When it comes to maintaining and repairing electric cutting machines, a clear understanding of their internal structure is essential. These tools consist of numerous interconnected elements, each with a specific function that contributes to the overall performance. Recognizing how these components work together ensures efficient operation and helps troubleshoot any potential issues that may arise during use.

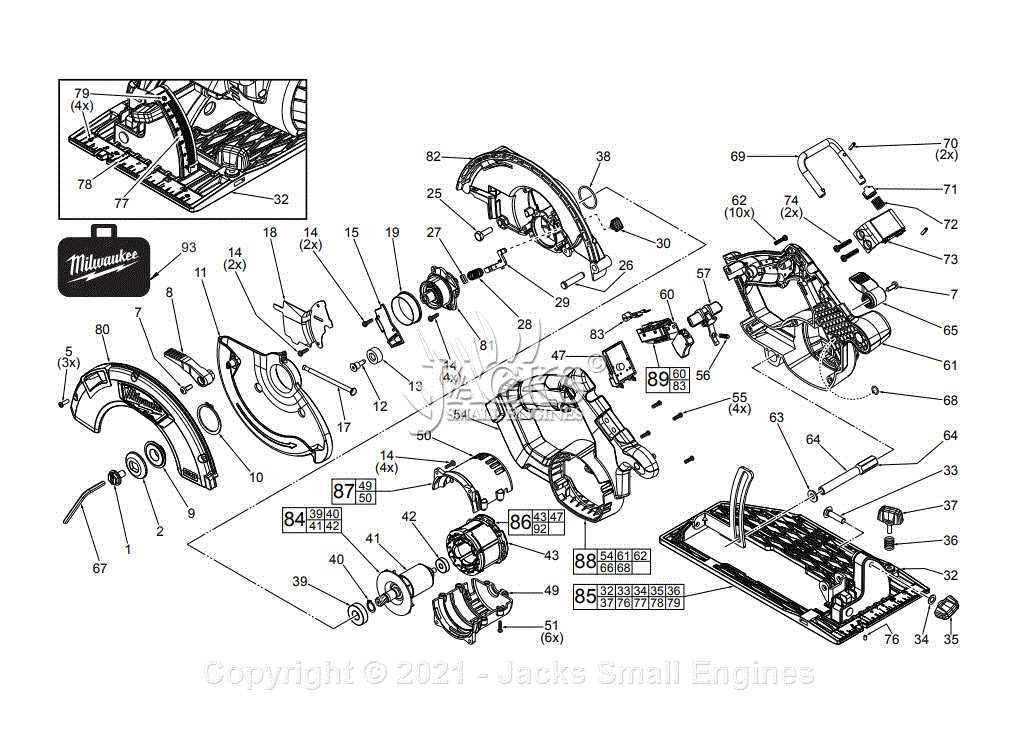

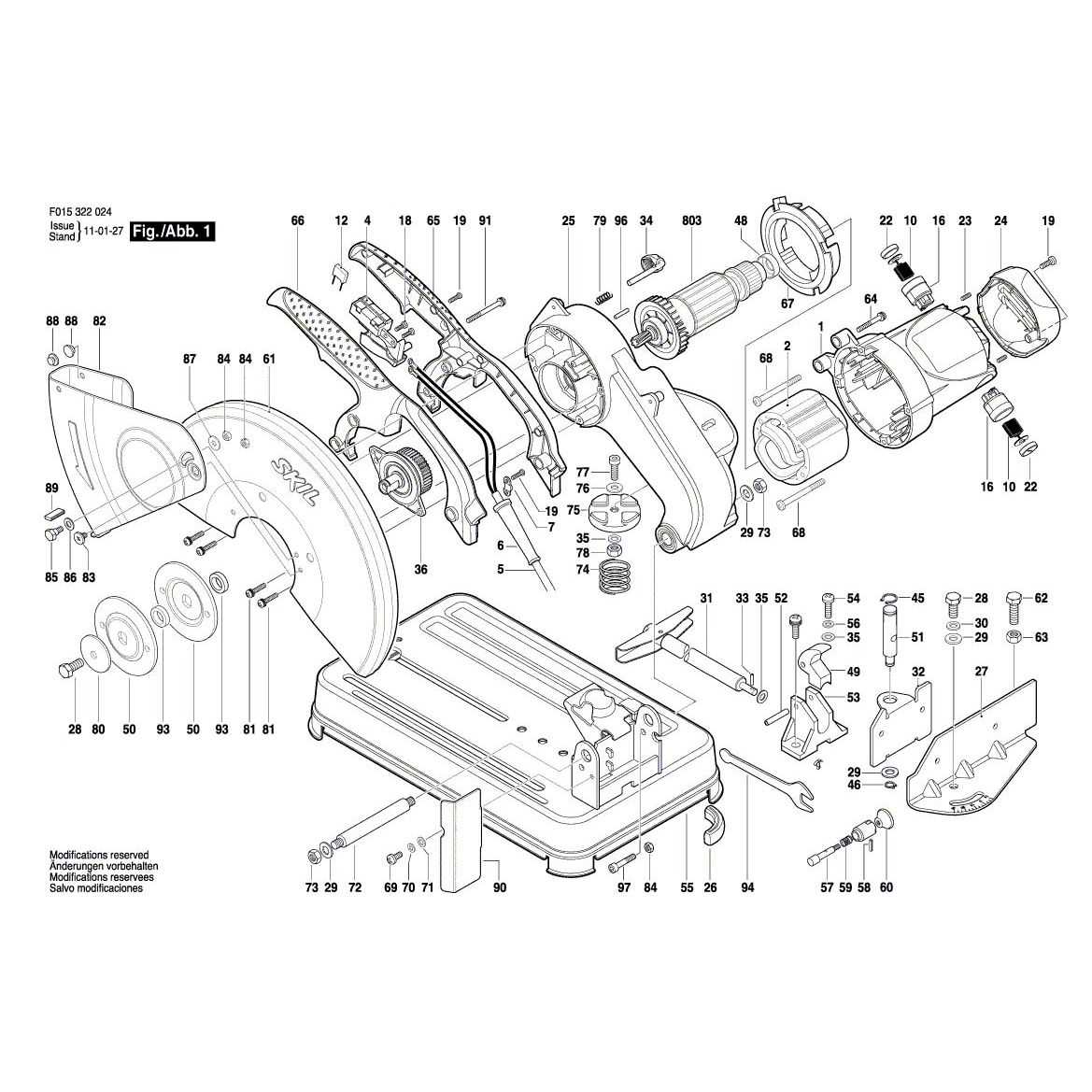

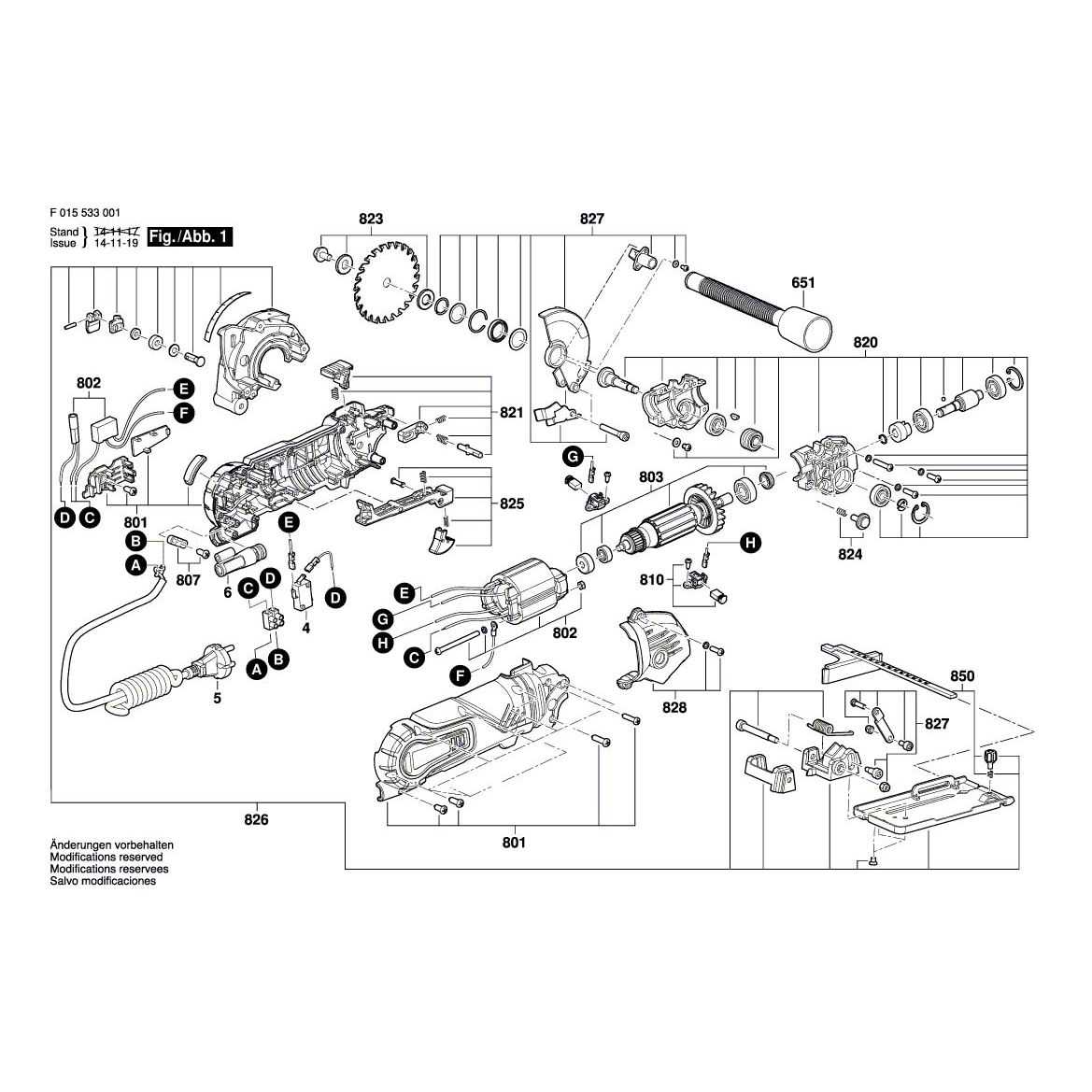

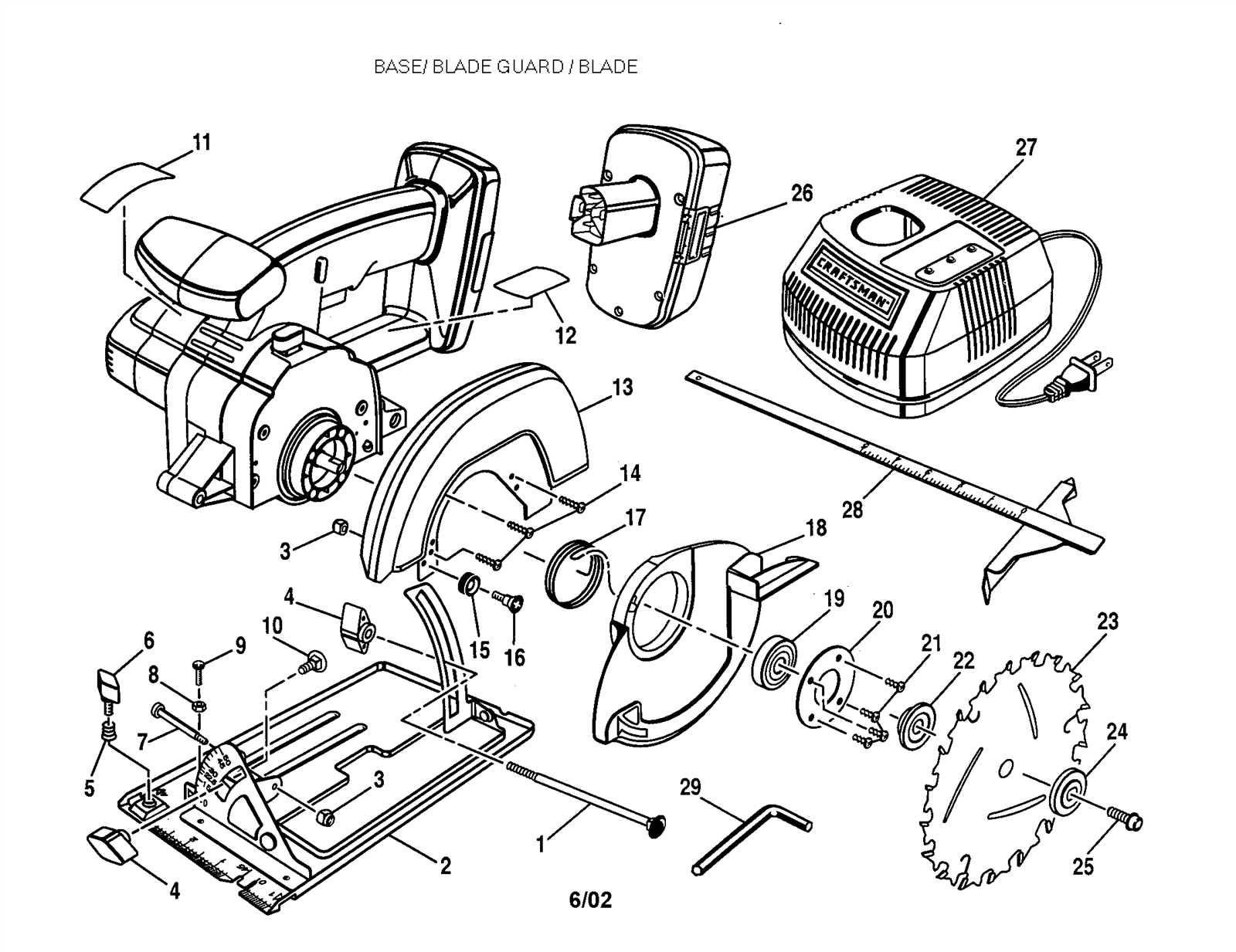

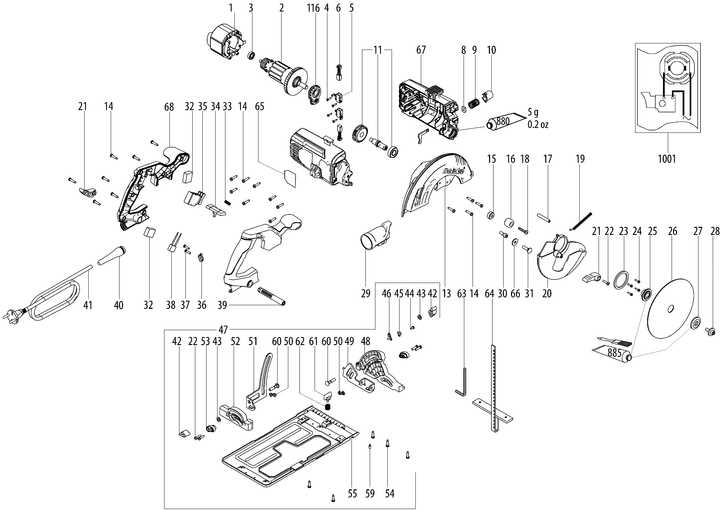

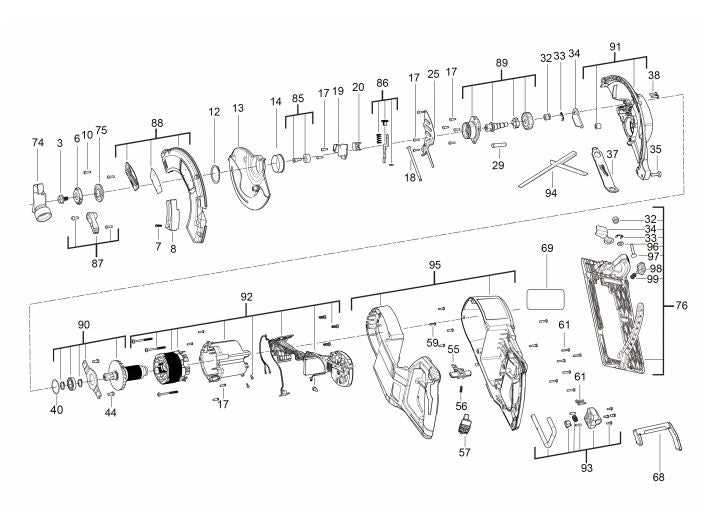

Detailed schematics play a crucial role in this process, offering a visual representation of each component and its relationship to the others. Such diagrams enable users to identify the exact placement of various parts, making it easier to replace or repair damaged pieces. By familiarizing oneself with these layouts, anyone can improve their technical skills and extend the life of the tool.

For both novice and experienced users, understanding the key features of a tool’s construction enhances both safety and performance. Knowing where and how to inspect or replace specific elements can save time, effort, and money while ensuring the tool remains reliable throughout its lifespan. Whether you are a professional in the industry or a hobbyist, being able to interpret these visual guides is an invaluable asset.

