In the realm of farming equipment, knowledge of individual elements is crucial for effective maintenance and repair. An intricate network of components works in harmony to ensure optimal performance of machinery. Familiarity with these parts can significantly enhance the longevity and efficiency of the entire system.

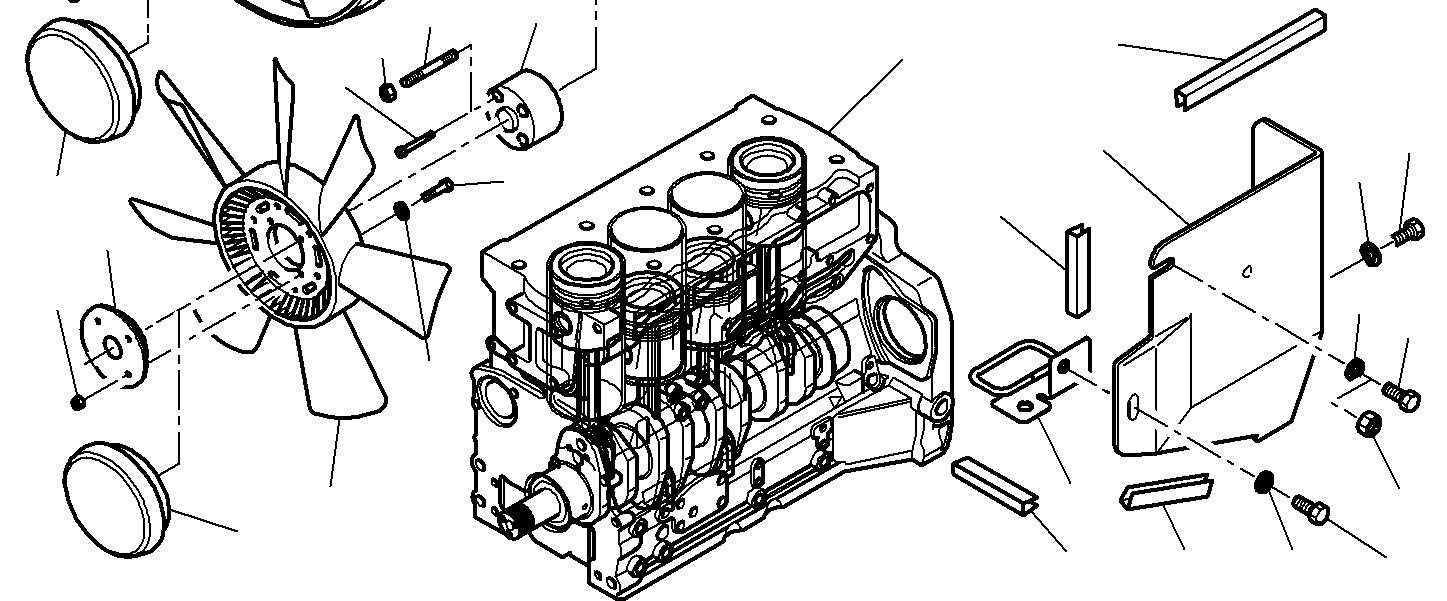

When tackling the challenges of machinery upkeep, having a comprehensive visual representation of each element is invaluable. Such illustrations facilitate a deeper understanding of how each piece interacts within the larger framework. This not only aids in troubleshooting but also empowers operators to perform routine checks with confidence.

Moreover, grasping the specifics of each component can lead to informed decisions regarding replacements and upgrades. This knowledge allows users to identify wear and tear early, potentially saving both time and resources in the long run. By delving into the intricacies of these mechanical systems, one can truly appreciate the engineering that underpins modern agricultural practices.

Massey Ferguson 175 Overview

This section provides a comprehensive understanding of a notable agricultural machine known for its reliability and efficiency in farming tasks. Designed to meet the diverse needs of modern agriculture, it combines robust engineering with user-friendly features that enhance productivity.

