In the world of material handling, efficient movement of goods is crucial for streamlined operations. Various tools are employed to facilitate this process, ensuring safety and effectiveness in transporting heavy items across different environments. Familiarity with the integral elements of these tools can greatly enhance their functionality and maintenance.

The mechanics behind these load-moving devices consist of several key components, each playing a significant role in their overall performance. A clear comprehension of how these elements interact and operate together can aid in both troubleshooting and optimal usage, leading to increased productivity in warehouses and other logistics settings.

This section aims to provide a comprehensive overview of the various segments that constitute manual load handlers. By delving into their design and arrangement, users will gain valuable insights into how to keep these tools in peak condition, ultimately ensuring smoother operations and longevity in their application.

Pallet Jack Overview

This section provides an insight into a vital piece of equipment widely utilized in warehouses and distribution centers. Its primary function is to facilitate the movement of heavy loads with ease and efficiency, enhancing productivity and safety in various settings.

Key Features

- Robust construction for durability

- Ergonomic design to reduce operator fatigue

- Adjustable lifting mechanisms for various load sizes

- Manoeuvrability in tight spaces

Common Uses

- Transporting goods within a warehouse

- Loading and unloading trucks

- Stocking shelves in retail environments

- Handling pallets in manufacturing facilities

Understanding the functions and advantages of this essential tool can significantly improve operational workflows and safety standards in material handling.

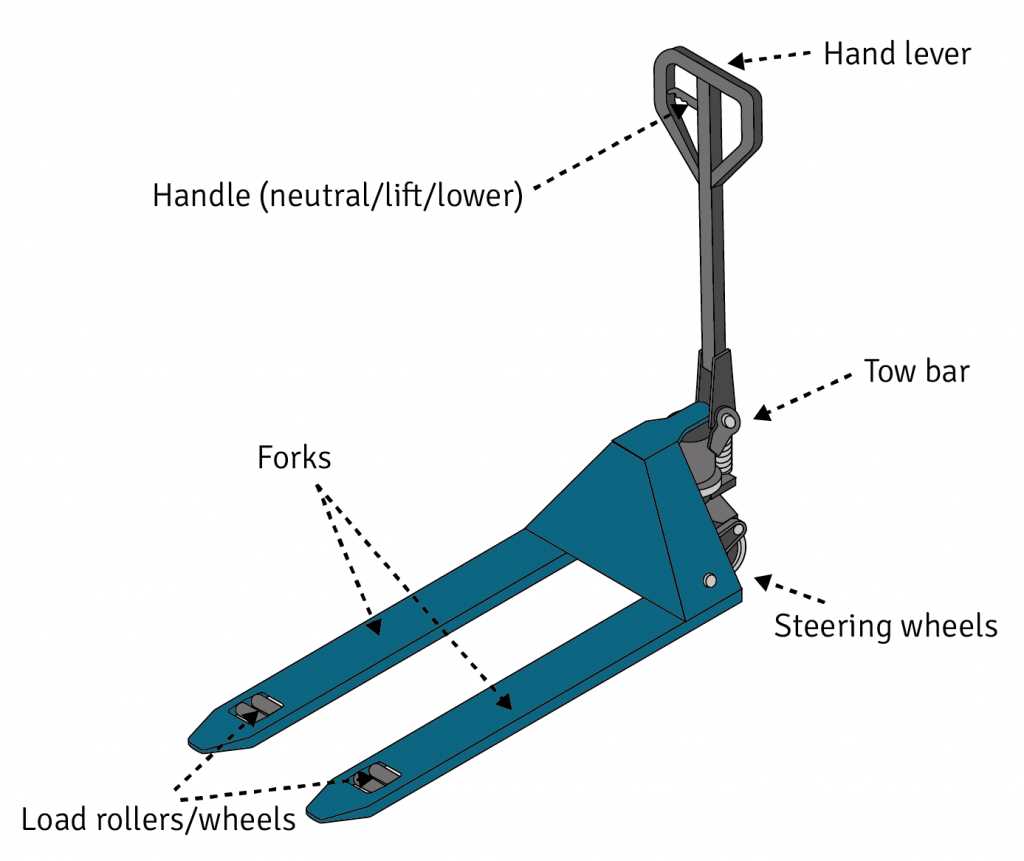

Essential Components of a Pallet Jack

Understanding the key elements of a manual lifting device is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring that the equipment functions smoothly and safely, making the transportation of goods more manageable in various settings.