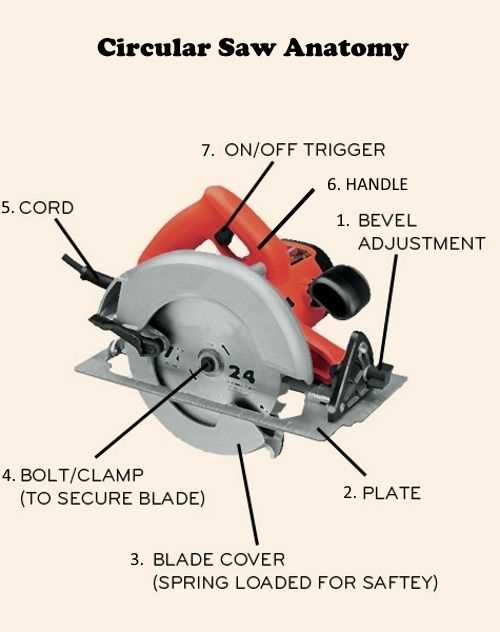

Understanding Skil Saw Components

To work effectively with power tools, it is essential to have a clear understanding of how each part functions and interacts with others. By familiarizing yourself with the core components of a cutting machine, you can ensure better maintenance, troubleshoot issues quickly, and maximize the tool’s performance. This section explores the key elements that make up such a device, detailing their roles and how they contribute to the overall operation.

Each element in the system serves a specific function, from guiding the motion of the blade to providing the necessary power for cutting through various materials. Knowing how to identify and manage these components can help you achieve precision and efficiency during use. Below are some of the fundamental elements that make up these tools:

- Motor: The heart of the tool, responsible for generating the power needed to rotate the cutting blade.

- Blade: The primary tool for cutting, available in various sizes and materials depending on the type of work being done.

- Guard: A safety feature designed to protect the user from accidental contact with the blade during operation.

- Handle: Provides the user with a comfortable and secure grip, allowing for control and maneuverability while cutting.

- Depth Adjustment Mechanism: Allows the user to modify the cutting depth based on the material’s thickness and desired cut.

- Power Switch: Controls the on/off function of the machine, typically designed for easy access while operating.

Understanding how these components work in unison helps ensure safety, efficiency, and longevity. Proper care and maintenance of each part contribute to optimal performance and a longer tool life. Regularly inspecting these elements can also prevent unexpected breakdowns and enhance the precision of your cuts.

How to Read a Skil Saw Diagram

Understanding the visual representation of a tool can greatly enhance your maintenance and repair skills. This guide will help you navigate the schematic, identifying each component and its function. Mastering this knowledge will ultimately lead to more efficient use and troubleshooting of the equipment.

Identifying Components

Begin by familiarizing yourself with the various elements illustrated in the schematic:

- Motor: Powers the tool’s operation.

- Base Plate: Provides stability during use.

- Blade: Cuts through material.

- Handle: Allows for maneuverability.

Understanding Connections

Next, pay attention to how the components interact:

- Trace the wiring to understand power flow.

- Observe the mechanical linkages for movement.

- Check the assembly layout for correct installation.

Common Skil Saw Parts and Their Functions

Understanding the essential components of a cutting tool is crucial for effective operation and maintenance. Each element plays a vital role in ensuring optimal performance, contributing to the overall efficiency and safety of the device.

Below are some of the key components commonly found in these tools and their respective functions:

- Motor: The powerhouse of the tool, responsible for generating the necessary torque and speed to perform cutting tasks.

- Blade: The cutting edge, designed for various materials, determining the quality and type of cut.

- Base Plate: The foundation that provides stability and support during operation, ensuring accuracy in cuts.

- Guard: A safety feature that covers the blade when not in use, minimizing the risk of accidental contact.

- Trigger Switch: The control mechanism that allows the user to start and stop the operation, crucial for safe handling.

- Bevel Adjustment Lever: Enables angle adjustments for angled cuts, enhancing versatility.

- Depth Adjustment Knob: Allows the user to set the cutting depth, which is important for various applications.

Familiarity with these components can significantly enhance the user experience and improve the maintenance of the tool, ensuring longevity and reliability in various cutting applications.

Choosing the Right Replacement Parts

Finding suitable components for your tools is crucial for optimal performance and longevity. The right selections can enhance functionality and ensure safety during use.

Here are key considerations to keep in mind:

- Compatibility: Ensure the new component matches your device’s specifications.

- Quality: Opt for high-grade materials to prevent premature wear and tear.

- Manufacturer Recommendations: Follow guidelines from the original maker for best results.

To make an informed decision, you might consider:

- Researching different brands and their reputations.

