Understanding the inner workings of agricultural machinery can significantly improve both its operation and maintenance. By exploring the arrangement and interaction of various components, operators can more effectively address potential issues, ensuring longer equipment life and more efficient fieldwork. This guide provides a detailed look at the key elements involved in the process.

The proper alignment and condition of each component play a critical role in the overall performance. From rotating mechanisms to the structural framework, every part contributes to the machine’s reliability. This examination will delve into how these elements function together, helping you maintain peak productivity and avoid costly downtimes.

By familiarizing yourself with the structure and purpose of each segment, you will gain valuable insights that can assist in both preventative measures and troubleshooting. The focus here is to empower users with the knowledge needed to keep their equipment in top shape, minimizing interruptions and maximizing results in the field.

Understanding the Components of a Farm Rake

The effectiveness of a field tool used for gathering hay or crop residue depends on the interaction between its various elements. Each part of the machinery works together to ensure smooth and efficient operation during the collection process, ensuring the even distribution and neat arrangement of materials.

Key elements include the mechanical arms, which perform the main task of gathering, and the rotating mechanism, designed to facilitate continuous movement. The structure often includes stabilizing features that maintain balance and alignment as the machine operates on uneven terrain, improving both performance and durability.

By examining these elements in detail, one can gain a better understanding of how this agricultural tool functions and the role each part plays in achieving a productive outcome during fieldwork.

Key Structural Elements of the Equipment

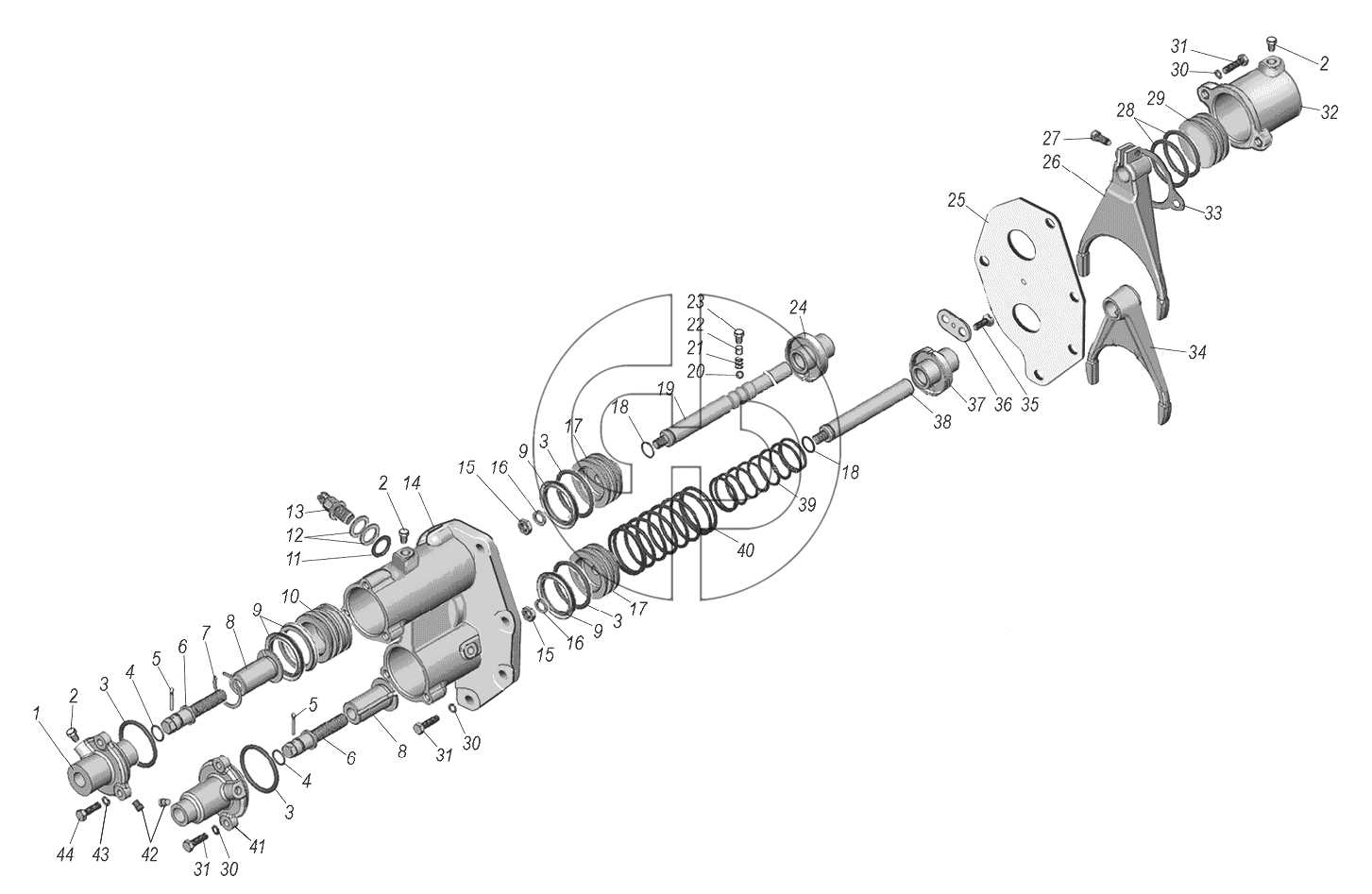

The device is built around several core components that work together to ensure its reliable functionality. Each section is designed to fulfill specific roles, contributing to the overall efficiency and durability of the unit. Understanding these essential components helps in both maintaining and optimizing the operation of the machinery.