| Component | Description |

|---|---|

| Handle | The control mechanism used by the operator to steer and lift the load. |

| Forks | The pronged extensions that slide under the load, allowing for lifting and moving. |

| Wheels | Support the unit’s movement and vary in size and material depending on the surface type. |

| Hydraulic Pump | Facilitates lifting by using fluid pressure to elevate the forks. |

| Frame | The structural foundation that holds all components together and provides stability. |

| Release Mechanism | Allows the operator to lower the forks and release the load with ease. |

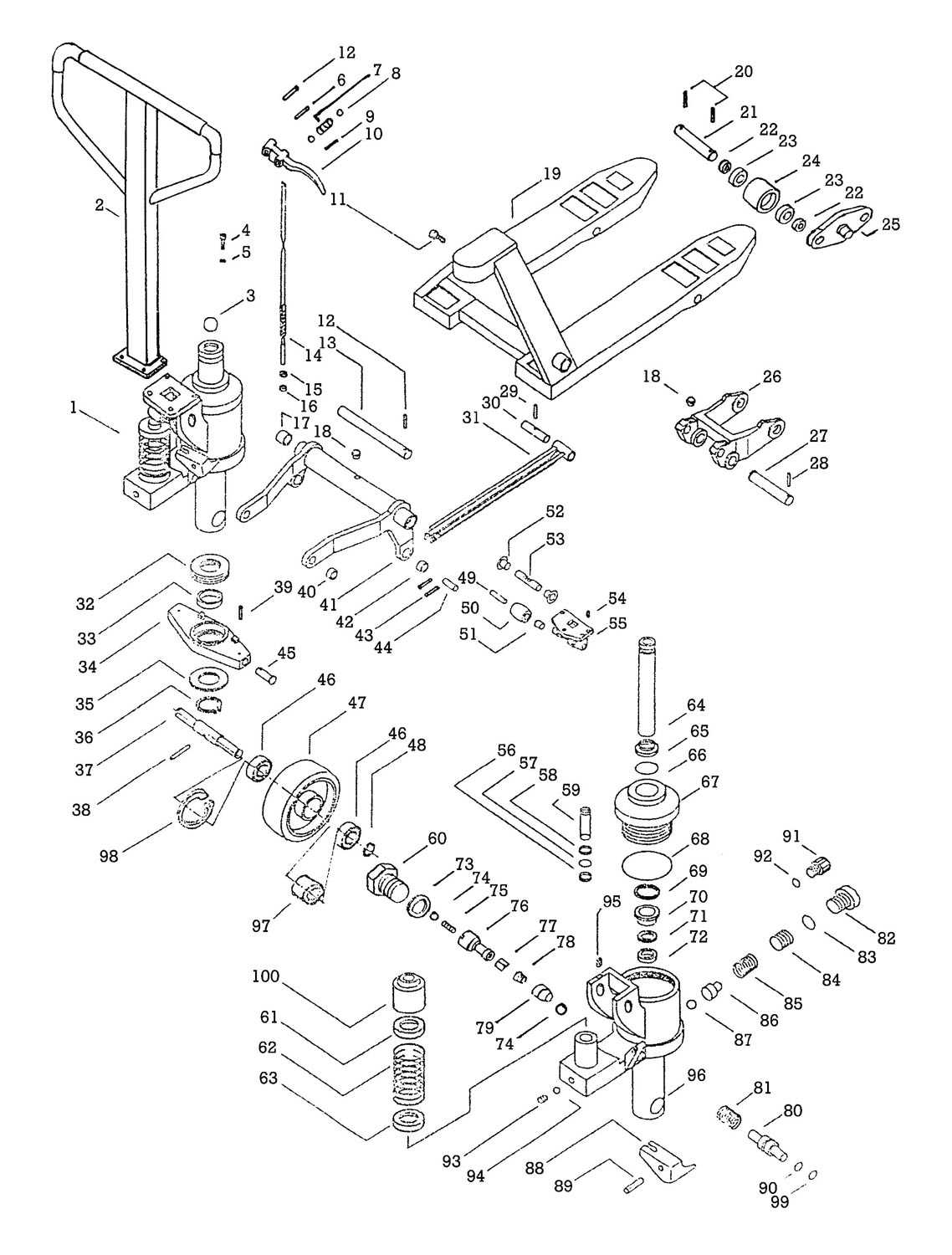

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in numerous industrial applications, utilizing fluid mechanics to transmit power efficiently. This technology enables heavy lifting and smooth operation of various machinery, offering advantages in strength and precision.

Key Components

- Hydraulic fluid: The medium used to transfer force.

- Pump: Converts mechanical energy into hydraulic energy.

- Actuators: Devices that perform work by converting hydraulic energy back into mechanical motion.

