In the realm of mechanical devices designed to enhance productivity, a comprehensive understanding of their fundamental elements is crucial. These intricate systems operate by converting power into kinetic energy, enabling various applications in both industrial and domestic settings. By gaining insight into the key components, users can ensure optimal performance and longevity.

Exploring the layout of these essential elements reveals how they interact to facilitate efficient operation. Each segment plays a distinct role, contributing to the overall functionality of the system. Knowledge of these individual components allows for informed maintenance and troubleshooting, minimizing downtime and maximizing effectiveness.

With the right information, users can navigate the complexities of their equipment with confidence. Familiarity with the arrangement and purpose of each part enhances the ability to diagnose issues and implement effective solutions. This understanding not only fosters a deeper appreciation for the technology but also empowers users to maintain their systems effectively.

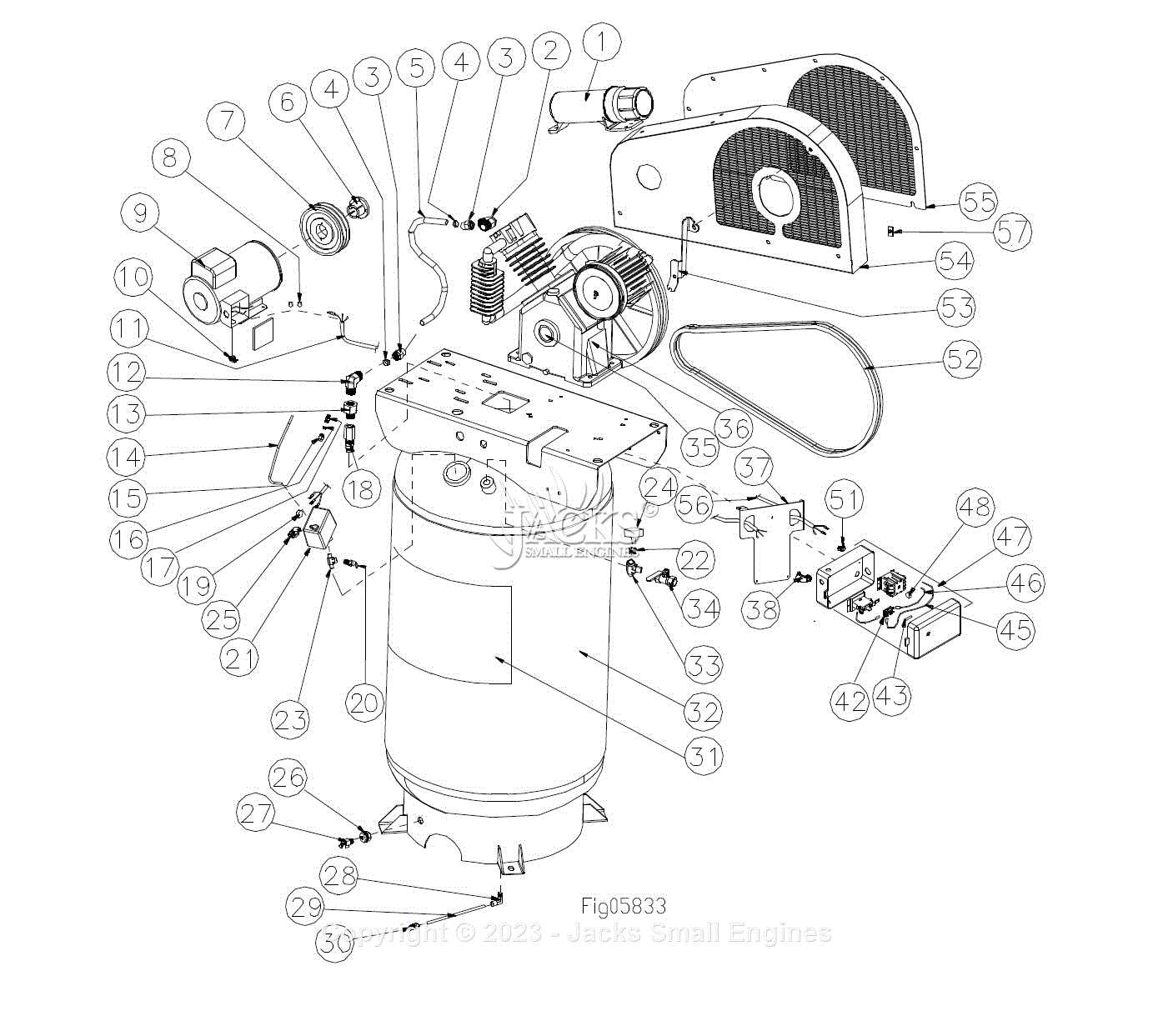

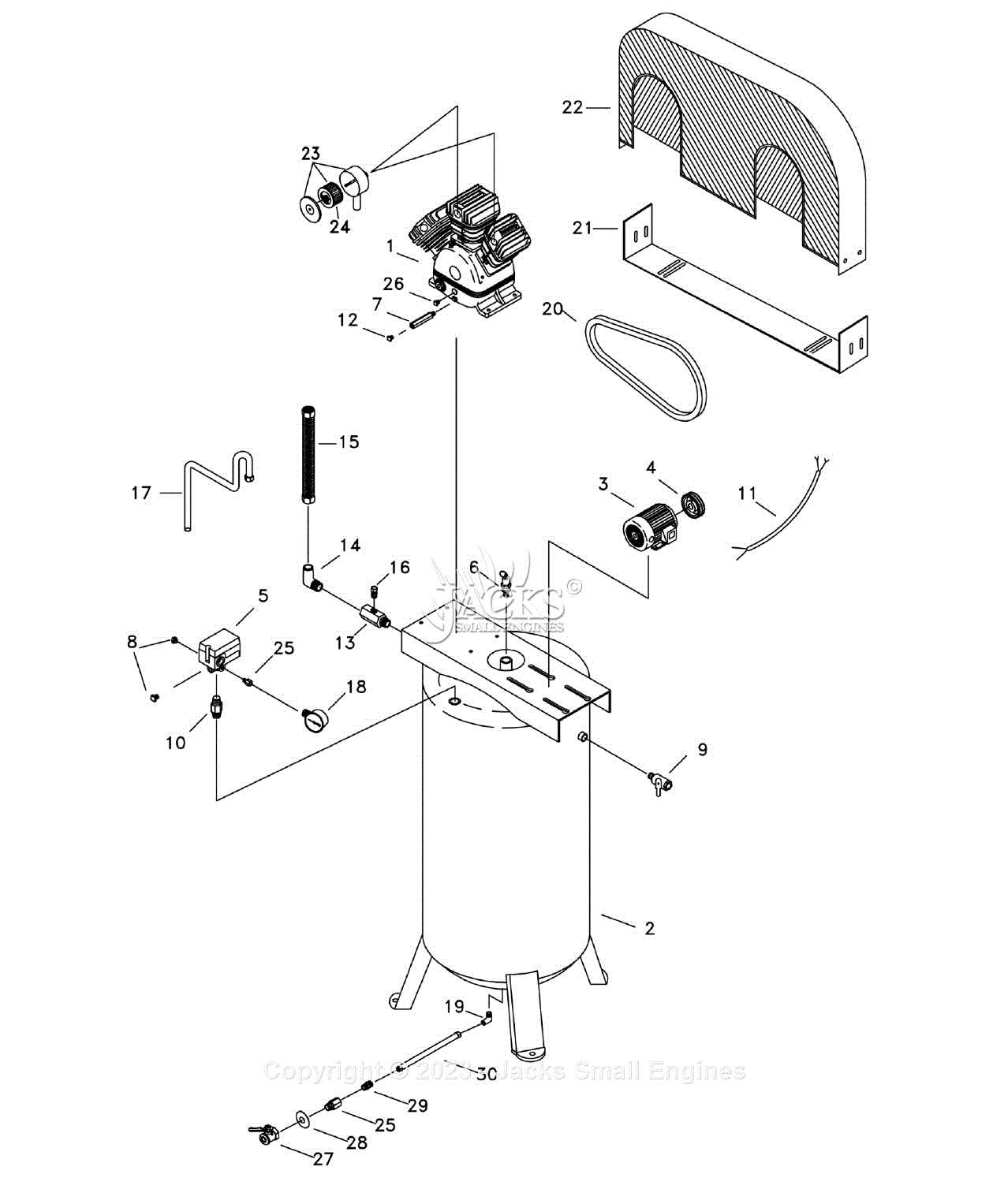

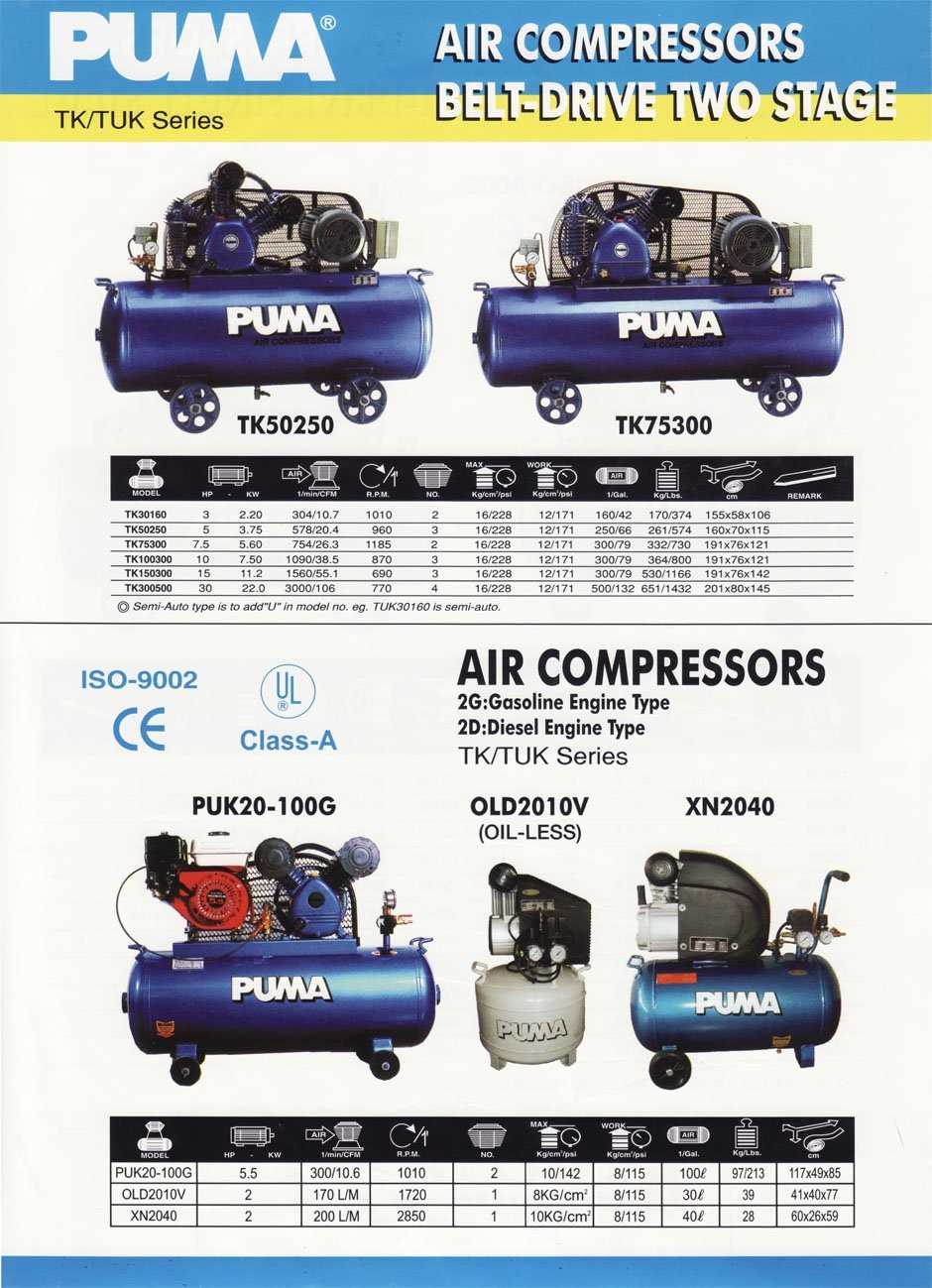

Puma Air Compressor Parts Overview

This section provides an insight into the various components that constitute a specific type of pressurization device. Understanding these elements is crucial for effective operation, maintenance, and troubleshooting.

