In the realm of construction, the functionality and efficiency of various machinery are paramount. Recognizing the essential elements that contribute to the overall performance of these tools can greatly enhance their usability and longevity. This section aims to explore the intricacies of a specific piece of equipment often utilized in building projects.

Identifying the various sections and their interconnections is crucial for maintenance and troubleshooting. By grasping how each component interacts within the larger system, users can ensure optimal operation and prevent potential failures. The goal is to empower operators with the knowledge needed to manage their machinery effectively.

Moreover, understanding these components allows for better decision-making when it comes to repairs and replacements. This deeper insight ultimately leads to improved productivity and a reduction in downtime, ensuring that projects proceed smoothly and efficiently. Delving into the layout of these essential elements can significantly enhance the user experience.

Understanding Whiteman Mortar Mixers

This section explores the intricacies of a specific type of construction equipment designed for blending materials efficiently. These devices play a crucial role in various building projects, providing consistent mixtures essential for structural integrity. By examining their components and functionality, one can appreciate how they enhance productivity on job sites.

Key Components

The effectiveness of this equipment hinges on several critical elements. Each part contributes to the overall performance and durability, ensuring that the blending process is both smooth and efficient.

| Component | Description |

|---|---|

| Drum | The primary container where the materials are combined, designed for optimal mixing. |

| Engine | Powers the operation, providing the necessary force to rotate the drum. |

| Frame | The structural support that holds all components together, ensuring stability during operation. |

| Blades | Strategically positioned within the drum to facilitate thorough mixing of materials. |

Importance of Maintenance

Key Components of Mortar Mixers

Understanding the essential elements of blending equipment is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and durability, contributing to the overall efficiency of the mixing process.

Mixing Drum

The mixing drum serves as the primary container where all materials are combined. Its design facilitates even distribution and ensures that the mixture achieves the desired consistency, crucial for successful application.

