When it comes to maintaining outdoor power equipment, having a clear understanding of the various components is essential. This section aims to provide an overview of the individual elements found within a widely used chainsaw model, focusing on their functions and interrelations. Knowing these parts can help users troubleshoot issues and perform effective repairs, ensuring that the equipment operates smoothly and efficiently.

Each component plays a vital role in the overall functionality of the machine. From the engine to the cutting system, understanding how these parts work together is crucial for anyone looking to maximize their equipment’s performance. Moreover, familiarity with these elements can significantly enhance the user experience by facilitating easier maintenance and part replacement.

In this guide, we will delve into the specifics of the essential features that make up this chainsaw model. By exploring the design and purpose of each section, users will gain valuable insights that contribute to better care and improved longevity of their equipment.

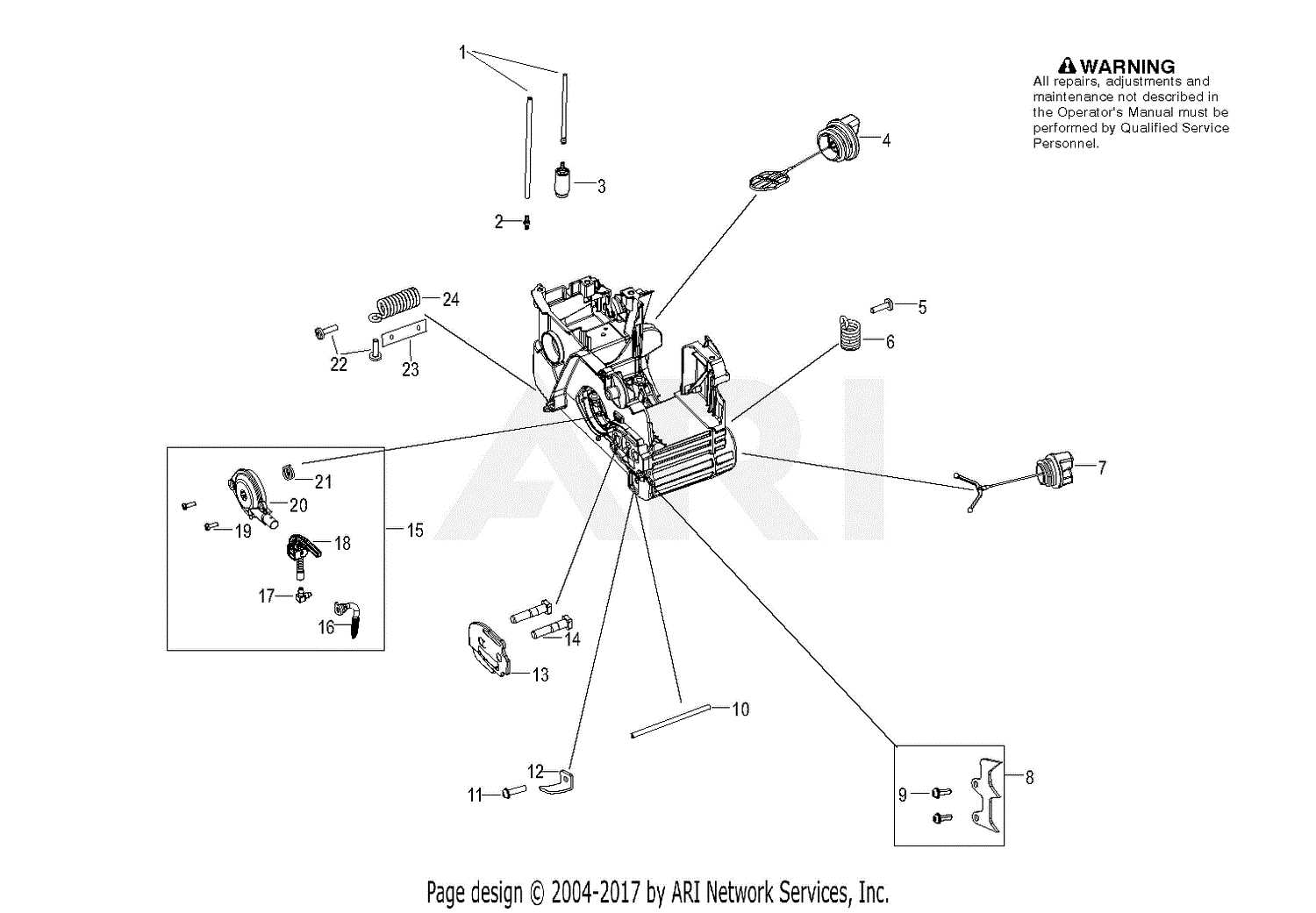

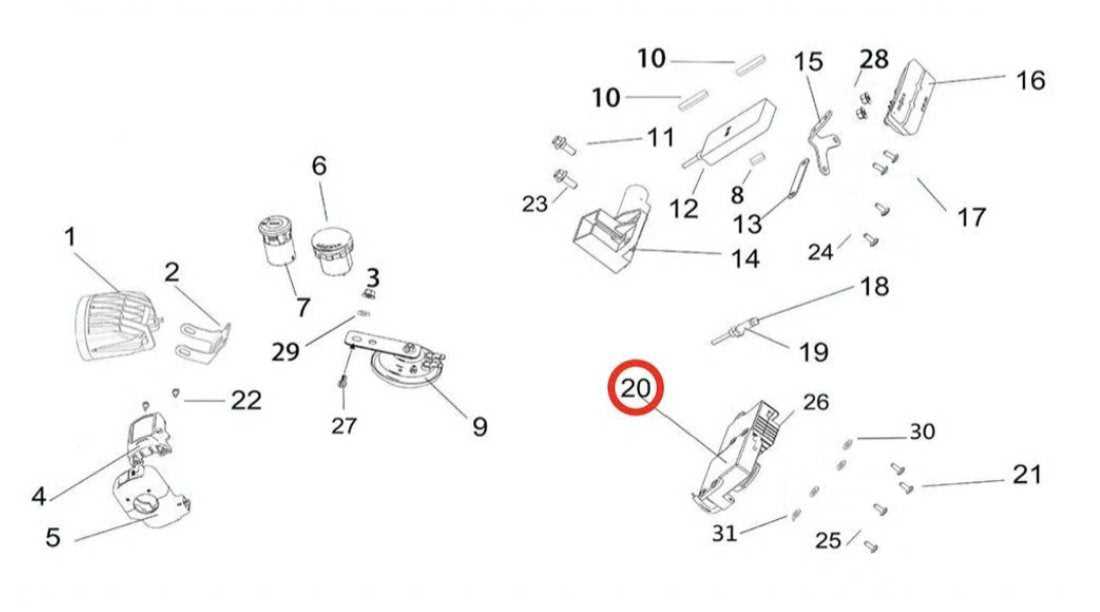

This section delves into the visual representation of components found in various machinery. Such illustrations serve as crucial guides for identifying individual elements, facilitating efficient assembly, maintenance, and troubleshooting processes. A comprehensive view of the various parts enhances the user’s ability to navigate through the equipment effectively.

Having a clear understanding of the layout not only simplifies repairs but also empowers users to perform routine checks with confidence. Each part is typically numbered or labeled, allowing for quick reference during service or when ordering replacements. Familiarity with these visuals can lead to a more seamless experience in managing equipment.