Key elements include:

- Motor: The driving force behind the mechanism, responsible for powering the system.

- Tank: A reservoir that stores the pressurized substance, allowing for efficient usage.

- Regulator: This component controls the pressure levels within the system, ensuring optimal performance.

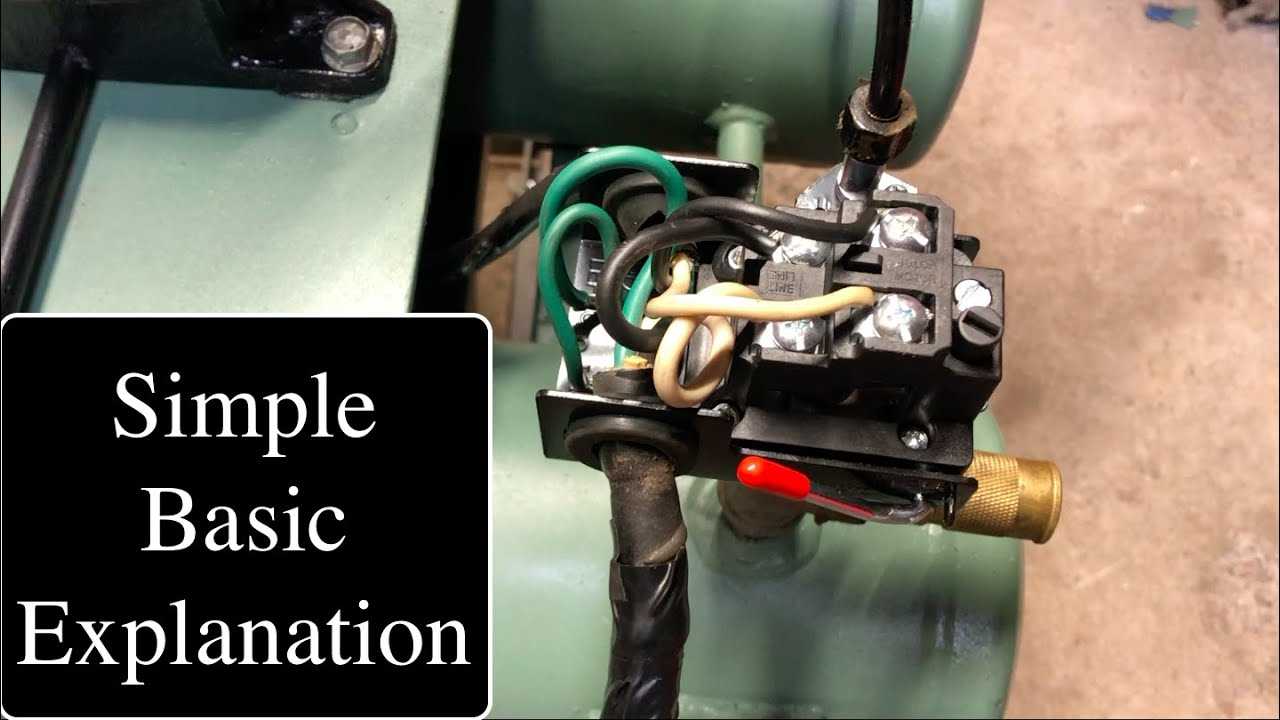

- Pressure Switch: An essential safety feature that activates or deactivates the system based on pressure levels.