Key Features

One of the standout aspects of this model is its powerful engine, which ensures high performance across various terrains. Additionally, the ergonomic design facilitates ease of operation, making it accessible for both experienced operators and newcomers. The incorporation of advanced technology allows for seamless integration with various attachments, enhancing versatility on the field.

Applications

This machine is widely utilized in multiple farming applications, from tillage to harvesting. Its adaptability makes it suitable for small to medium-sized operations, while its durability ensures longevity, providing a sound investment for agricultural professionals. The efficient fuel consumption further contributes to its appeal, minimizing operational costs while maximizing output.

Key Features of Massey Ferguson 175

This section highlights the essential characteristics that make this agricultural machine a reliable choice for various farming tasks. Its design and functionality are tailored to meet the demands of modern agriculture, ensuring efficiency and ease of use for operators.

Engine Performance

The powerhouse of this model is engineered to deliver robust performance. With impressive horsepower, it excels in both heavy-duty tasks and routine operations. The fuel efficiency is another notable aspect, allowing for longer working hours without frequent refueling.

User-Friendly Design

Ergonomically designed controls and a spacious operator station enhance comfort during prolonged use. The intuitive layout simplifies operation, making it accessible for both seasoned professionals and newcomers. Maintenance access is also straightforward, facilitating timely servicing and minimizing downtime.