Frame and Support Structure: This fundamental part ensures the stability and balance of the entire unit. It provides the necessary foundation, holding all other components in place and bearing the weight during operation.

Operational Mechanism: At the heart of the equipment lies a system responsible for movement and functionality. This section coordinates the mechanical actions needed for the unit to perform its primary task, with precise coordination between various moving elements.

Control System: This part allows the operator to adjust and manage the machine’s settings. With this feature, users can regulate its activity, ensuring smooth and controlled operation based

Wheel and Axle System Overview

The arrangement of circular components and rotational shafts is a fundamental aspect of agricultural equipment. These systems work together to provide movement, stability, and load distribution, ensuring smooth operation even on uneven surfaces. The efficient interaction between the rotating parts and the supporting structures plays a critical role in the overall performance.

The table below outlines the main elements of this mechanism, highlighting the key connections and components involved in ensuring effective operation:

| Component | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotational Axis | Central element providing support and facilitating motion. | ||||||||||||

| Outer Ring | Surrounding structure that interacts with the ground surface. | ||||||||||||

| Mounting Hardware | Fasteners and brackets that secure the elements to the main frame. | ||||||||||||

| Component | Function | Notes |

|---|---|---|

| Main Chassis | Serves as the backbone, supporting all connected mechanisms. | Essential for overall structural integrity. |

| Axle Assembly | Provides mobility and distributes weight evenly. | Requires regular inspection for wear. |

| Support Brackets | Reinforce the main framework and prevent structural stress. | Crucial for preventing misalignment. |

| Cross Beams | Offer additional strength

Tine Bar and Mounting System ExplainedThe tine bar and its corresponding mounting system play a crucial role in the functionality and efficiency of agricultural equipment used for harvesting. This assembly is designed to enhance the operational performance by ensuring that the tines are securely attached and effectively positioned for optimal material handling. Key aspects of the tine bar and mounting system include:

In summary, the tine bar and its mounting mechanism are integral to the effective performance of agricultural machinery, impacting the quality of the harvest and the ease of operation. Proper Maintenance for LongevityRegular upkeep is essential for ensuring the extended life of agricultural machinery. Adopting a proactive approach to maintenance not only enhances performance but also minimizes the likelihood of unexpected failures. By adhering to a systematic routine, operators can safeguard their investment and maintain efficiency. Routine InspectionsConducting consistent evaluations of equipment is crucial. This includes checking for signs of wear, loose components, and any irregularities in operation. Addressing minor issues promptly can prevent them from escalating into more significant problems. Keeping a detailed log of inspections aids in tracking performance trends and identifying recurring issues. Lubrication and CleaningProper lubrication of moving parts reduces friction and prolongs the lifespan of mechanical components. Ensure that all grease points are regularly serviced with the appropriate lubricant. Additionally, routine cleaning removes debris and dirt that can hinder performance. An unobstructed mechanism operates more efficiently, ultimately leading to increased productivity. Replacement Parts for Common WearMaintaining optimal performance in agricultural machinery is crucial for efficient operations. Over time, certain components may experience wear and tear due to regular use, necessitating timely replacements. Understanding which elements require attention can help ensure longevity and functionality. Key Components Prone to Wear

Choosing Quality AlternativesSelecting high-quality replacements is essential to maintain the efficiency of your equipment. Consider the following options:

Troubleshooting and Repair TipsAddressing common issues with agricultural machinery requires a systematic approach to identify and resolve problems effectively. Understanding the underlying components and their interactions is essential for efficient maintenance and timely repairs. This section offers guidance on diagnosing frequent challenges and implementing practical solutions. 1. Inspecting for Wear and Tear: Regularly examine key components for signs of damage or excessive wear. Look for cracks, rust, or deformation that could affect performance. Prompt replacement of worn parts can prevent further complications. 2. Lubrication Checks: Ensure that all moving elements are properly lubricated. Insufficient lubrication can lead to increased friction, causing components to overheat or fail prematurely. Use the recommended lubricant type for optimal results. 3. Monitoring Operational Efficiency: Keep an eye on the machine’s performance during operation. Unusual noises, vibrations, or changes in efficiency may indicate underlying issues. Addressing these signs early can help avoid costly breakdowns. 4. Electrical System Evaluation: Assess the wiring and connections for any signs of wear or corrosion. Faulty electrical components can lead to malfunction or complete failure. Replace damaged wires and connectors to maintain proper functionality. 5. Regular Maintenance Schedule: Establish a consistent maintenance routine to ensure all components are in good working condition. Regular checks and servicing can significantly extend the lifespan of the equipment and enhance its performance. |