In the realm of elevated machinery, a clear grasp of individual elements is essential for optimal functionality and safety. Each section plays a pivotal role, contributing to the overall efficiency of the apparatus. Recognizing these components allows operators and technicians to ensure the equipment operates at its best.

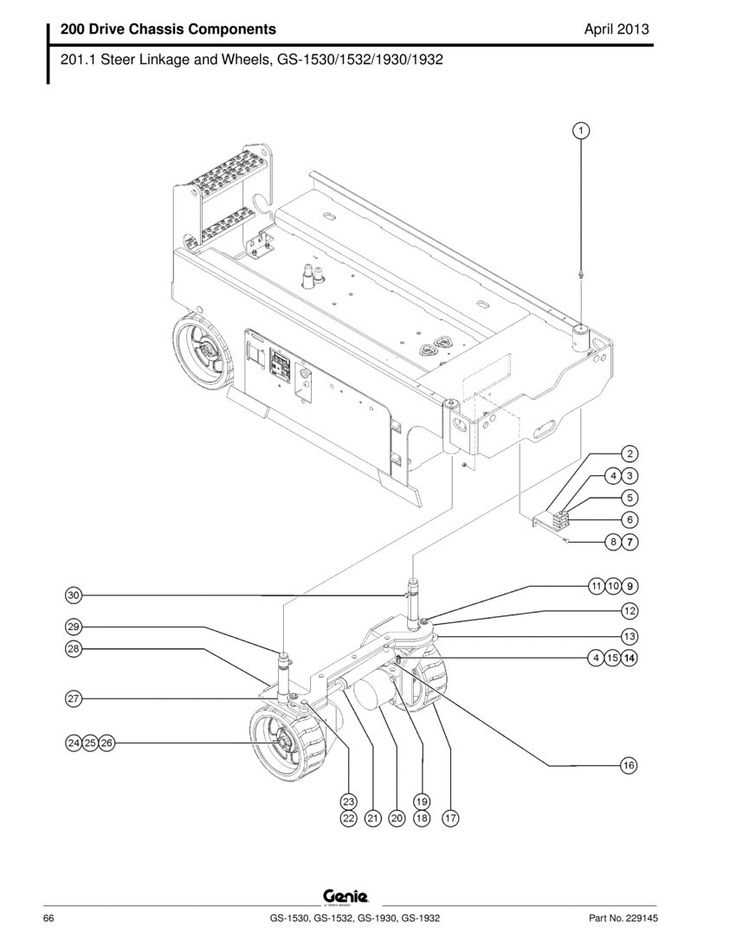

Visual representations of these elements facilitate a deeper comprehension, serving as valuable resources for maintenance and troubleshooting. By examining the intricate relationships between various parts, one can enhance operational proficiency and prevent potential malfunctions.

As we explore the intricacies of this equipment, we will delve into the ultimate significance of understanding its construction. This knowledge not only aids in efficient handling but also empowers users to make informed decisions regarding repairs and enhancements.

Understanding Snorkel Lifts

When it comes to aerial work platforms, a specific type has gained popularity due to its versatility and unique capabilities. These machines are designed to provide safe and efficient access to elevated areas, making them essential for various construction and maintenance tasks. Their distinctive structure allows operators to maneuver with ease while reaching impressive heights.

Key Features: The primary advantage of these elevated platforms lies in their ability to offer stability and flexibility. With adjustable height and a rotating platform, users can achieve precision in positioning while ensuring safety. The thoughtful engineering of these devices emphasizes user comfort and operational efficiency.

Applications: From industrial settings to outdoor events, the utility of these machines spans numerous industries. Their design accommodates both indoor and outdoor environments, allowing for effective use in a range of scenarios. As a result, they have become indispensable tools for professionals seeking reliable access to difficult-to-reach areas.

Components of Snorkel Lifts Explained

Understanding the intricate elements that make up aerial work platforms is essential for ensuring their efficient operation and maintenance. Each component plays a vital role in the overall functionality, safety, and reliability of these machines. This section delves into the various parts and their specific purposes, providing clarity on how they contribute to the unit’s performance.