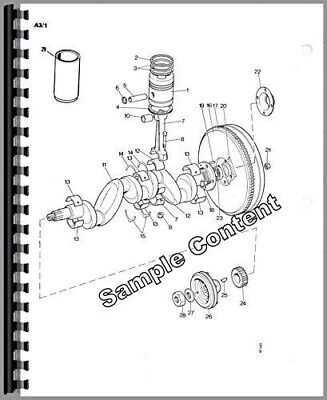

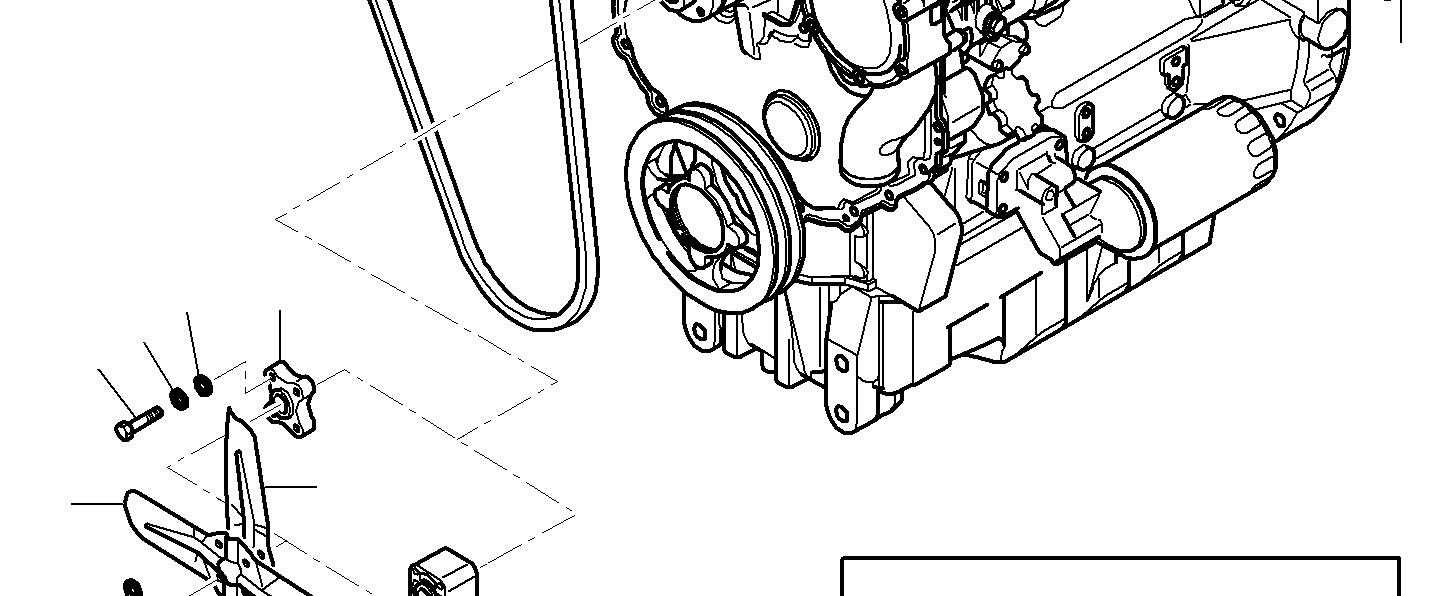

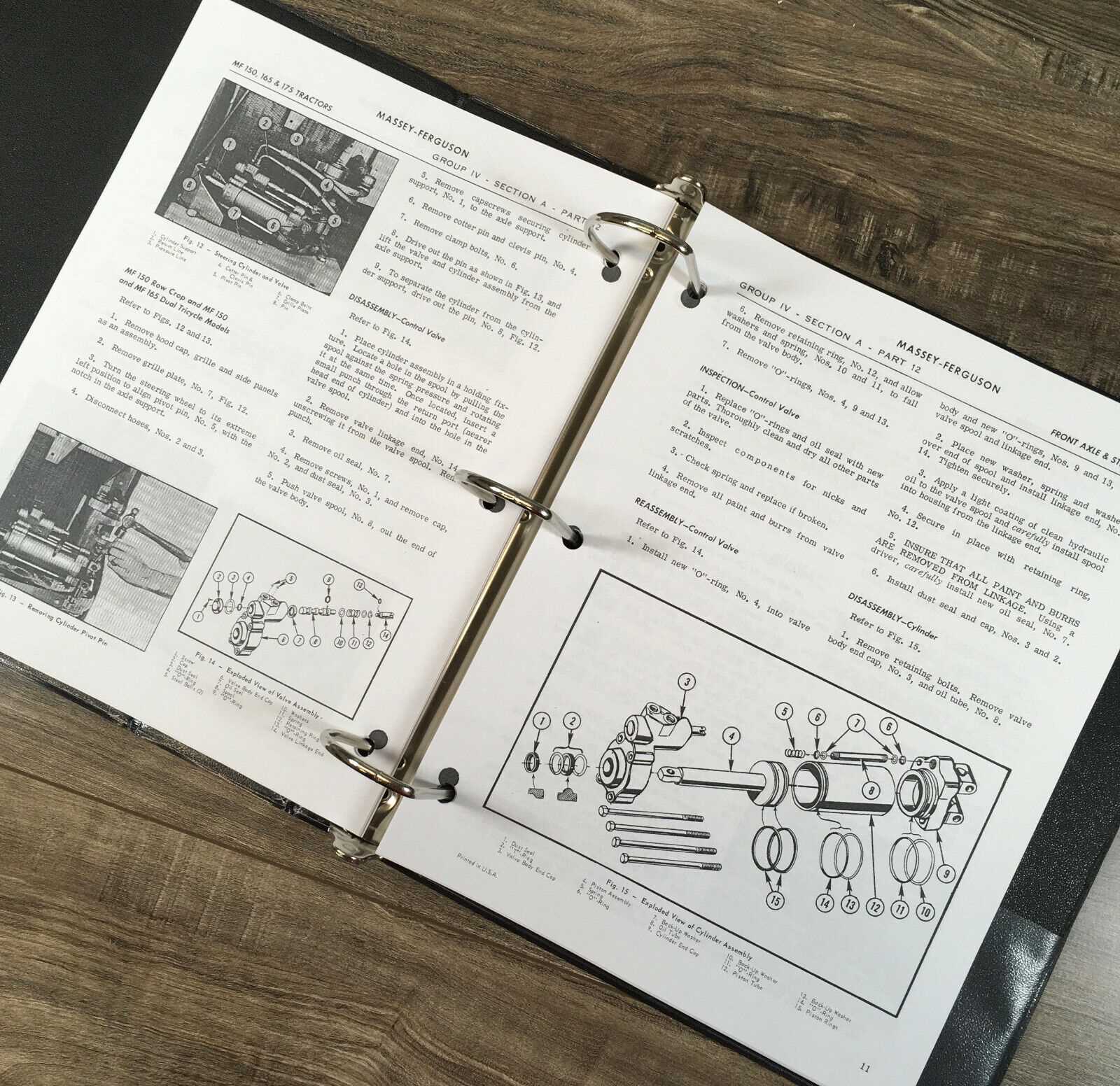

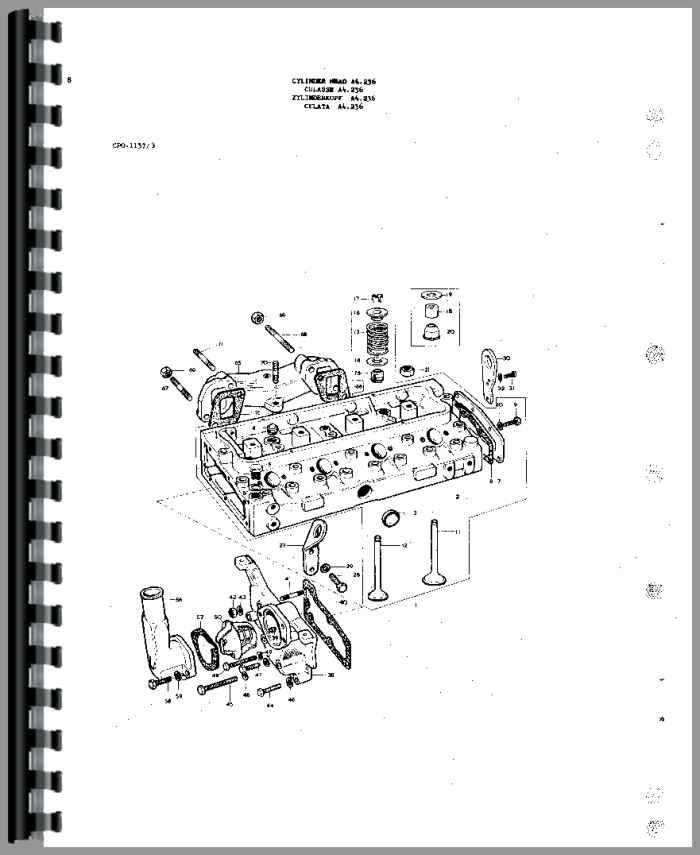

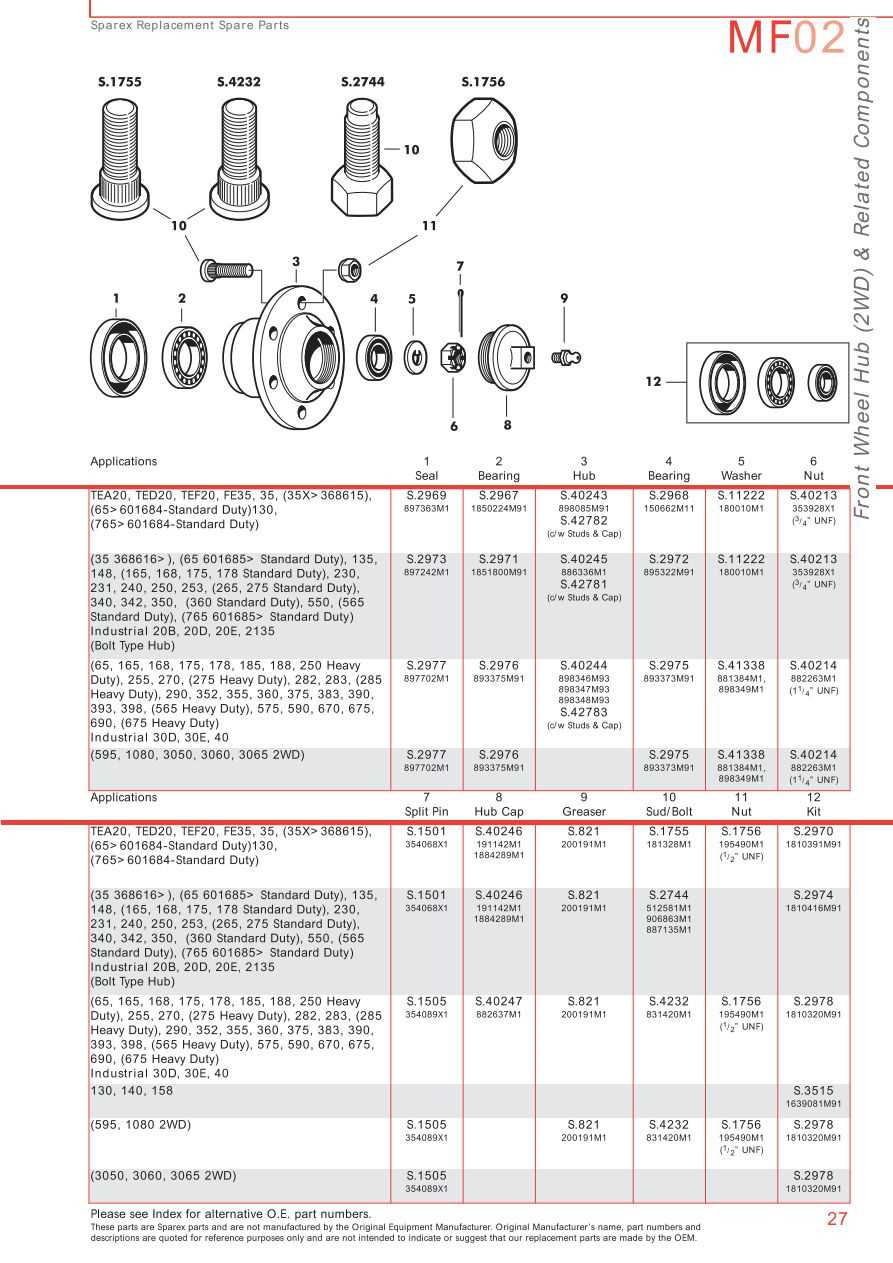

Importance of Parts Diagrams

Understanding the intricacies of machinery requires a visual representation that simplifies complex components. Such illustrations serve as essential tools for maintenance, repair, and overall functionality, allowing operators to identify and manage each element effectively.

Enhancing Maintenance Efficiency

Visual aids not only streamline the repair process but also minimize the likelihood of errors. By providing a clear overview, they help technicians quickly locate specific sections and understand their interrelations, leading to timely interventions and reduced downtime.

Facilitating Effective Communication

When sharing information among team members, these illustrations are invaluable. They enable clear communication regarding the assembly and disassembly of equipment, ensuring everyone is on the same page and enhancing collaborative efforts in troubleshooting and repairs.

