In the realm of mechanical equipment, the intricate design and functionality of various elements play a crucial role in ensuring optimal performance. Each component, no matter how small, contributes to the overall efficiency and reliability of the system. By grasping the relationship between these parts, users can enhance their understanding of the machinery and its capabilities.

The exploration of specific mechanisms often involves analyzing the layout and arrangement of their individual elements. This insight not only aids in maintenance and repairs but also empowers operators to troubleshoot effectively. Recognizing how each segment interacts with others fosters a deeper appreciation of the engineering behind the equipment.

As we delve into the intricacies of these systems, it becomes evident that clarity in the representation of components is essential. Visual aids serve as valuable resources, helping to demystify complex structures. By studying these illustrations, one can gain a comprehensive view of how each part functions and connects within the larger framework.

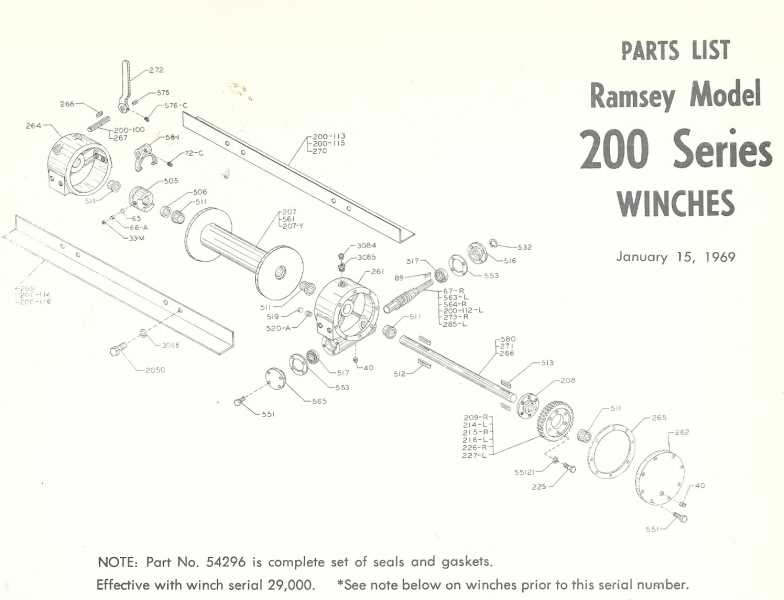

Understanding Ramsey Winch Components

To fully appreciate the mechanisms behind pulling and lifting devices, it’s essential to explore the various elements that contribute to their functionality. Each component plays a pivotal role in ensuring efficiency and reliability during operation.

- Drum: The cylindrical part where the cable is wound.

- Motor: The powerhouse that drives the system.

- Gearbox: Transmits power and controls the speed of the drum.

- Cable: The robust line used for towing and lifting tasks.

- Controller: The interface for operation, allowing user control over movement.

Understanding these components allows users to delve deeper into their assembly and operation, ultimately enhancing maintenance and troubleshooting skills.

