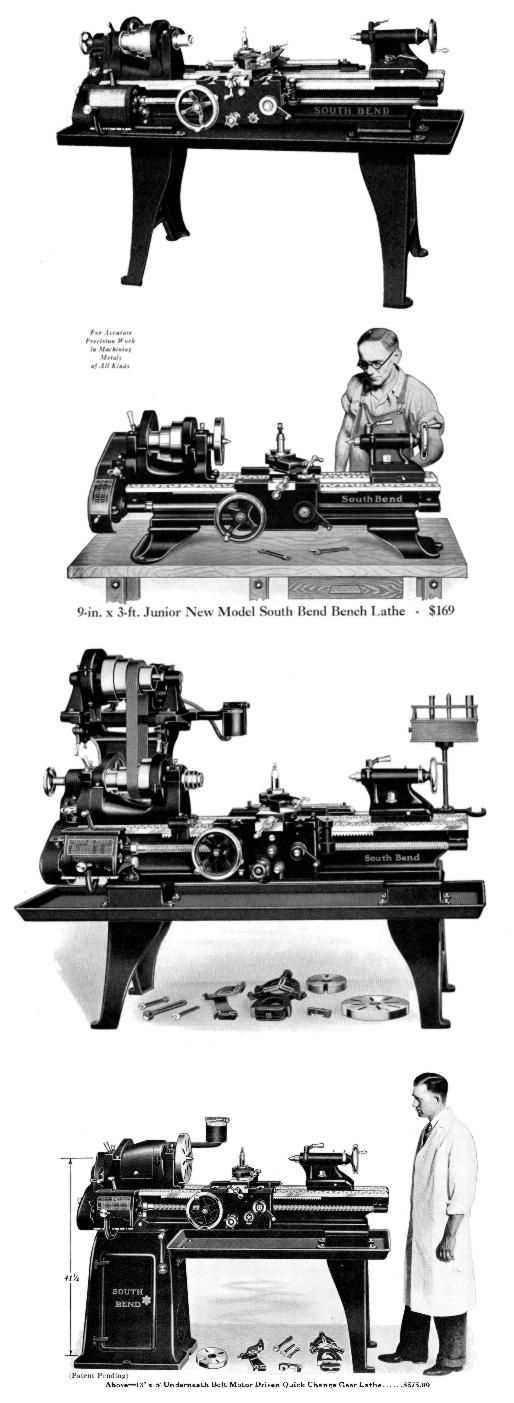

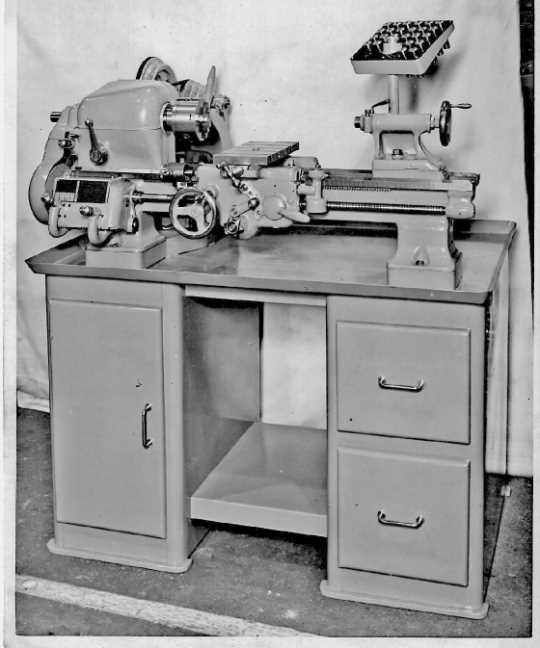

Upgrading Your Lathe Parts

Enhancing your machining equipment can significantly improve its performance and efficiency. Whether you are looking to replace worn components or upgrade to more advanced technology, these enhancements can lead to better precision, increased productivity, and a more enjoyable user experience.

Identifying Key Components for Improvement

Begin by assessing which elements of your machinery require attention. Focus on areas that impact overall functionality, such as the spindle, tool holder, or drive mechanisms. Upgrading these components can lead to noticeable gains in accuracy and stability, allowing for more intricate projects and finer finishes.

Choosing Quality Upgrades

When selecting new components, prioritize high-quality materials and reputable brands. Investing in durable parts will not only enhance the lifespan of your machinery but also ensure consistent performance. Researching user reviews and expert recommendations can help you make informed choices that align with your specific needs.

Resources for Further Learning

Expanding your knowledge in the realm of machining and mechanical tools can significantly enhance your skills and understanding. Various educational materials, including manuals, online courses, and community forums, can provide valuable insights and practical knowledge for enthusiasts and professionals alike.

One excellent starting point is to explore instructional books and guides focused on machining techniques. These resources often contain in-depth explanations and illustrations, making complex concepts easier to grasp. Additionally, numerous websites offer video tutorials and articles that demonstrate various methods and best practices in the field.

Engaging with online communities and forums can also be beneficial. Connecting with fellow enthusiasts allows for the exchange of ideas, troubleshooting advice, and shared experiences. Participating in discussions can lead to valuable tips and tricks that enhance your practical knowledge.

Furthermore, consider enrolling in workshops or courses offered by local technical schools or community colleges. Hands-on training can provide practical experience and an opportunity to learn from industry professionals. This immersive approach can solidify your understanding and skills in machining.

Community and Support Networks

Connecting with others who share similar interests and challenges can significantly enhance the learning experience and foster a sense of belonging. Support systems within a specific field provide individuals with valuable resources, guidance, and encouragement. Engaging with these networks allows enthusiasts to exchange ideas, troubleshoot issues, and celebrate achievements together.

Online Forums and Groups

Virtual communities play a crucial role in offering a platform for discussions, advice, and resource sharing. Participants can ask questions, share their projects, and receive feedback from peers. These online groups often host discussions on various topics, creating an inclusive environment where individuals can learn from one another’s experiences.

Local Workshops and Meetups

In-person gatherings offer a fantastic opportunity for networking and hands-on learning. Local workshops, seminars, and meetups enable enthusiasts to connect face-to-face, share knowledge, and collaborate on projects. These events help build camaraderie among participants, strengthening community ties and providing a rich learning atmosphere.