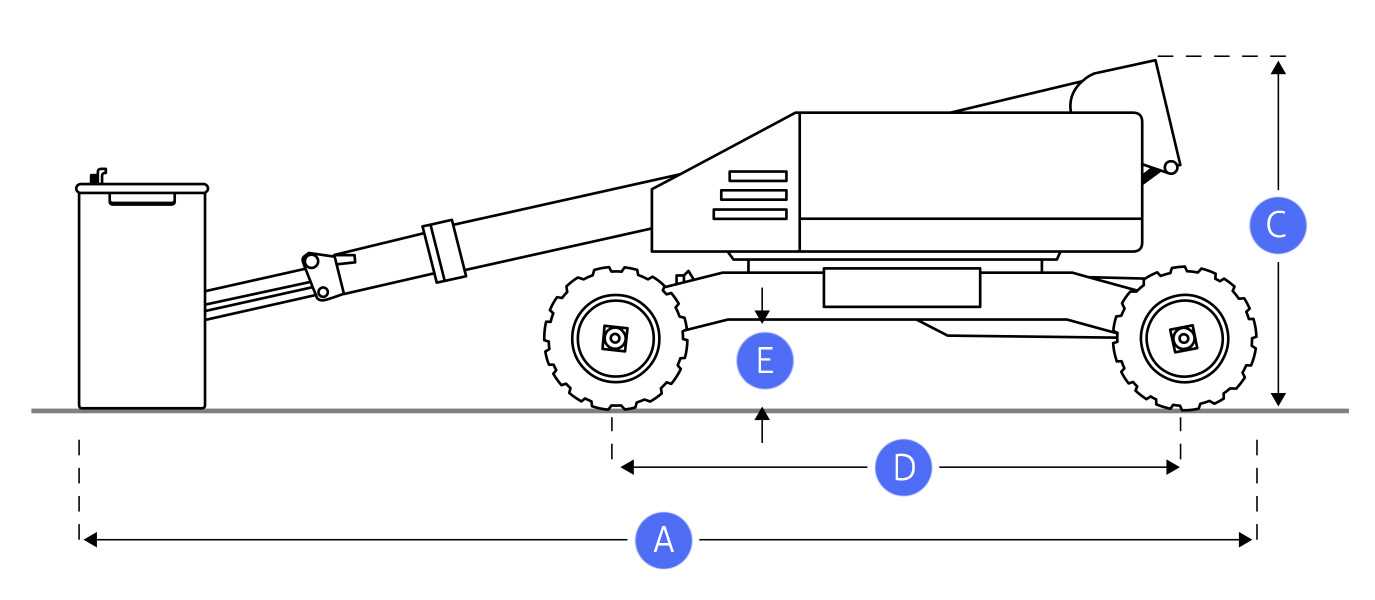

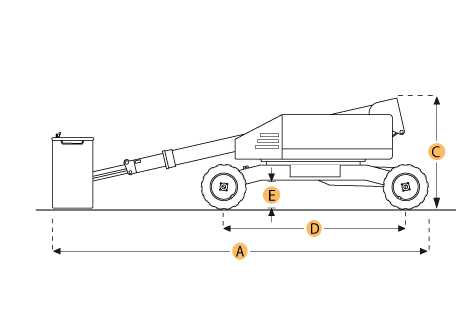

Base Frame: The foundation of the structure, the base frame supports all other components. It must be robust to withstand the weight and stresses of operation, ensuring stability during use.

Platform: The area where operators perform their tasks is designed for safety and accessibility. It often features guardrails and non-slip surfaces to prevent accidents while working at heights.