- Reading reviews and feedback from other users.

- Consulting with experts or professionals if needed.

By taking these steps, you can delve into the process and find the ultimate components for your needs.

Identifying Issues with Your Skil Saw

Understanding the common challenges that arise with power tools is essential for effective troubleshooting and maintenance. By recognizing the signs of malfunction, you can ensure your equipment operates at its best and avoid potential hazards.

Common Signs of Trouble

Watch for unusual noises, inconsistent cutting performance, or excessive vibrations. These indicators often suggest underlying mechanical or electrical problems that require immediate attention.

Steps to Diagnose Problems

Start by examining the components for visible wear or damage. Inspecting the motor, blades, and connections can provide valuable insights into the source of the issue. Regular maintenance and timely repairs are key to prolonging the lifespan of your tool.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and efficiency of your power tool. By implementing a consistent maintenance routine, you can significantly extend its lifespan and enhance its performance. Here are some practical suggestions to keep your equipment in top shape.

Cleaning and Inspection

- Regularly clean the exterior to prevent dust buildup.

- Inspect the blade for wear and replace it as necessary.

- Check for any loose screws or components before use.

Lubrication and Storage

- Apply lubricant to moving parts to reduce friction.

- Store the tool in a dry place to avoid moisture damage.

- Use a protective cover when not in use to shield against dust.

Skil Saw Blade Types and Specifications

Choosing the right cutting tool is essential for achieving precise and efficient results. Different blades are designed to handle specific tasks, from general wood cutting to more specialized applications like masonry or metalwork. The material, tooth configuration, and coating of the blade all play a critical role in determining its performance and longevity. In this section, we explore various blade types and their specifications to help you make an informed decision.

Types of Blades

- General Purpose Blades – Ideal for everyday wood cutting tasks, these blades offer a balance between performance and durability. They feature a standard tooth count and a moderate tooth design for smooth cuts.

- Fine Finish Blades – These blades have more teeth per inch, resulting in cleaner and smoother cuts, making them suitable for finishing work and precision tasks.

- Rip Blades – Designed for cutting along the grain, rip blades have fewer teeth, allowing for faster cuts but with a rougher finish. Perfect for breaking down large pieces of wood quickly.

- Masonry Blades – Engineered for cutting through harder materials like concrete, brick, and stone, these blades feature a diamond or carbide edge for added strength and durability.

- Metal Cutting Blades – Featuring special tooth configurations and coatings, these blades are crafted to handle metals like steel, aluminum, and copper without dulling quickly.

Blade Specifications

- Diameter – The size of the blade, typically measured in inches, affects the depth of cut. Larger blades allow for deeper cuts, while smaller ones are ideal for more precise, shallow cuts.

- Tooth Count – The number of teeth influences the cut quality. More teeth result in finer, smoother cuts, whereas fewer teeth are better for rougher cuts or faster material removal.

- Tooth Design – Teeth come in various shapes, such as flat-top, alternate top bevel (ATB), or triple-chip grind (TCG). Each design serves a specific purpose, from smooth cuts to faster material removal.

- Material – Blades can be made from high-speed steel (HSS), carbide, or even diamond for specialized tasks. Carbide-tipped blades are known for their durability and ability to cut through tough materials.

- Coating – Many blades are coated with materials like titanium or anti-stick coatings to reduce friction and heat buildup, extending blade life and improving cutting efficiency.

Step-by-Step Assembly of Skil Saw Parts

Assembling your tool requires careful attention to detail and a clear understanding of each component’s role. This guide will walk you through the necessary steps to put together the various elements effectively, ensuring optimal performance and safety. Following this structured approach will help both novice and experienced users achieve a seamless assembly.

| Step | Description |

|---|---|

| 1 | Gather all essential components and tools required for assembly. |

| 2 | Identify the main body and ensure it is clean and free from debris. |

| 3 | Attach the motor securely, following the designated alignment. |

| 4 | Connect the power supply, ensuring all electrical components are insulated. |

| 5 | Install the blade holder and confirm it is tightened properly to prevent slippage. |

| 6 | Integrate the safety guard, making sure it moves freely without obstruction. |

| 7 | Complete the assembly by reviewing each connection and ensuring everything is in place. |

Upon finishing these steps, conduct a thorough inspection before use. This final check will help prevent issues and enhance safety during operation.