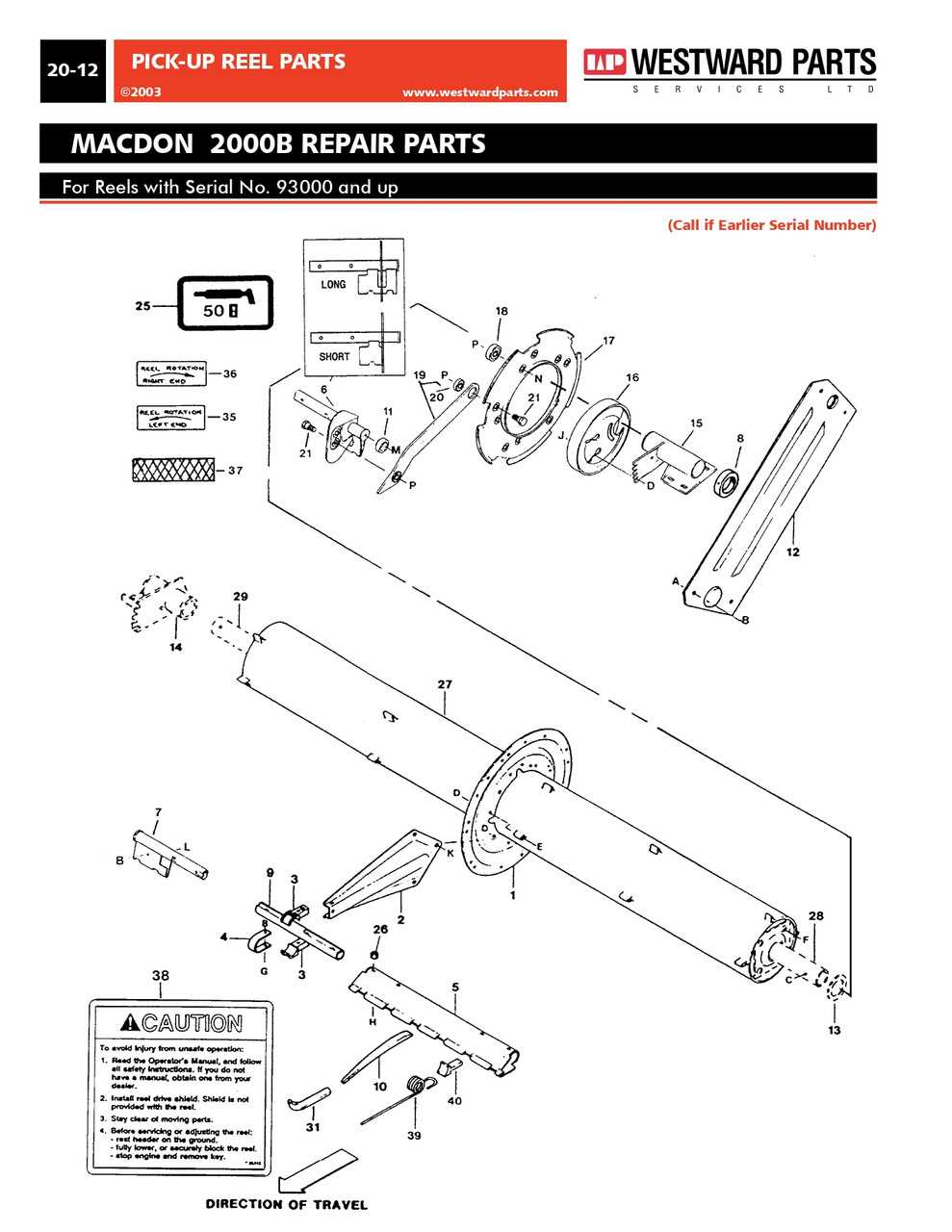

Importance of Accurate Parts Diagrams

Precision in representation is crucial for any mechanical system. Well-crafted visual aids not only facilitate understanding but also enhance the efficiency of maintenance and repairs. Accurate illustrations serve as a foundational tool for technicians, ensuring that every component is correctly identified and addressed during servicing.

Enhanced Communication

Clear and precise illustrations promote effective dialogue among team members. When everyone refers to the same visual representation, misunderstandings are minimized, leading to smoother collaboration. This alignment is essential for successful project execution and timely completion of tasks.

Streamlined Maintenance Processes

Detailed representations allow for quicker troubleshooting and repairs. Technicians can quickly locate and identify the necessary elements, significantly reducing downtime. Efficiency in maintenance not only saves time but also contributes to the longevity of the machinery, ensuring optimal performance.

In summary, high-quality illustrations are indispensable in any mechanical environment. They foster clear communication and enhance operational efficiency, ultimately supporting the overall success of maintenance efforts.

Common Issues with Winch Parts

Mechanical devices designed for hauling can encounter various complications over time. Understanding these issues can significantly enhance performance and longevity. This section highlights frequent problems users may face and offers insights into addressing them effectively.

Wear and Tear

Durability is a key factor in the functionality of any hauling mechanism. Over time, components may suffer from friction and stress, leading to diminished efficiency. Regular inspections can identify worn elements before they lead to failure. Components like cables and gears often show the most signs of fatigue.

Electrical Failures

Another common concern involves electrical malfunctions. These can arise from poor connections, corroded terminals, or damaged wiring. Ensuring all electrical components are secure and free from debris can help mitigate these issues. Additionally, routine testing of the system can catch potential problems early, preventing costly repairs.