- Valves: These components manage the flow of the pressurized substance, directing it where needed.

- Hoses: Flexible tubes that transport the pressurized substance from one part to another.

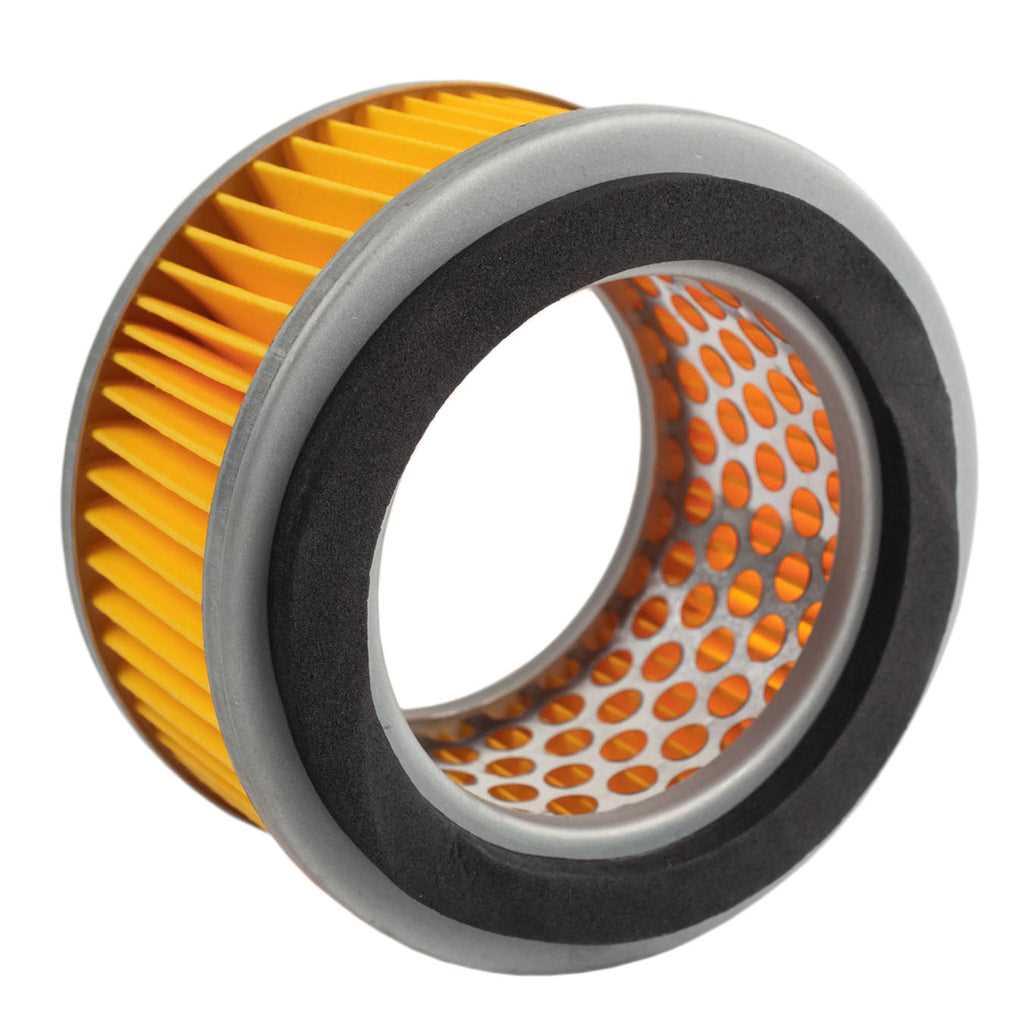

- Filters: Devices that remove impurities from the substance, promoting longevity and reliability.

Familiarity with these essential elements helps in identifying issues and ensures proper functionality over time.

Understanding Compressor Components

Exploring the various elements that constitute a pressure-enhancing device is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance, contributing to the overall efficiency and reliability of the system. Gaining insight into these elements aids in troubleshooting and enhances longevity.

