Exploring the intricacies of flush systems reveals a fascinating interplay of various elements that ensure efficient water management in sanitation. These mechanisms are essential for maintaining hygiene and functionality in both residential and commercial settings.

By examining the different segments that comprise these systems, one can appreciate the engineering behind their operation. Each component plays a pivotal role, contributing to the overall effectiveness and reliability of the flushing process.

In this section, we will delve into the specific elements involved, highlighting their unique features and ultimate importance in achieving optimal performance. Understanding these components not only enhances our knowledge but also aids in troubleshooting and maintenance.

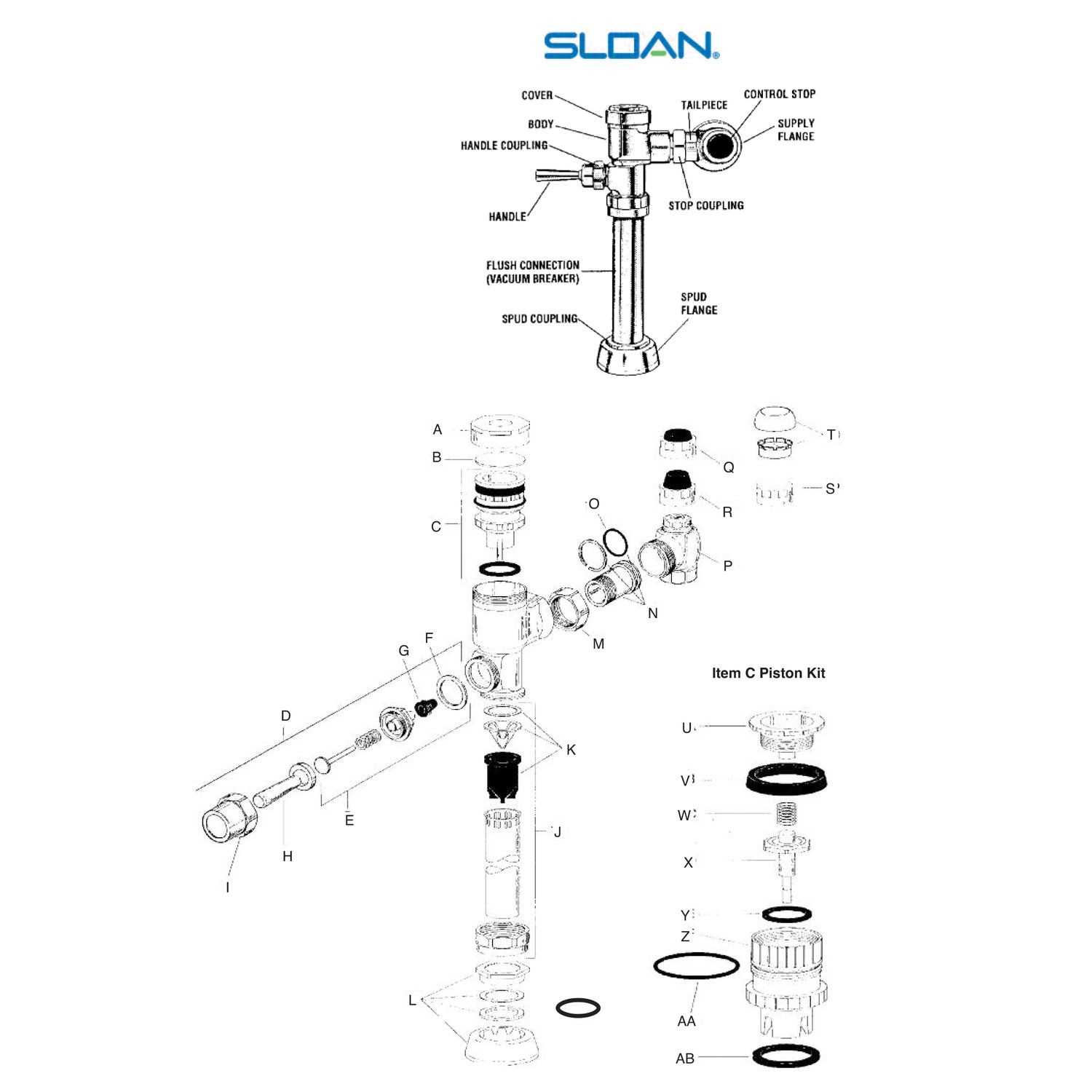

Sloan Valve Overview

This section provides a comprehensive look at a crucial component commonly found in restroom fixtures. Designed to enhance efficiency and reliability, this device plays a vital role in the management of water flow, ensuring optimal performance while minimizing waste.