How to Identify Parts Quickly

Efficient identification of components is essential for seamless operations. Understanding how to recognize different elements can save time and enhance productivity. Here are some strategies to streamline the process:

- Familiarize Yourself: Get to know the standard terminology and features of each component.

- Use Visual Aids: Refer to clear illustrations or charts that highlight each part and its function.

- Organize Components: Keep similar items grouped together for easier access and identification.

- Labeling: Clearly label storage areas to quickly find the required pieces.

- Practice Regularly: Frequent handling of components will improve your recognition skills.

Implementing these techniques can significantly enhance your ability to pinpoint components efficiently and effectively.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By following a few simple practices, you can significantly extend the life of your machinery and enhance its performance. Implementing a structured maintenance routine not only prevents unexpected breakdowns but also promotes safety during operation.

Regular Inspections

Conducting frequent checks is crucial for identifying potential issues before they escalate. Look for signs of wear, corrosion, or damage in the components. Inspect cables, fasteners, and connections to ensure everything is functioning optimally. Keeping a maintenance log can help track your inspections and any repairs made.

Proper Lubrication

Lubrication is key to minimizing friction and wear in moving parts. Use high-quality lubricants suitable for your machinery, and apply them as recommended by the manufacturer. Regularly clean any excess grease to prevent dirt accumulation, which can lead to further complications.

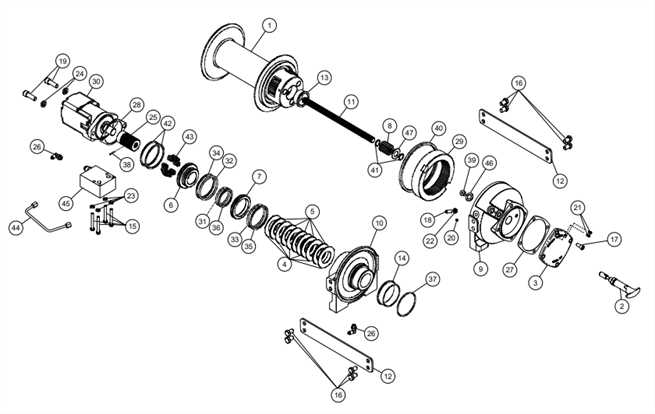

Upgrading Your Winch: What to Know

Enhancing your towing system can significantly improve performance and reliability. Whether you’re looking to boost power, increase efficiency, or add new features, understanding the essential components and their functionalities is crucial for a successful upgrade.

Key Considerations for Enhancement

Before diving into modifications, evaluate your current setup and identify your specific needs. Consider factors such as load capacity, speed, and environmental conditions. This assessment will guide you in selecting compatible upgrades that ensure optimal performance.

Components to Explore

When looking at potential enhancements, focus on the following elements:

| Component | Description | Benefits |

|---|---|---|

| Motor | The heart of the system that provides the necessary power. | Increased torque and speed for improved efficiency. |

| Drum | The cylinder where the line is wound. | Better line management and increased line capacity. |

| Remote Control | Device for operating from a distance. | Enhanced safety and convenience during operation. |

| Line | The cable or strap used for towing. | Increased strength and durability for heavy loads. |

By carefully considering these components and making informed choices, you can achieve a more robust and reliable towing system tailored to your needs.

Safety Considerations When Using Winches

When operating heavy lifting equipment, it is essential to prioritize safety to prevent accidents and ensure effective performance. Understanding the inherent risks and implementing proper precautions can significantly reduce the likelihood of mishaps. A comprehensive approach to safety involves both knowledge of the equipment and adherence to established guidelines.

Proper Training: Individuals should receive thorough training before using lifting devices. Knowledge of the equipment’s capabilities and limitations is crucial for safe operation. Training should cover not only technical aspects but also emergency procedures and the importance of communication among team members.

Inspection and Maintenance: Regular inspection and maintenance are vital to ensure the equipment remains in good working condition. Before each use, operators should check for wear and tear, ensure that all components function correctly, and address any issues immediately. Maintaining equipment according to manufacturer recommendations helps prevent unexpected failures.

