In any efficient water circulation system, a comprehensive understanding of its integral components is crucial for optimal performance. Each element plays a specific role in ensuring the smooth operation and longevity of the entire system. By familiarizing oneself with the arrangement and function of these components, users can significantly enhance their maintenance strategies and troubleshoot issues more effectively.

Visual aids, such as schematics, serve as valuable tools for both novice and experienced users. They provide a clear representation of how various elements interact within the system, facilitating a deeper comprehension of its mechanics. This not only empowers users to carry out repairs and replacements confidently but also minimizes downtime and improves overall efficiency.

Moreover, recognizing the significance of each component allows for informed decision-making when it comes to upgrades or replacements. Understanding the intricate relationships between different elements can lead to better choices that enhance the system’s performance and sustainability. This knowledge is an invaluable asset for anyone involved in the maintenance or improvement of water circulation systems.

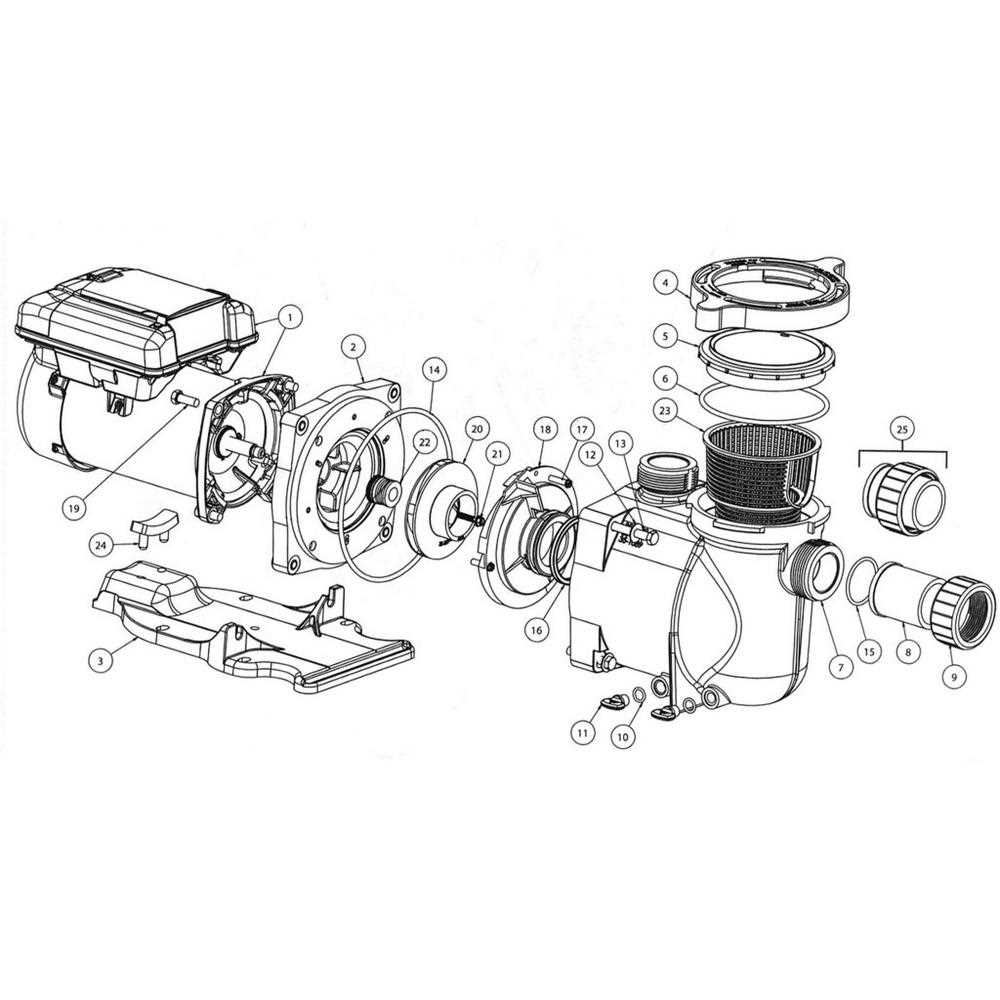