Typically utilized in commercial settings, these mechanisms are engineered to withstand heavy usage. Their construction often includes durable materials that contribute to longevity and resilience. Additionally, many models feature advanced technology that facilitates automatic operation, promoting hygiene and convenience for users.

Understanding the functionality and design of these systems can assist in maintaining and troubleshooting common issues. Knowledge of the internal workings allows for more effective management, ensuring that the fixture operates smoothly and efficiently over time.

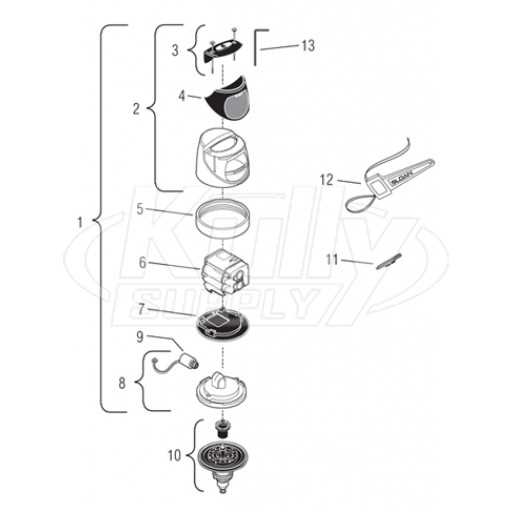

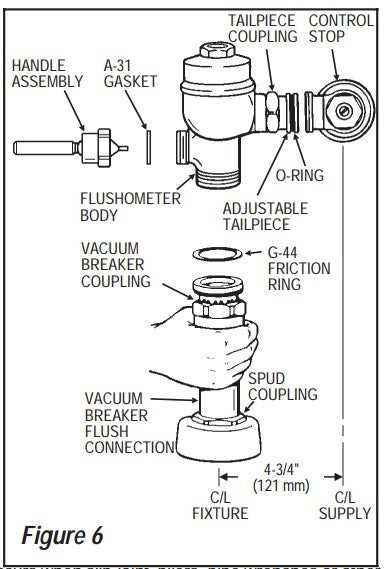

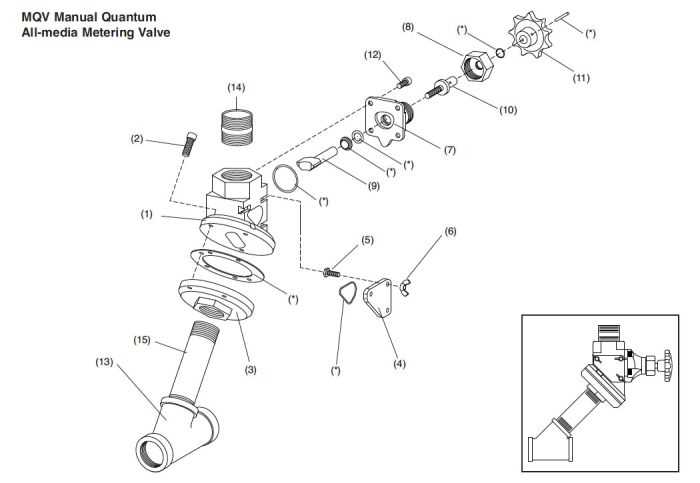

Understanding Valve Components

This section explores the essential elements that make up a mechanism designed for controlling fluid flow. Each component plays a crucial role in ensuring efficiency and functionality in various systems.