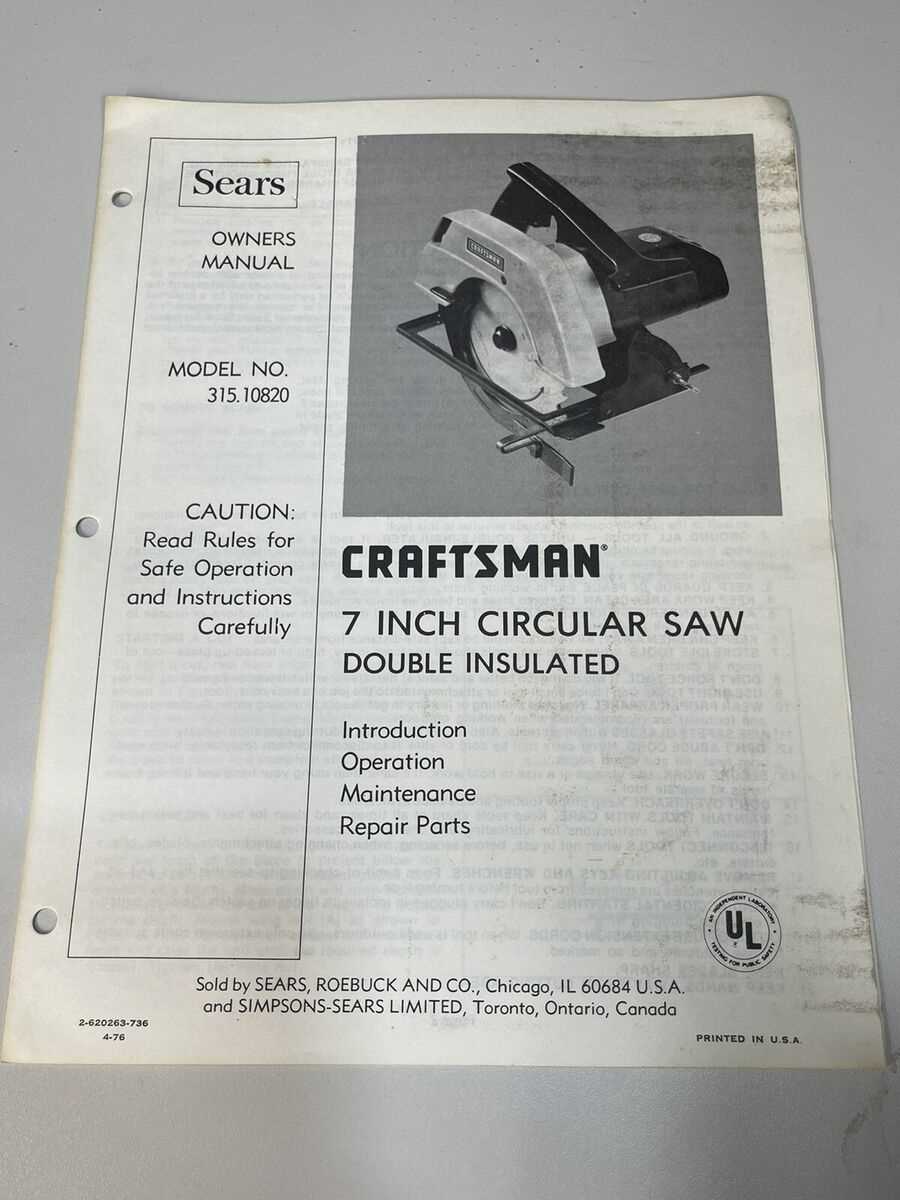

Where to Find Skil Saw Parts Diagrams

Locating detailed schematics for power tools can significantly enhance your ability to maintain and repair them effectively. Understanding the components and their arrangements not only aids in troubleshooting but also facilitates the replacement of worn or damaged elements. Here are some reliable resources to help you find the necessary illustrations for your tool.

Manufacturer Websites

One of the most reliable sources for finding accurate illustrations is the official website of the manufacturer. These sites often provide comprehensive resources, including downloadable manuals and specific component layouts. Utilizing the search function with your tool’s model number can yield precise results, ensuring you access the most relevant information.

Online Repair Forums and Communities

Engaging with online communities focused on power tool repair can also be beneficial. Many enthusiasts and professionals share their knowledge, including diagrams and repair tips. Websites dedicated to tool repairs may host user-generated content that can guide you through common issues. Additionally, social media groups often provide a platform for sharing resources, making it easier to find the illustrations you need.