In the realm of maintenance and repair, comprehending the intricate relationships between various elements of machinery is crucial. This knowledge empowers users to enhance performance and extend the lifespan of their devices. The ability to visualize how each component fits together creates a stronger foundation for effective troubleshooting and maintenance strategies.

Exploring the intricacies of mechanical assemblies reveals the importance of each segment in contributing to the overall functionality. By familiarizing oneself with the specific roles of individual pieces, operators can identify issues swiftly and implement solutions more efficiently. This understanding ultimately leads to a more seamless operation.

For enthusiasts and professionals alike, having access to clear representations of these intricate systems serves as a valuable resource. Whether it’s for routine checks or extensive repairs, an organized view of all the necessary elements can greatly simplify the process. Delving into the details allows users to tackle challenges head-on and ensures optimal performance at all times.

Understanding the Scotts S2046 Design

The design of this machine reflects a harmonious blend of functionality and efficiency, tailored to meet the demands of modern gardening and landscaping. Its architecture prioritizes user experience, enabling seamless operation while ensuring durability and reliability. This section delves into the essential features that contribute to its overall performance and appeal.

Key Features of the Design

The innovative elements incorporated into the design not only enhance performance but also facilitate maintenance. Below are some notable attributes:

| Feature | Description |

|---|---|

| Engine Efficiency | Utilizes advanced technology to optimize fuel consumption and power output. |

| Ergonomic Controls | Designed for comfort, allowing operators to work for extended periods without fatigue. |

| Durable Materials | Constructed with high-quality components that withstand harsh outdoor conditions. |

| Compact Design | Allows for easy maneuverability in tight spaces, making it ideal for diverse landscapes. |

Impact on User Experience

This design approach significantly enhances the user experience, transforming routine tasks into efficient operations. By focusing on user-centric features, it minimizes the learning curve, allowing both novice and experienced users to achieve optimal results effortlessly.

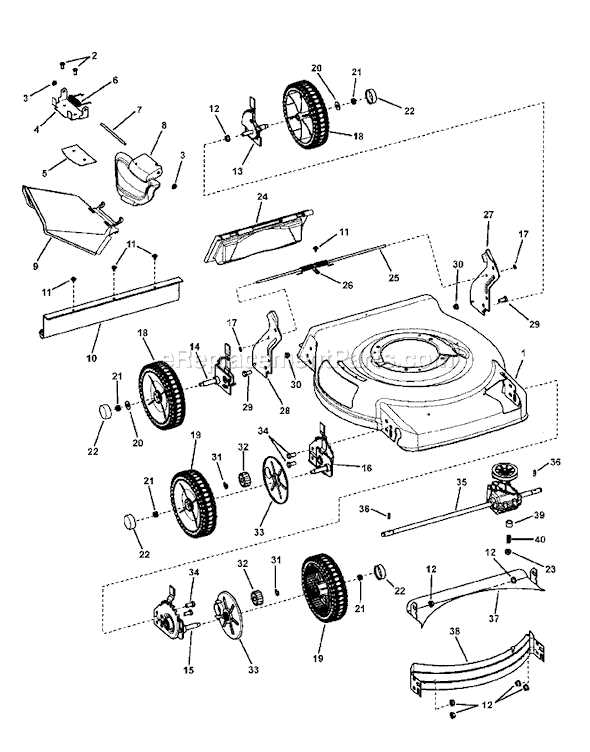

Key Components of the S2046 Model

The intricate design of this model encompasses several essential elements that work in harmony to ensure optimal performance. Understanding these fundamental components is crucial for users aiming to maintain efficiency and longevity in operation. Each part plays a significant role, contributing to the overall functionality and reliability of the machine.