- Body: The main structure that houses all internal mechanisms.

- Bonnet: A cover that provides access to the internal elements for maintenance.

- Stem: A rod that connects the actuator to the internal seat, enabling control.

- Seat: The surface where the closing element meets to stop flow.

- Actuator: The device responsible for moving the closing element.

Understanding these components helps in maintaining optimal performance and troubleshooting any issues that may arise.

Importance of Proper Installation

Correct setup of plumbing components is crucial for ensuring optimal performance and longevity of the system. When installed accurately, these mechanisms can function seamlessly, reducing the risk of leaks, malfunctions, and costly repairs. A thorough understanding of the installation process not only enhances efficiency but also promotes safety in the overall operation.

Enhanced Efficiency

When components are positioned correctly, they work in harmony, allowing for smooth operation. Proper alignment and secure fittings minimize resistance and ensure that water flow is unimpeded. This leads to lower energy consumption and improved performance, which is vital in both residential and commercial settings.

Prevention of Damage

Improper installation can result in various issues, including water leakage and pressure fluctuations. Such problems can cause significant damage over time, leading to costly repairs and even potential hazards. Investing time in a meticulous setup not only safeguards the system but also extends its lifespan, reducing the need for frequent replacements.

Common Issues with Sloan Valves

Many users encounter a variety of challenges with their restroom fixtures. Understanding these problems can help in timely troubleshooting and maintenance. This section will explore typical concerns, highlighting their causes and potential solutions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inconsistent Water Flow | Clogged components, incorrect adjustments | Inspect for blockages and adjust settings |

| Leakage | Worn seals, improper installation | Replace damaged seals and ensure proper fitting |

| Noisy Operation | High water pressure, loose fittings | Check water pressure and tighten connections |

| Frequent Clogging | Debris buildup, design issues | Regular cleaning and proper waste disposal |

| Sensor Malfunction | Battery failure, dirt on sensor | Replace batteries and clean the sensor |

Maintenance Tips for Longevity

Ensuring the durability of your plumbing fixtures requires regular attention and care. Simple maintenance practices can significantly extend the lifespan of these essential components, preventing costly repairs and replacements in the long run.

Regular inspections are crucial. Check for leaks, unusual noises, or irregular functioning, as these can indicate underlying issues. Promptly addressing any anomalies can prevent further damage.

Cleaning is another key aspect. Remove mineral buildup and debris from components to maintain optimal performance. Utilizing appropriate cleaning solutions will help avoid corrosion and ensure smooth operation.

Proper installation and adjustments are vital for functionality. Make sure that all fittings are securely in place and that settings are tailored to the specific needs of your system. This helps prevent unnecessary wear and tear.

Finally, consider periodic professional evaluations. Experts can identify potential problems that may go unnoticed and provide tailored advice on maintenance practices specific to your system.

