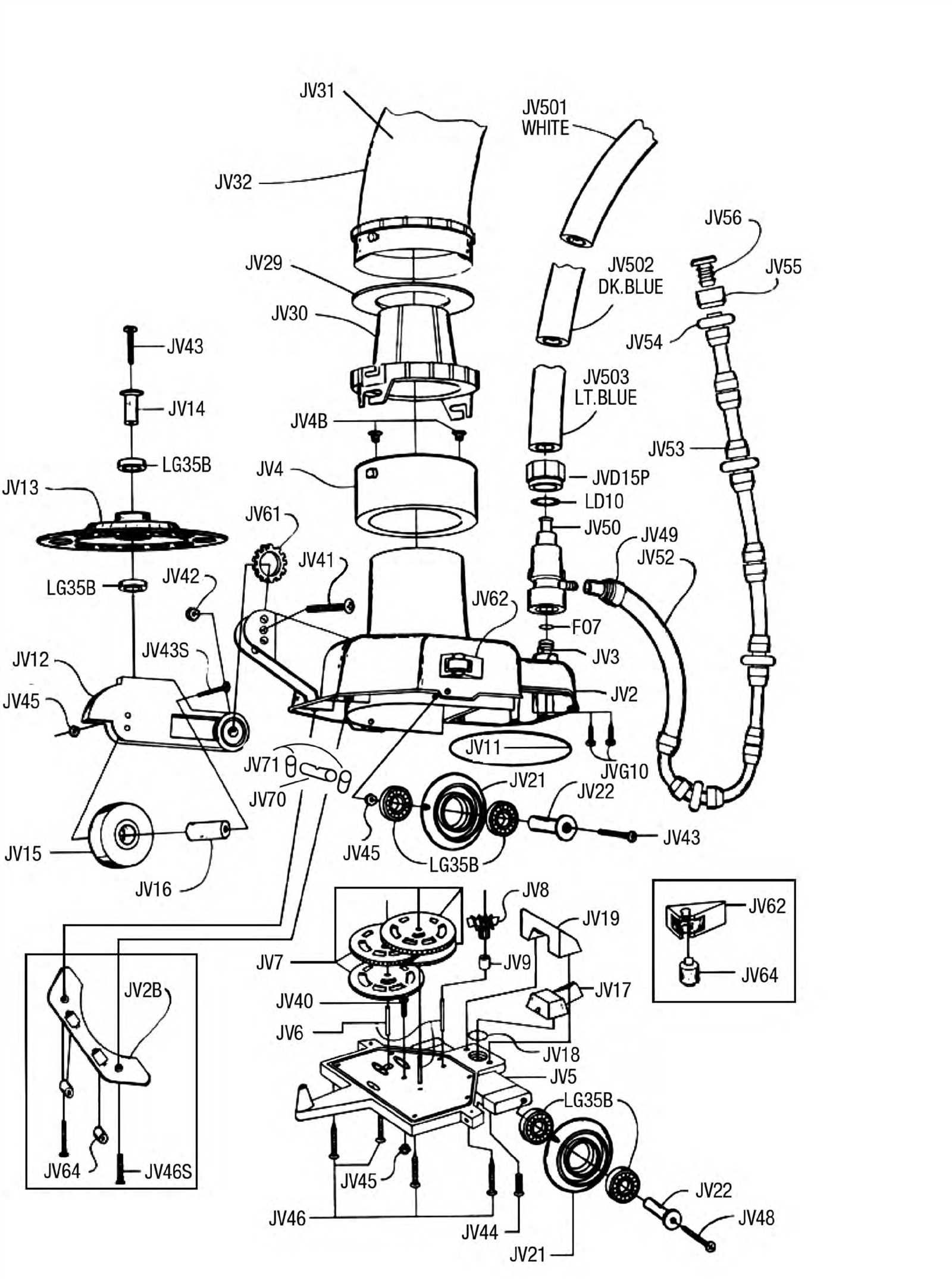

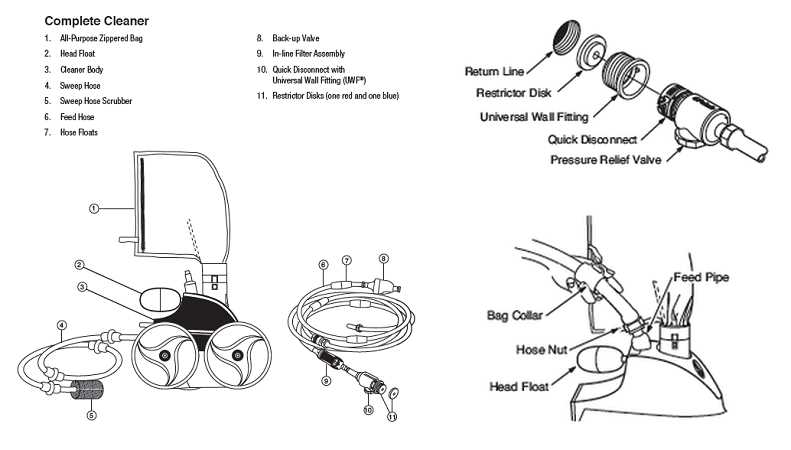

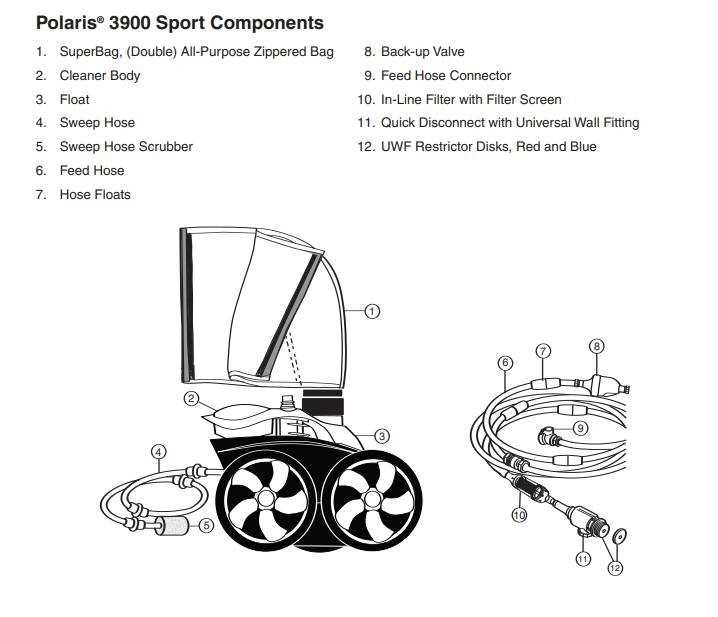

In the realm of outdoor machinery, having a clear visual reference for components is essential for both maintenance and repair. Whether you are a seasoned technician or a casual user, familiarity with the intricate layout of each element can significantly enhance your efficiency and understanding of the unit’s operation.

Every mechanical system comprises numerous intricate pieces that work in unison to deliver optimal performance. Gaining insights into these elements not only streamlines troubleshooting but also empowers users to undertake necessary adjustments with confidence. With a structured representation, the complexity of these systems becomes more manageable, allowing for easier navigation and identification.

For anyone looking to optimize their equipment’s longevity and functionality, having access to a detailed schematic is invaluable. This resource serves as a roadmap, guiding users through the various sections and highlighting the relationship between components. Embracing such knowledge fosters a proactive approach to care and maintenance, ensuring that your machinery remains in peak condition.

Understanding Polaris 3900 Parts Diagram

Comprehending the intricate layout of components for any machine is crucial for maintenance and repair. Familiarity with these schematics not only aids in identifying individual elements but also enhances overall functionality. By delving into this subject, users can ensure their devices operate smoothly and efficiently.

Key Benefits of Understanding Component Layouts

- Enhanced Maintenance: Recognizing each component facilitates timely upkeep.

- Efficient Repairs: Quick identification of faulty parts leads to faster resolutions.

