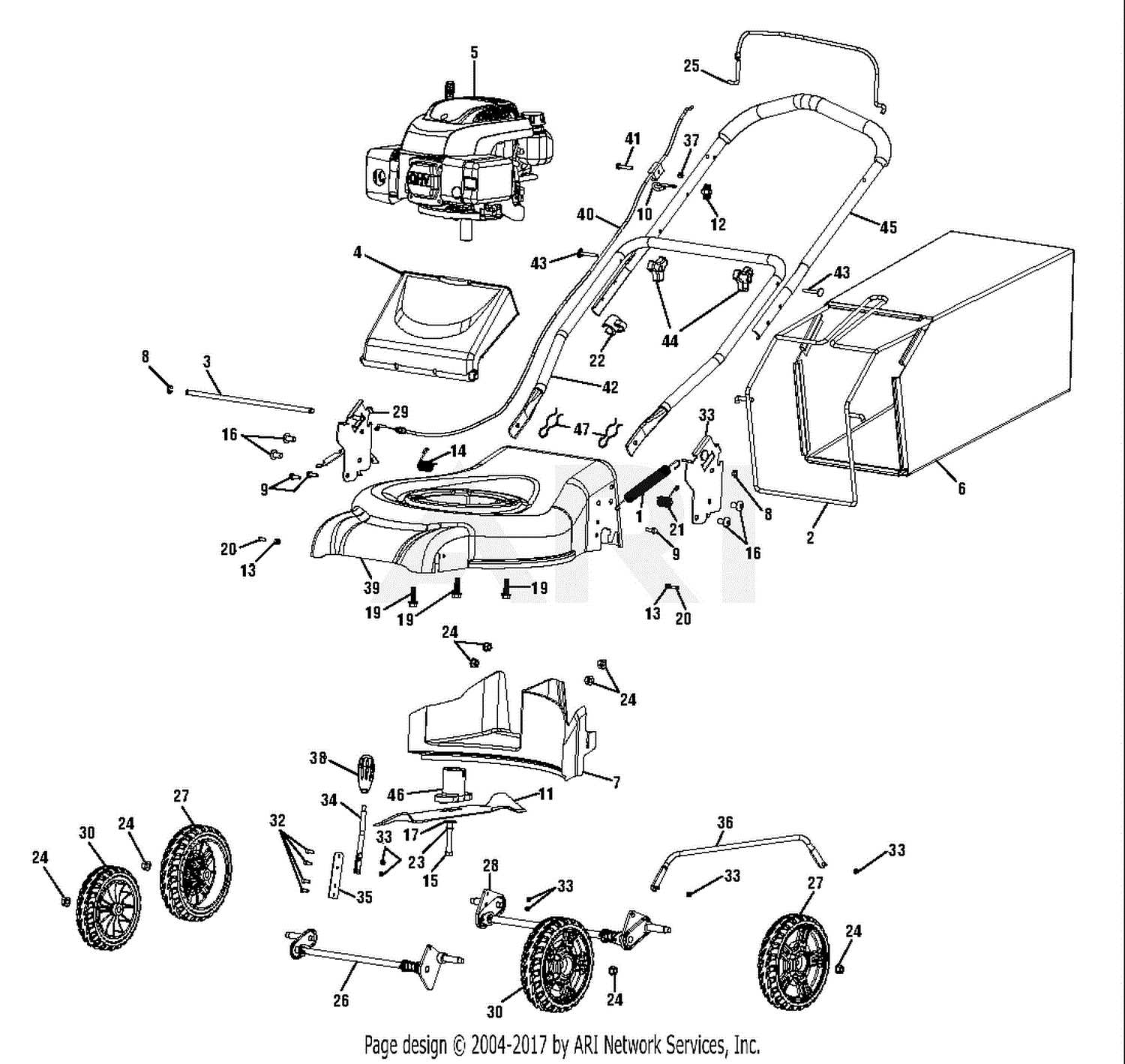

When it comes to the upkeep of outdoor spaces, it’s essential to understand how different mechanical components work together. Each piece of the machine has a distinct role, contributing to the smooth operation and efficiency. Learning how these elements interconnect can make it easier to troubleshoot, maintain, or even upgrade your equipment.