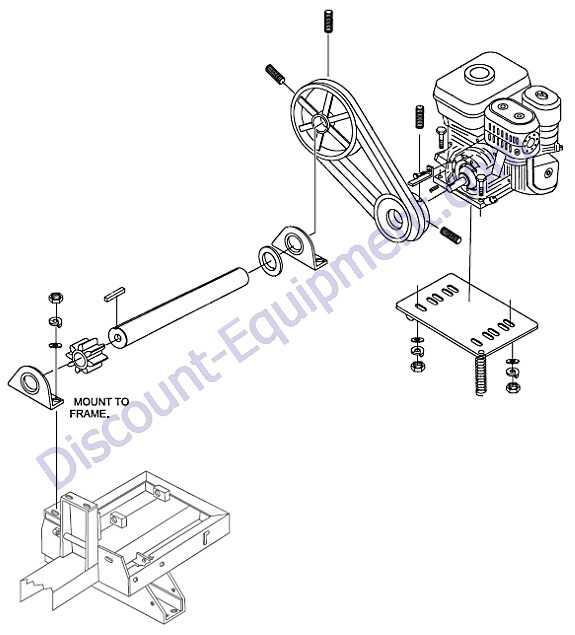

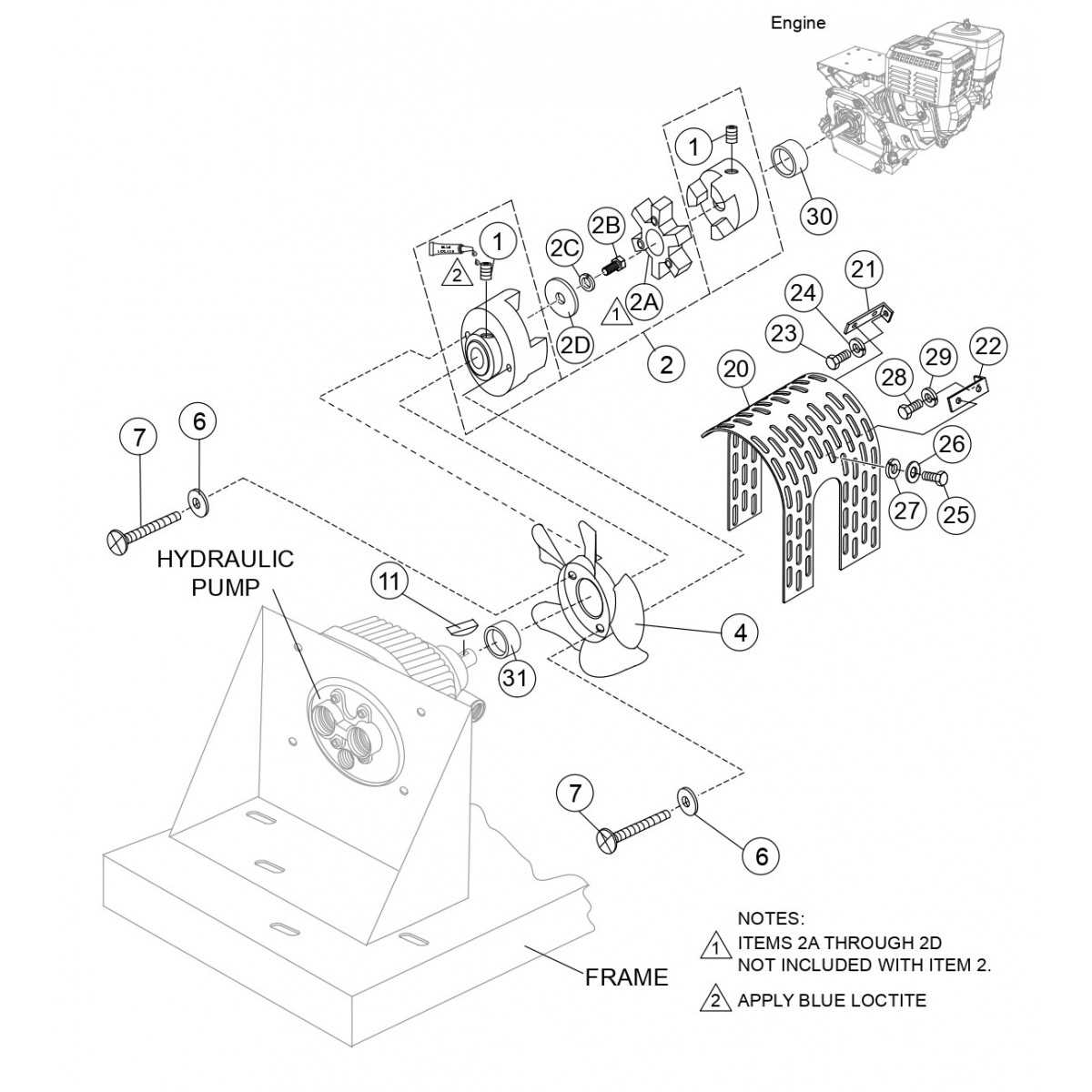

Drive System

The drive system powers the entire unit, converting energy into mechanical motion. It is vital for ensuring that the drum rotates at the correct speed, affecting the blending quality and time efficiency.

Importance of Quality Mixer Parts

The durability and efficiency of construction equipment largely depend on the quality of its components. Investing in high-grade materials not only enhances performance but also ensures longevity, reducing the likelihood of breakdowns. This is essential for maintaining productivity on job sites and achieving the best results.

Enhanced Performance

Cost Efficiency

Quality components may seem like a larger initial investment, but they save money in the long run. Reduced maintenance costs and extended service life lead to greater overall savings.

| Benefits | Impact |

|---|---|

| Durability | Less frequent replacements |

| Efficiency | Higher output and quality |

| Reliability | Fewer delays and interruptions |

How to Identify Mixer Issues

Recognizing potential problems with your equipment is crucial for maintaining performance and safety. By being aware of certain signs, you can take timely action to prevent further complications.

- Unusual Noises: Listen for grinding, clanking, or squeaking sounds during operation.

- Poor Performance: Note any decrease in efficiency, such as incomplete mixing or inconsistent texture.

