When tackling the challenges of cold weather, it’s crucial to have a clear comprehension of the machinery involved in clearing pathways. This section aims to unravel the intricate relationships between various elements of winter maintenance tools, highlighting their roles and functionalities.

Efficiency in these operations largely depends on understanding how each component interacts within the larger system. By examining these relationships, users can enhance their performance during demanding conditions.

Furthermore, delving into these essential mechanisms not only improves operational effectiveness but also aids in troubleshooting potential issues. Recognizing the ultimate importance of each part can lead to more informed decisions and successful maintenance practices.

Understanding Snow Plow Components

In the realm of winter weather management, a variety of essential elements work in concert to ensure efficient clearing of icy surfaces. Each component plays a crucial role in the overall functionality, contributing to the effectiveness of the entire system. Familiarity with these individual segments enhances comprehension of their operation and maintenance.

The primary structure serves as the backbone, supporting other integral components. Attached mechanisms facilitate movement and direction, allowing for precise maneuvering. Additional features, such as control systems, enable the operator to manage various functions seamlessly, ensuring optimal performance in challenging conditions.

Understanding the materials and designs used in these constructs can also reveal insights into their durability and efficiency. By recognizing the significance of each part, operators can better maintain and troubleshoot their equipment, ultimately leading to improved service during harsh weather scenarios.

Types of Snow Plow Blades

When it comes to clearing surfaces during winter conditions, the selection of appropriate implements plays a crucial role in efficiency and effectiveness. Various configurations are designed to tackle different types of terrain and snow accumulation, ensuring optimal performance regardless of the challenges presented by the weather.

Standard Blades

The most common variety, standard blades, are characterized by their straightforward design and versatility. These implements are typically made from durable materials, allowing them to handle light to moderate accumulations with ease. Their flat edges facilitate a smooth push, making them ideal for residential driveways and small parking areas.

V-Shaped Blades

V-shaped configurations are specifically engineered for heavier and more compacted snow. Their pointed design allows for effective cutting through dense layers, enabling operators to efficiently manage large volumes. This type is particularly beneficial in commercial applications where substantial clearance is required, as it effectively channels material to the sides.

In addition to standard and V-shaped options, other specialized implements cater to unique environments and requirements, enhancing the overall performance of winter maintenance operations.

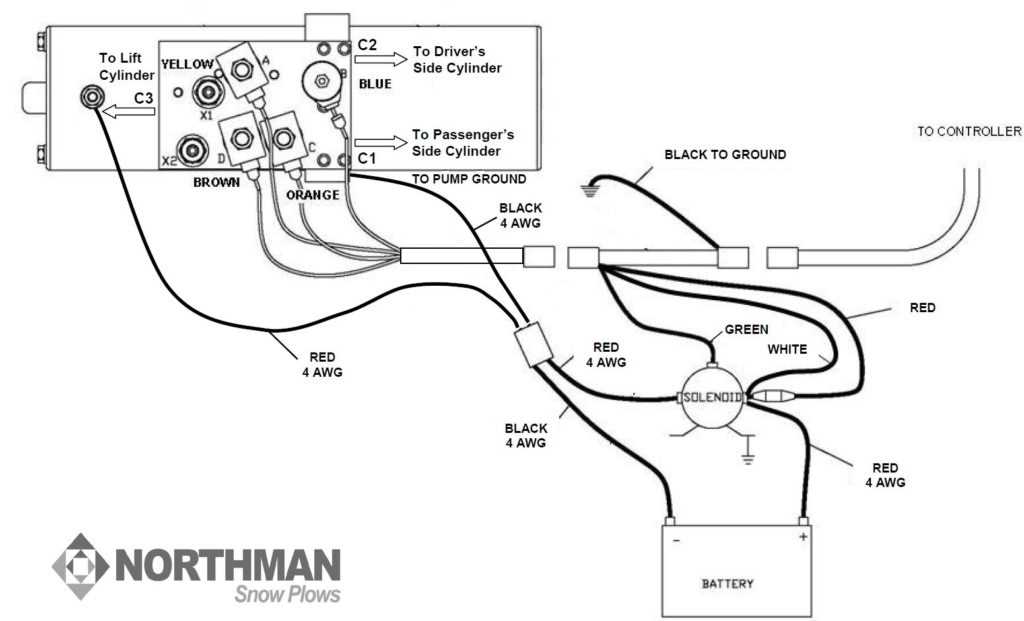

Hydraulic System Overview

The hydraulic system is a vital component in machinery, enabling efficient movement and control through fluid dynamics. This system utilizes pressurized liquid to transmit force, allowing for the operation of various mechanical elements with precision and power.