Understanding Component Functions

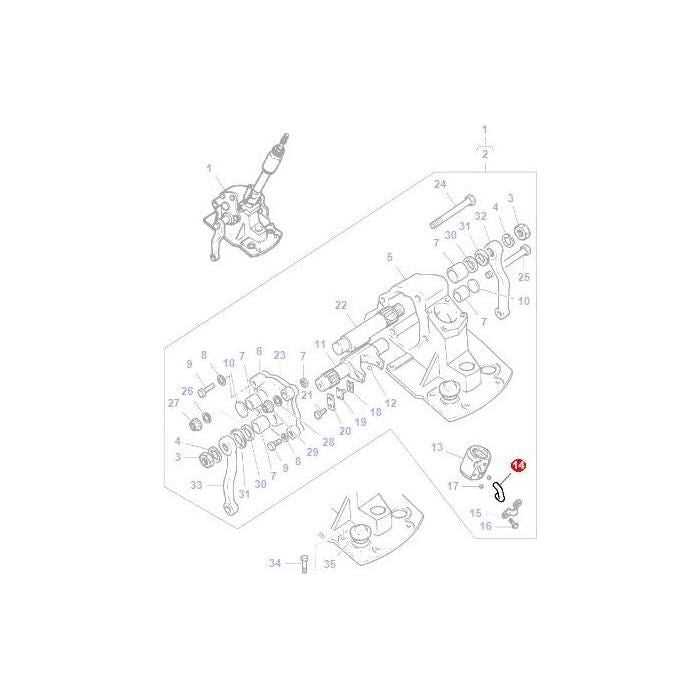

Grasping the roles of individual elements within a machinery system is crucial for optimal performance and maintenance. Each component contributes to the overall functionality, influencing efficiency and reliability. Recognizing these functions allows users to make informed decisions regarding upkeep and troubleshooting.

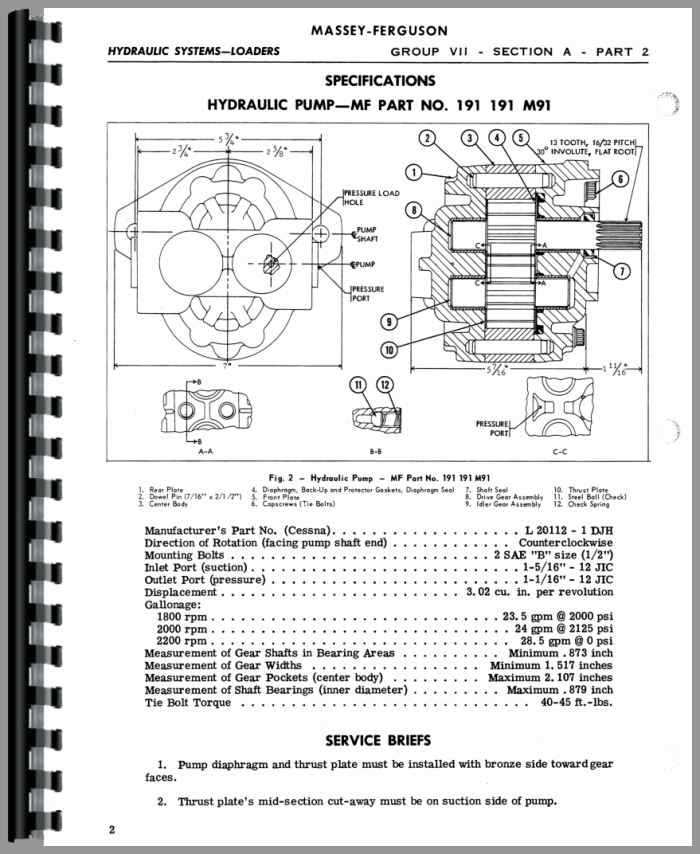

Key Elements and Their Roles

Various sections of machinery work in unison to achieve seamless operation. For instance, the power transmission unit transfers energy, while the hydraulic system ensures smooth movement. Understanding these roles helps in diagnosing issues and planning for repairs.

Impact on Performance

The interplay between components significantly affects overall effectiveness. When one element underperforms, it can lead to cascading failures in others. Therefore, a thorough comprehension of each part’s function is vital for maintaining peak operational standards.

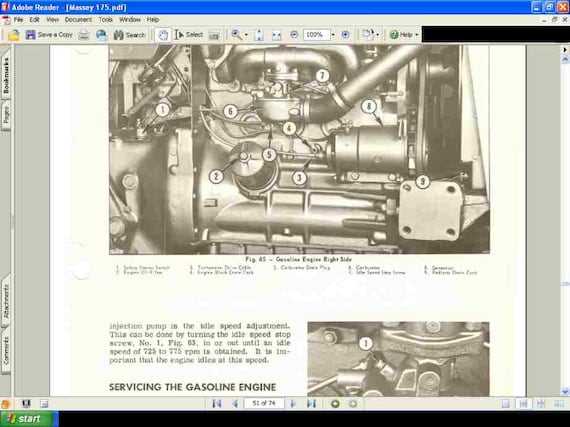

Common Issues with Massey Ferguson 175

This section addresses frequent challenges faced by operators of a certain classic agricultural machine. Understanding these issues is essential for effective maintenance and prolonging the lifespan of the equipment.

