In the realm of gas storage and distribution, a thorough comprehension of the various elements involved is essential for both safety and efficiency. Each component plays a pivotal role in ensuring that the system operates smoothly, preventing leaks and optimizing performance. Familiarity with these individual segments not only aids in maintenance but also enhances overall operational knowledge.

When examining the assembly as a whole, one must recognize how each section interacts with the others. From the securing mechanisms to the safety devices, every piece contributes to the integrity of the entire structure. Grasping the function and layout of these elements empowers users to make informed decisions regarding installation, usage, and troubleshooting.

By delving into the specifics of each individual component, one can cultivate a deeper understanding of their significance within the broader system. This exploration will illuminate the intricate design and engineering that goes into crafting reliable storage solutions, highlighting the importance of proper handling and care in any application.

Understanding Propane Tank Components

This section explores the essential elements that make up storage vessels for fuel, highlighting their functionality and importance in ensuring safe and efficient usage.

Key Elements

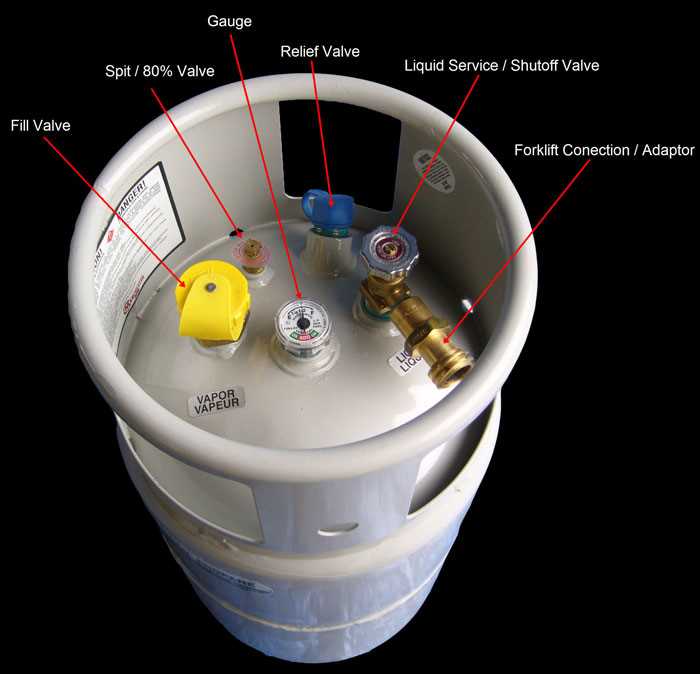

- Body: The main structure that holds the fuel.

