The exploration of intricate layouts serves as a crucial foundation for comprehending the functionality and maintenance of various systems. These visual representations not only aid in identifying each element’s role but also facilitate efficient troubleshooting and repairs. Grasping the arrangement of components ensures users can effectively manage and utilize their equipment.

In this section, we will delve into the various aspects of visual schematics that illustrate how different elements are interconnected. By examining these layouts, users can gain insights into the operational mechanics and improve their hands-on skills. Whether for educational purposes or practical application, understanding these illustrations is essential for effective equipment management.

Emphasizing clarity and accuracy, the layouts act as a guide for both novice and experienced users. With a detailed approach, we aim to highlight key relationships among components, ensuring a comprehensive understanding of the subject matter. This knowledge empowers individuals to take informed actions in their tasks and enhances overall proficiency.

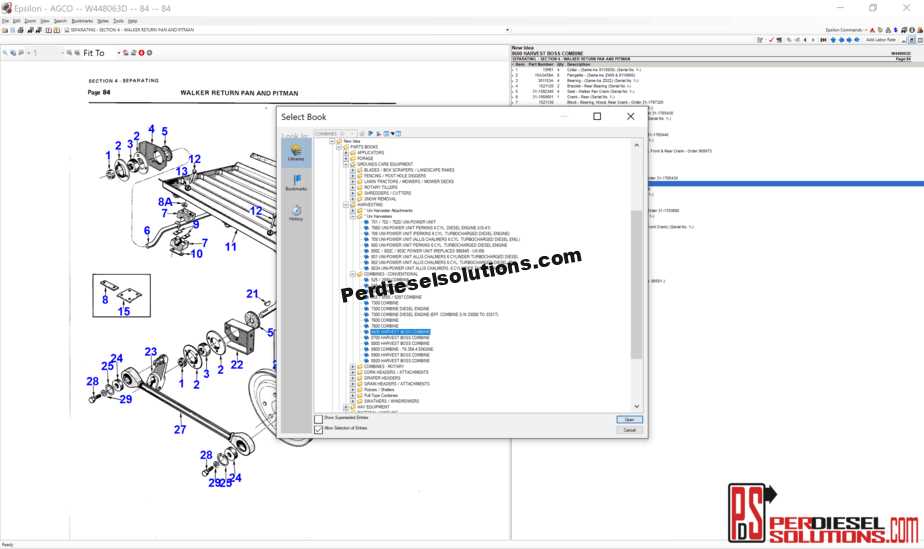

New Idea 5409 Parts Overview

This section provides a comprehensive look at the components associated with the specified agricultural machinery. Understanding the various elements involved is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal functionality and performance.

| Component Name | Description | Functionality |

|---|---|---|

| Frame Assembly | The main structural support of the equipment. | Provides stability and durability during operation. |

| Drive System | Includes the motor and transmission elements. | Transmits power to the working components. |

| Control Panel | Interface for managing operations. | Allows the operator to control settings and monitor performance. |

| Harvesting Mechanism | Assembly responsible for gathering crops. | Ensures efficient collection of harvested materials. |

| Wheels and Tires | Components that facilitate movement. | Enable mobility across various terrains. |

Main Components of the 5409 Model

This section explores the essential elements that contribute to the functionality and performance of the specified model. Each component plays a crucial role in ensuring that the system operates smoothly and efficiently. Understanding these features can enhance user knowledge and improve maintenance practices.

Key Features

- Structural Framework: Provides stability and support for all components.

- Power System: Supplies the necessary energy for operation.

- Control Unit: Manages the operations and settings of the device.

Additional Elements

- Cooling Mechanism: Ensures optimal temperature during use.

- Safety Devices: Protects against potential hazards.

- Connectivity Interfaces: Enables communication with other devices.

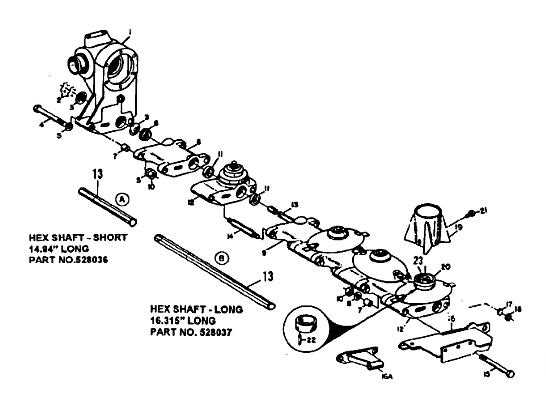

Blade Assembly Structure and Function

The configuration of a cutting component is essential for the effective operation of various machinery. This section delves into the intricate design and roles of the elements that compose the blade assembly, highlighting how each part contributes to the overall performance and efficiency.

Key Components of the Assembly

The blade assembly consists of several vital elements, including the main cutting edge, supporting structures, and securing mechanisms. Each component plays a crucial role in ensuring precision during operation. The cutting edge, often crafted from durable materials, is designed to withstand wear while providing optimal cutting efficiency.

Operational Significance

Understanding the function of each part within the assembly enhances the ability to maintain and troubleshoot the equipment effectively. The supporting structures not only provide stability but also allow for the necessary adjustments to adapt to different operational conditions. The securing mechanisms ensure that the blade remains firmly attached during use, minimizing the risk of accidents.

Cutting Mechanism: Key Elements

The efficiency of any cutting apparatus relies on its fundamental components, which work together to achieve precision and effectiveness. Understanding these critical elements is essential for optimizing performance and ensuring the longevity of the equipment.