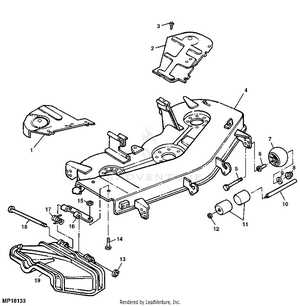

Having a clear view of the internal setup helps in identifying individual segments, especially when the need for repairs or replacements arises. Knowing where each element fits allows for seamless servicing, ensuring that every mechanism functions as intended. This understanding not only extends the lifespan of your device but also enhances its performance.

In this guide, we’ll walk through the various segments of outdoor equipment, offering insight into how each component plays a part in the overall functionality. With this knowledge, you’ll be better equipped to handle any issues that may arise, keeping your machinery in prime condition.

Essential Components of Scotts Lawn Mowers

The machinery designed for outdoor maintenance relies on several key elements to function efficiently. Each component plays a vital role in ensuring smooth operation and optimal performance. Understanding these elements helps in maintaining and prolonging the lifespan of the equipment.

Core Mechanical Parts

- Engine: The powerhouse responsible for driving the mechanism, providing the necessary force for cutting and movement.

- Blade System: Sharp metal pieces that handle the primary task of cutting, ensuring an even and clean trim.

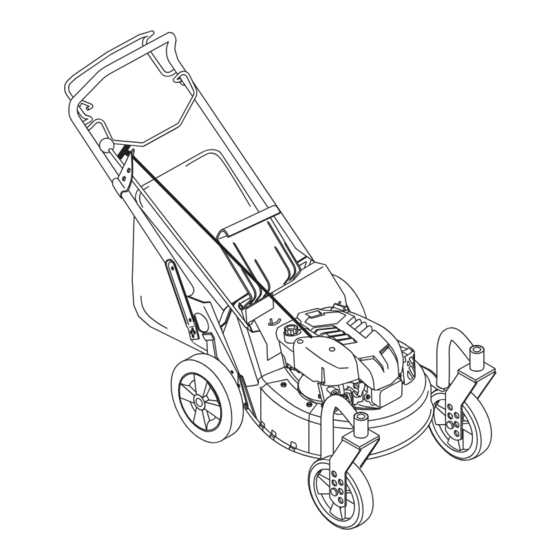

- Wheels: Attached to the base, these enable mobility and make it easier to maneuver the equipment across different terrains.

Operational Controls

- Throttle: Regulates the speed of the engine, allowing the operator to adjust the pace as needed.