Key elements of a hydraulic system include:

- Hydraulic Fluid: The medium that transmits force, typically oil, which provides lubrication and cooling.

- Pumps: Devices that generate hydraulic pressure, drawing fluid from a reservoir and pushing it through the system.

- Cylinders: Actuators that convert hydraulic pressure into linear motion, performing tasks such as lifting or pushing.

- Valves: Components that regulate fluid flow, directing it to different parts of the system as needed.

- Reservoirs: Storage tanks that hold hydraulic fluid, ensuring a consistent supply for operation.

Understanding the function and interaction of these elements is crucial for effective maintenance and operation, ensuring reliability and efficiency in various applications.

Common applications of hydraulic systems include:

- Construction machinery

- Agricultural equipment

- Industrial machinery

- Automotive systems

In summary, a well-functioning hydraulic system is essential for the smooth operation of numerous machines, leveraging the power of fluid dynamics to enhance productivity and effectiveness.

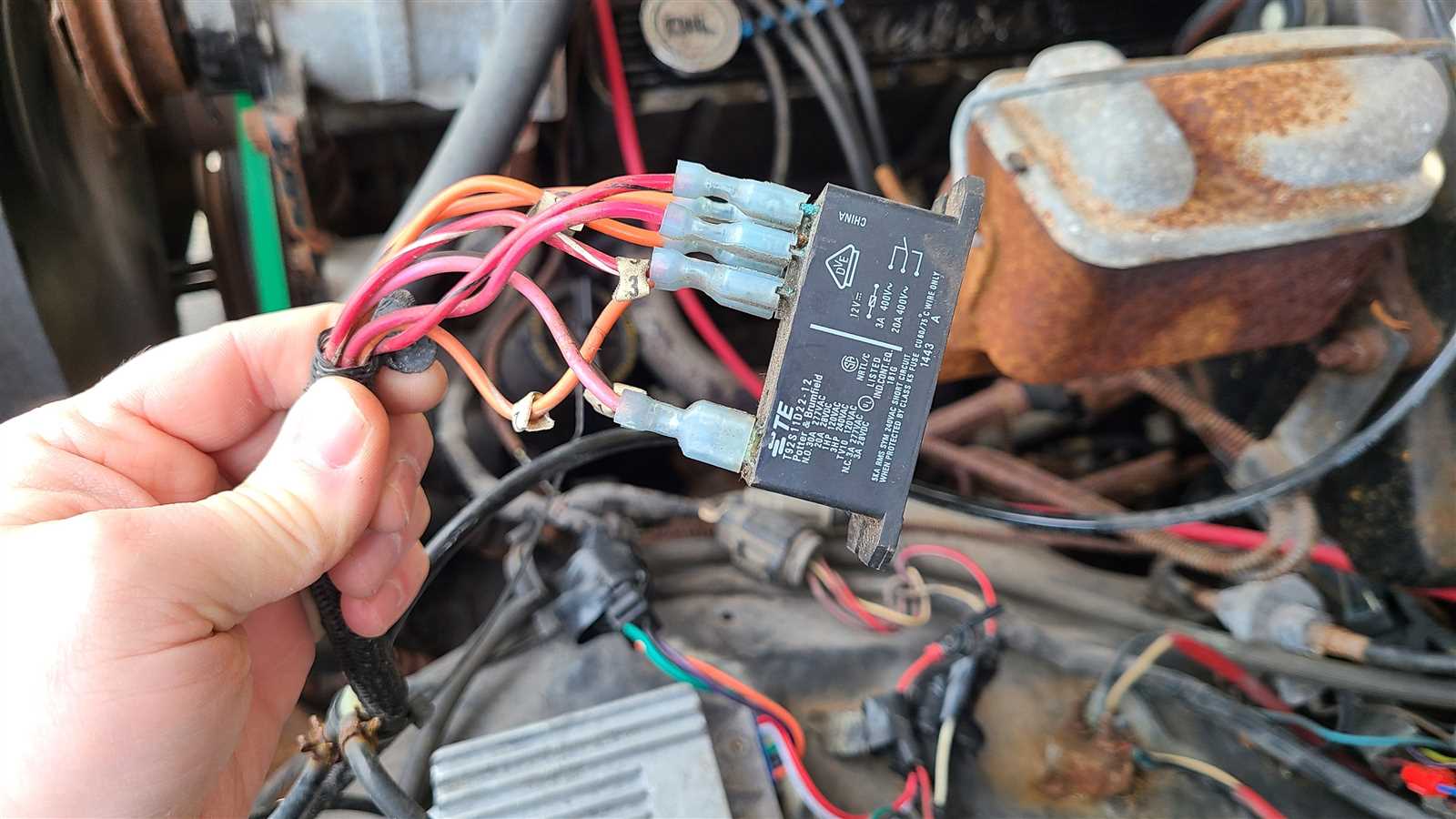

Electrical Parts and Their Functions

