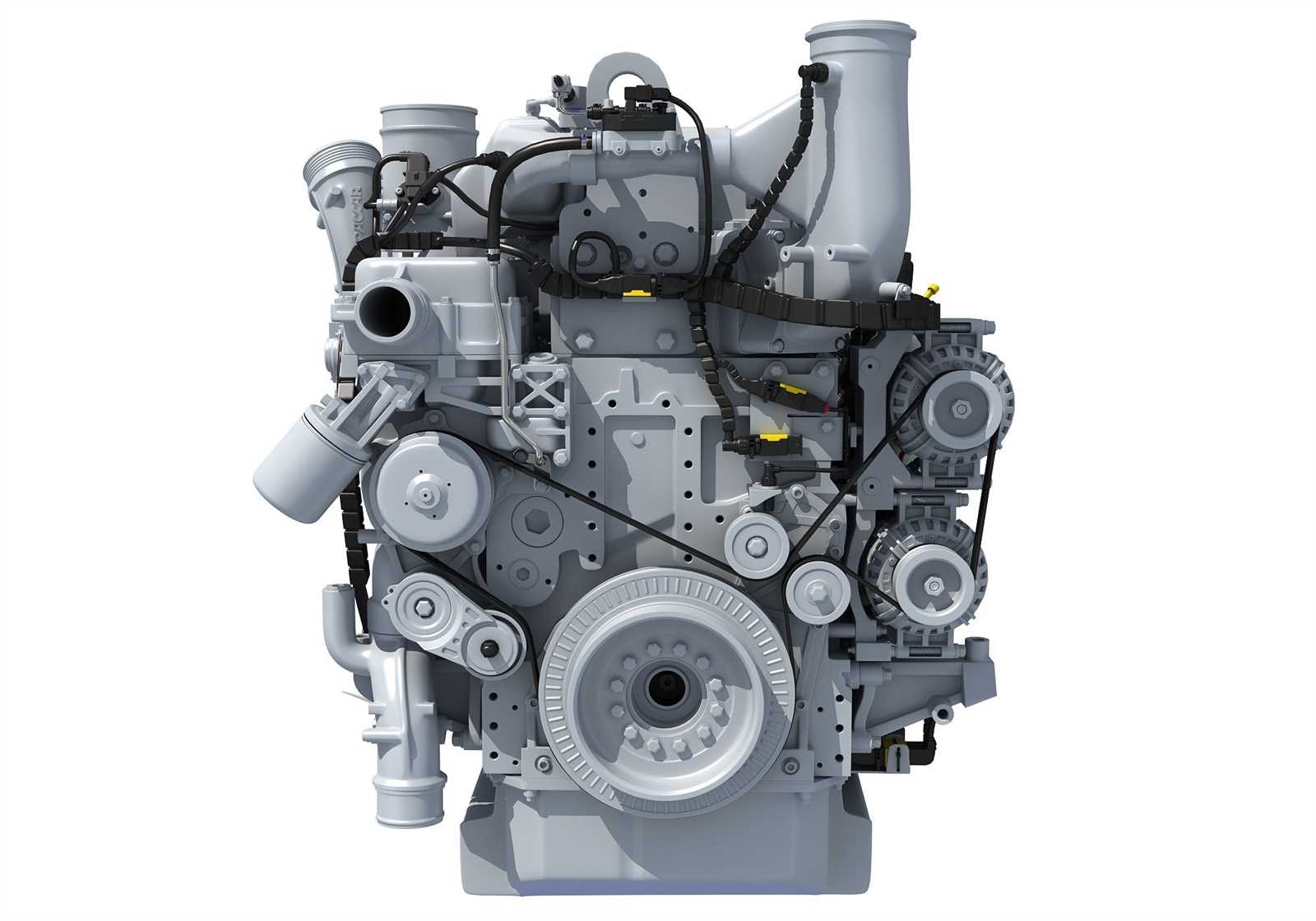

In the intricate world of heavy machinery, having a comprehensive understanding of engine configurations is essential for optimal performance and maintenance. Each assembly plays a pivotal role in ensuring the smooth operation of vehicles designed for rigorous tasks. A thorough exploration of these components allows operators and technicians to grasp how everything works together effectively.

Visual representations of these assemblies serve as invaluable tools for anyone looking to troubleshoot or enhance the functionality of their machinery. By delving into the specifics of each section, one can identify wear points and potential issues before they escalate. This proactive approach ultimately leads to increased efficiency and longevity.

Moreover, recognizing the interconnections between various elements aids in informed decision-making during repairs and upgrades. Understanding these relationships is crucial for maintaining the ultimate performance of any machine, making this knowledge a vital asset in the field.