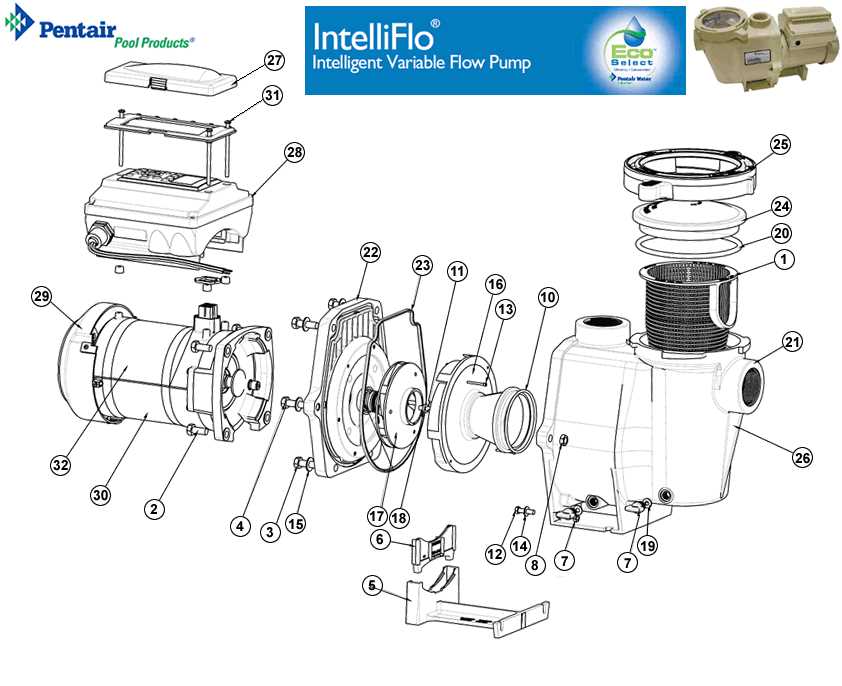

Pentair Challenger Pump Overview

This section provides a comprehensive overview of a reliable and efficient water circulation device widely used in residential and commercial settings. Known for its robust design and high performance, this equipment plays a crucial role in maintaining optimal water quality and flow in swimming pools and various aquatic environments.

The following key features highlight the advantages of this remarkable apparatus:

- Durability: Constructed with high-quality materials to withstand harsh conditions.

- Energy Efficiency: Designed to minimize energy consumption while maximizing output.

- Quiet Operation: Engineered for low noise levels, ensuring a peaceful environment.

- Easy Maintenance: Simple access to components for routine checks and repairs.

In addition, the equipment offers various models tailored to different needs, making it versatile for diverse applications. Users benefit from:

- Enhanced water flow management.

- Improved filtration processes.

- Long-lasting performance with minimal downtime.

This advanced machinery stands out as a dependable choice for those seeking to optimize their water systems, ensuring both functionality and reliability in everyday use.