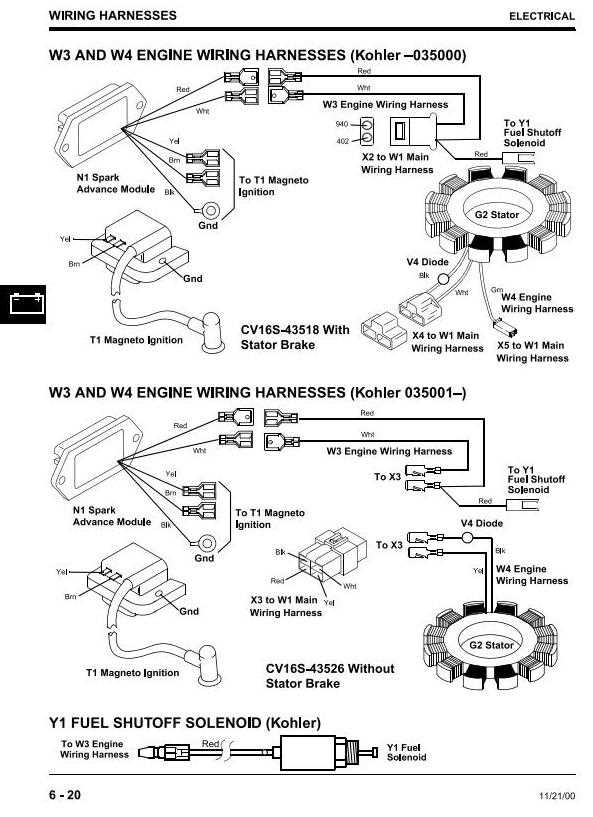

Powertrain System

The powertrain is a pivotal aspect, responsible for transferring energy and ensuring smooth operation. This system typically includes the engine, transmission, and drive components, all meticulously engineered to provide maximum torque and efficiency. Regular inspection of these parts is vital to prevent wear and maintain peak performance.

Chassis and Suspension

The chassis forms the backbone of the unit, providing structural integrity and support. Coupled with a sophisticated suspension system, it ensures stability and comfort during operation. Components such as shock absorbers and springs are designed to absorb impacts, enhancing the user experience and safeguarding against potential damage.

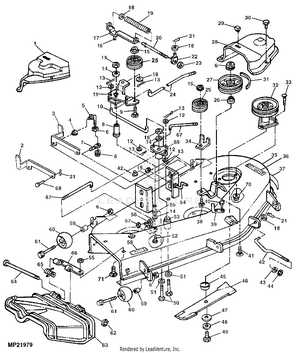

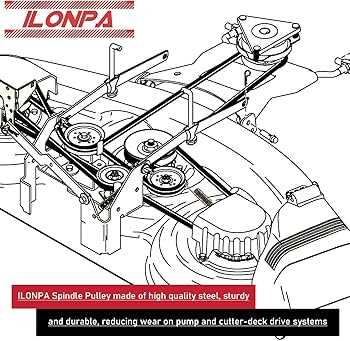

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians, enabling them to identify individual elements, their functions, and interconnections. These illustrations enhance communication between manufacturers, service personnel, and end-users, ensuring clarity in operations and support.

Benefits of Visual Representations

Utilizing visual schematics provides numerous advantages. Firstly, they simplify complex assemblies, making it easier to comprehend intricate designs. Secondly, they help in pinpointing specific components when ordering replacements or conducting repairs, reducing the likelihood of errors and saving time.

Facilitating Maintenance and Repair

When issues arise, having access to accurate visual references is vital. They assist in diagnosing problems quickly, allowing for efficient troubleshooting. Moreover, these illustrations serve as training resources for new technicians, ensuring they become familiar with the layout and functionality of various parts.

| Benefit | Description |

|---|---|

| Simplification | Breaks down complex systems into understandable components. |

| Efficiency | Speeds up repair processes by providing clear identification. |

| Training Aid | Serves as a learning tool for technicians and users alike. |

| Accurate Communication | Facilitates better interaction between manufacturers and service teams. |

How to Read a Parts Diagram

Understanding a visual representation of components is essential for efficient maintenance and repairs. These illustrations provide valuable insights into the various elements of a machine, highlighting their relationships and functionalities. Familiarizing oneself with these visuals can streamline troubleshooting and ensure proper assembly.