Environment Awareness: The surroundings in which lifting tasks are conducted play a significant role in safety. Operators must be aware of potential hazards such as uneven terrain, overhead obstacles, and adverse weather conditions. Assessing the environment beforehand allows for better planning and risk mitigation.

Use of Personal Protective Equipment: Personal protective gear should always be worn when engaging with lifting apparatus. This may include gloves, helmets, and steel-toed boots, which provide an extra layer of safety against injuries. Proper attire is essential for minimizing risks during operation.

Clear Communication: Establishing clear lines of communication among team members is crucial during lifting operations. Using hand signals or two-way radios can ensure that everyone is aware of the plan and any changes that may arise. Effective communication helps prevent misunderstandings that could lead to accidents.

By implementing these safety measures, operators can significantly reduce risks associated with lifting operations, ensuring a safer and more efficient working environment.

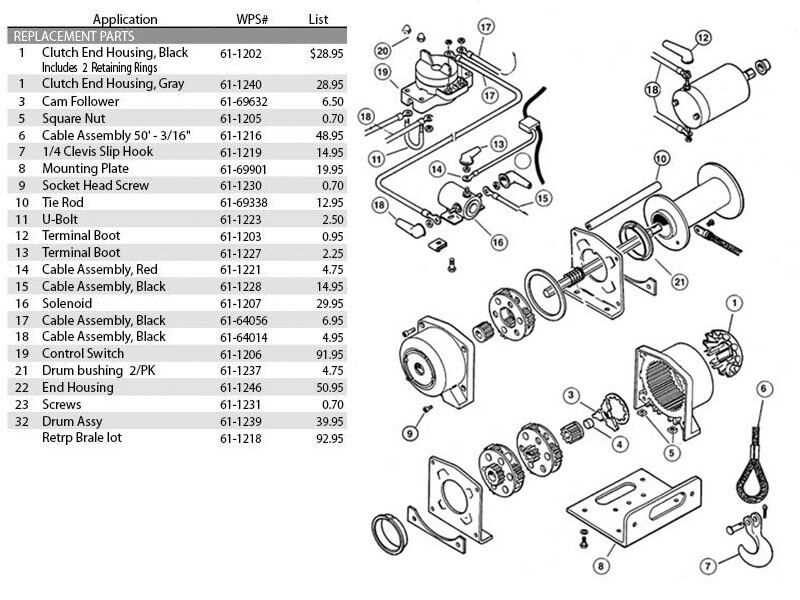

Where to Find Quality Replacement Parts

When the need arises for reliable components, locating high-quality alternatives is crucial for maintaining performance and safety. Numerous sources offer a variety of options tailored to specific requirements.

Online Retailers

- Specialized e-commerce sites dedicated to equipment.

- General marketplaces with extensive catalogs.

- Manufacturer’s official websites for authentic items.

Local Suppliers

- Authorized dealerships providing expert advice and genuine components.

- Local hardware stores that stock commonly used items.

- Trade shows and expos featuring various vendors and products.

Comparing Ramsey to Other Winch Brands

When evaluating different manufacturers of pulling devices, it’s essential to consider various factors such as performance, durability, and user experience. Each brand brings unique features and capabilities to the table, which can significantly influence decision-making for both recreational and industrial applications. This section aims to highlight how one prominent manufacturer stands out against its competitors.

Performance Metrics

Performance is often a primary concern for consumers. Metrics such as load capacity, speed, and power efficiency are crucial when assessing options. The following table outlines some key specifications from various brands, illustrating their strengths and weaknesses.

| Brand | Load Capacity (lbs) | Speed (ft/min) | Power Source |

|---|---|---|---|

| Brand A | 8,000 | 15 | Electric |

| Brand B | 9,500 | 12 | Hydraulic |

| Brand C | 7,000 | 18 | Electric |

| Brand D | 10,000 | 10 | Hydraulic |

Durability and Build Quality

Another important aspect is the durability and overall build quality. Consumers often seek products that can withstand harsh environments and heavy usage. Materials used, along with design features, play a significant role in longevity. While some brands focus on lightweight options, others prioritize robust construction, which can be more suitable for demanding conditions.