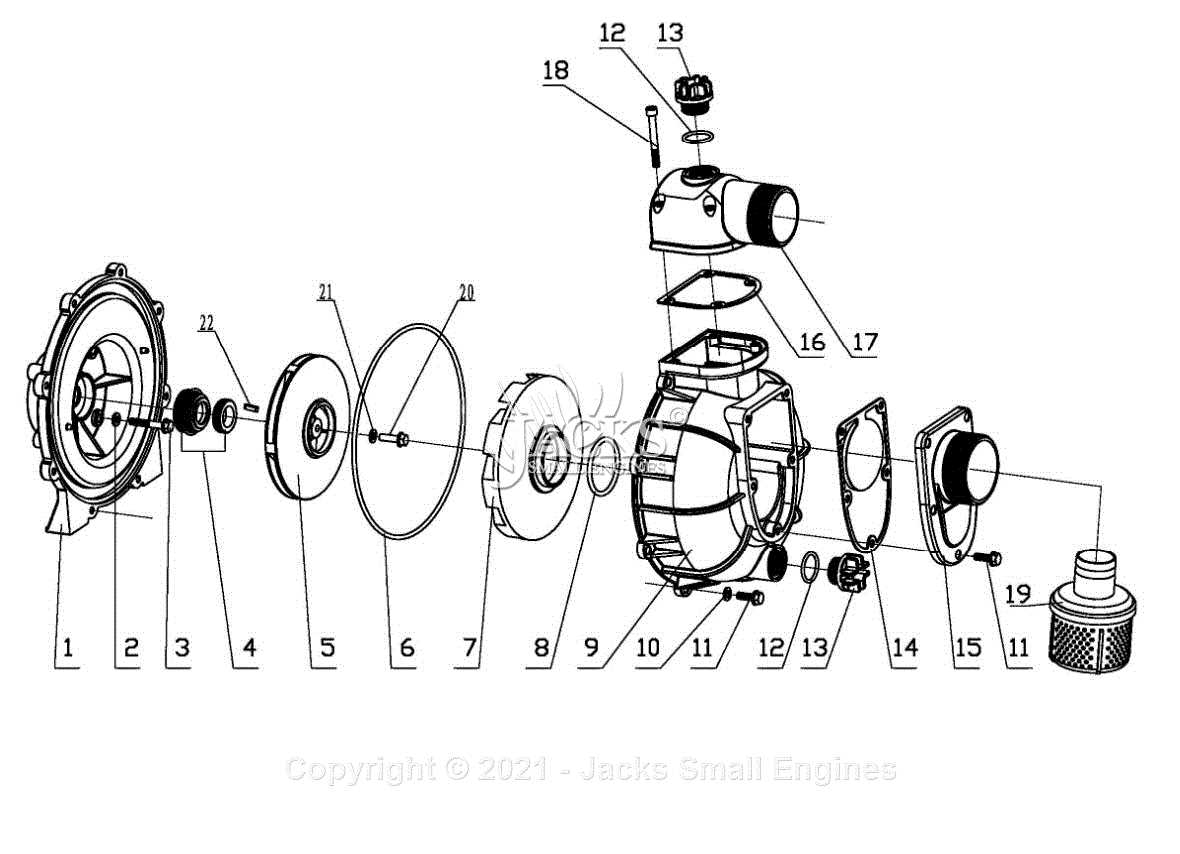

Key Components of the Pump

Understanding the essential elements of a hydraulic system is crucial for its optimal performance. Each component plays a significant role in ensuring efficient operation and longevity. This section delves into the primary elements that contribute to the functionality and reliability of the system.

Motor Assembly

The motor assembly serves as the heart of the mechanism, providing the necessary energy for operation. This component transforms electrical energy into mechanical energy, driving the entire system. Its efficiency directly influences the overall performance, making it vital to choose a high-quality motor for seamless functionality.

Impeller and Diffuser

Within the system, the impeller is responsible for moving fluid through the mechanism. It generates flow by converting rotational energy into kinetic energy. The diffuser then plays a critical role in transforming this kinetic energy into pressure, enabling effective circulation. Proper maintenance of these components is essential for preventing wear and ensuring optimal fluid dynamics.