- Visual Inspection: Check for visible wear, cracks, or loose components on the exterior.

By monitoring these indicators, you can ensure that your machinery operates at its best.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By implementing a few essential practices, you can significantly extend the lifespan of your machinery and enhance its performance. This section provides valuable insights into maintaining your device for optimal functionality.

Regular Cleaning

Keeping your machinery clean is crucial for preventing the buildup of debris and contaminants. After each use, make it a habit to remove any residue. Utilize a soft brush and water to gently clean surfaces, ensuring all components are free from dust and dirt. Regular cleaning not only improves performance but also helps in identifying any wear and tear early on.

Periodic Inspections

Conducting thorough inspections at regular intervals is vital for detecting potential issues before they escalate. Check for signs of wear, loose connections, and any irregular sounds during operation. Additionally, ensure that all moving parts are well-lubricated, as this reduces friction and promotes smoother operation. Addressing minor problems promptly can save time and costly repairs down the line.

Common Replacement Parts Explained

In any machinery, certain components are prone to wear and tear over time, necessitating replacement to ensure optimal performance. Understanding these essential elements can aid in maintenance and prolong the lifespan of the equipment. This section delves into the most frequently replaced components, their functions, and why they are crucial for the efficient operation of your device.

One of the primary items to consider is the mixing drum, which is essential for blending materials thoroughly. A worn drum can lead to uneven mixtures, impacting the quality of the final product. Regular inspection and timely replacement can mitigate this issue.

Another significant component is the motor, responsible for driving the entire system. If the motor begins to fail, it may exhibit signs such as unusual noises or decreased performance. Addressing motor issues promptly can prevent further complications and ensure reliable functionality.

Additionally, belts and pulleys play a critical role in transferring power within the equipment. Over time, these can experience wear, leading to slippage or failure. Replacing these parts as needed is vital for maintaining consistent operation.

Finally, seals and gaskets should not be overlooked. These components prevent leaks and protect internal mechanisms from external elements. Regular maintenance checks can help identify degradation and allow for swift replacements, thus ensuring continued efficiency.

Benefits of Using Genuine Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. These original elements are specifically designed to fit seamlessly, providing reliability that enhances the overall functionality of your machinery. By opting for genuine alternatives, you invest in the long-term health of your investment, avoiding potential issues that may arise from inferior substitutes.

Enhanced Performance

Authentic components are engineered to meet the highest standards of quality. This results in improved efficiency, allowing your machine to operate at its best. Enhanced performance not only boosts productivity but also reduces the likelihood of breakdowns, ensuring that your operations run smoothly.

Cost-Effectiveness

While genuine items may come at a higher initial cost, they often prove to be more economical in the long run. The durability and reliability of these components lead to fewer replacements and repairs, ultimately saving you money. Investing in quality pays off by minimizing downtime and maximizing your equipment’s lifespan.