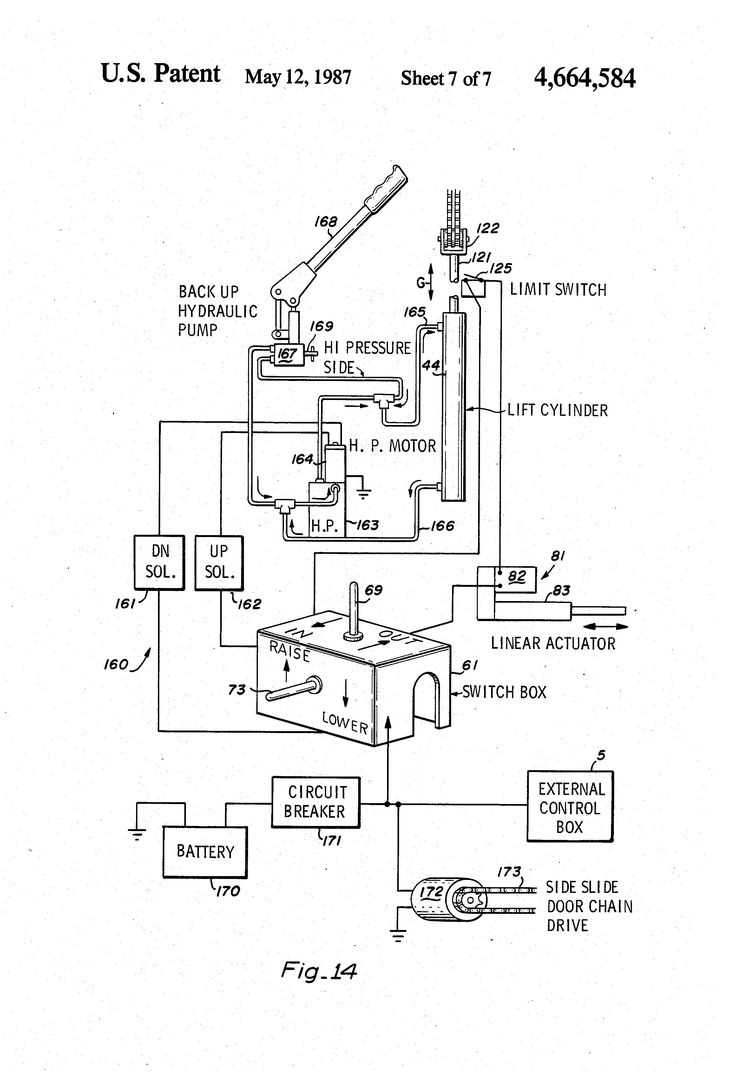

Hydraulic System: This system is crucial for movement and positioning. It consists of pumps, hoses, and cylinders that enable the machine to extend and retract, providing the necessary elevation and reach.

Control System: Operators rely on this interface to manage the machine’s functions. It typically includes joysticks and buttons, allowing for precise maneuvering and adjustments during operation.

Safety Features: Various mechanisms, such as emergency stop buttons, tilt sensors, and overload protection systems, are integrated to enhance user safety. These features are essential for preventing accidents and ensuring compliance with regulations.

Wheels and Tires: Designed for mobility, these components allow the machinery to be transported easily between job sites. They must be durable and suited for various terrains to ensure reliable movement.

By examining these components, one can appreciate the complexity and engineering involved in creating efficient aerial work platforms. Each part is meticulously designed to work in harmony, ensuring optimal performance and safety in demanding environments.

Importance of Parts Diagrams

Visual representations of mechanical components play a crucial role in the maintenance and repair of various equipment. They provide a clear and organized overview of individual elements, facilitating a deeper understanding of how each component interacts within a larger system. This clarity aids technicians in efficiently identifying issues, performing repairs, and ensuring proper assembly.

Moreover, these visuals serve as essential tools for training and reference. They help both novice and experienced personnel grasp the intricate details of machinery quickly, minimizing errors during maintenance tasks. The accessibility of such resources empowers teams to work more effectively, ultimately leading to enhanced productivity and safety.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clarifies the relationships between different components. |

| Efficiency in Repairs | Speeds up troubleshooting and assembly processes. |

| Training Resource | Acts as a valuable tool for educating new staff. |

| Improved Safety | Reduces the likelihood of mistakes during maintenance. |

Common Snorkel Lift Models

This section provides an overview of various popular models used in aerial access equipment. Each model is designed to meet specific operational needs and environmental conditions, offering unique features that enhance productivity and safety for users. Understanding these models can assist operators in selecting the most suitable machinery for their tasks.

Popular Models Overview

| Model Name | Working Height | Platform Capacity |

|---|---|---|

| GS-1930 | 25 ft | 500 lbs |

| GT-4047 | 47 ft | 1,000 lbs |

| SB-46 | 46 ft | 750 lbs |

Key Features

Each model offers distinct advantages such as compact design for narrow spaces, robust performance for heavy loads, and enhanced maneuverability for various terrains. Choosing the right equipment is essential for maximizing efficiency and ensuring safety during operations.

Identifying Key Lift Parts

Understanding the essential components of aerial work platforms is crucial for efficient operation and maintenance. Each element plays a specific role in ensuring safety and functionality. Familiarity with these elements helps users recognize issues and perform necessary inspections effectively.

Main Components to Recognize

- Chassis: The base structure that provides stability and support.

- Platform: The area where operators stand, often equipped with safety rails.

- Control Panel: The interface that allows users to operate the equipment smoothly.

- Hydraulic System: The mechanism that facilitates lifting and lowering actions.

- Power Source: The engine or battery that powers the entire system.

Identifying Key Functions

- Ensure the chassis is free from damage for optimal support.

- Regularly check the platform for wear and tear to maintain safety.