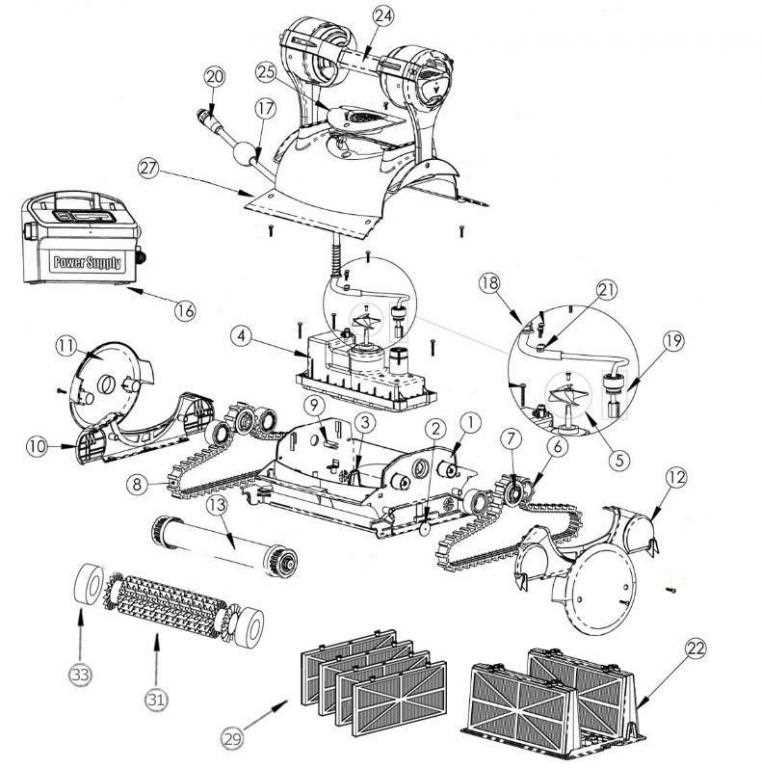

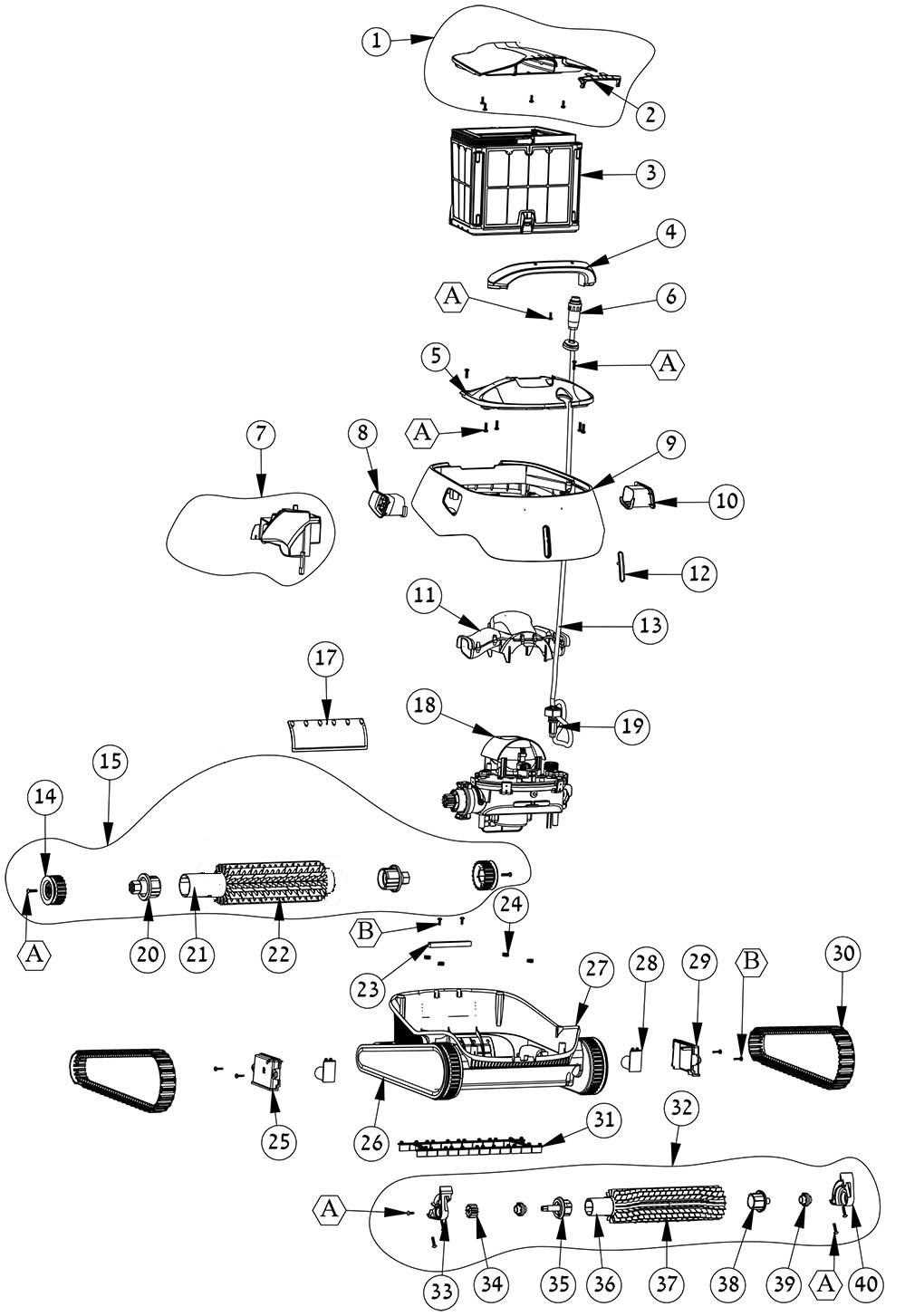

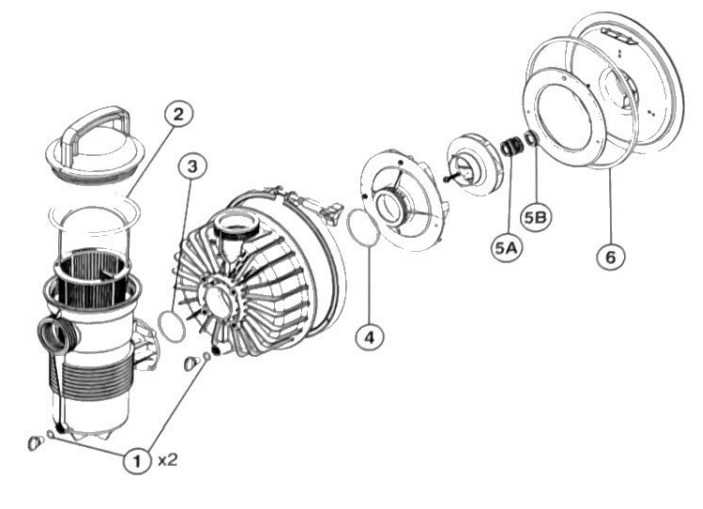

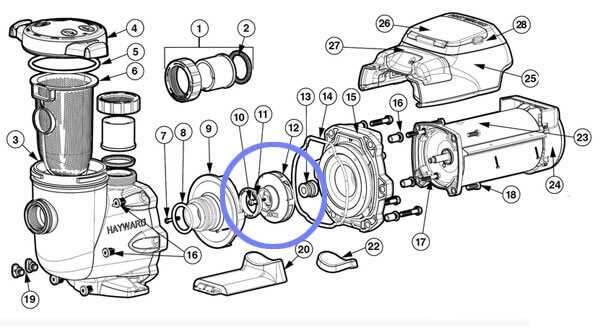

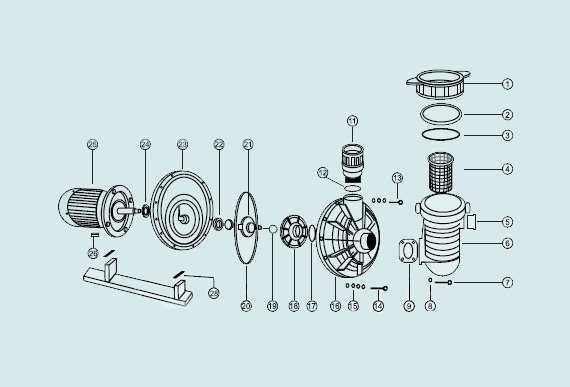

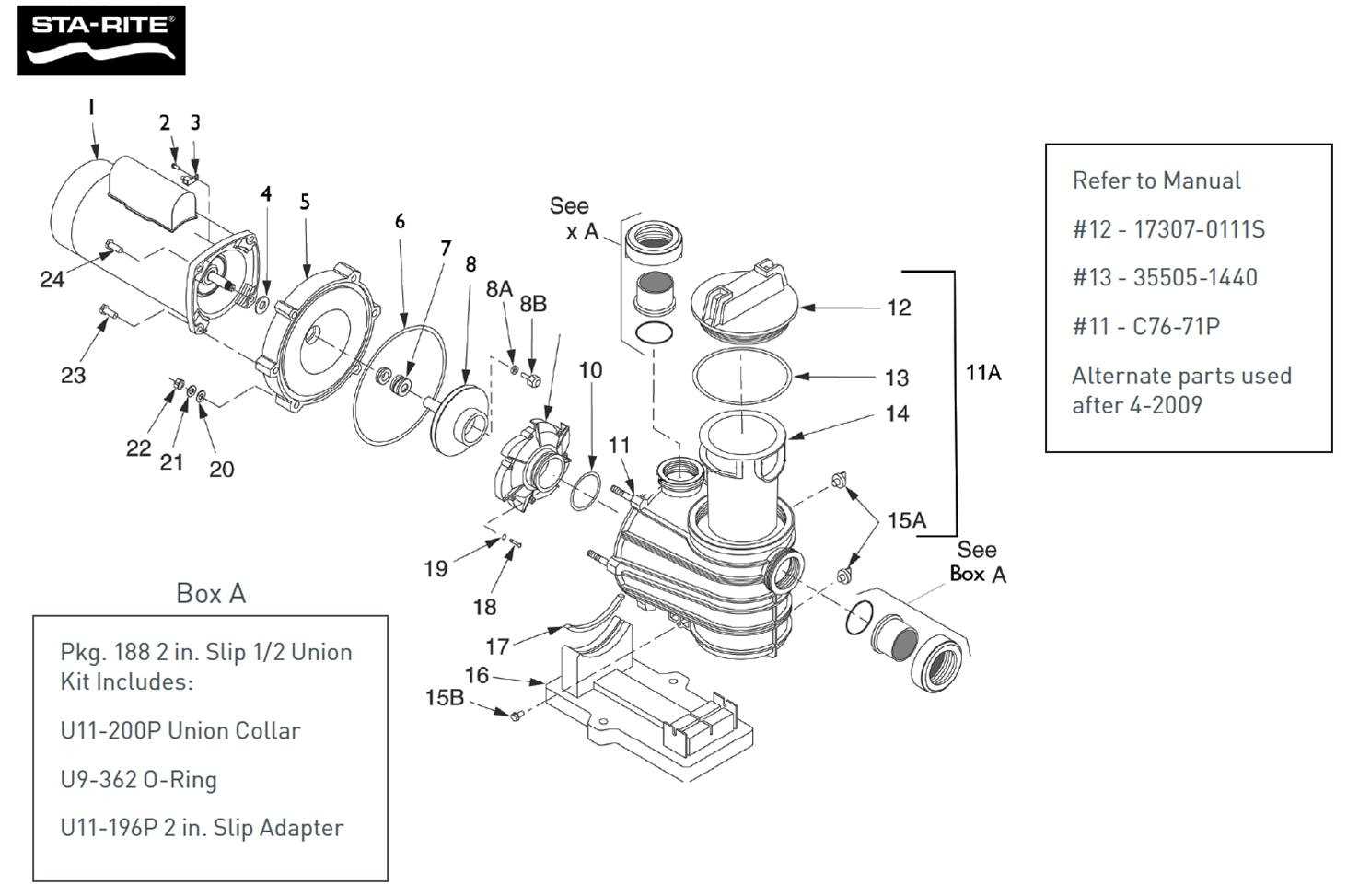

Understanding Pump Diagrams

Visual representations play a crucial role in comprehending the intricacies of mechanical systems. By utilizing illustrations, users can gain insights into the arrangement and function of various components. This understanding is essential for effective maintenance and troubleshooting, ensuring that systems operate smoothly and efficiently.

These visual aids typically highlight key elements and their interconnections, allowing for a clearer grasp of how each part contributes to the overall functionality. Familiarity with these representations can significantly enhance one’s ability to diagnose issues and perform necessary repairs.

| Component | Description |

|---|---|

| Motor | Drives the entire assembly, converting electrical energy into mechanical motion. |

| Impeller | Moves fluid through the system, creating pressure and flow. |

| Volute | Guides the fluid into the discharge outlet, enhancing efficiency. |

| Seal | Prevents leakage between components, ensuring safe operation. |

| Strainer | Filters out debris, protecting internal parts from damage. |

Common Issues with Challenger Pumps

In the realm of fluid circulation systems, various challenges can arise that hinder optimal performance. Understanding these common complications is crucial for effective maintenance and troubleshooting. Whether it’s due to mechanical wear or external factors, identifying the symptoms early can save time and resources.

1. Clogging and Blockages: One frequent issue is the accumulation of debris and sediment within the system. This can restrict flow and lead to overheating. Regular inspections and cleanings can help mitigate this problem.