Key Elements of the System

Among the fundamental components, one finds the housing, which provides protection and support for the internal mechanisms. The motor serves as the driving force, converting electrical energy into mechanical energy. Additionally, the valves facilitate the flow of the medium, regulating pressure and ensuring that the system operates smoothly.

Importance of Maintenance

Regular upkeep of these components is essential for sustaining performance. Neglecting routine checks can lead to inefficiencies and potential breakdowns. Utilizing high-quality replacements when needed not only improves functionality but also extends the lifespan of the device. Understanding the significance of each part empowers users to take proactive measures for maintenance and repair.

Importance of Maintenance in Compressors

Regular upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. Proper care not only enhances efficiency but also minimizes the risk of unexpected failures. This proactive approach is essential for maintaining reliability and functionality in various applications.

Scheduled inspections and timely replacements of worn components are vital for avoiding costly downtimes. By adhering to a maintenance routine, operators can identify potential

Common Issues with Air Compressors

Many users encounter a variety of challenges when utilizing pressurized gas systems. Understanding these common difficulties can lead to better maintenance and prolonged lifespan of the equipment.

| Issue | Description | Possible Solutions |

|---|---|---|

| Insufficient Pressure | The unit fails to reach the desired pressure level. | Check for leaks in hoses and fittings; ensure proper settings are applied. |

| Overheating | The device becomes excessively hot during operation. | Allow adequate ventilation; inspect cooling mechanisms for blockages. |

| Noisy Operation | Excessive noise can indicate a malfunction. | Tighten loose components; lubricate moving parts. |

| Frequent Cycling | The equipment turns on and off more often than expected. | Check pressure settings; examine the pressure switch for defects. |

| Moisture in Output | Water accumulation in the output line can affect performance. | Use a moisture separator; regularly drain the tank to remove excess water. |