- Improved Performance: Knowledge of how parts interact can optimize overall operation.

Common Elements in Component Schematics

- Labels: Each part is usually identified with a specific label for easy reference.

- Connections: Understanding how components connect helps in troubleshooting issues.

- Dimensions: Knowing the size of each part can assist in finding appropriate replacements.

By mastering the layout of these elements, users can not only improve their understanding of the machinery but also extend its lifespan through informed care and proactive measures.

Importance of Accurate Parts Identification

Precise recognition of components is crucial for the maintenance and functionality of any mechanical system. An accurate understanding of each element ensures efficient repairs, reduces downtime, and enhances overall performance. Without proper identification, users may face unnecessary complications and increased costs.

Benefits of Accurate Component Recognition

- Efficiency: Quick and correct identification speeds up the repair process.

- Cost Savings: Reduces the risk of purchasing incorrect items, avoiding wasted resources.

- Safety: Ensures that the right components are used, preventing potential hazards.

- Longevity: Correct parts contribute to the extended life of machinery.

Challenges of Incorrect Identification

- Increased Downtime: Misidentified components can lead to delays in repairs.

- Higher Expenses: Errors in ordering can result in financial loss due to return processes.

- Performance Issues: Incompatible elements can compromise the system’s functionality.

Accurate identification of each component is essential for optimal operation and maintenance, making it a foundational aspect of effective management in any mechanical endeavor.

Common Issues with Polaris 3900 Models

Many users encounter a range of challenges with these popular aquatic cleaning devices. Understanding the most frequent problems can help in troubleshooting and maintenance, ensuring optimal performance and longevity. Below are some of the key issues that may arise during use.

Clogging: One of the most prevalent concerns is clogging in the filtration system. Debris can accumulate, reducing efficiency and hindering the cleaning process. Regular maintenance and inspection of the intake and filtration components are essential to prevent this issue.

Battery Life: Users often report diminished battery performance over time. This can lead to shorter operational periods and may require battery replacement. Proper charging practices and usage can help extend battery lifespan.

Navigation Problems: Malfunctioning navigation sensors can cause the device to struggle with movement, impacting its ability to cover the entire area effectively. Checking and cleaning the sensors regularly can mitigate these issues.

Wear and Tear: Components may experience wear due to regular use, affecting overall functionality. Keeping an eye on parts such as wheels, brushes, and belts will help in identifying when replacements are necessary to maintain peak performance.

Water Leakage: Occasionally, users notice water leaking from the unit. This may indicate issues with seals or internal components. Addressing these leaks promptly is crucial to avoid further damage.

By being aware of these common issues, users can take proactive steps in maintenance and repairs, ensuring their devices continue to operate smoothly and efficiently.

Where to Find Parts Diagrams Online

Locating detailed visual representations of components for various machines can greatly simplify the repair and maintenance process. These illustrations are essential for identifying individual elements and understanding how they fit together. Fortunately, numerous resources are available online to assist enthusiasts and professionals alike in their search for these valuable guides.

Official Manufacturer Websites

One of the most reliable sources for accurate representations is the official websites of manufacturers. These platforms often provide comprehensive catalogs and user manuals that include detailed illustrations of the equipment. By navigating to the support or resources section, users can access a wealth of information tailored specifically to their models.

Online Retailers and Forums

In addition to manufacturer sites, online retailers specializing in machinery and equipment often feature visual guides. Community forums dedicated to specific types of machinery can also be invaluable. Members frequently share links to diagrams or upload their own, creating a collaborative environment for troubleshooting and repair.

In conclusion, leveraging these online resources can enhance your understanding of machine components and facilitate smoother maintenance tasks. Whether through official sites or community contributions, finding the right visual aids has never been easier.

Step-by-Step Guide to Repair

This section provides a detailed approach to troubleshooting and fixing your equipment efficiently. By following a structured process, you can identify issues and apply effective solutions, ensuring optimal performance and longevity.

Preparation Phase

- Gather necessary tools and materials.