- Valves: Control the flow and direction of the hydraulic fluid.

How It Works

- The pump draws fluid from a reservoir and pressurizes it.

- This pressurized fluid travels through hoses to actuators.

- Valves direct the flow, enabling specific movements or operations.

- Once the work is done, the fluid returns to the reservoir, completing the cycle.

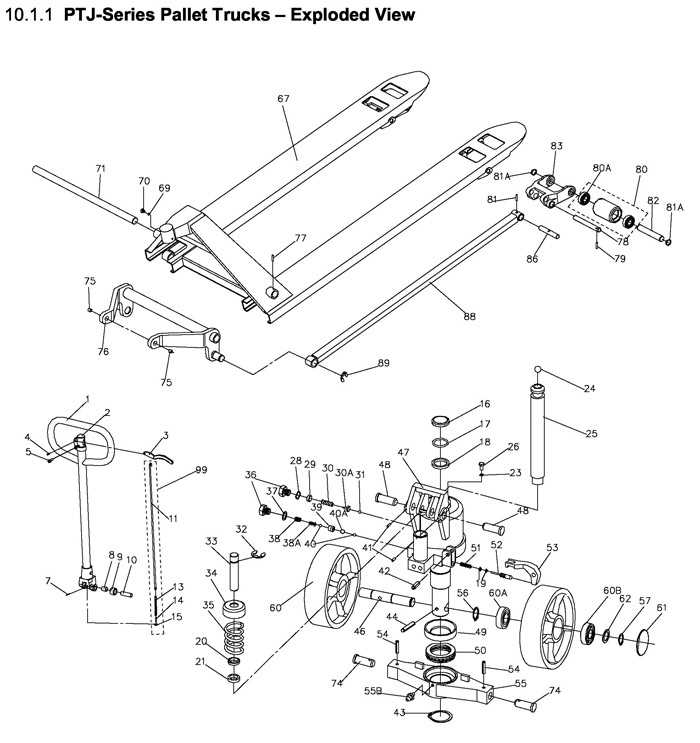

Common Parts and Their Functions

Understanding the various components of a lifting device is essential for effective operation and maintenance. Each element plays a vital role in ensuring smooth functionality and safety during use. Familiarity with these components not only aids in troubleshooting but also enhances overall efficiency.

Wheels: These are critical for mobility, enabling smooth transport across various surfaces. They must be durable to withstand heavy loads and frequent movement.

Handle: The control mechanism for maneuvering the equipment, the handle allows the operator to lift and lower the load. Its design is crucial for ergonomic use, minimizing strain during operation.