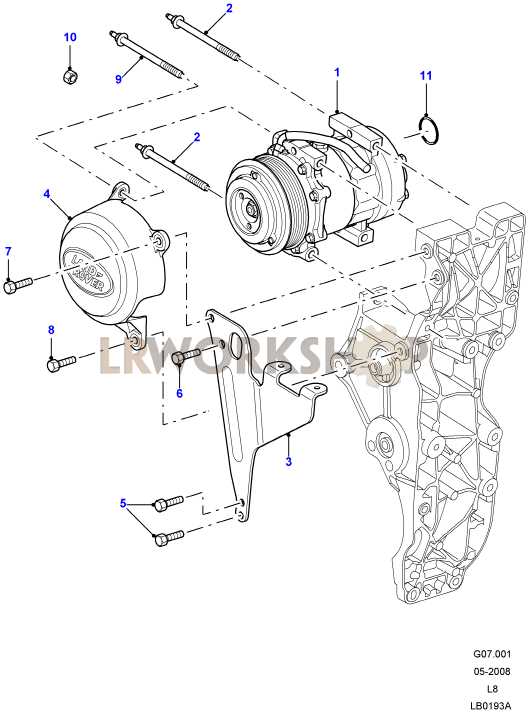

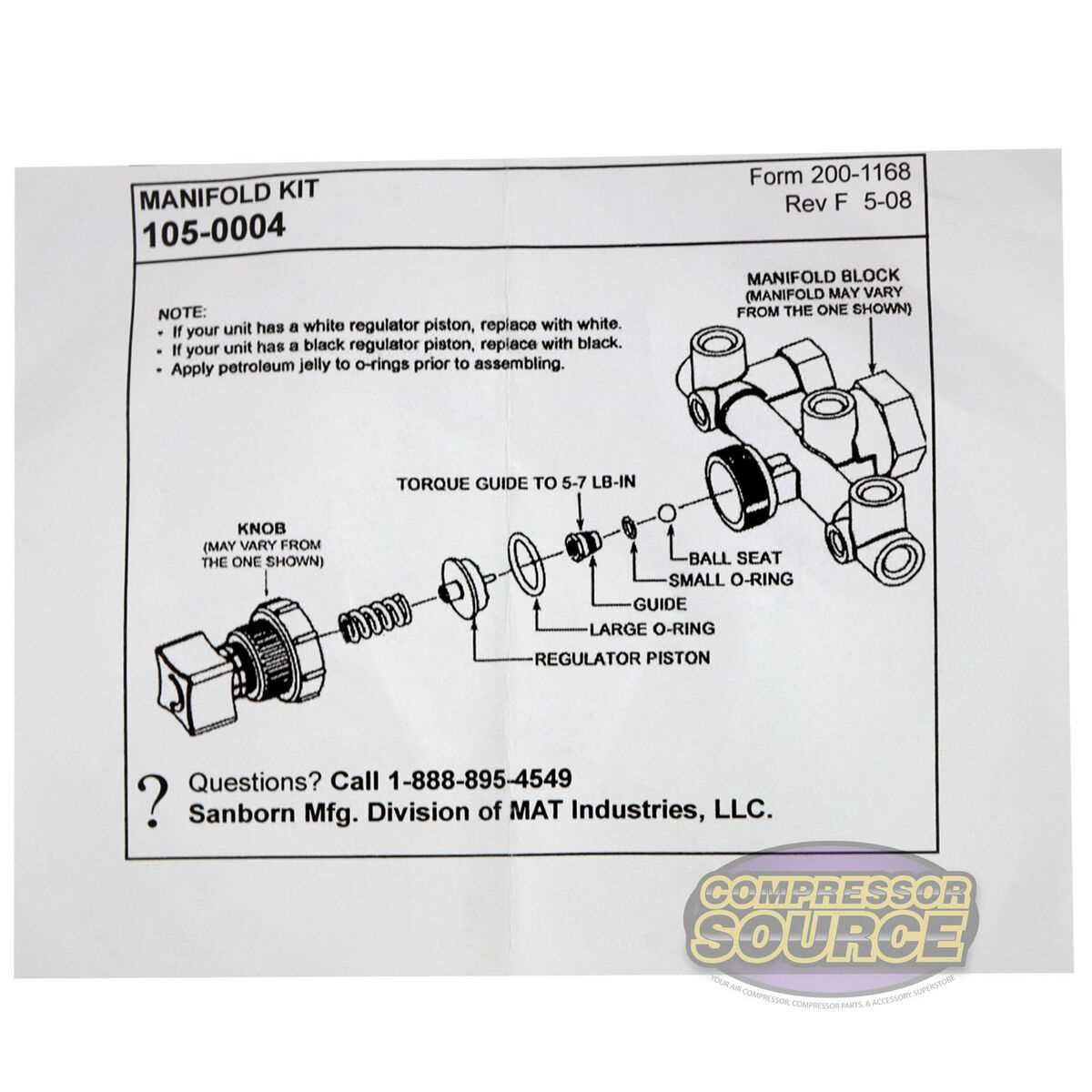

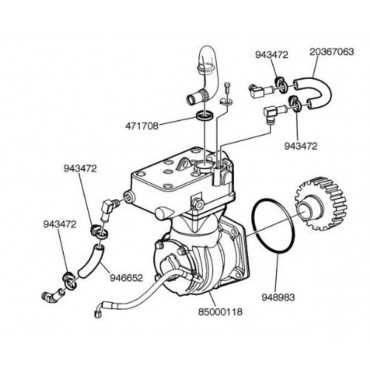

How to Read Parts Diagrams

Understanding the visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as guides, helping users identify various elements and their relationships within a mechanism. Familiarity with these visuals enhances the ability to navigate through the intricacies of machinery and ensures informed decision-making during repairs.

Familiarize Yourself with Symbols

Each illustration utilizes specific symbols to denote various elements. Learning these representations is crucial for accurate interpretation. Below are common symbols you might encounter:

- Circle: Typically represents a component or part.

- Arrow: Indicates movement or direction.

- Square: Often used for connectors or junctions.