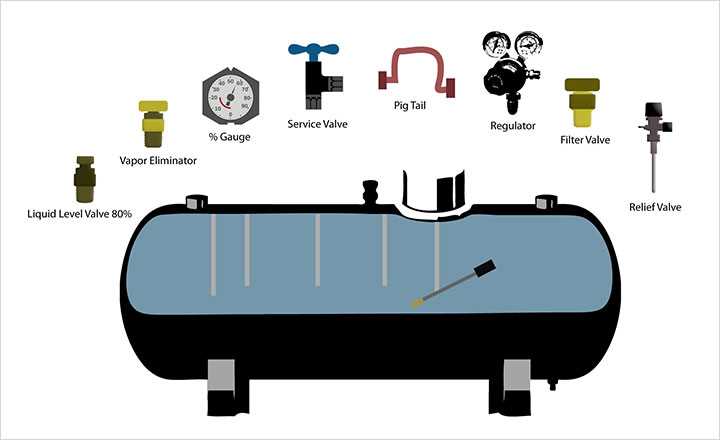

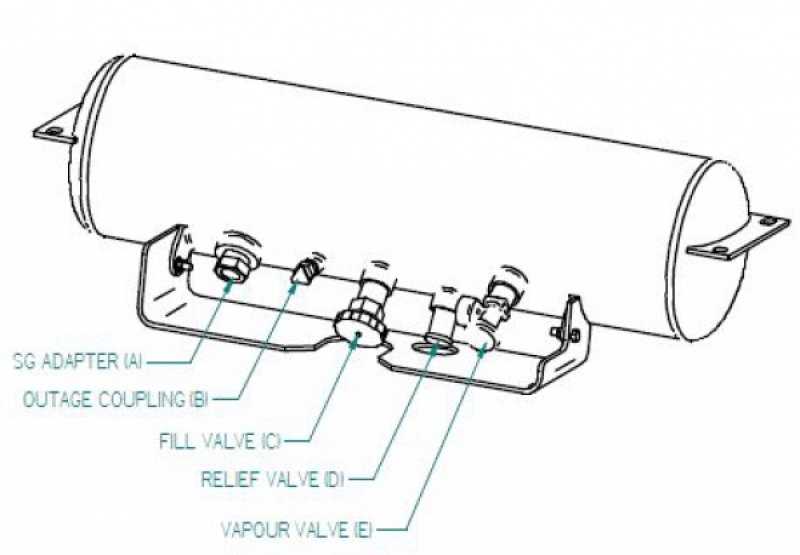

- Valve: A crucial component for controlling the flow of gas.

- Relief Valve: Ensures pressure regulation and safety during operation.

- Footring: Provides stability and support to the entire structure.

Functionality and Safety

- Each component plays a vital role in the overall operation.

- Understanding these elements can enhance safety measures.

- Regular maintenance of these features is essential for longevity.