Primary Components

Among the vital parts, the blade stands out as the heart of the cutting mechanism. Its design and material significantly influence the cutting capability and the type of materials that can be processed. A well-crafted blade ensures smooth operation and reduces wear over time.

Support Structure

The frame provides the necessary stability for the entire system. It plays a crucial role in minimizing vibrations and maintaining alignment during operation. A robust frame contributes to the overall durability and reliability of the apparatus, making it essential for consistent results.

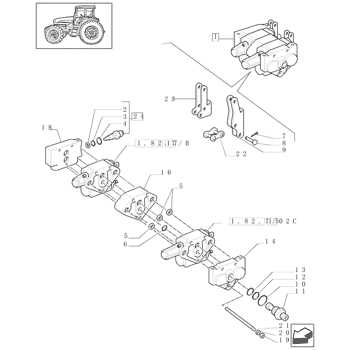

Drive System and Its Components

The drive system serves as the essential mechanism that transfers power from the engine to the wheels, enabling motion and control of the vehicle. It encompasses various elements that work in harmony to ensure efficient performance and reliability under different conditions. Understanding the intricacies of this system is crucial for maintaining optimal functionality.

At the core of the drive system is the transmission, which regulates gear ratios to balance power and speed. The drivetrain, including the driveshaft, differential, and axles, plays a pivotal role in distributing power to the wheels. Additionally, components such as the clutch and torque converter facilitate smooth transitions between gears, enhancing driving comfort. Each element within the drive system contributes to the overall performance, ensuring the vehicle operates smoothly and efficiently.

Regular maintenance and timely inspections of the drive system components are vital for preventing potential issues. By ensuring all parts function correctly, one can achieve a seamless driving experience and extend the lifespan of the vehicle.

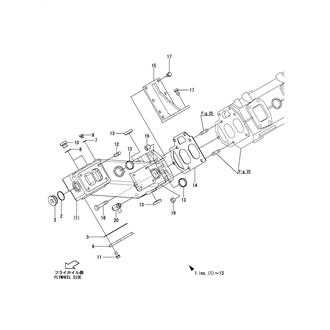

Gearbox Layout and Functionality

The gearbox is a critical component in any machinery, facilitating the transfer of power from the engine to the wheels. Its design intricacies determine the efficiency and performance of the overall system. Understanding its structure and operation is essential for optimizing functionality and ensuring longevity.

Structural Overview

The configuration of a gearbox typically includes several key elements. These components work in unison to manage torque and speed effectively. A well-designed gearbox can significantly enhance performance while minimizing wear and tear on the engine.

| Component | Description |

|---|---|

| Input Shaft | Transmits power from the engine to the gearbox. |

| Gear Set | Consists of various gears that modify torque and speed ratios. |

| Output Shaft | Delivers power from the gearbox to the drive mechanism. |

| Bearings | Support rotating parts and reduce friction within the system. |

Operational Mechanics

The operation of the gearbox involves a series of gear engagements that alter the output speed and torque according to the needs of the vehicle. This mechanism allows for smooth transitions between different speed ranges, contributing to an efficient driving experience.

Frame and Support Elements Breakdown

This section provides a comprehensive overview of the structural components that provide stability and durability to the system. Understanding these elements is crucial for ensuring proper assembly and functionality, as they form the backbone of the overall design.

Key Structural Components

- Chassis: The main framework that supports the entire unit, providing a solid foundation.

- Supports: Additional components that reinforce the chassis, enhancing stability under various loads.

- Brackets: Metal or plastic fittings that secure parts together, contributing to the structural integrity.

Assembly Considerations

- Ensure all components are aligned correctly during installation to prevent misalignment.

- Use appropriate fasteners for securing elements to avoid potential failures.

- Regularly inspect for wear or damage to maintain optimal performance.

Hydraulic System Parts Description

The hydraulic system plays a crucial role in the operation of various machinery, providing the necessary force for movement and control. This section will explore the key components that contribute to the functionality of this essential mechanism, focusing on their roles and interconnections.

| Component | Description |

|---|---|

| Pump | The device responsible for generating hydraulic pressure by converting mechanical energy into hydraulic energy. |

| Actuator | A mechanism that converts hydraulic energy back into mechanical motion, enabling movement in various applications. |

| Reservoir | A storage tank that holds hydraulic fluid, ensuring a consistent supply to the system. |

| Valves | Devices that control the flow and direction of hydraulic fluid within the system, regulating pressure and ensuring efficient operation. |

| Hoses and Tubes | Flexible or rigid conduits that transport hydraulic fluid between components, maintaining the system’s integrity and efficiency. |

Maintenance and Replacement Guidelines

Proper upkeep and timely substitutions are essential for ensuring optimal performance and longevity of equipment. Adhering to recommended practices not only enhances functionality but also minimizes potential issues that may arise from neglect. This section outlines effective strategies for maintaining your machinery and guidelines for when to consider replacements.

Routine Maintenance Practices

Regular inspections and servicing are vital in detecting wear and tear before they escalate into significant problems. Check components frequently for signs of deterioration, and follow the manufacturer’s recommendations for cleaning and lubrication. Keeping a detailed maintenance log can help track service intervals and identify recurring issues.

When to Consider Replacements

While regular maintenance extends the life of your machinery, there comes a point when certain elements need replacing. Pay attention to performance indicators; a noticeable decline in efficiency or unusual noises can signal that components are nearing the end of their usable life. Consult your service manual for specifications on replacement intervals and compatibility of new parts.