Understanding the components that facilitate the operation of machinery is crucial for effective maintenance and troubleshooting. Each element plays a specific role, ensuring the entire system functions smoothly and efficiently.

Key Components

- Batteries: Provide the necessary electrical energy to power the system.

- Relays: Act as switches to control high-power circuits using low-power signals.

- Fuses: Protect the electrical system from overloads by breaking the circuit when current exceeds safe levels.

- Sensors: Monitor various parameters such as temperature and pressure, sending data to the control unit.

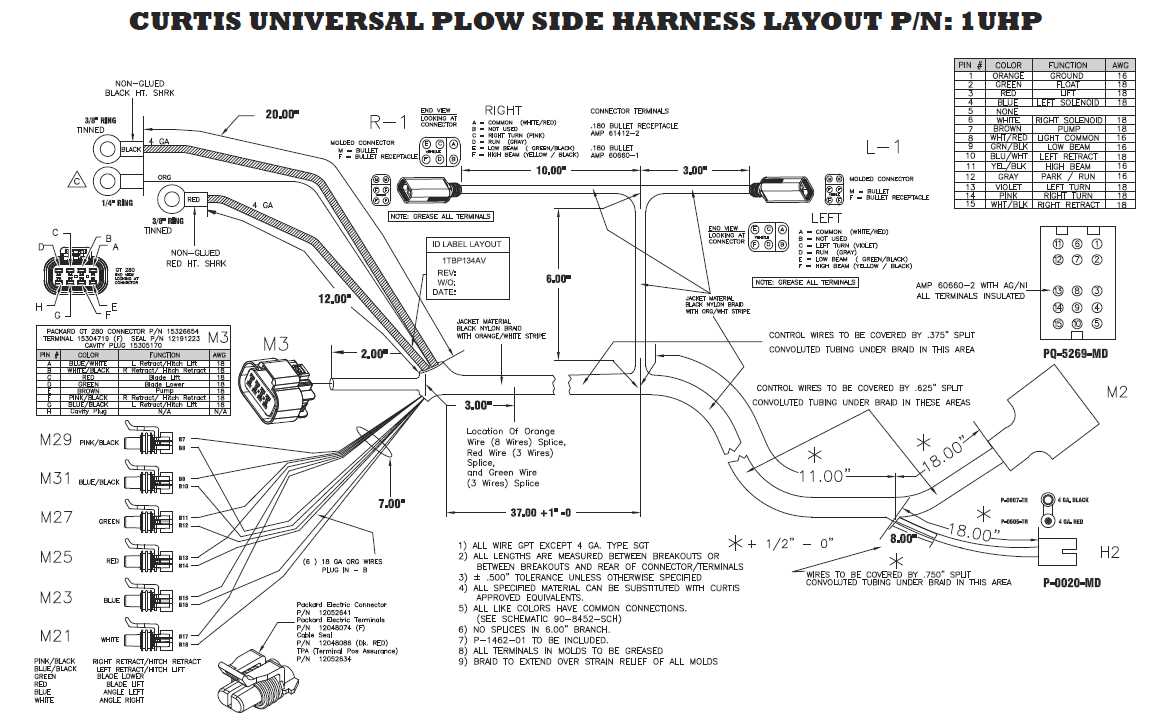

- Wiring Harnesses: Organize and protect the electrical wiring throughout the machinery.

Functionality Overview

The interaction of these components is vital for seamless operation. For instance:

- The battery powers the system, enabling all electrical components to function.

- Relays manage power distribution, allowing for safe control of high-demand devices.

- Fuses serve as critical safety devices, preventing damage from electrical faults.

- Sensors provide real-time data, ensuring the system operates within designated parameters.

- Wiring harnesses ensure a reliable and organized connection among various elements.

