Understanding the various components that make up a small gasoline motor is essential for both maintenance and repair. This section aims to provide a comprehensive look at the essential elements that contribute to the functionality and efficiency of these machines. By exploring the layout and relationships among these components, users can enhance their knowledge and skills in handling similar machinery.

In this overview, we will break down the fundamental aspects that constitute the assembly of these motors. Each element plays a pivotal role in ensuring optimal performance and longevity. From the ignition system to the fuel delivery mechanisms, familiarity with these features is crucial for troubleshooting and effective operation.

Whether you’re an enthusiast looking to enhance your understanding or a professional seeking to refine your skills, this guide serves as a valuable resource. Grasping the intricacies of each component can lead to more informed decisions during repairs and upgrades, ultimately improving the overall user experience.

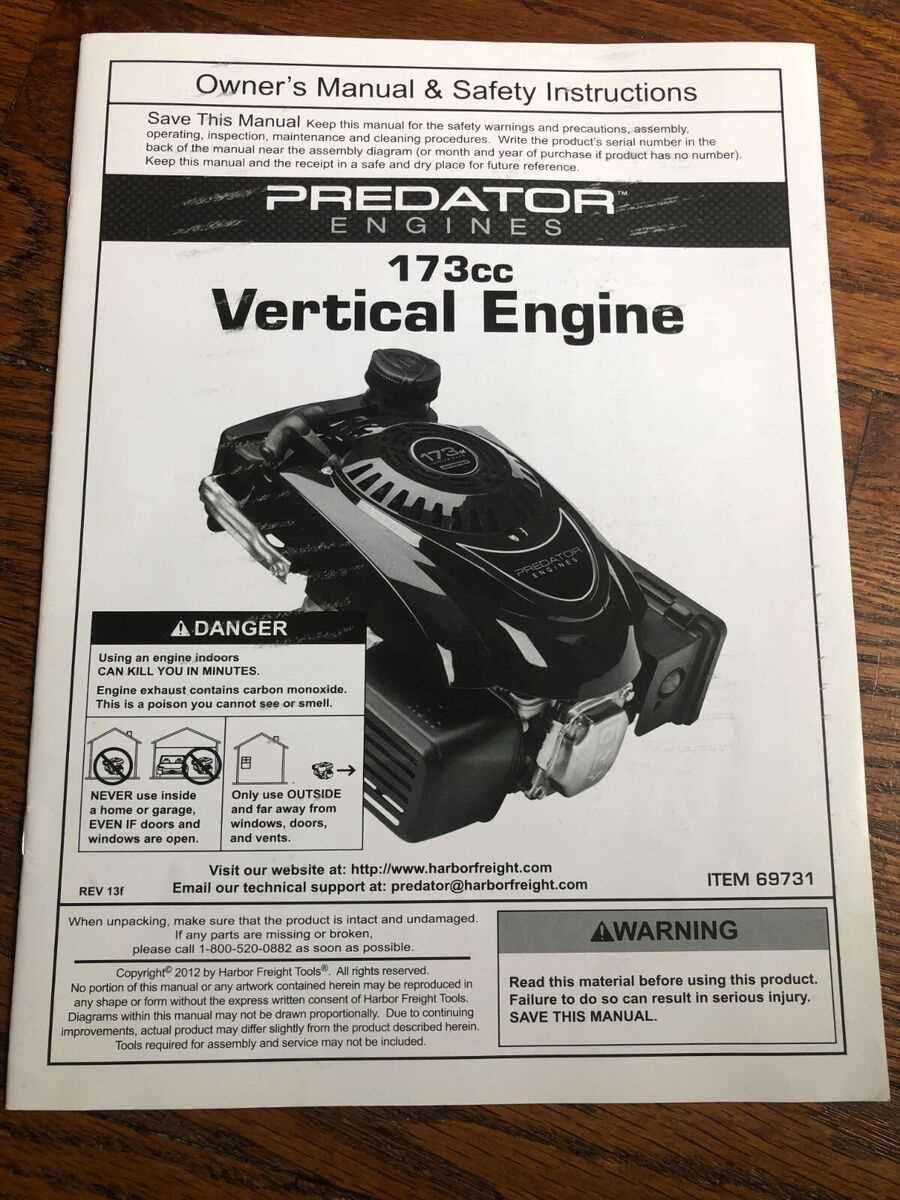

Overview of Predator 173cc Engine

This section provides a comprehensive look into a popular small power unit commonly used in various applications. It encompasses the essential features and functionalities that make this unit a reliable choice for enthusiasts and professionals alike.

Key Features

- Compact design suitable for limited spaces

- High efficiency for optimal performance

- Durable construction to withstand tough conditions

- Easy maintenance and part replacement

Applications

The power unit finds its place in a range of uses, including:

- Go-karts

- Lawn mowers

- Generators

- Pressure washers

With its versatility and robust performance, this small engine continues to be a favorite among users seeking reliable and efficient solutions for their outdoor power needs.

Key Components of the Engine

Understanding the fundamental elements of a small power unit is essential for effective maintenance and optimal performance. Each component plays a vital role in ensuring smooth operation and efficiency. Familiarity with these key elements aids in troubleshooting and enhances the overall lifespan of the machinery.

Fuel System: The fuel system is responsible for delivering the necessary fuel to the combustion chamber. It includes components such as the fuel tank, lines, and filter, ensuring that clean fuel is supplied for efficient operation.

Ignition System: The ignition system is crucial for starting the power unit. It typically consists of a spark plug, ignition coil, and wiring, working together to generate the spark required for combustion.