Essential Parts of a Propane Tank

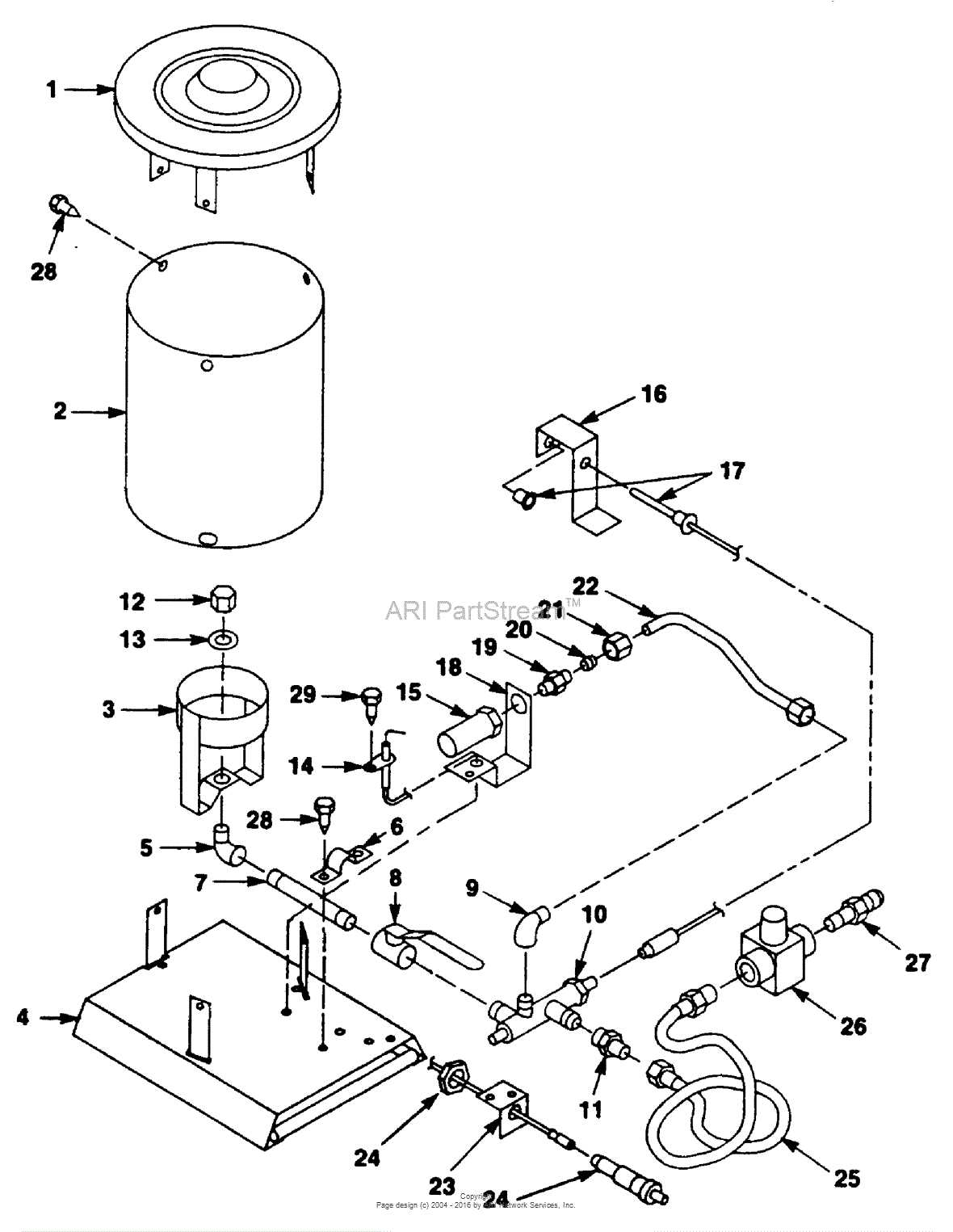

Understanding the fundamental components of a storage vessel for gaseous fuel is crucial for safe handling and efficient usage. Each element plays a significant role in ensuring the functionality and reliability of the system, contributing to overall safety and performance.