Overview of the Engine

This section provides a comprehensive understanding of a particular high-performance engine widely recognized in the transportation industry. Known for its advanced technology and efficiency, this powertrain is designed to meet the demands of heavy-duty applications while ensuring optimal fuel economy and reliability.

Key Features

The engine boasts several standout characteristics that enhance its functionality. These features include cutting-edge engineering, improved thermal efficiency, and reduced emissions, all contributing to its reputation as a leader in the market. Below are some of the essential specifications:

| Feature | Description |

|---|---|

| Displacement | 12.9 liters |

| Horsepower Range | 380 to 565 HP |

| Torque Range | 1,450 to 2,050 lb-ft |

| Fuel System | Common rail direct injection |

Applications

This powertrain is utilized in various commercial vehicles, including trucks and buses. Its adaptability allows it to perform efficiently across different terrains and operational conditions, making it a preferred choice for fleet operators seeking reliability and performance.

Key Features of the Engine

This section highlights the essential characteristics that define the performance and reliability of this advanced power unit. From innovative engineering to superior efficiency, each aspect contributes to its reputation in the heavy-duty vehicle industry.

Performance and Efficiency

The engine is designed to deliver exceptional power while maintaining fuel efficiency. Its advanced turbocharging technology allows for improved air intake, optimizing combustion and enhancing overall performance. This results in a robust output that meets the demands of rigorous driving conditions.

Durability and Reliability

Built with high-quality materials and precision engineering, the unit ensures longevity and dependable operation. It features a resilient cooling system and advanced lubrication techniques that minimize wear and tear, making it suitable for prolonged use in challenging environments.

| Feature | Description |

|---|---|

| Turbocharging | Enhances air intake for better combustion and power output. |

| Fuel Efficiency | Engineered to maximize performance while reducing fuel consumption. |

| Durable Materials | Constructed with high-strength components for longevity. |

| Advanced Cooling | Effective cooling system to prevent overheating during operation. |

| Reliable Lubrication | Improves engine life by reducing friction and wear. |

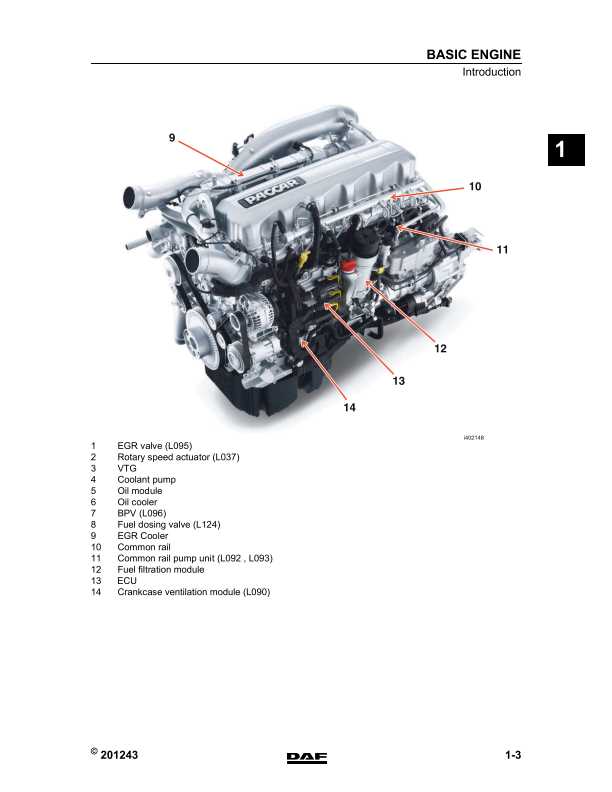

Understanding the Parts Diagram

Grasping the intricacies of a mechanical schematic is crucial for anyone involved in maintenance and repair. These visual representations provide essential insights into the components of an engine, illustrating how each piece fits and functions within the larger assembly. A well-crafted schematic can simplify troubleshooting and enhance efficiency during repairs.

Key benefits of utilizing such a visual guide include:

- Enhanced comprehension of individual components

- Streamlined identification of potential issues

- Improved efficiency in the repair process

When analyzing a schematic, consider the following elements:

- Component Labels: Each part is typically labeled, making it easier to reference specific items.

- Connections: Arrows and lines indicate how components interact, helping to visualize the flow of energy or fluids.

- Assembly Order: Some diagrams include a sequence for assembly or disassembly, which can be invaluable for maintenance tasks.

Understanding these elements allows for a more effective approach to repairs, ensuring that every action taken contributes to the overall functionality of the system.

Importance of Genuine Parts

Using authentic components in machinery is crucial for maintaining optimal performance and longevity. These original items are specifically engineered to meet exact specifications, ensuring reliability and efficiency.

