When it comes to maintaining the efficiency and longevity of your machinery, comprehending the individual elements that make up the system is crucial. Each component plays a specific role, contributing to the overall functionality and performance. Familiarizing yourself with these essential pieces can enhance your ability to troubleshoot issues and ensure optimal operation.

Exploring the intricate relationships between these components provides valuable insights into how they interact and function together. By gaining a clearer picture of the arrangement and characteristics of these elements, you can more effectively diagnose problems and carry out repairs when necessary. This understanding not only streamlines maintenance but also promotes better decision-making regarding upgrades and replacements.

Whether you are a seasoned technician or a novice user, having access to a clear representation of these elements is indispensable. Such visual aids not only enhance comprehension but also serve as a practical reference during hands-on work. Empowering yourself with this knowledge fosters confidence and encourages a proactive approach to equipment care.

Understanding Rolair Compressors

In the realm of pneumatic tools and equipment, a certain type of machinery stands out for its reliability and efficiency. These devices play a crucial role in powering various tools and applications, ensuring that tasks are completed smoothly and effectively. A deeper comprehension of their components and functionality can significantly enhance their performance and longevity.

At the core of these machines lies a collection of essential elements that work in unison. Each component has a specific function, contributing to the overall efficiency and reliability of the equipment. Familiarity with these components not only aids in troubleshooting but also informs maintenance practices, allowing users to keep their machinery in peak condition.

| Component | Function |

|---|---|

| Pump | Generates the necessary air pressure for operation. |

| Motor | Powers the pump, enabling air compression. |

| Tank | Stores compressed air for consistent output. |

| Regulator | Controls the pressure of the output air. |

| Hoses | Facilitate the transfer of air to tools. |

By understanding these critical components and their functions, users can maximize efficiency, ensure safety, and extend the lifespan of their equipment. Proper knowledge also leads to informed decisions regarding upgrades and replacements, fostering a more productive work environment.

Importance of Compressor Parts

The functionality and efficiency of a pressure generation system heavily rely on its individual components. Each element plays a crucial role in ensuring optimal performance, longevity, and safety. Understanding the significance of these elements can lead to better maintenance practices and overall system reliability.

Well-designed components contribute to effective operation by minimizing wear and tear, reducing energy consumption, and enhancing output quality. Regular inspection and timely replacement of worn elements are essential for preventing costly breakdowns and ensuring smooth functionality. A proactive approach to maintaining these critical components can also extend the lifespan of the entire assembly.

| Component | Function | Impact of Failure |

|---|---|---|

| Motor | Drives the system | Loss of power, complete shutdown |

| Tank | Stores compressed air | Pressure loss, risk of rupture |

| Regulator | Controls pressure levels | Unstable output, potential damage |

| Filter | Removes impurities | Contaminated output, decreased efficiency |

By recognizing the importance of each component and maintaining them diligently, users can ensure reliable operation and achieve maximum efficiency from their systems.

Common Components in Rolair Models

Understanding the essential elements found in various models can greatly enhance maintenance and operational efficiency. These units are comprised of several key components that work synergistically to achieve optimal performance. Familiarity with these elements can lead to better troubleshooting and repairs.

Pumps are critical, providing the necessary pressure to perform tasks effectively. They are often designed for durability and high efficiency. Pressure switches are also vital, regulating the system’s pressure and ensuring safe operation. Additionally, valves play an important role in controlling the flow of air, while tanks serve as storage units, holding compressed air for later use.

Another significant aspect includes filters, which ensure the air quality by removing impurities. Furthermore, motors drive the pumps and are integral to the entire process, requiring regular maintenance to prevent downtime. By delving into these common components, users can achieve the ultimate efficiency in their applications.