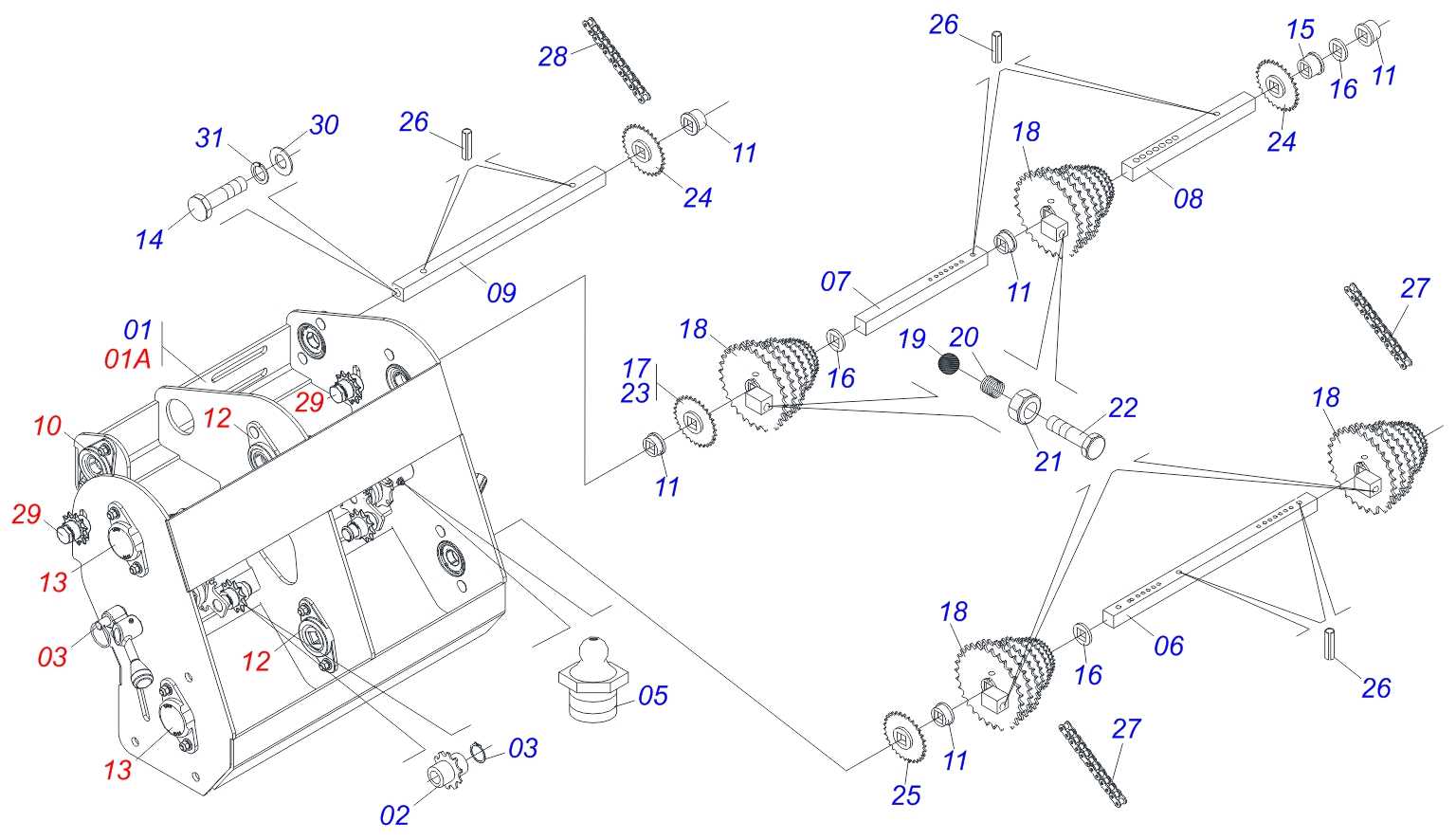

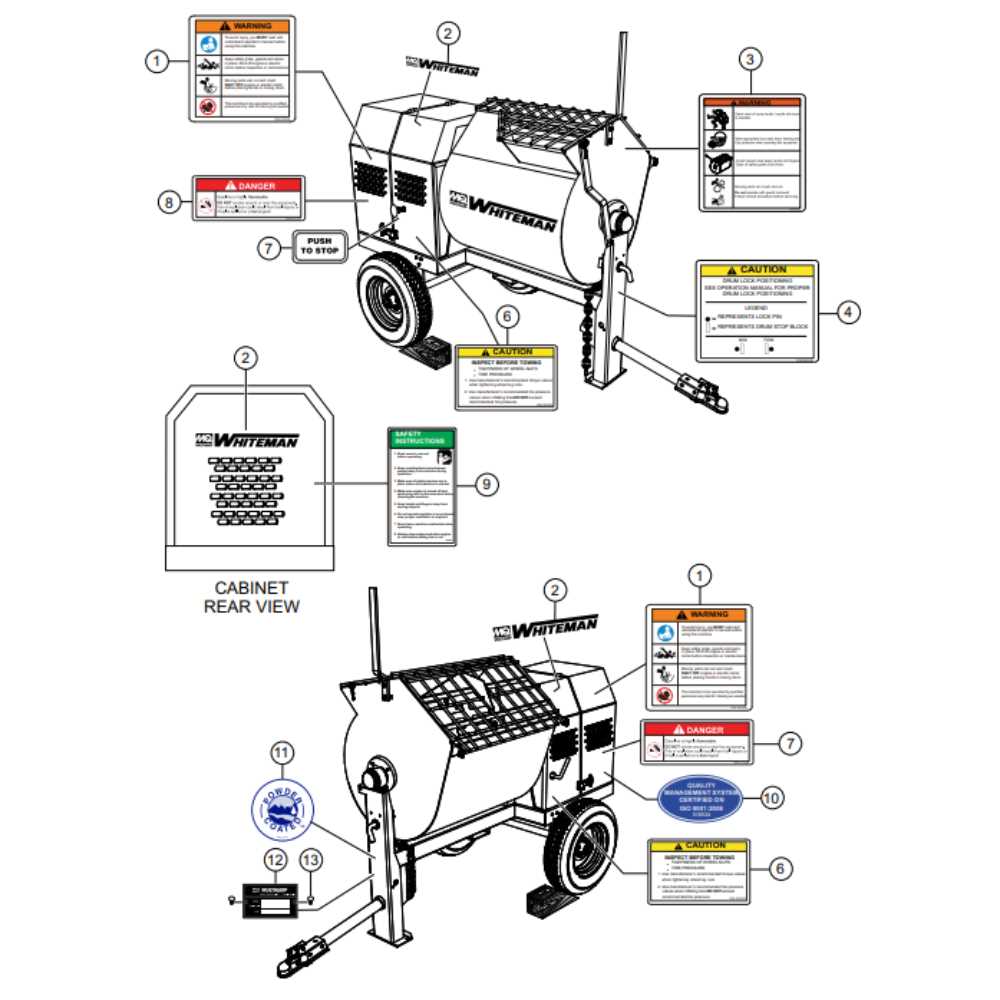

Visual Guide to Mixer Diagrams

This section provides an insightful overview of various schematics associated with mixing equipment. Understanding these illustrations can greatly enhance your knowledge of how different components interact, ensuring effective operation and maintenance. Each visual representation serves as a valuable resource for both beginners and seasoned professionals alike.

Importance of Clear Illustrations

Clear visuals are essential for grasping complex systems. They simplify the understanding of intricate setups by breaking down components into easily recognizable elements. This clarity helps users identify specific sections, troubleshoot issues, and streamline the assembly process, ultimately leading to improved performance.

Key Components to Recognize

Familiarizing yourself with the primary elements is crucial for efficient operation. Notable features often include the drive mechanism, mixing blades, and safety attachments. Recognizing these components not only aids in proper handling but also empowers users to carry out necessary adjustments and repairs confidently. Investing time in studying these visuals can pay off in the long run.

Choosing the Right Mixer for Projects

Selecting the appropriate equipment for construction tasks is crucial for achieving efficiency and quality. Various factors come into play, including the scale of the work, the type of materials involved, and the desired outcome. Understanding these elements will help you make an informed decision when it comes to your next endeavor.

Factors to Consider

- Project Scale: Determine whether your task is small-scale or large-scale. This will influence the capacity and power required.

- Material Type: Consider the consistency and viscosity of the materials you will be working with, as some devices are better suited for specific mixtures.

- Portability: If you need to move equipment frequently, look for models that are lightweight and easy to transport.

- Power Source: Evaluate whether you need electric, gas, or manual operation based on your work environment.

Types of Equipment Available

- Electric Models: Ideal for indoor use and small to medium projects; they are typically quieter and easier to operate.

- Gas-Powered Versions: Suitable for outdoor tasks and larger projects where mobility and power are essential.

- Manual Options: Best for smaller jobs and those with limited space; they require physical effort but are cost-effective.

- Specialized Variants: Consider unique tools designed for specific tasks, such as high-viscosity mixes or large batches.

Ultimately, the right choice hinges on understanding your specific needs and the demands of your project. Careful consideration of these factors will ensure you select the most effective equipment to achieve successful results.