The effective operation of various water treatment solutions depends heavily on the proper arrangement and maintenance of their individual elements. Understanding the layout of internal mechanisms ensures smooth functionality and prevents potential disruptions.

Efficient component management allows for timely replacements and adjustments, extending the service life of the system. Each detail, whether it’s a valve, cartridge, or seal, plays a crucial role in maintaining optimal performance.

Familiarity with specific system elements helps users identify potential issues and handle routine maintenance with confidence. A thorough examination of the equipment’s internal structure promotes better upkeep and reduces downtime, ensuring continuous operation.

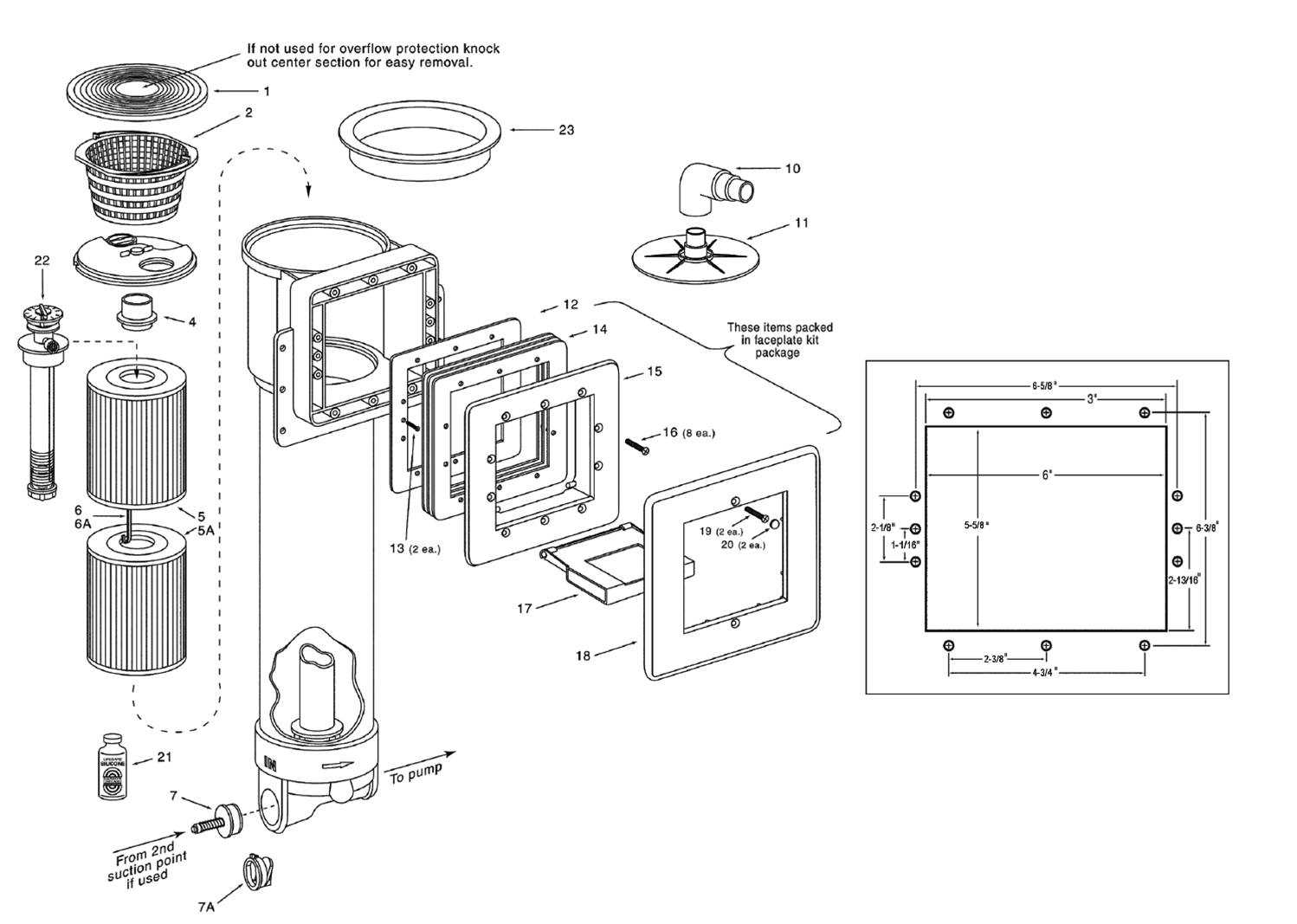

Pentair Rainbow 320 Parts Diagram

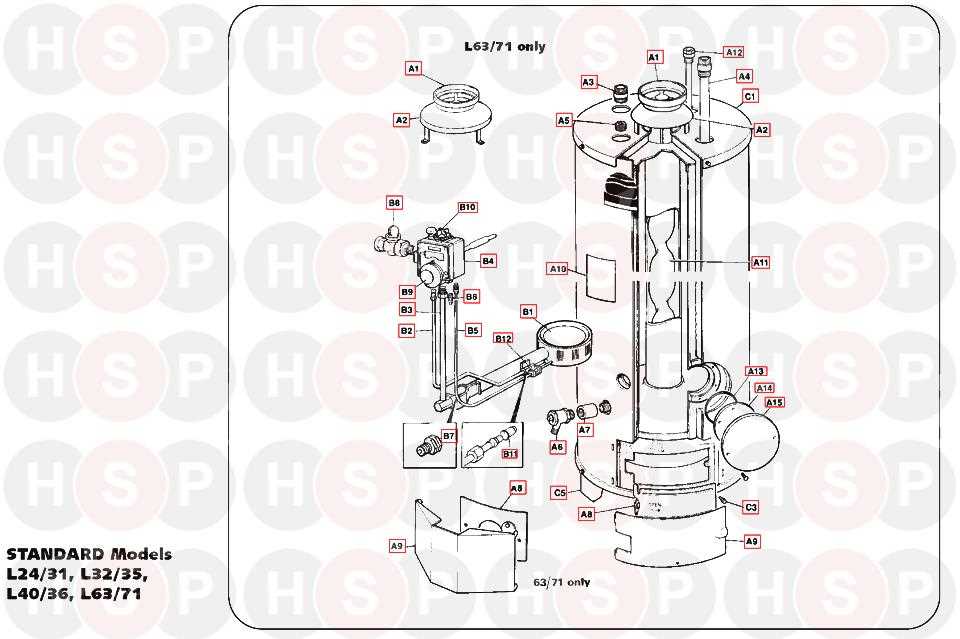

The section explores the components and structure of a device commonly found in water treatment systems. Understanding its internal design helps users ensure proper maintenance and efficient operation, extending the lifespan of the equipment.

Overview of Essential Components

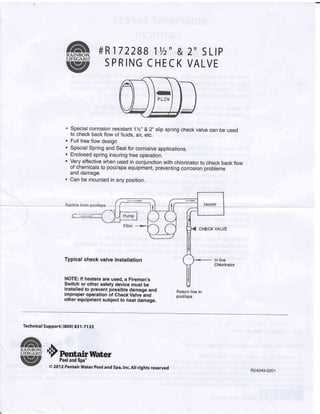

Key elements include a flow regulator, sealing rings, and an adjustable control valve. Each part plays a crucial role in ensuring smooth water circulation and precise chemical distribution throughout the system.

Maintenance and Replacement Guidelines

Regular inspection of gaskets and seals can prevent leaks, while timely replacement of worn components helps maintain performance. A control valve in good condition allows for precise adjustments, optimizing efficiency and safety.

Main Components Overview

The structure of this equipment relies on several interconnected elements designed to ensure smooth operation and long-lasting performance. Each component plays a crucial role in maintaining functionality, contributing to both safety and efficiency.

Flow Control Unit

This section regulates the movement of fluids, ensuring the correct amount reaches the intended destination. It helps prevent blockages and supports consistent circulation, keeping the system balanced and operating optimally.

Sealing Mechanism

A properly functioning sealing mechanism is essential to prevent leaks and maintain pressure. Built to withstand various conditions, it protects internal components from external contaminants while minimizing wear over time.

How to Identify Key Elements

Understanding the essential components of a system allows for better maintenance and troubleshooting. Recognizing the primary elements helps users ensure optimal functionality and prevents potential failures.

First, analyze the system’s layout. Look for distinctive sections such as control units, connectors, or flow mechanisms. These sections often contain essential elements that influence the system’s operation.

Next, identify unique markers or labels. Many parts are marked with specific codes or symbols to indicate their role within the structure. Comparing these labels with reference materials can speed up the identification process.

Finally, examine the materials and connections. Some key elements are made from unique materials to ensure durability. Noticing patterns in how components link together can also reveal which parts are critical for smooth operation.