Start by identifying the overall layout, which often includes labels and reference numbers. Each section typically corresponds to a specific part, allowing for easy cross-referencing with lists or catalogs. Pay attention to any accompanying notes that may indicate assembly sequences or specific tools required for replacement.

Next, focus on the symbols and lines that connect different elements. These connections often signify how components interact, which is crucial for diagnosing issues. Understanding these relationships can help identify not only faulty parts but also prevent potential damage during repairs.

Lastly, practice makes perfect. Reviewing multiple illustrations over time will enhance your ability to quickly interpret and navigate through complex representations, ultimately leading to more effective problem-solving in maintenance tasks.

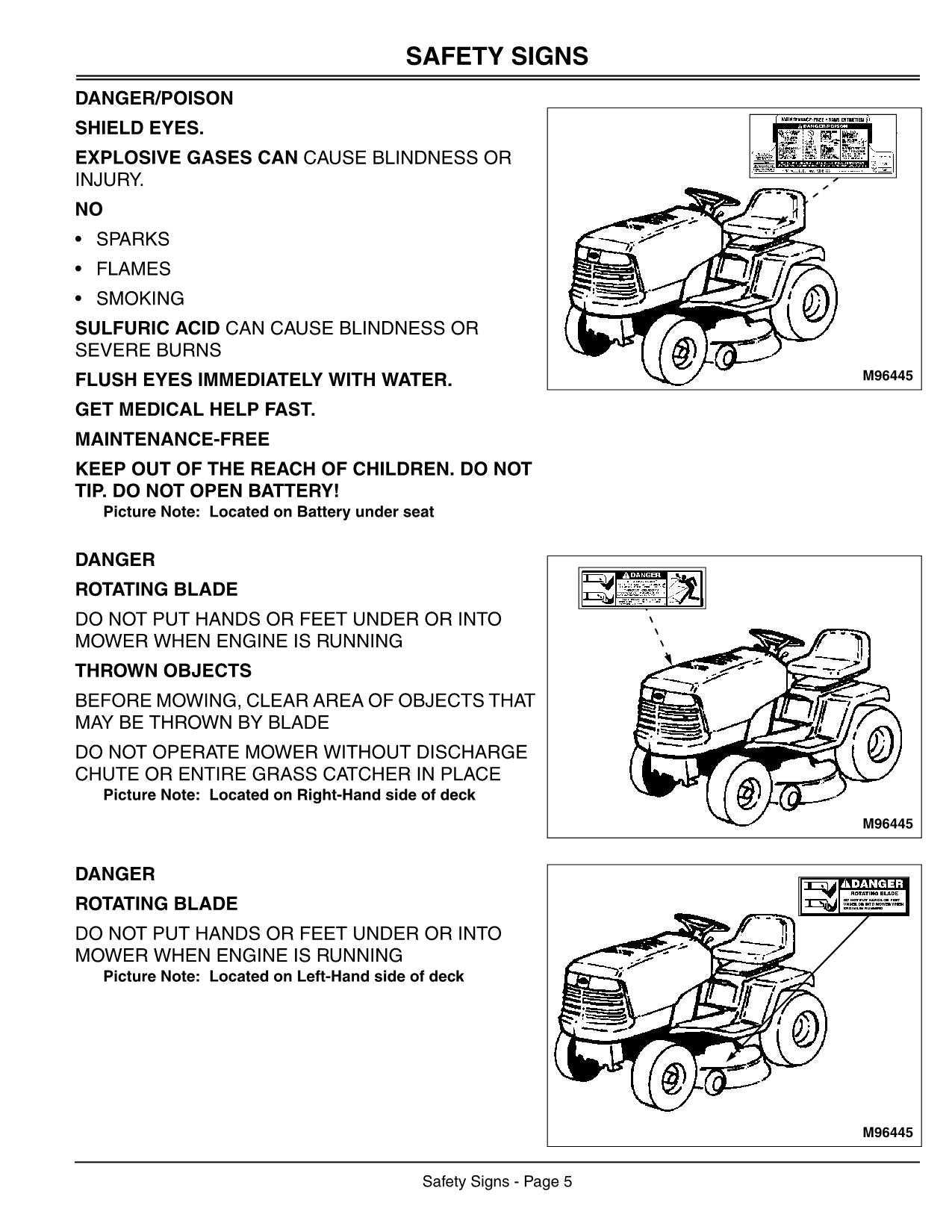

Common Issues and Solutions

This section explores typical challenges faced by users of garden maintenance equipment and offers practical solutions to enhance performance and longevity.

-

Engine Difficulties:

When the engine fails to start, check the fuel level and battery condition. Often, stale fuel or a weak battery can be culprits.

-

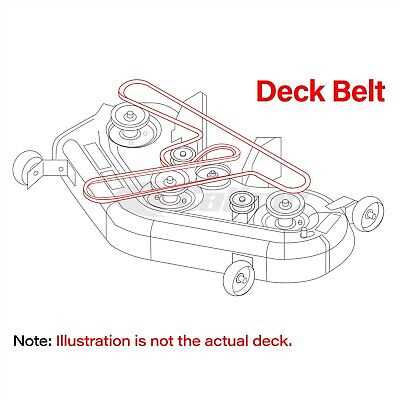

Cutting Inefficiency:

If the blades are not cutting effectively, inspect for dullness or damage. Regular sharpening and timely replacements can resolve this issue.

-

Overheating:

Overheating may occur due to debris buildup. Regular cleaning of air filters and cooling vents helps maintain optimal temperature.

-

Uneven Performance:

Inconsistent operation can stem from uneven tire pressure or improper adjustments. Check and adjust as necessary to ensure a smooth experience.

Addressing these common issues promptly can significantly improve functionality and user satisfaction.

Finding Replacement Parts Easily

Locating necessary components for equipment maintenance can often be a daunting task. However, with the right approach and resources, the process can become seamless and efficient.

To streamline your search, consider the following strategies:

- Utilize manufacturer websites to access official catalogs and specifications.

- Join online forums and communities dedicated to your equipment type.