- Familiarize yourself with the control panel to understand operation options.

- Inspect the hydraulic system for leaks or malfunctions.

- Monitor the power source for reliability during use.

By recognizing and understanding these critical components, operators can enhance safety and prolong the lifespan of the equipment.

Maintenance Tips for Snorkel Lifts

Regular upkeep is essential for ensuring optimal performance and longevity of aerial work platforms. Proper care not only enhances safety but also reduces the risk of unexpected breakdowns, ultimately saving time and costs.

Routine Inspections

Conduct frequent checks to identify any signs of wear or damage. Pay attention to hydraulic systems, electrical components, and structural integrity to maintain reliable operation.

Cleaning and Lubrication

Keep all surfaces clean and free from debris. Regularly lubricate moving parts to minimize friction and prevent premature wear, ensuring smooth functionality throughout the machine’s life.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Daily |

| Hydraulic Fluid Check | Weekly |

| Battery Maintenance | Monthly |

| Full System Check | Quarterly |

Safety Features of Snorkel Lifts

Ensuring the safety of operators and workers is paramount in any equipment designed for elevated tasks. Various innovative features have been integrated into aerial platforms to enhance stability, control, and overall safety during operation. Understanding these features is crucial for maximizing efficiency while minimizing risk.

Key Safety Mechanisms

The following mechanisms play a vital role in maintaining a secure working environment:

| Feature | Description |

|---|---|

| Emergency Stop | A readily accessible button that halts all operations immediately in case of an emergency. |

| Guardrails | Robust railings surrounding the work platform to prevent falls and enhance stability. |

| Load Sensors | Devices that monitor weight limits, ensuring the platform is not overloaded. |

| Outriggers | Extendable supports that stabilize the machine on uneven ground, reducing the risk of tipping. |

Training and Compliance

Regular training programs for operators are essential to ensure proper use of these safety features. Adhering to industry standards and regulations further enhances the operational safety of aerial platforms, making them reliable tools in various construction and maintenance tasks.

Where to Find Replacement Parts

Locating essential components for machinery can be crucial for maintaining efficiency and safety. Various avenues exist for sourcing these vital items, ensuring you can restore functionality without delay.

Online Retailers: Numerous e-commerce platforms specialize in industrial equipment, offering a wide array of components. Websites often provide detailed specifications and customer reviews, aiding your selection process.

Authorized Dealers: Connecting with official distributors guarantees access to high-quality replacements. They can offer expert advice and support, ensuring you choose the correct items for your needs.

Local Suppliers: Exploring nearby suppliers can yield immediate solutions. Building relationships with local businesses may also lead to favorable pricing and availability.

Manufacturer Websites: Visiting the manufacturer’s site often reveals direct purchasing options. Many companies also provide comprehensive catalogs, making it easier to identify required components.

Networking with Industry Professionals: Engaging with peers in your industry can unveil hidden resources. Fellow operators may share valuable insights into where to procure reliable replacements efficiently.

Upgrading Your Snorkel Lift

Enhancing your aerial work platform can significantly improve its performance, efficiency, and safety. By implementing modern upgrades, you can extend its lifespan and ensure it meets current operational standards. This section explores various strategies to optimize your equipment for better functionality and reliability.

1. Evaluate Existing Features: Before proceeding with any enhancements, it’s crucial to assess the current capabilities of your machinery. Identify any shortcomings or outdated technologies that could benefit from improvement. This evaluation will guide your upgrade decisions.

2. Incorporate Advanced Technology: Upgrading to more sophisticated control systems can enhance precision and responsiveness. Consider integrating smart sensors and monitoring systems that provide real-time data, ensuring safer operations and better management of resources.

3. Upgrade Safety Mechanisms: Prioritize safety by installing advanced safety features. These may include improved harness systems, automatic shut-off mechanisms, and enhanced stability controls. Such additions not only protect operators but also reduce the risk of accidents on the job site.

4. Optimize Power Systems: Assess the power source of your equipment. Upgrading to a more efficient engine or battery system can result in lower fuel consumption and reduced emissions, contributing to a greener work environment.

5. Enhance Mobility and Terrain Adaptability: Consider modifications that improve your machinery’s ability to navigate challenging terrains. Adding all-terrain capabilities can expand the range of jobs you can tackle, increasing overall productivity.

By thoughtfully implementing these upgrades, you can maximize the potential of your equipment, ensuring it remains competitive and effective in the ever-evolving landscape of construction and maintenance work.