Installation Tips for Efficient Setup

Proper installation ensures optimal functionality and long-term reliability. A structured approach helps prevent common issues and saves time during maintenance. Below are essential guidelines to streamline the setup process and enhance equipment performance.

- Read the user manual carefully to understand the assembly process and all included components.

- Ensure that all tools and materials required for installation are prepared in advance.

- Place the equipment in a location with easy access for future inspections and maintenance.

- Verify that all seals and connections are secure to avoid leaks or performance issues.

- Follow local codes and safety regulations to ensure compliance and safe operation.

- Test the system after installation to confirm

Signs of Wear and Replacement Advice

Regular maintenance of equipment is essential for ensuring smooth operation and preventing unexpected failures. Identifying early signs of deterioration allows for timely intervention, reducing the risk of costly repairs and downtime. This section provides practical tips on recognizing wear and knowing when to replace components.

Common Indicators of Wear

Over time, various elements of the system may begin to degrade due to exposure to environmental factors or continuous usage. Look out for the following symptoms:

- Visible cracks, corrosion, or discoloration

- Unusual sounds such as squeaking or grinding

- Reduced efficiency or output performance

- Leaks or moisture buildup in unexpected areas

- Inconsistent pressure or flow rates

Proper Maintenance for Long-Term Use

Ensuring the longevity of your equipment requires consistent care and attention. Regular upkeep not only enhances performance but also prolongs the lifespan of components, preventing premature wear and costly repairs. Adopting a systematic approach to maintenance can yield significant benefits, making it essential for all users to understand and implement effective practices.

Regular Cleaning

Routine cleaning is crucial in maintaining optimal functionality. Accumulation of debris and contaminants can hinder performance and lead to malfunctions. It’s advisable to follow the manufacturer’s recommendations for cleaning procedures, using suitable tools and products that won’t cause damage.

Inspection and Replacement

Periodic inspection of components is vital. Identifying signs of wear or damage early allows for timely replacement, ensuring that all parts operate efficiently. Establishing a schedule for these checks will help maintain peak performance and avoid unexpected breakdowns.

Comparing Models and Versions

When examining various models within a specific product line, it is essential to consider the distinctions in design and functionality that may affect user experience. Each iteration often brings enhancements or modifications aimed at improving performance and user satisfaction.

Key factors to consider when comparing different versions include:

- Design Changes: Variations in the exterior may influence usability and aesthetics.

- Technical Specifications: Updates in features such as motor power, filtration capabilities, and control systems can significantly affect efficiency.

- Accessories Compatibility: Not all models may support the same attachments or additional components, which can limit functionality.

- Maintenance Requirements: Some versions may require more frequent upkeep or specific tools for maintenance tasks.

Ultimately, assessing these aspects will guide users in selecting the most suitable option for their needs, ensuring optimal performance and satisfaction with their purchase.

Common Issues and Quick Solutions

In the realm of cleaning equipment, users often encounter various challenges that can disrupt their experience. Recognizing these common problems and understanding how to resolve them promptly can significantly enhance efficiency and satisfaction. Below are some prevalent issues and their respective solutions to ensure optimal performance.

- Clogged Filters: Blockages can hinder functionality and reduce effectiveness.

- Regularly check and clean filters to maintain airflow.

- Replace worn-out filters as needed.

- Poor Suction: Insufficient suction can stem from several factors.

- Inspect hoses for leaks or blockages.

- Ensure the motor is functioning correctly and has power.

- Examine moving parts for wear or misalignment.

- Lubricate components that require it to reduce friction.

- Check the battery charge level regularly.

- Replace old batteries to ensure optimal operation.

By staying proactive and addressing these common issues swiftly, users can ensure their cleaning equipment operates smoothly and efficiently.

Where to Find Compatible Parts

Locating suitable components for your equipment can enhance its performance and extend its lifespan. Various resources are available for finding the right replacements that fit seamlessly with your model. Understanding where to search will make the process more efficient and effective.

Online Retailers

Numerous online platforms specialize in offering a wide range of compatible components. These websites often provide detailed descriptions and specifications, making it easier to identify the right items. Additionally, customer reviews can help guide your purchasing decisions.

Local Distributors

Visiting local suppliers can be advantageous, especially if you prefer to examine items in person. Many distributors maintain stock of commonly needed components and can provide expert advice on compatibility and installation.

| Resource Type | Advantages |

|---|---|

| Online Retailers | Convenience, wide selection, customer reviews |

| Local Distributors | In-person assistance, immediate availability, expert advice |