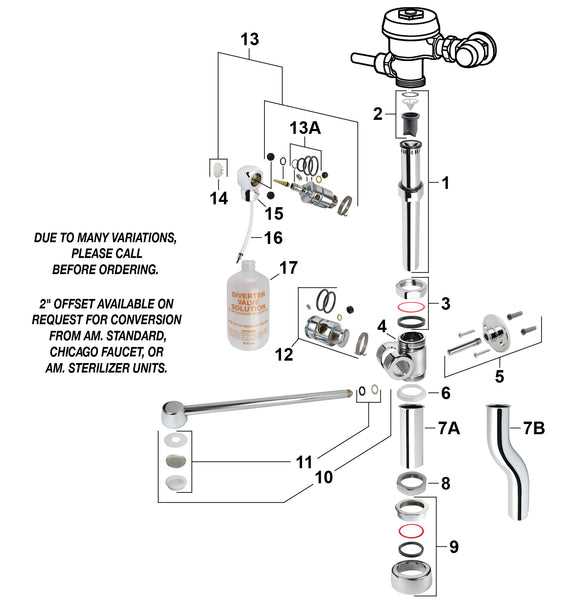

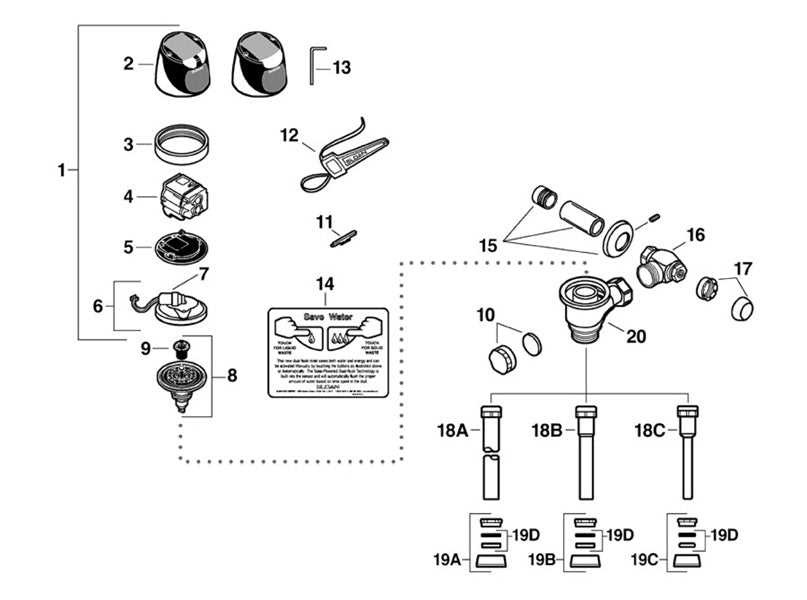

Identifying Replacement Parts

Recognizing the necessary components for maintenance is essential for ensuring optimal performance and longevity of any system. Accurate identification can prevent complications and facilitate smooth replacements.

- Start by reviewing the model specifications.

- Examine any existing components for visible markings or numbers.

- Consult user manuals or manufacturer websites for guidance.

In addition to these steps, consider the following strategies:

- Utilize online forums or communities dedicated to repair and maintenance.

- Contact customer support for expert advice.

- Visit local suppliers who may offer assistance in identifying the correct items.

By applying these methods, you can ensure that you acquire the ultimate replacements for your needs, leading to efficient repairs and improved functionality.

How to Read Diagrams

Understanding visual representations is essential for interpreting complex information effectively. Whether you are looking at schematics, layouts, or illustrations, these graphical tools simplify communication and enhance comprehension. Knowing how to navigate these visuals can significantly improve your ability to troubleshoot, assemble, or analyze various systems.

Identifying Symbols and Notations

Each visual representation contains specific symbols and notations that convey distinct meanings. Familiarizing yourself with these icons is crucial. Common elements often include lines, arrows, and geometric shapes, each serving a unique purpose. For instance, arrows may indicate flow direction, while different line styles can signify various connections. Pay close attention to any accompanying legends or keys, as they provide valuable context.

Understanding Relationships and Components

Visuals often depict relationships between components, illustrating how they interact within a system. Analyzing these connections allows you to grasp the overall functionality. Look for clusters of related items or sections, and note how they connect with one another. Recognizing these interactions helps in predicting how changes in one element may affect the entire system.

Tools Needed for Repair

Effective maintenance and restoration require the right set of instruments to ensure precision and efficiency. Having the appropriate tools not only facilitates the repair process but also helps in achieving long-lasting results. Below are essential items to consider for your repair tasks.

Essential Instruments

Wrenches are fundamental for loosening and tightening components. Various sizes may be needed depending on the fittings involved. A screwdriver set is also crucial for adjusting or removing screws securely. Additionally, a pair of pliers can assist in gripping and manipulating smaller pieces, making them indispensable for any repair job.

Measurement and Inspection Tools

Calipers and tape measures are vital for ensuring accurate measurements during the process. Having a flashlight or headlamp can significantly improve visibility in tight spaces. Lastly, a multimeter is helpful for diagnosing electrical components, ensuring they function correctly before reassembly.