Cooling System: To prevent overheating, the cooling system regulates the temperature within the power unit. It may involve air or liquid cooling mechanisms, including a cooling fan and radiator, ensuring the components remain within safe temperature ranges.

Lubrication System: Proper lubrication minimizes friction between moving parts, reducing wear and tear. This system includes an oil pump, filter, and reservoir, maintaining the necessary oil levels for smooth operation.

Crankshaft and Piston: The crankshaft converts linear motion from the piston into rotational motion, powering the unit. The piston moves within the cylinder, compressing the fuel-air mixture for combustion, playing a critical role in the overall power generation process.

Understanding Engine Assembly Process

The assembly of a motor involves a series of meticulously organized steps that transform individual components into a cohesive unit. This intricate process requires precision and attention to detail to ensure optimal performance and longevity of the machinery. A clear understanding of the sequential tasks involved can significantly enhance the quality of the final product.

Key Stages of Assembly

Beginning with the preparation of each element, it is essential to clean and inspect them for any defects. The next phase typically involves the installation of the crankshaft, followed by the connecting rods and piston assemblies. Each step must be executed with careful consideration to torque specifications and alignment to prevent future malfunctions.

Finalization and Testing

Upon completion of the initial assembly, the final steps include attaching accessories and ensuring that all fasteners are secured. Afterward, a series of tests are conducted to verify functionality, efficiency, and safety. These evaluations are crucial in confirming that the assembled unit meets the required performance standards before it is put into operation.

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan of your outdoor power equipment. By following a consistent maintenance routine, you can prevent wear and tear, ensuring optimal performance and reliability over time. Here are some key practices to consider.

Routine Checks

- Inspect fuel levels regularly to ensure the machine operates smoothly.

- Check the oil quality and change it as recommended by the manufacturer.

- Examine air filters for dirt and debris, replacing them if necessary.

- Look for signs of corrosion on electrical components and connections.

Seasonal Maintenance

- Before storing the equipment for long periods, clean it thoroughly to remove any dirt and residue.

- Sharpen blades or cutting elements at least once a season to maintain efficiency.

- Check belts and cables for fraying or wear, replacing them as needed.

- Run the equipment periodically during storage to keep all components in good working order.

Common Issues and Troubleshooting

When working with small machinery, users may encounter various challenges that affect performance and efficiency. Understanding these common problems and their solutions is essential for maintaining optimal functionality. This section explores prevalent issues faced by users, along with effective troubleshooting methods to address them.

Fuel-Related Problems

One frequent issue arises from fuel quality and delivery. Stale or contaminated fuel can lead to poor combustion and decreased performance. Checking fuel lines for blockages and ensuring the use of fresh, high-quality fuel can significantly improve operation. Additionally, cleaning the fuel filter should be a regular maintenance task to prevent clogs that hinder flow.

Starting Difficulties

Another common concern is difficulty in starting the machine. This can stem from several factors, including battery issues, faulty spark plugs, or improper choke settings. Users should inspect the spark plug for wear and ensure it is functioning correctly. Adjusting the choke and making sure the battery is charged can also help in resolving starting problems.

Parts Replacement Guidelines

When it comes to maintaining optimal performance in small machinery, ensuring timely replacements is crucial. Regularly updating components not only enhances functionality but also prolongs the lifespan of the entire unit. This section outlines essential recommendations for swapping out various elements, ensuring smooth operation and reliability.

Before initiating any replacements, it is vital to follow these key steps:

| Step | Guideline |

|---|---|

| 1 | Always consult the manufacturer’s manual for specifications on compatible replacements. |

| 2 | Use high-quality components to ensure longevity and performance. |

| 3 | Make sure to turn off and disconnect the power supply before starting any replacement process. |

| 4 | Keep a clean workspace to avoid contamination or damage to new components. |

| 5 | Test the unit thoroughly after replacements to confirm proper functionality. |

Tools Needed for Repairs

To ensure efficient maintenance and repair of small machinery, having the right set of tools is essential. Proper equipment not only facilitates the repair process but also enhances safety and accuracy while working on mechanical components.

Basic Hand Tools: A reliable toolkit should include standard hand tools such as wrenches, pliers, and screwdrivers. These are fundamental for loosening and tightening various fasteners, making them indispensable for any repair job.

Specialized Tools: Depending on the complexity of the task, specialized tools may be required. This could include torque wrenches for precise tightening, socket sets for reaching tight spaces, or specific measuring tools for accurate assessments.

Safety Equipment: Always prioritize safety when working on machinery. Gloves, safety glasses, and masks should be part of your gear to protect against potential hazards during repairs.

Cleaning Supplies: Maintaining cleanliness is vital for effective repairs. Keep cleaning agents, brushes, and cloths on hand to remove dirt and debris, ensuring that all parts are in optimal condition.

Having these essential tools ready will not only streamline the repair process but also contribute to a more productive and safer working environment.

Compatibility with Other Models

When considering whether certain mechanical components can be used across different systems, it is essential to evaluate design similarities and specifications. Many parts share common features that make them suitable for integration into various applications. Understanding the interchangeability between different configurations helps maximize efficiency and reduce costs.

Commonly Compatible Features

- Mounting points and size dimensions

- Standardized connection interfaces

- Uniform power output specifications

Models with Shared Characteristics

Several models within the same category often feature compatible components, allowing for a broader range of applications. These models typically adhere to similar manufacturing standards, ensuring that parts can be swapped or modified as needed without significant adjustments.

- Configurations with matching displacement and performance specs

- Designs using similar cooling and exhaust systems