Lifting Mechanism: This component is responsible for raising and lowering the load. It typically involves a hydraulic system that provides the necessary force, allowing for smooth adjustments to the height.

Frame: The structural backbone that supports all other components, the frame ensures stability and strength. It is designed to bear substantial weight while maintaining balance during transport.

Forks: These are the two prongs that slide under the load. They must be designed to accommodate different sizes and shapes, providing secure support during lifting and moving.

Release Valve: This mechanism controls the descent of the load. By regulating hydraulic fluid flow, it allows for gradual lowering, enhancing safety during operation.

Each component is integral to the device’s overall performance, making it crucial to understand their functions for optimal use and maintenance.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By following a few essential practices, you can significantly extend the lifespan and reliability of your machinery, minimizing the risk of unexpected breakdowns and costly repairs.

1. Regular Inspections: Conduct routine checks to identify any signs of wear and tear. Look for loose connections, rust, and other potential issues that may affect performance.

2. Keep it Clean: Maintaining a clean environment for your tools is crucial. Regularly remove debris, dirt, and grease, as these can interfere with functionality and lead to premature damage.

3. Lubrication: Ensure that all moving parts are properly lubricated. This reduces friction and wear, promoting smoother operation and extending the life of the components.

4. Avoid Overloading: Always adhere to weight limits to prevent strain on the machinery. Overloading can lead to structural damage and reduce efficiency.

5. Proper Storage: Store equipment in a dry, sheltered area to protect it from environmental factors such as moisture and extreme temperatures, which can cause corrosion and degradation.

6. Training and Handling: Ensure that operators are well-trained in the correct handling techniques. Improper use can lead to damage and unsafe conditions.

By incorporating these maintenance tips into your routine, you can enhance the performance and longevity of your equipment, ensuring it remains a valuable asset for years to come.

Troubleshooting Common Issues

In any material handling equipment, certain problems may arise that affect performance and safety. Understanding these issues and their potential solutions is essential for maintaining efficiency in operations.

Identifying Symptoms

Recognizing the signs of malfunction can help in addressing problems promptly. Common symptoms include:

- Unresponsive movement

- Unusual noises during operation

- Difficulty in lifting loads

- Inconsistent steering control

Possible Solutions

Once the symptoms are identified, consider the following troubleshooting steps:

- Inspect for any visible damage or wear on components.

- Check fluid levels and ensure there are no leaks.

- Examine the wheels and casters for blockages or obstructions.

- Review the operational manual for specific guidelines related to the issue.

Choosing the Right Pallet Jack

Selecting the ideal equipment for material handling is crucial for efficiency and safety in any workspace. Understanding the specific requirements of your operations can help ensure that you choose a model that meets your needs effectively.

| Feature | Considerations |

|---|---|

| Load Capacity | Determine the maximum weight you will need to lift. |

| Fork Length | Choose the appropriate length based on the size of your loads. |

| Wheels | Select materials and types based on surface conditions. |

| Ergonomics | Ensure ease of use to reduce operator fatigue. |

| Durability | Consider the construction materials for longevity. |

Importance of Quality Parts

The reliability and efficiency of any material handling equipment hinge on the components that make it function. When these elements are of high quality, they contribute significantly to overall performance and longevity. Conversely, inferior components can lead to frequent breakdowns and costly repairs.

Here are several reasons why choosing superior elements is crucial:

- Durability: High-quality materials resist wear and tear, ensuring a longer lifespan.

- Performance: Well-manufactured components operate smoothly, enhancing the overall efficiency of the equipment.

- Safety: Reliable elements reduce the risk of accidents, protecting operators and reducing liability for businesses.

- Cost-Effectiveness: Investing in quality components minimizes the need for replacements and repairs, leading to savings in the long run.

In conclusion, prioritizing top-notch elements is essential for maintaining operational excellence and ensuring a safe working environment. Businesses that recognize this will benefit from increased productivity and reduced downtime.