By comprehensively understanding these electrical components and their roles, users can enhance the reliability and longevity of the equipment.

Common Wear Items in Snow Plows

When it comes to winter maintenance equipment, certain components tend to experience more frequent deterioration due to their constant exposure to harsh conditions. Understanding these elements is crucial for effective upkeep and operational efficiency.

Blades

The cutting edges of the machinery are often the first to show signs of wear. Over time, they can become dull, affecting performance. Regular inspection and timely replacement are essential to ensure optimal function.

Hardware and Fasteners

Components such as bolts and nuts can corrode or loosen over time. This deterioration can lead to instability and potential failure during operation. It’s vital to check these items regularly and replace any that exhibit signs of wear.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the durability and efficiency of your equipment. Implementing a routine maintenance schedule can prevent unexpected breakdowns and extend the lifespan of vital components. Here are some key strategies to keep your machinery in optimal condition.

Routine Inspections

Conducting frequent inspections is crucial. Look for signs of wear and tear, and address any issues promptly to avoid more significant problems down the line.

Cleaning and Lubrication

Maintaining cleanliness is important for functionality. Regularly remove debris and dirt, and ensure that all moving parts are adequately lubricated to reduce friction and wear.

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for visible damage or wear. |

| Cleaning | After Each Use | Remove dirt and debris. |

| Lubrication | Monthly | Use appropriate lubricants for moving parts. |

| Fluid Check | Every 3 Months | Ensure fluid levels are adequate. |

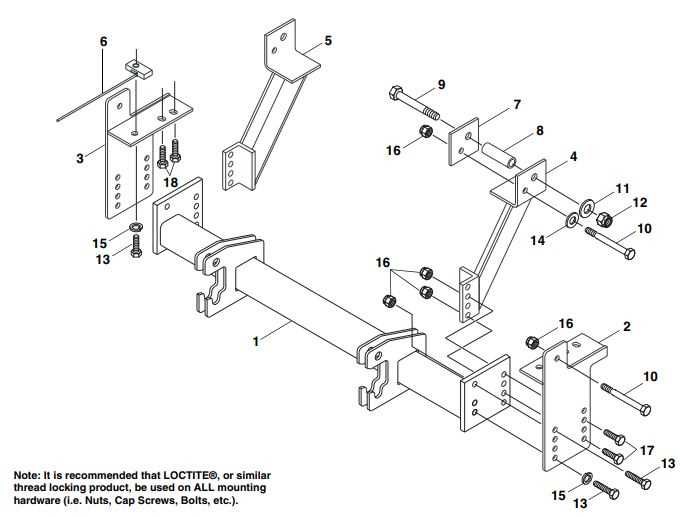

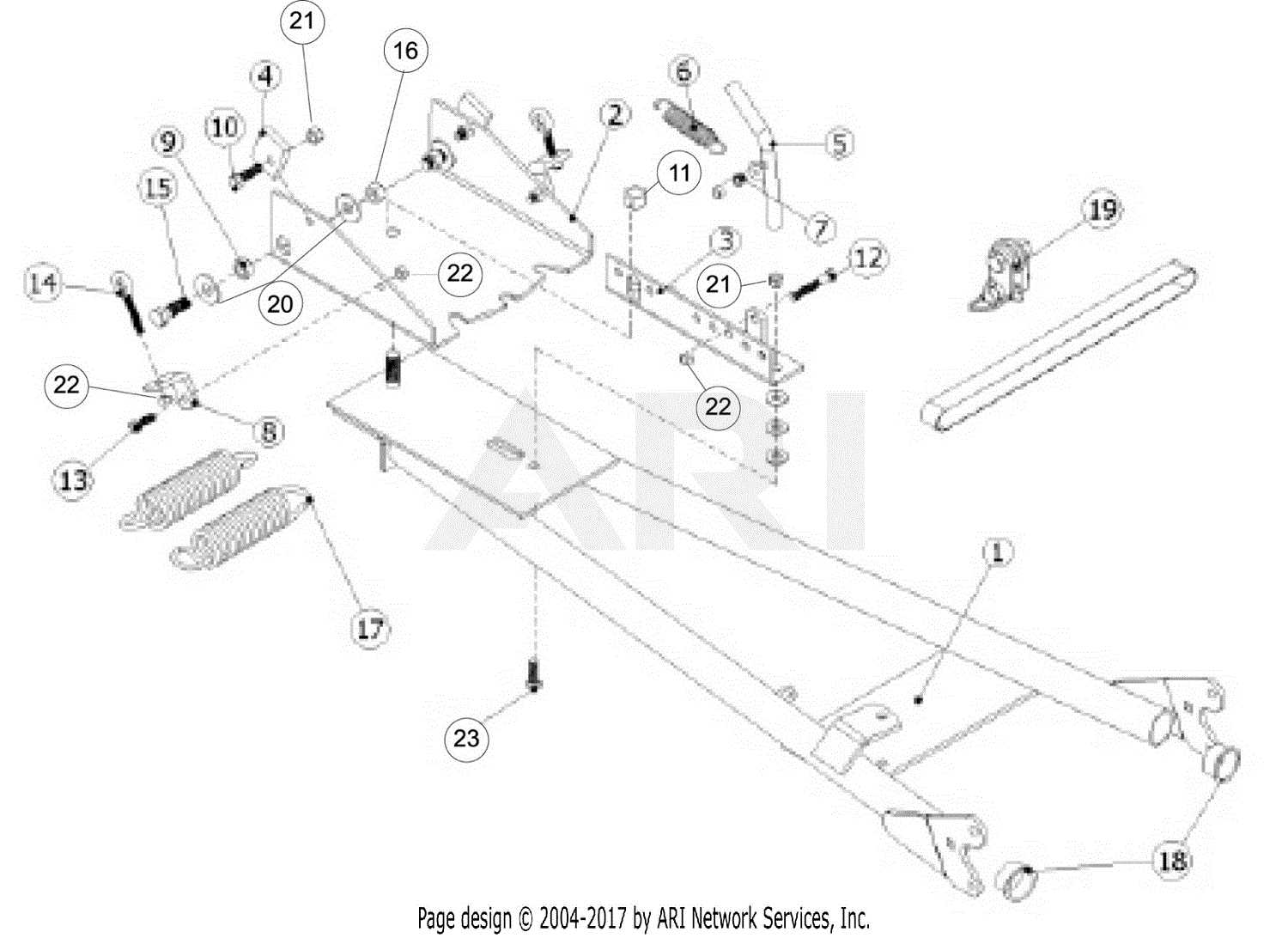

Identifying Replacement Parts

Understanding how to recognize and locate components for your equipment is crucial for maintenance and functionality. By familiarizing yourself with essential elements, you can ensure optimal performance and longevity.

Common Components to Recognize

- Blades: Often the most visible part, critical for effective operation.

- Hydraulic systems: Essential for movement and control.

- Mounting brackets: Necessary for securing elements in place.