| Component Number | Description | Function |

|---|---|---|

| 1 | Engine | Power source for the machinery. |

| 2 | Fuel Tank | Holds the fuel necessary for operation. |

| 3 | Air Filter | Prevents debris from entering the engine. |

| 4 | Blade Assembly | Primary cutting component for tasks. |

| 5 | Starter Mechanism | Engages the engine to initiate operation. |

Common Replacement Parts Available

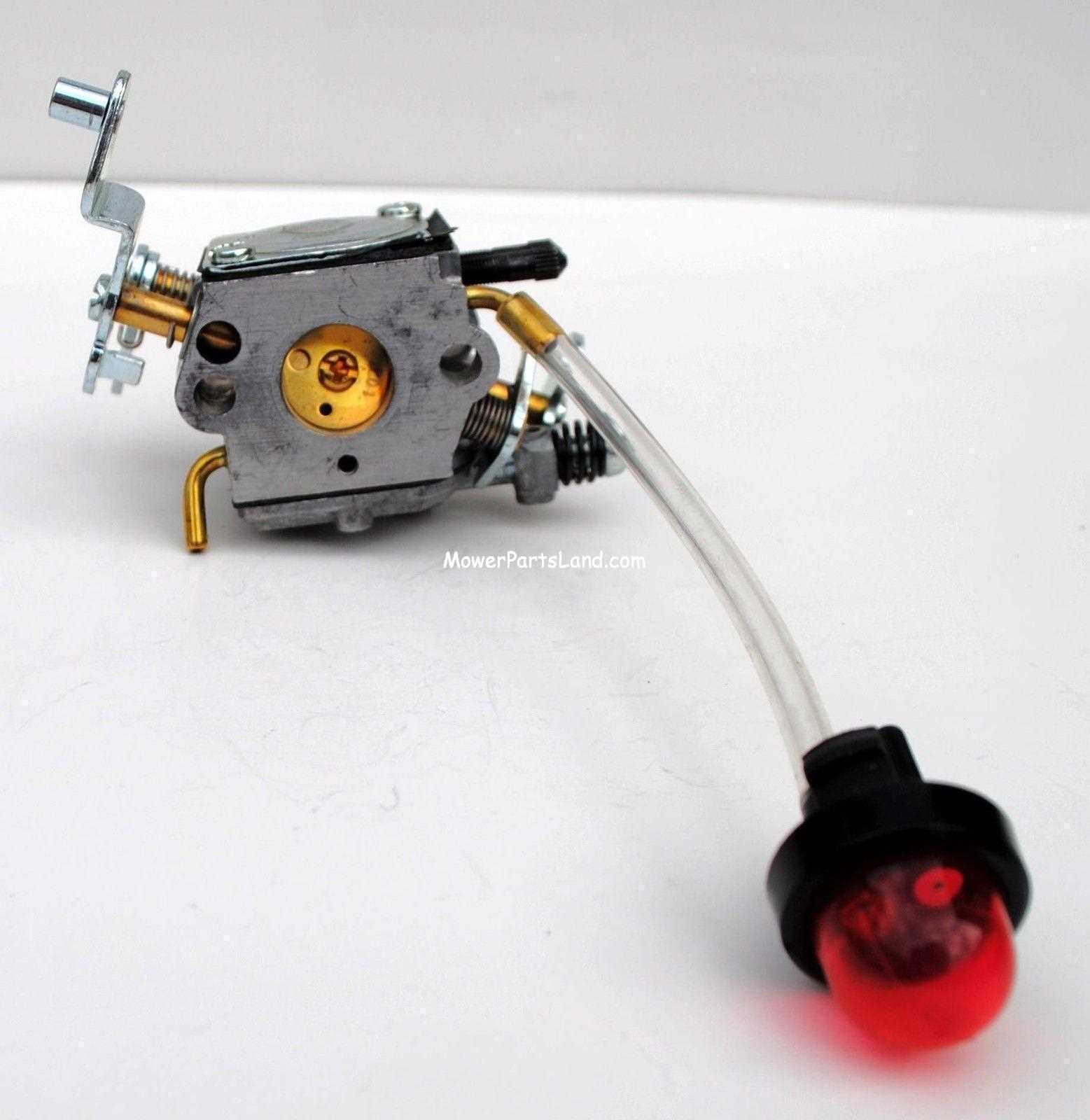

When maintaining or repairing outdoor power equipment, it’s essential to know the frequently needed components. These elements ensure the functionality and longevity of the machine, making it crucial to replace them when necessary. Here, we outline the typical replacement components available for your convenience.

| Component | Description | Function |

|---|---|---|

| Air Filter | Cleans the air entering the engine | Prevents debris from damaging internal components |

| Spark Plug | Ignites the air-fuel mixture in the combustion chamber | Ensures efficient engine operation |

| Fuel Filter | Removes impurities from fuel before reaching the engine | Protects the engine from contaminants |

| Starter Rope | Used to start the engine manually | Provides the initial crank for engine ignition |

| Chain Bar | Supports the cutting chain during operation | Ensures stability and proper cutting action |

Tools Required for Maintenance

Regular upkeep of outdoor equipment is essential for ensuring optimal performance and longevity. Utilizing the correct instruments during maintenance tasks can significantly simplify the process and enhance the effectiveness of the work performed. Below is a list of necessary tools that can assist in maintaining your machinery efficiently.

Essential Hand Tools

Having the right hand tools on hand is crucial. Items such as wrenches, screwdrivers, and pliers are fundamental for performing various adjustments and repairs. A set of quality tools can facilitate quick and precise work, ensuring that components are secured and aligned correctly.

Protective Gear

Safety should always be a priority during maintenance activities. Utilizing protective gear, including gloves, goggles, and ear protection, can help prevent injuries. Being equipped with proper safety equipment allows for a more focused and secure working environment.