- Review the user manual for specific guidelines.

- Ensure a clean and organized workspace.

Repair Process

- Identify the problem by observing symptoms.

- Disconnect power sources to ensure safety.

- Inspect components for wear and damage.

- Replace or repair faulty parts as needed.

- Reassemble the unit carefully, following the reverse order of disassembly.

- Test the equipment to confirm successful repairs.

By adhering to this systematic approach, you can effectively restore functionality and extend the lifespan of your device.

Comparing Original and Aftermarket Parts

When it comes to maintaining and upgrading machinery, the choice between genuine components and alternatives is a critical decision. Each option presents distinct advantages and disadvantages that can significantly impact performance, longevity, and cost-effectiveness.

Original components are designed specifically for the equipment, ensuring compatibility and reliability. Here are some of their key benefits:

- Quality Assurance: These items undergo rigorous testing to meet manufacturer standards.

- Perfect Fit: Tailored design ensures seamless integration with existing systems.

- Warranty Coverage: Often come with extended warranties that protect your investment.

On the other hand, aftermarket alternatives can be appealing for various reasons:

- Cost Savings: Typically priced lower than their original counterparts, making them budget-friendly.

- Variety: A wide range of options can cater to specific needs or preferences.

- Innovation: Some alternatives may offer enhanced features or improved performance.

Ultimately, the decision should consider factors such as budget, intended use, and desired performance. Weighing the pros and cons of each type can lead to a more informed choice, ensuring optimal functionality and satisfaction with your equipment.

Tips for Maintaining Your Polaris 3900

Proper upkeep of your cleaning device is essential for optimal performance and longevity. By following a few simple guidelines, you can ensure that your equipment runs smoothly and efficiently, providing you with consistently excellent results.

- Regularly inspect the components for wear and tear, replacing any damaged parts promptly.

- Clean the filters and brushes regularly to prevent blockages and maintain suction power.

- Check the hoses for kinks or clogs that could impede functionality.

Additionally, it is advisable to keep the device free of debris and dirt. This not only helps with performance but also extends the life of the unit.

- Before each use, remove any large objects from the area to avoid damage.

- After each session, rinse the unit to eliminate any residue that may accumulate.

- Store the device in a dry, cool place to prevent any moisture-related issues.

Implementing these maintenance tips will help keep your equipment in top shape, ensuring it operates effectively for years to come.

How to Read Technical Diagrams

Understanding technical illustrations is essential for effective assembly, maintenance, and troubleshooting of various machinery. These visuals provide crucial information about components, their arrangements, and functions. Mastering the art of interpreting these graphics can significantly enhance your ability to work with complex systems.

To begin, familiarize yourself with common symbols and conventions used in these illustrations. Each representation carries specific meanings that can clarify the relationships between parts.

- Symbols: Learn the standard icons representing different elements, such as connectors, fasteners, and electrical components.

- Lines: Pay attention to the types of lines–solid, dashed, or dotted–as they indicate various types of connections or pathways.

- Labels: Read all labels carefully; they often include vital information about component specifications or operational parameters.

Next, consider the layout of the illustration. An organized structure often reveals how components interact within the overall system.

- Hierarchy: Identify the main elements and their subordinate components to grasp the overall functionality.

- Flow: Trace the lines or arrows that depict the flow of processes, which can help you understand how parts work together.

- Sections: Look for any sectional views that provide insights into the internal structure of more complex assemblies.

Lastly, practice is key. Regularly consulting these visuals while working will help reinforce your understanding and improve your efficiency in handling various tasks.

Frequently Asked Questions About Components

This section addresses common inquiries regarding the various elements that make up your vehicle’s assembly. Understanding these inquiries can help streamline maintenance and ensure optimal performance.

Common Questions

- What should I consider when choosing replacements?

- How can I identify a malfunctioning element?

- Are there any compatibility issues with different models?

Maintenance Tips

- Regularly inspect components for wear and tear.

- Use manufacturer-recommended items for replacements.

- Keep detailed records of all installed parts.