Here are several reasons why selecting genuine components is essential:

- Quality Assurance: Authentic components undergo rigorous testing and quality checks, providing peace of mind regarding their durability.

- Compatibility: Original items are designed to fit seamlessly with the equipment, reducing the risk of malfunction or damage.

- Warranty Protection: Utilizing genuine components often helps maintain warranty coverage, safeguarding your investment.

- Performance Optimization: Original items contribute to enhanced performance, ensuring the machinery operates at its best.

- Resale Value: Keeping machinery in top condition with authentic components can significantly enhance its resale value.

In conclusion, investing in original items is a wise decision for anyone seeking to maximize the efficiency and lifespan of their machinery. By choosing authenticity, you ensure that your equipment continues to operate reliably and effectively over time.

Common Issues and Solutions

In the realm of heavy-duty engines, operators often encounter various challenges that can affect performance and reliability. Understanding these common issues and their corresponding solutions is essential for maintaining optimal operation and longevity.

- Overheating:

- Check the coolant levels regularly.

- Inspect the radiator for clogs or leaks.

- Ensure the thermostat is functioning properly.

- Fuel System Problems:

- Examine fuel filters for blockages.

- Verify the fuel injectors are clean and operational.

- Check for air leaks in the fuel lines.

- Oil Leaks:

- Identify the source of the leak, such as gaskets or seals.

- Replace worn or damaged components promptly.

- Monitor oil levels frequently to prevent damage.

- Electrical Issues:

- Inspect battery connections and cables for corrosion.

- Test fuses and relays for functionality.

- Check the wiring harness for signs of wear or damage.

- Performance Degradation:

- Regularly clean or replace air filters.

- Ensure proper fuel quality is being used.

- Conduct regular engine diagnostics to identify issues early.

By addressing these common challenges proactively, operators can enhance the performance and reliability of their engines, ensuring smoother operations and reducing the risk of costly repairs.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of heavy machinery requires a proactive approach to upkeep. Regular maintenance not only enhances the efficiency of your equipment but also extends its lifespan significantly. Here are essential strategies to keep in mind for ongoing care and maintenance.

Regular Inspection

- Conduct routine checks on fluid levels, including oil, coolant, and fuel.

- Inspect belts and hoses for wear and tear.

- Examine electrical connections to ensure they are secure and free of corrosion.

Scheduled Servicing

- Follow the manufacturer’s recommended service intervals for comprehensive checks.

- Replace filters regularly to maintain optimal performance.

- Perform software updates if applicable to enhance functionality.

By implementing these practices, you can significantly enhance the reliability and efficiency of your machinery, ensuring it serves you well for years to come.

How to Read the Diagram

Understanding the visual representation of components is crucial for effective maintenance and repair. This guide will help you navigate the essential features and symbols commonly found in such illustrations, ensuring clarity in identifying each element.

Key Features to Identify

- Symbols: Familiarize yourself with standard icons used for various parts.

- Labels: Pay attention to descriptive text that provides names and specifications.

- Connections: Note the lines indicating relationships and flow between components.

Steps for Effective Reading

- Start from the top-left corner and move systematically through the visual.

- Match symbols with their respective explanations in the legend.

- Refer to color coding if available, as it often indicates different categories or functions.