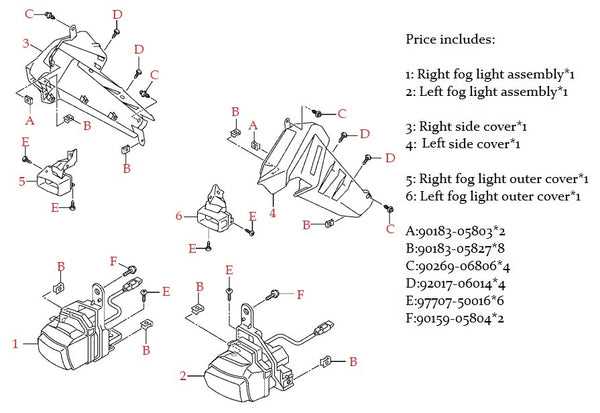

Assembly Instructions for Key Components

This section provides essential guidance for assembling critical elements of the equipment. Proper installation is vital for optimal performance and longevity, ensuring that each component functions seamlessly within the overall system. Follow these instructions carefully to avoid any complications during the assembly process.

| Component | Assembly Steps | Notes |

|---|---|---|

| Engine | 1. Align the engine with the mounting brackets. 2. Secure it using the provided bolts. 3. Connect the fuel lines as specified. |

Ensure the engine is properly aligned to avoid misalignment. |

| Handle | 1. Attach the handle to the main body. 2. Tighten the screws to secure it in place. |

Verify that the handle is firmly fixed to ensure stability. |

| Blade Assembly | 1. Place the blade onto the spindle. 2. Use the locking nut to secure the blade tightly. |

Check for any play in the blade to prevent accidents during operation. |

Troubleshooting Common Issues

Identifying and resolving frequent problems can enhance the performance and longevity of your equipment. By understanding typical malfunctions and their causes, users can take proactive measures to ensure smooth operation. This section aims to provide guidance on common challenges faced during usage.

Engine Won’t Start: If the engine fails to ignite, check the fuel level and ensure that it is fresh. Old or contaminated fuel can hinder starting. Additionally, inspect the spark plug for wear and replace it if necessary.

Excessive Vibration: Unusual vibrations may indicate a loose or damaged component. Ensure that all screws and bolts are secure. If the issue persists, examine the cutting attachment for any signs of damage.

Loss of Power: A decrease in power output can result from a clogged air filter or muffler. Regularly cleaning or replacing these components can restore optimal performance.

Difficulty with Throttle Response: If the throttle does not respond smoothly, it may be a sign of a faulty throttle cable or a buildup of debris in the carburetor. Cleaning these areas can often resolve the issue.

Where to Purchase Authentic Parts

When it comes to maintaining outdoor equipment, sourcing genuine components is essential for optimal performance and longevity. Authentic pieces ensure compatibility and reliability, preventing potential issues that can arise from using substandard alternatives. Understanding where to find these quality items can significantly impact the overall functionality of your machinery.

Official Retailers and Distributors

One of the best ways to acquire original components is through authorized retailers and distributors. These establishments typically offer a wide selection of certified products, ensuring that customers receive items that meet manufacturer standards. Visiting a local dealer not only provides access to quality parts but also expert advice on installation and maintenance.

Online Marketplaces

Another convenient option is to explore various online marketplaces. Many reputable websites specialize in genuine components, often featuring customer reviews and ratings that can help guide your purchasing decisions. When shopping online, it’s crucial to verify the seller’s credibility and ensure they offer return policies for added security.

Customer Reviews and Feedback

This section focuses on the insights and evaluations shared by users regarding their experiences with a specific outdoor power equipment model. Reviews often reflect the performance, reliability, and overall satisfaction levels of customers, providing valuable information for potential buyers. By analyzing customer opinions, it becomes easier to identify the strengths and weaknesses of the product, helping others make informed decisions.

Performance Insights

Users frequently highlight the effectiveness and efficiency of the equipment in various tasks. Many customers appreciate its power and ability to handle demanding jobs with ease. Positive feedback often includes remarks on its durability and the consistent results it delivers, making it a preferred choice among outdoor enthusiasts.

Areas for Improvement

While the majority of reviews are favorable, some customers have pointed out aspects that could be enhanced. Common concerns include issues related to maintenance and specific features that may not meet user expectations. Constructive criticism from users serves as a guide for manufacturers, emphasizing the importance of continuous improvement in product design and functionality.