Follow the Flow of Components

It is vital to track the flow of components as depicted in the visuals. This helps in understanding how parts interact with each other. Here are steps to effectively follow the flow:

- Start from the main element.

- Trace connections to secondary components.

- Note any dependencies or linkages.

- Review the entire assembly for a complete understanding.

Identifying Essential Spare Parts

Understanding the crucial components of any machinery is vital for effective maintenance and performance. Recognizing these fundamental elements enables users to ensure optimal functionality and longevity of their equipment.

Key Components to Monitor

Regular inspection and knowledge of the main components can help identify potential issues before they escalate. Here are some essential elements to keep in mind:

- Valves: Essential for regulating the flow of air within the system.

- Filters: Important for maintaining air quality and preventing contamination.

- Hoses: Vital for connecting various sections and allowing the movement of air.

- Belts: Crucial for power transmission between components.

- Pistons: Play a significant role in compressing the air.

Signs of Wear and Tear

Being aware of the signs indicating the need for replacement is crucial. Common indicators include:

- Unusual noises during operation.

- Decreased efficiency or output.

- Visible leaks in hoses or connections.

- Increased vibration during use.

By staying informed about these critical components and their condition, users can take proactive measures to ensure their machinery remains in peak operating condition.

Installation Tips for Replacement Parts

Replacing components in a mechanical system can significantly enhance performance and extend its lifespan. Following precise guidelines ensures that the installation process is efficient and effective, minimizing potential issues down the line.

Here are some essential tips to consider during the installation of new components:

- Read the Manual: Always consult the user manual or installation guide specific to the system you are working on. This document provides vital information regarding compatibility and assembly procedures.

- Gather Necessary Tools: Before beginning the installation, make sure you have all required tools at hand. Having the right equipment will facilitate a smoother process.

- Inspect Old Components: Examine the components you are replacing. Identifying any underlying issues can help prevent similar problems in the future.

- Ensure Cleanliness: Keep the workspace clean and free of debris. A tidy environment reduces the risk of contamination and improves the overall installation experience.

- Follow Proper Sequence: Install new components in the order specified in the manual. Adhering to the recommended sequence can help avoid complications and ensure optimal performance.

- Check Connections: After installation, double-check all connections and fittings. Properly secured components are crucial for the system’s efficiency and safety.

- Test the System: Once everything is in place, perform a test run to ensure everything functions as intended. Monitoring for any unusual sounds or vibrations can help identify issues early on.

By following these guidelines, you can ensure a successful replacement process, enhancing the overall functionality of your mechanical equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and ensure a smooth workflow. Proper precautions not only protect the individual performing the repairs but also extend the lifespan of the equipment being serviced. Adhering to safety guidelines minimizes risks associated with mechanical failures and other hazards.

Personal Protective Equipment

- Always wear safety goggles to shield your eyes from debris and particles.

- Use gloves to protect your hands from sharp edges and hazardous substances.

- Ensure appropriate footwear is worn to provide support and protection from heavy items.

- Consider wearing ear protection if operating in a noisy environment.

Work Environment Safety

- Maintain a clean and organized workspace to reduce trip hazards.

- Ensure proper ventilation when working with chemicals or lubricants.

- Keep fire extinguishers accessible in case of emergencies.

- Use tools and equipment that are in good condition and suitable for the task.

Where to Find Quality Parts

Locating high-quality components for your machinery can be essential for maintaining optimal performance and longevity. It is crucial to source these items from reliable suppliers who guarantee authenticity and durability.

Online retailers often provide a vast selection, making it easier to compare options and prices. Look for platforms that specialize in industrial equipment, as they typically offer extensive inventories and detailed descriptions to help you make informed decisions. Additionally, consider checking customer reviews to gauge the reliability of the seller.

Local distributors can also be a great resource. Establishing a relationship with a trusted dealer can ensure that you receive expert advice and access to genuine replacements tailored to your specific needs.

Networking within industry forums or communities can lead to valuable recommendations. Engaging with other users may reveal hidden gems or lesser-known suppliers that offer exceptional quality at competitive prices.