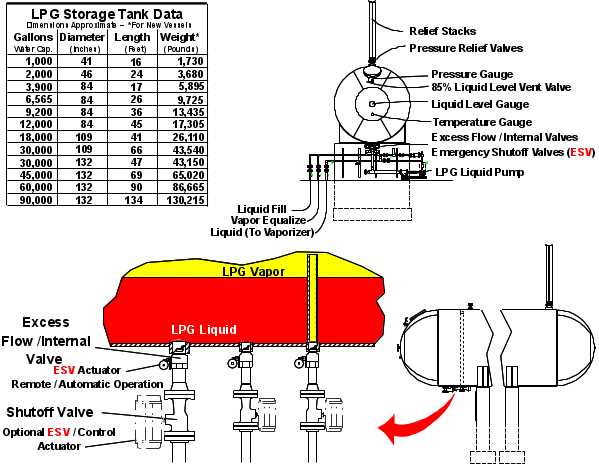

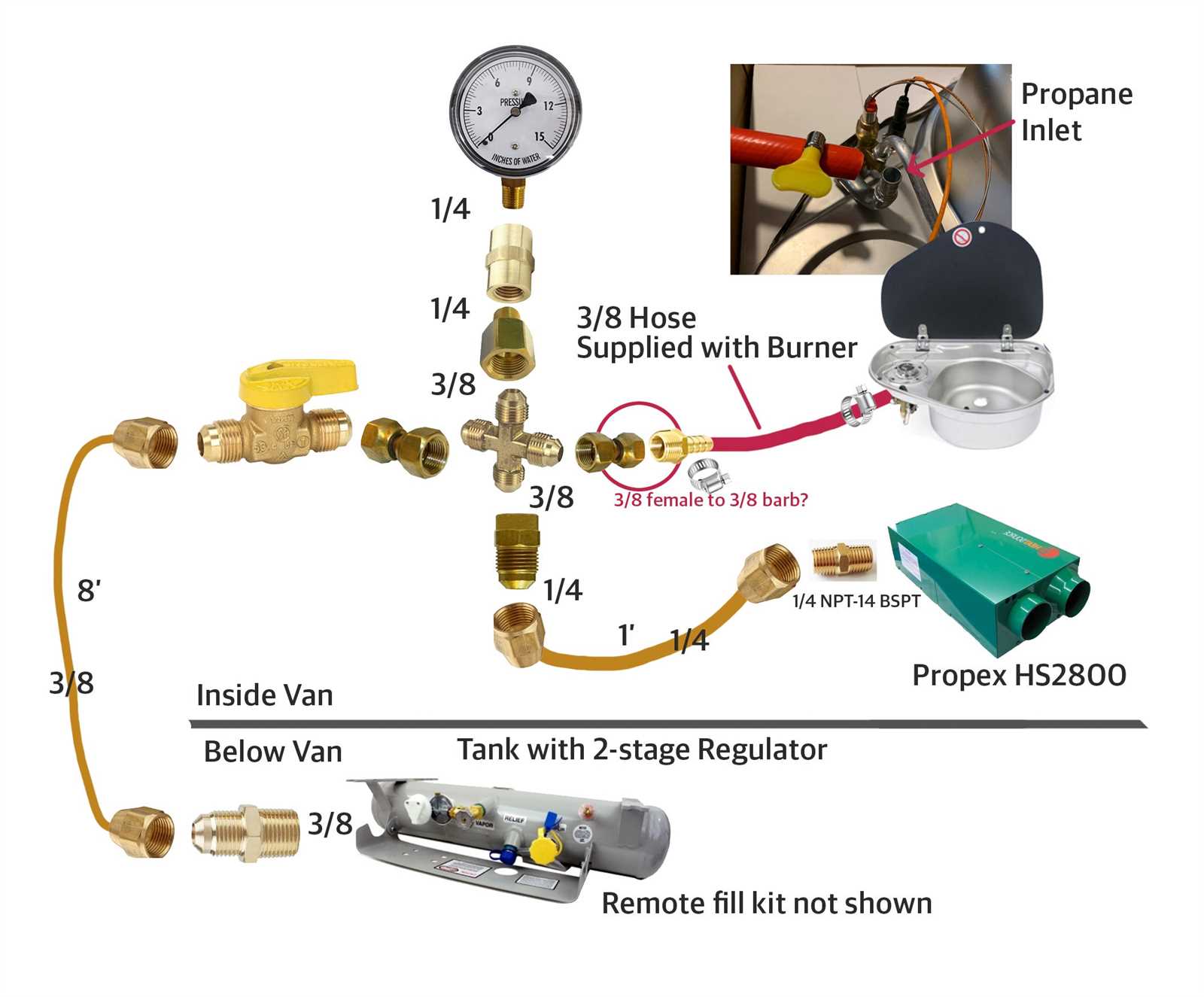

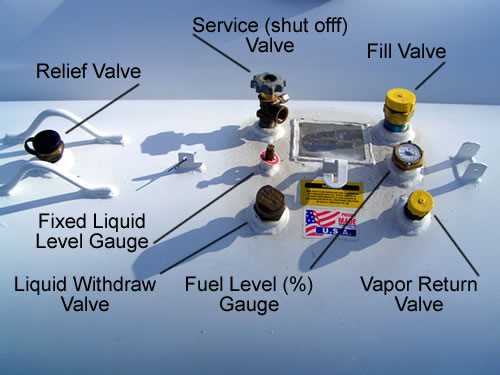

The main structure is designed to contain the fuel under pressure, while the valve system regulates flow and prevents leaks. An essential feature is the safety relief valve, which allows excess pressure to escape, safeguarding against overpressure scenarios. Additionally, a gauge is often included to monitor the remaining volume of the substance, providing users with vital information for planning refills.

Support structures, such as feet or cradles, ensure stability during storage and transport. Furthermore, protective coatings and insulation may be applied to enhance durability and efficiency. Familiarity with these key components empowers users to maintain their systems effectively and responsibly.

How Propane Tanks Function

Understanding the operation of storage vessels for gaseous fuels is essential for safe usage and maintenance. These containers are designed to hold compressed gas in a liquid state, allowing for efficient storage and transportation. When released, the liquid transforms back into gas, providing an energy source for various applications.

Storage and Compression

The vessel is built to withstand high pressure, ensuring the gas remains in a liquid form until needed. This design utilizes a specific structure to manage the internal pressure and temperature, which is critical for optimal performance. When the valve is opened, the liquid inside expands and converts to a gas as it escapes into the atmosphere.

Regulation and Safety

To ensure safe operation, these containers are equipped with safety mechanisms that regulate flow and pressure. Valves play a crucial role, allowing users to control the release of gas while preventing any hazardous situations. Regular inspections and maintenance are necessary to uphold safety standards and prolong the lifespan of the vessel.

Safety Features in Propane Systems

Ensuring the well-being of users and the environment is paramount in the design and implementation of gas storage and delivery systems. Various mechanisms and devices are incorporated to mitigate risks associated with the use of pressurized fuels. These safety features play a crucial role in preventing accidents and ensuring efficient operation.

- Relief Valves: These components automatically release excess pressure to prevent explosions or ruptures.

- Check Valves: Designed to allow flow in one direction only, these valves help prevent backflow, ensuring that fuel does not return to the source.

- Safety Shutoff Systems: These systems automatically terminate fuel flow in the event of a malfunction or leak detection.

- Level Indicators: Gauges provide real-time information on the amount of fuel remaining, helping users to monitor and avoid overfilling.

In addition to these features, regular maintenance and inspections are vital to uphold safety standards. Educating users about proper handling and emergency procedures further enhances the reliability of these systems, promoting a safer environment for all.