Engine Problems

Engine-related difficulties are among the most prevalent concerns. These may include starting issues, overheating, or unusual noises, often stemming from fuel system malfunctions or wear and tear.

Hydraulic System Failures

The hydraulic system can experience several complications, such as leaks or inadequate pressure. These problems can significantly impact the machine’s operational efficiency.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Starting issues | Engine won’t turn over | Check battery and starter |

| Overheating | Temperature gauge rising | Inspect coolant levels |

| Hydraulic leaks | Visible fluid under the machine | Replace damaged seals |

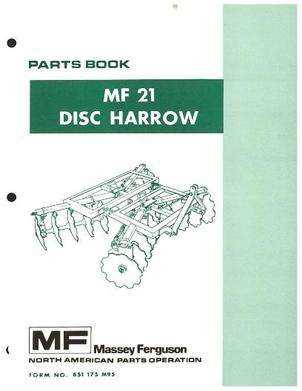

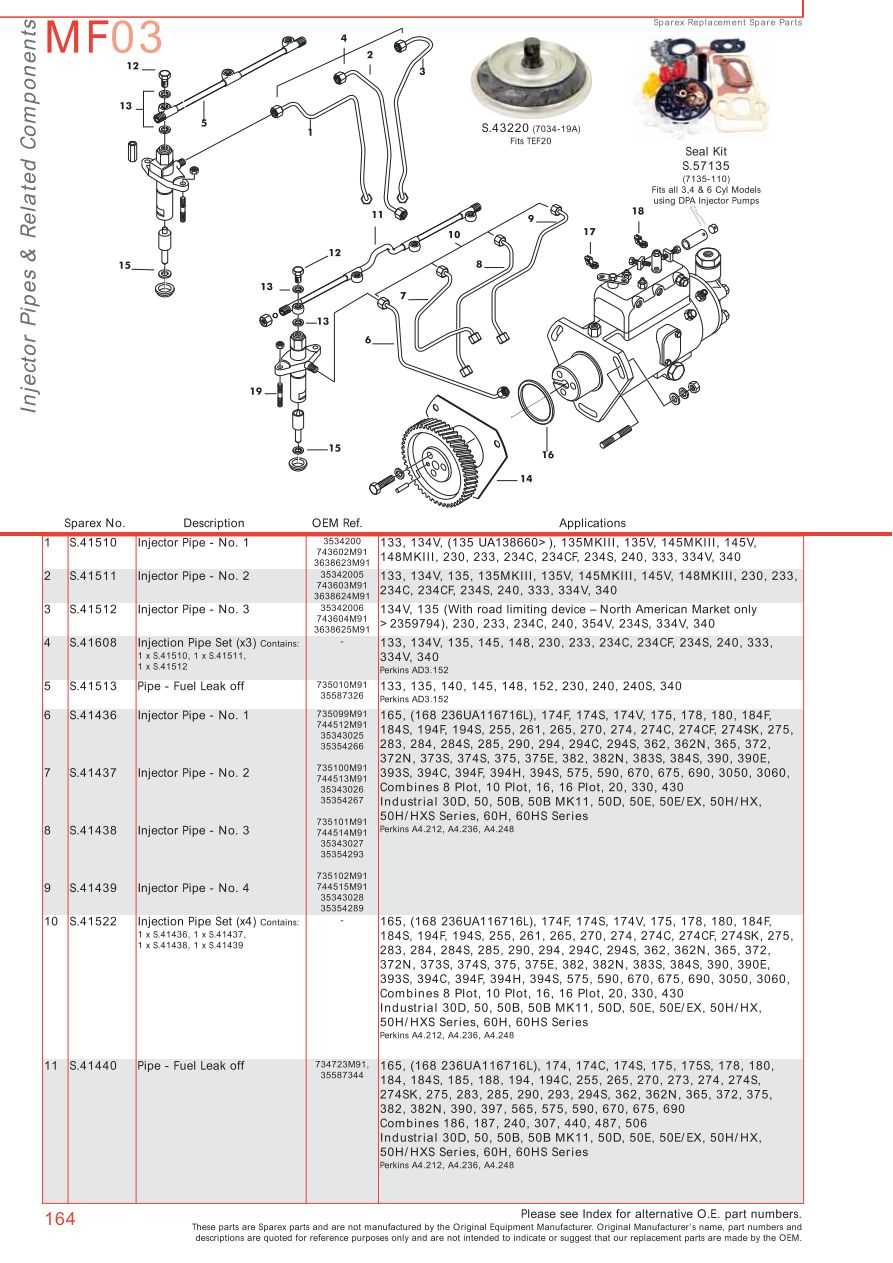

Finding Replacement Parts Efficiently

Locating suitable components for machinery can often feel overwhelming. With numerous options available, it is essential to adopt an effective approach to streamline the process. Understanding where to search and how to assess the quality of the items can significantly enhance your experience, ensuring that you acquire the correct items quickly and easily.

Utilizing Online Resources

The internet serves as a powerful tool for sourcing necessary components. Various websites provide extensive catalogs that allow users to search for specific items using model numbers or descriptions. This method not only saves time but also helps in comparing prices and finding reviews from other customers.

Consulting with Professionals

Engaging with experts in the field can provide valuable insights and recommendations. Mechanics and equipment dealers often possess extensive knowledge about the best sources for quality components, and they can guide you in identifying reliable suppliers.

| Resource Type | Benefits |

|---|---|

| Online Marketplaces | Wide selection, price comparison |

| Manufacturer Websites | Authentic products, detailed specifications |

| Local Dealers | Personalized service, immediate availability |