- Drive belts: Key for transmitting power between different parts.

Steps to Identify Components

- Refer to the owner’s manual: It typically includes a list of components and their functions.

- Inspect the equipment: Look for labels or part numbers on the elements.

- Consult online resources: Many websites offer detailed guides and visuals for identification.

- Contact a specialist: When in doubt, an expert can provide insights on specific parts.

Safety Features to Consider

When operating heavy machinery designed for clearing surfaces, ensuring user and bystander safety is paramount. Various features enhance protection, making operations smoother and more secure. Understanding these elements can significantly reduce the risk of accidents and improve overall functionality.

Key Safety Elements

- Emergency Shut-off Switch: Quick access to an emergency stop feature can prevent serious incidents.

- Visibility Enhancements: Lights and reflective materials improve visibility during low-light conditions.

- Operator Protection: Enclosed cabins or guards protect the user from environmental hazards.

- Stability Controls: Features that enhance balance prevent tipping or sliding during operation.

Operational Precautions

- Regularly inspect safety features to ensure they are functioning correctly.

- Familiarize yourself with the emergency procedures before commencing operations.

- Utilize personal protective equipment (PPE) such as gloves, helmets, and eye protection.

- Maintain a safe distance from bystanders and obstacles during operation.

Upgrading Your Snow Plow System

Enhancing your winter equipment can significantly improve its performance and efficiency. By exploring various advancements, you can ensure that your setup meets the demands of harsh weather conditions, offering better maneuverability and reliability.

Investing in higher-quality components not only boosts functionality but also extends the lifespan of your system. Consider upgrading to modern technologies that enhance control and adaptability, allowing for smoother operation during challenging circumstances.

Additionally, assessing your current configuration and identifying areas for improvement can lead to smarter investments. Upgrades may include better hydraulic systems, improved blades, or advanced electronic controls that ultimately contribute to a more effective winter solution.