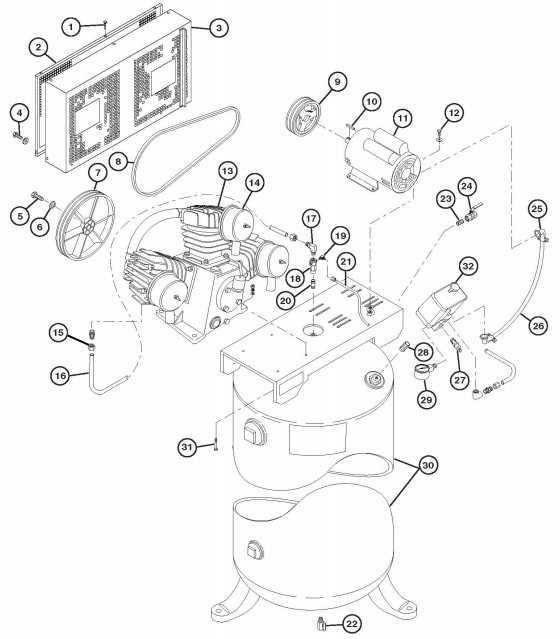

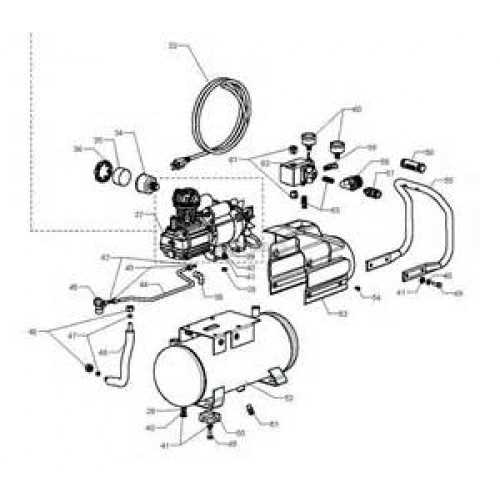

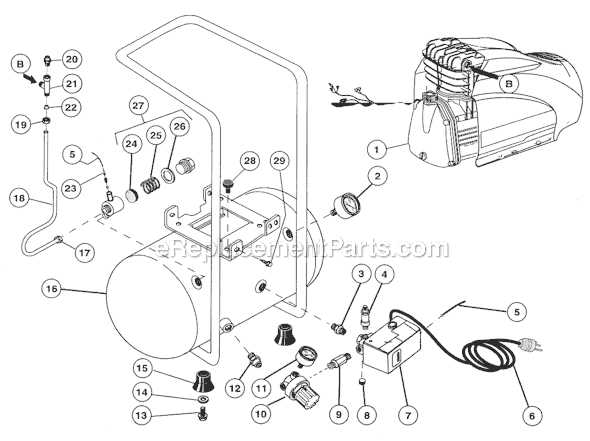

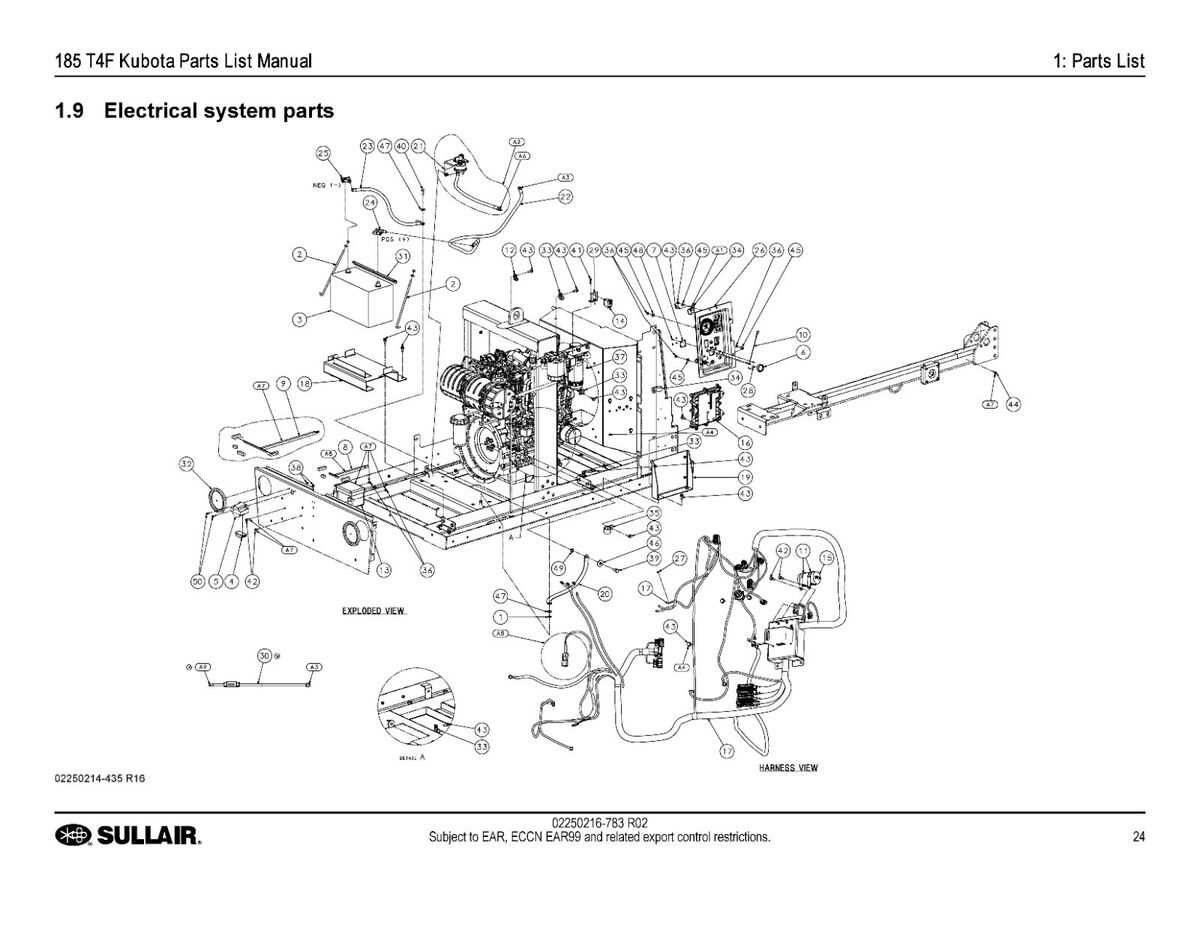

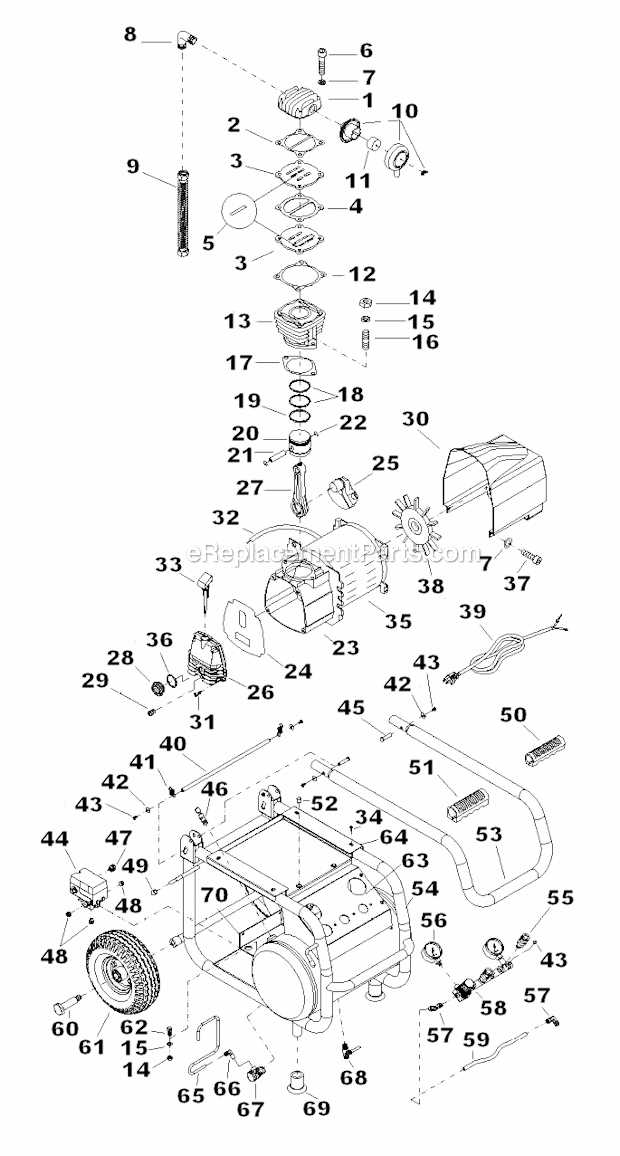

How to Read a Parts Diagram

Understanding the layout of mechanical components can significantly enhance your ability to troubleshoot and maintain equipment. A well-organized visual representation provides clarity, helping you identify individual elements and their interconnections.