- Contact local dealers for expert advice and availability of components.

Additionally, leveraging digital marketplaces can yield a variety of options:

- Search for trusted online retailers that specialize in equipment accessories.

- Check auction sites for second-hand or surplus items.

- Use comparison tools to find the best prices and options.

Ultimately, being informed and resourceful will significantly enhance your ability to acquire the right items for your needs.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of any outdoor equipment. By following a few simple practices, you can ensure optimal performance and minimize the risk of costly repairs.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep your machine free from debris and dirt to prevent buildup that can affect performance. |

| Inspect Components | Frequent checks on key parts help identify wear and tear early, allowing for timely replacements. |

| Lubrication | Applying appropriate lubricants to moving parts reduces friction and enhances efficiency. |

| Store Properly | During off-seasons, ensure equipment is stored in a dry, sheltered place to avoid rust and damage. |

| Follow Manufacturer’s Guidelines | Adhering to the recommended maintenance schedule is vital for optimal function and longevity. |

Comparing the S2046 with Other Models

When evaluating different lawn care machines, it is essential to understand how various models stack up against each other. This comparison highlights key features, performance capabilities, and user experiences, allowing potential buyers to make informed decisions.

Performance and Efficiency

Many machines in this category offer unique strengths in terms of power and fuel efficiency. While some prioritize high-speed operations, others focus on delivering superior torque for challenging terrains. Understanding these distinctions helps in selecting the most suitable equipment for specific landscaping tasks.

Features and User Experience

Different models come equipped with a range of functionalities that enhance usability. From intuitive controls to innovative cutting systems, these features can significantly impact the overall user experience. Comparing these elements allows users to identify which machine best aligns with their needs and preferences.