- Height Adjustment Lever: A mechanism that lets users change the cutting

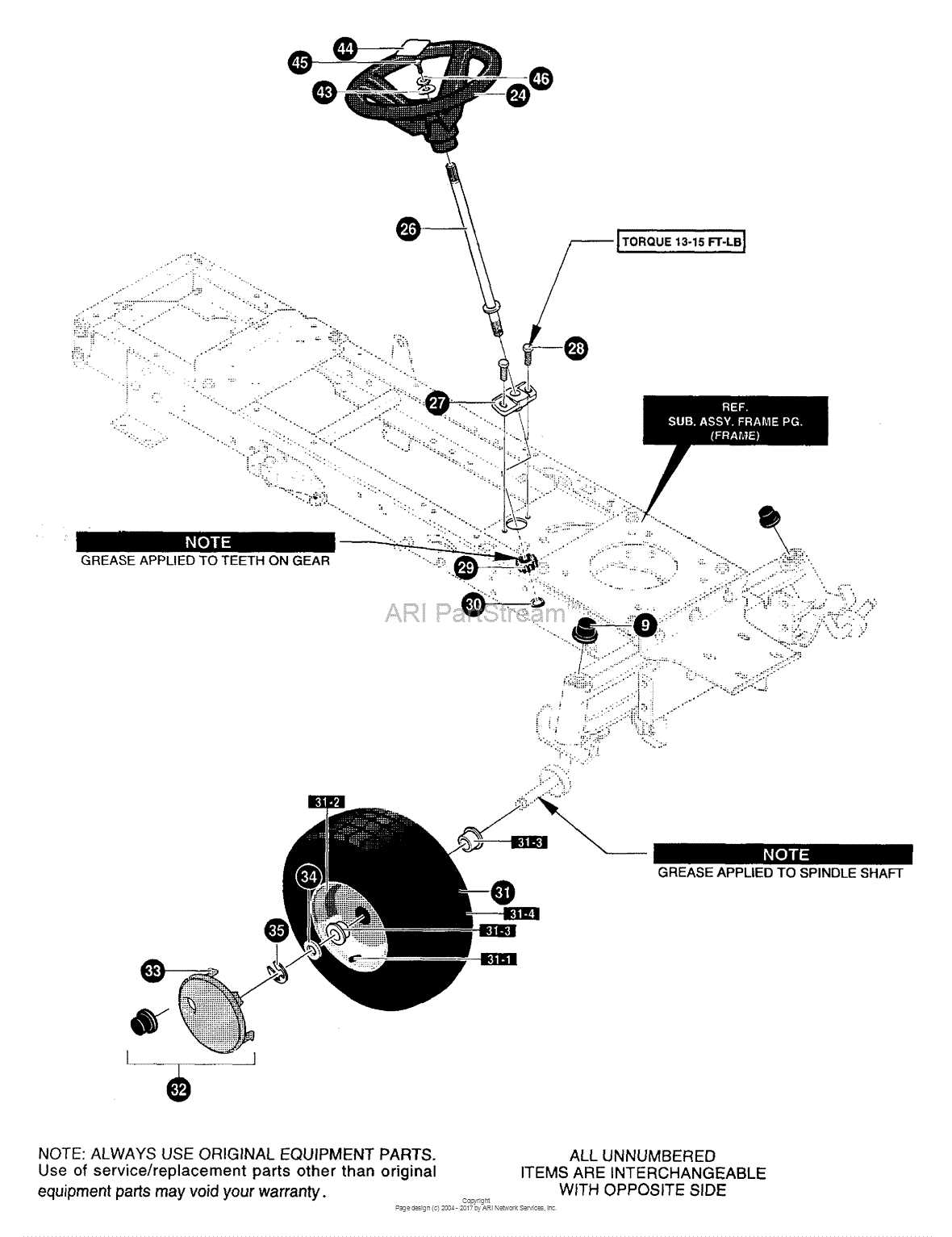

Identifying the Blades and Cutting System

The efficiency of any grass-cutting equipment is highly dependent on its cutting mechanism. Understanding the types of blades and the overall cutting system is crucial for maintaining optimal performance and ensuring a smooth, even cut. This section will provide an overview of the main components involved in the trimming process and how to identify them for proper upkeep.

Types of Cutting Blades

Blades are designed to serve different purposes, from basic trimming to mulching or bagging. The type of blade used influences how the grass is handled and dispersed. For example, a high-lift blade excels at creating strong airflow to push clippings into a collection bag, while mulching blades are crafted to finely chop and redistribute clippings back onto the ground. Knowing the distinctions between these blades can help in choosing the right option for specific yard needs.

The Mechanics of the Cutting System

The cutting system, which includes the blade arrangement and motor-driven components, is engineered to provide a consistent cutting height and an even trim. Regular maintenance of these parts ensures longevity and prevents any imbalance that could lead to uneven cuts. Each cutting mechanism, depending on its con

Engine Parts and Their Functionality

The engine consists of numerous essential components that work together to provide the necessary power for the machine to operate effectively. Each element plays a specific role in ensuring smooth performance and durability, contributing to the overall efficiency of the system. Understanding the key mechanisms behind these components can help in troubleshooting issues and maintaining optimal functionality.