First, familiarize yourself with the symbols and notations used in the illustration. Each icon typically represents a specific component, and knowing these will allow you to easily locate parts within the schematic.

Next, pay attention to the numbering system or labels. These often correlate with a list detailing specifications, making it easier to find replacement items or additional information about each element.

Additionally, observe the layout for relationships among components. Understanding how each part interacts can provide insight into the overall function and assist in diagnosing potential issues.

By taking the time to carefully analyze these visuals, you can ultimately enhance your efficiency and effectiveness when working with machinery.

Identifying Key Components

Understanding the essential elements of an air pressure machine is crucial for effective operation and maintenance. Each component plays a specific role in ensuring the system functions optimally, contributing to overall efficiency and longevity. By recognizing these key parts, users can troubleshoot issues and perform necessary repairs with confidence.

| Component | Description |

|---|---|

| Motor | Provides the necessary power to drive the system, converting electrical energy into mechanical energy. |

| Pump | Compresses air and creates pressure, playing a vital role in the performance of the unit. |

| Tank | Stores compressed air for later use, allowing for a steady supply during operation. |

| Regulator | Controls the output pressure, ensuring it meets the requirements of connected tools or equipment. |

| Pressure Switch | Automatically turns the motor on and off to maintain the desired pressure level in the tank. |

| Filter | Removes contaminants from the air supply, protecting both the machine and connected tools. |

Troubleshooting Common Issues

Identifying and resolving frequent problems can greatly enhance the performance and longevity of your equipment. Understanding potential malfunctions will allow you to take timely action and ensure smooth operation.

| Issue | Possible Cause | Solution |

|---|---|---|

| No power | Faulty outlet or power supply | Check connections and test with another device |

| Unusual noises | Loose components or worn parts | Tighten screws and inspect for wear |

| Overheating | Blocked vents or inadequate lubrication | Clear vents and ensure proper oil levels |

| Inconsistent performance | Air leaks or incorrect settings | Inspect for leaks and adjust settings accordingly |

Maintenance Tips for Longevity

Proper care is essential for extending the lifespan of any machinery. Regular upkeep not only enhances performance but also prevents costly repairs and downtime. Following a structured maintenance routine will ensure optimal functioning and reliability.

Regular Inspections

- Check for leaks or wear in hoses and connections.

- Inspect components for any signs of rust or corrosion.

- Ensure all fasteners are tightened to avoid vibrations.

Routine Cleaning

- Clean filters regularly to maintain airflow and efficiency.

- Remove dust and debris from all accessible areas.

- Use a damp cloth for wiping down surfaces to prevent buildup.

By adhering to these guidelines, users can significantly enhance the durability and functionality of their equipment, ensuring it operates smoothly for years to come.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is essential. Finding the right sources can significantly enhance performance and longevity. There are various avenues to explore for acquiring the necessary items, each offering unique benefits and options for different needs.

Authorized Dealers

One of the most reliable options is to check with authorized dealers. These suppliers typically offer original items that meet the manufacturer’s specifications. You can be assured of quality and compatibility, which can save you time and potential issues down the line. Many of these dealers also provide helpful customer service, guiding you through the selection process.

Online Marketplaces

Another great resource is online marketplaces. Websites dedicated to industrial equipment often stock a wide array of components. Here, you can compare prices, read reviews, and sometimes find used or refurbished items at a fraction of the original cost. However, it’s crucial to check the credibility of the seller to ensure you are purchasing reliable goods.

In conclusion, whether you choose authorized suppliers or explore digital platforms, making informed choices will lead to successful maintenance and operation of your machinery.

Comparing Different Rolair Models

This section explores various models within a well-known brand, focusing on their distinct features and specifications. By examining each variant, users can make informed choices based on their specific needs and preferences.

| Model | Power (HP) | Tank Size (Gallons) | Max Pressure (PSI) |

|---|---|---|---|

| Model A | 2.0 | 4 | 125 |

| Model B | 2.5 | 8 | 150 |

| Model C | 3.0 | 10 | 175 |

Understanding these specifications helps users identify the ultimate match for their tasks, ensuring efficiency and effectiveness in their operations.