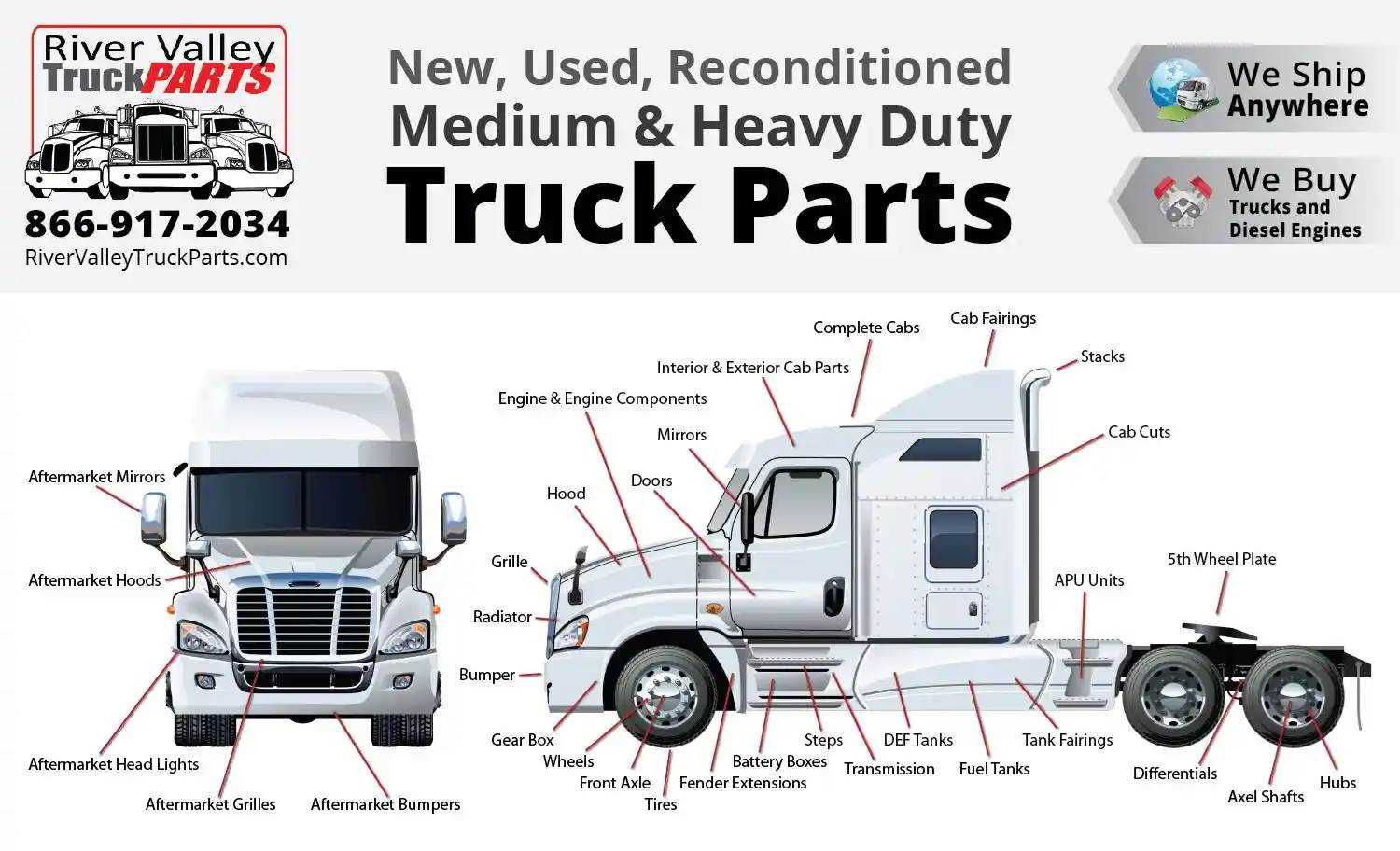

Where to Buy Replacement Parts

Finding high-quality components for your heavy-duty vehicle can be challenging, yet it is crucial for maintaining optimal performance. Various sources offer reliable options for acquiring these essential items, ensuring that you can keep your machine running smoothly.

Authorized Dealers

One of the most trustworthy avenues is through authorized dealers. They provide original equipment and have extensive knowledge about the products they sell. Here are some benefits of choosing this option:

- Genuine components ensure compatibility and reliability.

- Access to expert advice and support.

- Warranty on parts purchased, offering peace of mind.

Online Retailers

The digital marketplace is a convenient alternative for those looking for components. Numerous online platforms specialize in heavy-duty vehicle supplies. Consider the following when shopping online:

- Check customer reviews to gauge the reliability of the seller.

- Compare prices across different websites for the best deal.

- Verify return policies to ensure customer protection.

By exploring these avenues, you can efficiently source the necessary components to keep your vehicle in top shape.

Comparison with Other Engines

When evaluating various heavy-duty powertrains, it’s essential to consider their unique characteristics, performance metrics, and applications. This section delves into how one specific model stacks up against its contemporaries, focusing on aspects such as efficiency, durability, and maintenance requirements.

Efficiency is a crucial factor for fleet operators. The engine in question is renowned for its fuel economy, often outperforming similar units from competing manufacturers. This advantage translates to reduced operational costs, making it an attractive option for long-haul transportation.

In terms of durability, many users have reported exceptional longevity, often extending the life of their vehicles beyond industry norms. This resilience can be attributed to robust engineering and high-quality materials, setting it apart from others that may require more frequent repairs.

Maintenance practices can greatly influence overall performance. This particular engine features a design that simplifies routine check-ups and repairs, allowing for quicker turnaround times and less downtime. In contrast, some rival models may demand more extensive service interventions, impacting overall efficiency.

Additionally, the power delivery of this engine is noted for its smoothness and responsiveness, contributing to improved driving experience and vehicle handling. Comparatively, other engines may exhibit lag or inconsistent performance, especially under heavy loads.

Overall, when juxtaposed with other available options, this engine demonstrates significant strengths that can enhance operational efficiency, reduce costs, and improve user satisfaction in demanding applications.