Pistons are responsible for transferring energy by converting fuel into motion through combustion. This process drives the internal motion that powers the entire system.

The cylinder serves as the chamber where fuel is ignited, and pistons move up and down, creating the necessary force to propel the machinery. It is crucial for maintaining the pressure and heat that fuel combustion requires.

Spark plugs ignite the fuel-air mixture within the cylinder, triggering the combustion process. Without these, the energy needed for motion cannot be produced.

Valves control the

Understanding the Drive Mechanism

The propulsion system in this equipment is crucial for ensuring smooth and efficient movement. By converting energy into motion, it allows the device to navigate across different surfaces effortlessly. This process involves a combination of mechanical components working together in harmony to transfer energy to the wheels or tracks.

Below is a basic breakdown of how this system operates:

Component Function Transmission Transfers energy from the motor to the wheels, controlling speed and direction. Drive Belt Connects the engine to the transmission, ensuring power flow. Axles Deliver rotational energy to the wheels, enabling movement. Wheels Allow the equipment to move and maintain stability on various terrains. Wheels and Height Adjustment Mechanism

Proper control of the vehicle’s terrain engagement and cutting depth depends heavily on the design of its mobility components and the system responsible for modifying the operating height. These features ensure smooth movement across different surfaces and allow for tailored performance based on the user’s preferences and the environment’s demands.

Wheel Structure

The vehicle’s traction relies on well-designed wheels that provide stability and grip. These components typically feature durable materials to withstand various outdoor conditions. Their placement and size are carefully engineered to distribute weight evenly, ensuring maneuverability and preventing surface damage.

Height Adjustment System

The mechanism for modifying the operating level enables quick and efficient changes to the unit’s performance. Users can adjust the ground clearance by manipulating a lever system, often designed for ease of use. This allows adaptation to varying conditions, ensuring optimal operation whether in low or high settings.

- Multiple height settings for versatile use

- Lever or dial-operated for user-friendly adjustments

- Durable construction to withstand repeated adjustments

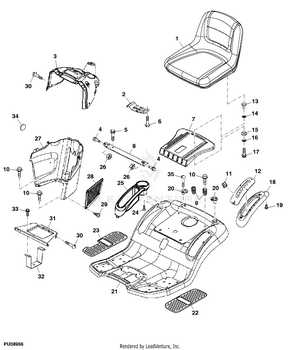

Handle Assembly and User Controls

The handle assembly is a critical component that enhances user experience by providing essential controls and support for operation. Understanding its structure and functionality ensures effective handling and manipulation of the equipment during use.

This assembly typically includes various elements, such as grips, levers, and controls, which are strategically positioned to facilitate ease of access. Each control is designed to perform specific functions, enabling users to adjust settings efficiently. Proper knowledge of these controls helps in achieving optimal performance and safety while operating the equipment.

In addition, the ergonomic design of the handle plays a significant role in user comfort, reducing fatigue during extended use. Ensuring that all components of the handle assembly are well-maintained and functioning correctly is essential for the longevity and reliability of the equipment.

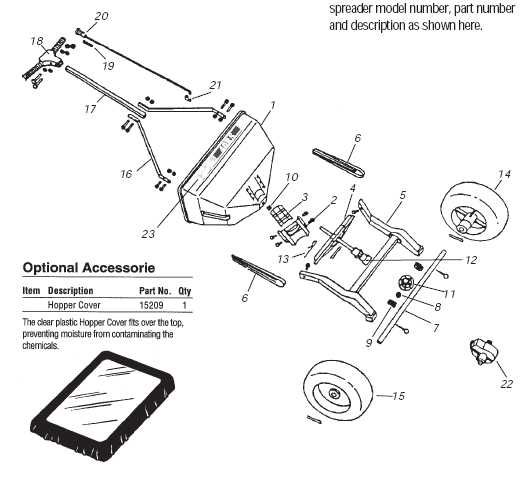

Fuel System and Carburetor Details

The efficient operation of small engine machinery relies heavily on the fuel delivery mechanism and the component responsible for mixing air and fuel. Understanding these elements is crucial for maintaining optimal performance and longevity.