| Forums and Community Groups | Advice from experienced users, troubleshooting tips |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of machinery requires regular upkeep and attention to detail. Implementing a routine maintenance schedule not only extends the lifespan of equipment but also enhances performance, ultimately leading to increased productivity. Here are some essential practices to consider for maintaining your machinery effectively.

Regular Inspections

Conducting frequent inspections is crucial for identifying wear and tear before it becomes a significant issue. Check fluid levels, belts, and hoses regularly to ensure they are in optimal condition. Look for any signs of leaks or unusual noises that may indicate potential problems. Addressing these concerns promptly can prevent costly repairs down the line.

Proper Lubrication

Lubrication plays a vital role in reducing friction and wear on moving parts. Use the recommended lubricants and adhere to the specified intervals for application. Keeping components well-lubricated not only improves efficiency but also minimizes the risk of overheating and mechanical failure, contributing to the overall longevity of the equipment.

Resources for Parts Diagrams

Accessing detailed schematics is essential for anyone involved in machinery maintenance or repair. These resources provide valuable insights into component layout and functionality, aiding in efficient troubleshooting and replacement.

- Official Manufacturer Websites: Many companies offer downloadable manuals and technical drawings directly on their sites.

- Online Forums: Community-driven platforms often have users sharing their own resources and insights, including links to diagrams.

- Repair Manuals: Numerous publishers produce comprehensive guides that include illustrations and parts lists.

- Specialized Retailers: Websites that sell machinery parts frequently feature schematics for their products to assist customers.

When searching for specific schematics, consider utilizing search engines effectively. Incorporating keywords related to your equipment’s model and type will yield more relevant results.

In addition to digital resources, local libraries or technical schools may have printed manuals available. Engaging with knowledgeable professionals in repair shops can also lead to discovering valuable references.