2. Noise and Vibration: Unusual sounds or excessive vibrations may indicate underlying mechanical issues. These can stem from misaligned components or worn bearings, requiring immediate attention to prevent further damage.

3. Insufficient Flow Rate: A decline in the flow rate often signals potential problems within the system. This could be due to worn seals or improper installation. Monitoring performance metrics regularly can aid in early detection.

4. Leaks: Fluid leaks are a common concern that can arise from deteriorating seals or loose fittings. Addressing leaks promptly is essential to maintain efficiency and prevent environmental contamination.

5. Electrical Failures: Issues with the electrical components, such as wiring or switches, can disrupt functionality. Ensuring that all electrical connections are secure and well-maintained is key to preventing these failures.

Being aware of these potential issues and implementing regular maintenance can enhance the reliability and longevity of your system.

Replacing Pump Parts Effectively

Maintaining the functionality of your equipment is essential for ensuring longevity and optimal performance. When it comes to changing components, having a systematic approach can make the process smoother and more efficient. This section outlines practical steps to follow for effective replacements, minimizing downtime and enhancing reliability.

Preparation Steps

- Gather necessary tools and materials before starting the task.

- Review the user manual or service guide for specific instructions.

- Ensure you have a clean, organized workspace to prevent losing small components.

Replacement Process

- Turn off the power supply to the system to ensure safety.

- Carefully disassemble the unit, noting the order and orientation of each component.

- Inspect each item for wear or damage, replacing only those that require it.

- Install the new components, ensuring a secure fit and proper alignment.

- Reassemble the system in the reverse order of disassembly.

- Reconnect the power supply and perform a test run to check for proper operation.

By following these steps, you can effectively maintain your equipment and ensure its reliable operation for years to come.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular attention not only enhances performance but also reduces the likelihood of unexpected failures. By implementing a routine maintenance schedule, you can significantly increase reliability and efficiency.

Regular Inspections

Conducting frequent inspections allows you to identify potential issues before they escalate. Pay close attention to wear and tear, leaks, and unusual noises, which can indicate underlying problems.

Cleaning and Lubrication

Keeping components clean and well-lubricated is vital for smooth operation. Accumulated debris can cause obstructions, while proper lubrication reduces friction and wear. Make it a habit to clean parts regularly and apply lubricant where necessary.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Monthly | Early problem detection |

| Deep Cleaning | Quarterly | Enhanced efficiency |

| Lubrication | Bi-Annually | Reduced wear |

| System Check | Annually | Overall health assessment |

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing quality components is crucial for ensuring optimal performance. Whether you are dealing with a malfunction or planning an upgrade, knowing where to look for reliable replacements can save time and money.

Online Retailers

The internet is a treasure trove of resources for obtaining components. Many websites specialize in selling high-quality replacements directly to consumers. Look for reputable suppliers with positive reviews to ensure you receive genuine products.

Local Suppliers

Visiting local stores can be an effective way to find the components you need. Hardware shops and specialized distributors often carry a selection of items and can provide valuable advice. Establishing a relationship with local vendors can also lead to better deals and support.

| Source Type | Benefits |

|---|---|

| Online Retailers | Wide selection, convenience, competitive pricing |

| Local Suppliers | Personalized service, immediate availability, expert advice |

| Manufacturer Direct | Guaranteed compatibility, warranty options, high quality |

Comparison with Other Pump Models

Understanding the differences between various models in the market can significantly influence the selection process for consumers. Each design offers unique features, efficiencies, and applications that cater to specific needs. By examining these distinctions, users can make informed decisions that align with their operational requirements.

Key Features

- Flow Rate: Different models provide varying capacities, impacting the overall performance.

- Energy Efficiency: Some designs are optimized for lower energy consumption, reducing operational costs.

- Durability: Material quality and construction methods influence longevity and reliability.

Performance Analysis

- Maintenance: Certain options require less frequent upkeep, making them more convenient for users.

- Noise Level: The acoustics can vary significantly; some models operate quietly, enhancing user comfort.

- Cost: Initial investment and long-term expenses should be evaluated to determine overall value.

Ultimately, comparing these characteristics helps consumers identify the most suitable option for their specific applications, ensuring optimal performance and satisfaction.