At the heart of the fuel system lies the fuel tank, which stores the liquid necessary for combustion. Proper maintenance of this tank ensures a clean supply of fuel to the engine. Here are some key components:

- Fuel Filter: Prevents contaminants from entering the fuel line.

- Fuel Pump: Delivers fuel from the tank to the carburetor under pressure.

- Fuel Line: Transports fuel between the tank and the carburetor.

The carburetor plays a vital role in the combustion process by mixing the correct ratios of air and fuel. Its design influences how well the engine runs under various conditions. Key features include:

- Choke Valve: Regulates airflow during cold starts for easier ignition.

- Throttle Valve: Controls the engine’s speed by adjusting the amount of air entering.

- Jet System: Fine-tunes fuel flow to maintain the desired mixture ratio.

Regular inspection and maintenance of these components can prevent performance issues and enhance the efficiency of the engine, ensuring it operates smoothly and reliably.

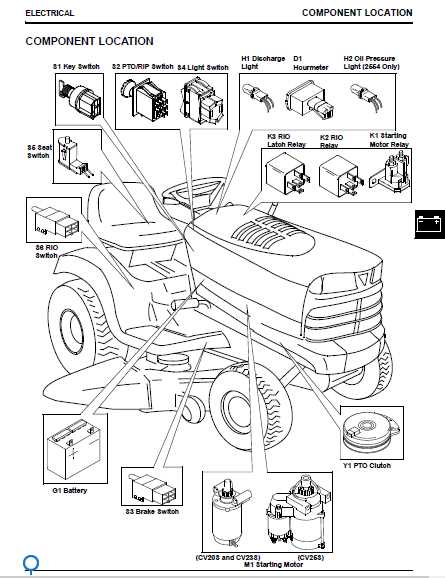

Electrical System and Safety Features

The functionality of outdoor maintenance equipment relies significantly on its electrical components and integrated safety mechanisms. These elements work cohesively to ensure efficient operation while prioritizing user protection during use. Understanding how these systems are designed can enhance the overall performance and reliability of the machinery.

The electrical configuration typically includes a battery, wiring harness, and control switches, each playing a vital role in the operation of the device. Below is a table outlining key components of the electrical system and their functions:

Component Function Battery Stores and supplies electrical energy for starting and operation. Wiring Harness Distributes electrical power to various components. Control Switches Allows the user to start, stop, or adjust settings. Fuse Protects the electrical system from overload and short circuits. Safety Interlocks Prevents operation unless safety conditions are met. In addition to the electrical components, safety features are essential for reducing risks associated with equipment operation. These mechanisms include emergency shut-off systems, user-friendly controls, and robust construction to prevent accidental injuries. Familiarity with these features contributes to a safer and more efficient working environment.