Common Issues with Propane Tanks

Understanding the typical challenges associated with these storage solutions is essential for maintaining safety and efficiency. Various factors can lead to complications that may affect performance and reliability. Recognizing these common problems allows users to take proactive measures to ensure proper functionality and safety.

Leakage Problems

One of the most concerning issues involves leakage, which can result from various factors such as wear and tear or poor installation. Regular inspections and proper handling can minimize the risk of hazardous leaks.

Pressure Imbalance

Another frequent issue is pressure imbalance, which can cause inefficient operation or even equipment failure. Monitoring pressure levels regularly helps prevent complications and ensures optimal performance.

| Issue | Description | Preventive Measures |

|---|---|---|

| Leakage | Gas escaping from the storage unit, posing safety risks. | Regular inspections and prompt repairs. |

| Pressure Imbalance | Improper pressure levels leading to operational inefficiencies. | Routine pressure checks and maintenance. |

| Corrosion | Deterioration of materials due to environmental exposure. | Use protective coatings and regular cleaning. |

Maintenance Tips for Propane Equipment

Regular upkeep of gas storage and distribution systems is essential for ensuring safety, efficiency, and longevity. By adhering to a few straightforward practices, users can prevent issues and enhance the performance of their equipment. This section outlines key strategies for maintaining these systems effectively.

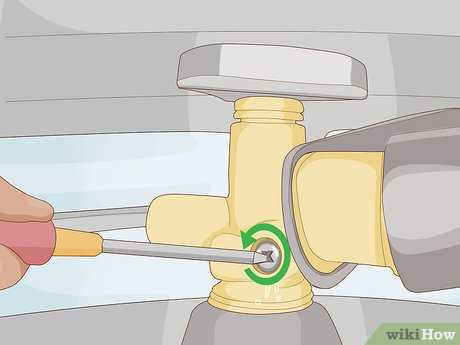

Routine Inspection

Conducting frequent checks can identify potential problems before they escalate. Look for signs of wear, corrosion, or leaks. Ensure that all connections are secure and that components are functioning correctly.

Cleaning Procedures

Keeping the equipment clean is vital for optimal operation. Accumulated dirt and debris can obstruct performance. Regularly wipe down surfaces and ensure that vents and filters are clear.

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for leaks and wear. |

| Cleaning | Quarterly | Remove dust and debris. |

| Professional Service | Annually | Schedule a thorough evaluation. |

By following these simple maintenance tips, users can enhance safety and efficiency, ensuring reliable operation for years to come.

Identifying Tank Labels and Codes

Understanding the labels and codes on fuel containers is crucial for ensuring safety and compliance. These markings provide essential information regarding the contents, handling procedures, and regulations that govern the use of these vessels. Familiarizing yourself with these identifiers can help prevent accidents and facilitate proper usage.

Key elements to look for include:

- Manufacturer Information: This often includes the name, address, and contact details of the producer.

- Capacity Markings: Indicates the maximum volume the container can safely hold.

- Certification Codes: Details regarding regulatory approvals, ensuring that the container meets safety standards.

- Warning Symbols: Visual cues that signify hazards associated with the container’s contents.

- Expiration Dates: Important for understanding the lifespan and safe usage period of the vessel.

To effectively interpret these markings, follow these steps:

- Locate the label on the container, usually found on the body or the collar.

- Examine each element carefully, taking note of any symbols or codes present.

- Refer to relevant guidelines or standards documents for clarification on specific codes.

- Keep a record of any important information for future reference.

By paying attention to these identifiers, users can ensure safer handling and compliance with applicable regulations.

Proper Propane Storage Practices

Storing fuel safely is crucial for both environmental and personal safety. Following best practices can minimize risks associated with flammable materials while ensuring accessibility for legitimate uses. Understanding the correct methods for keeping these resources is essential for any user.

General Guidelines

- Keep the storage area well-ventilated to prevent the accumulation of gas.

- Store containers upright and secure to prevent tipping.

- Ensure that the area is away from heat sources, direct sunlight, and open flames.

- Regularly inspect for leaks or damage to the containers.

Location Considerations

- Choose a flat, stable surface that is free from debris.

- Avoid placing storage units indoors or in confined spaces.

- Designate a storage location that is at least 10 feet away from buildings or structures.

- Keep the area clear of flammable materials such as paper, wood, or chemicals.