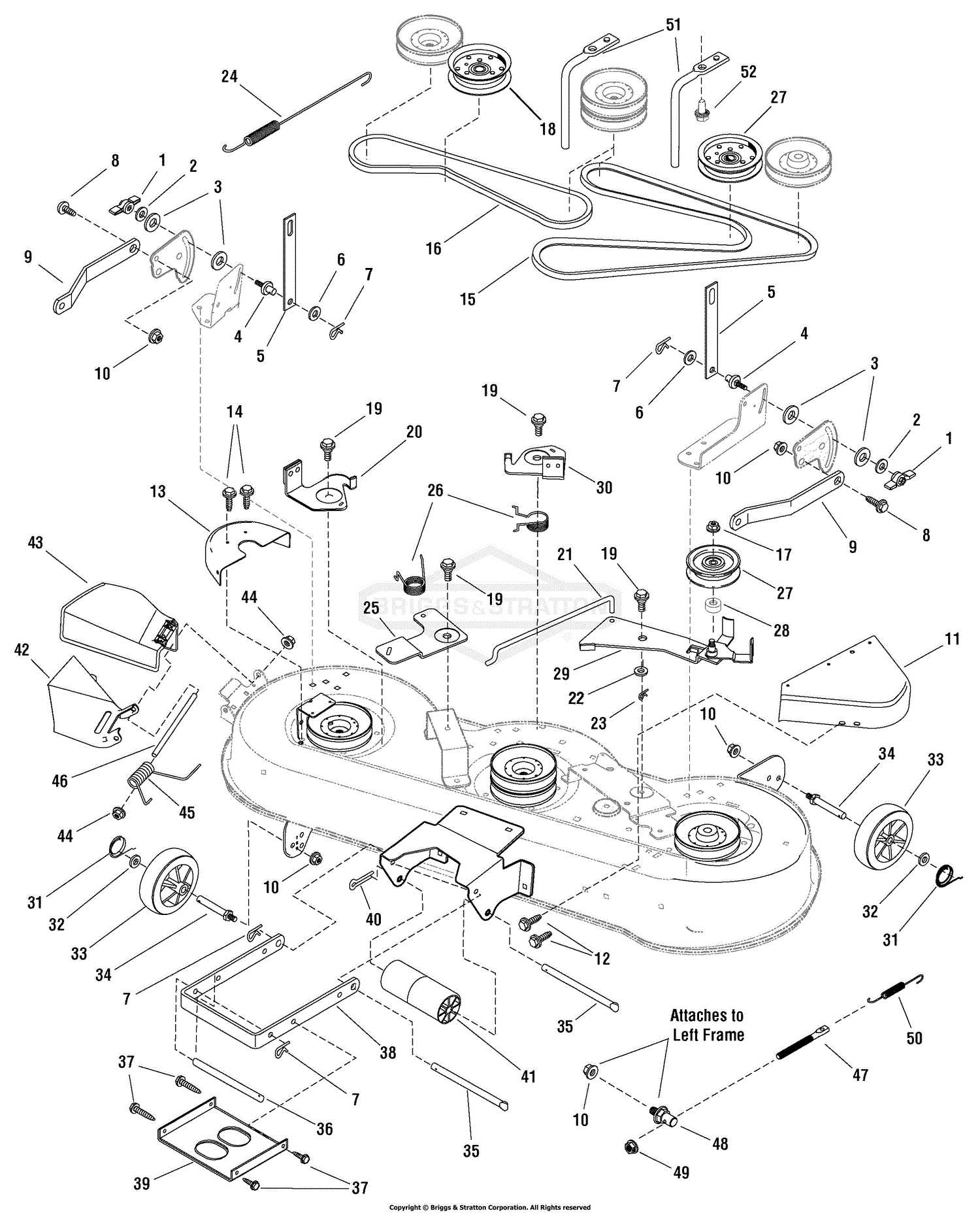

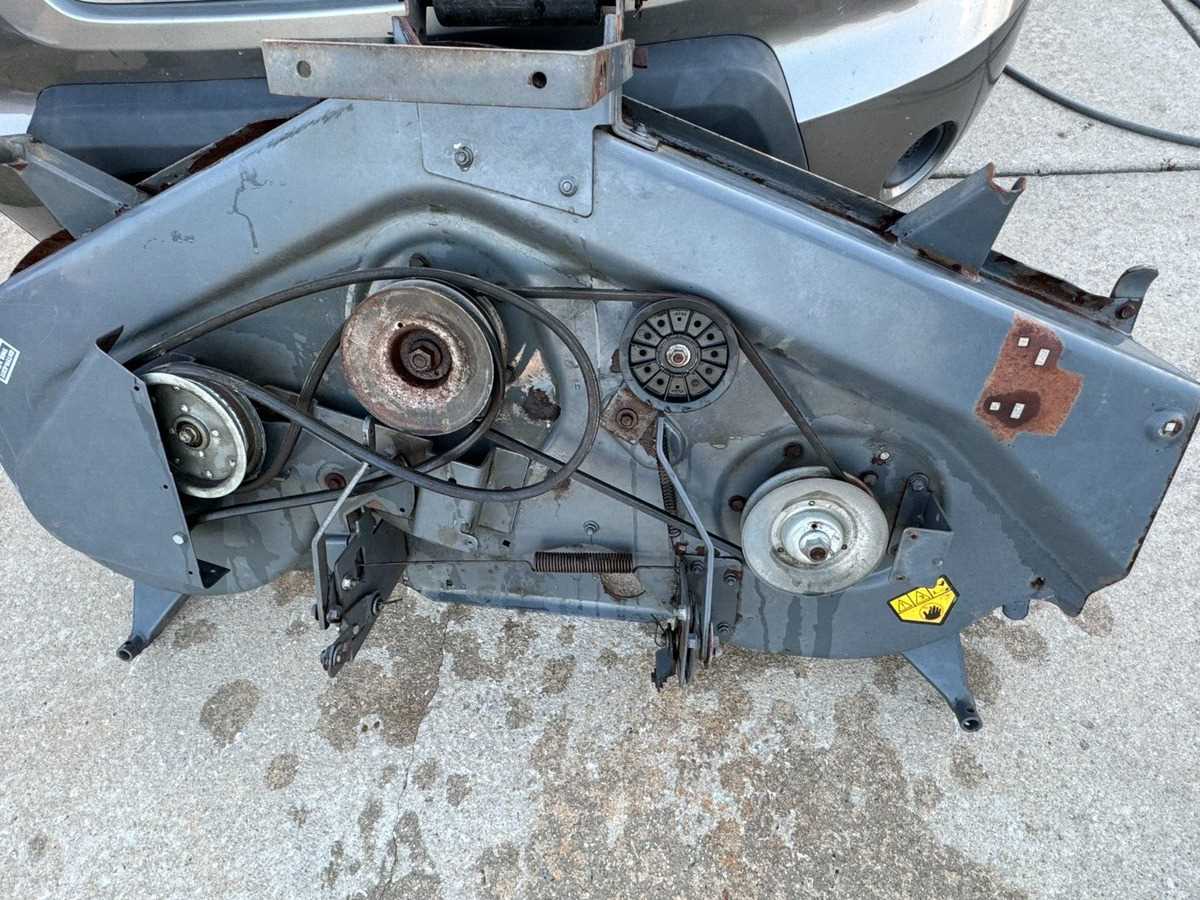

Maintaining and Replacing Mower Belts

Regular upkeep and timely substitution of the driving components are essential for ensuring optimal performance and longevity of your equipment. Proper maintenance can prevent unnecessary wear and tear, enhancing efficiency during operation.

Here are some key steps to follow for maintaining and replacing these crucial components:

- Inspection:

Frequent checks should be conducted to identify signs of wear, fraying, or damage. Look for any unusual noises during operation, which may indicate issues with these components.

- Cleaning:

Ensure the area around the components is free from debris and dirt. Regular cleaning can help prolong their life and improve overall functionality.

- Adjustment:

Components should be properly aligned and tensioned according to the manufacturer’s specifications. Incorrect tension can lead to slippage or premature wear.

- Replacement:

If signs of deterioration are present, replacing the components is vital. Ensure you select the correct size and type for your equipment. Follow these steps:

- Disconnect the power source to avoid accidents.

- Remove any covers or shields to access the components.

- Carefully remove the old components, taking note of their arrangement.

- Install the new components in the same configuration as the old ones.

- Reconnect any covers or shields and restore the power source.

By following these guidelines, you can enhance the efficiency and reliability of your equipment, ensuring a smooth operation throughout its lifespan.