In the realm of woodworking and construction, mastering the functionality of precision cutting equipment is essential for achieving accurate results. Each tool is designed with a variety of elements that contribute to its overall performance and effectiveness. By familiarizing oneself with these individual components, users can optimize their workflow and enhance the quality of their craftsmanship.

Whether you are a seasoned professional or a novice enthusiast, recognizing how each piece works together is vital. This knowledge not only aids in the maintenance and care of the equipment but also empowers users to troubleshoot issues as they arise. The intricacies of these instruments can significantly impact the efficiency and precision of any project.

Exploring the various elements that comprise these cutting tools unveils a world of possibilities for improvement and innovation. Understanding the relationship between different components allows for informed decisions when selecting and utilizing the right tool for specific tasks. As you delve into this topic, you’ll discover how each part plays a crucial role in the art of precision cutting.

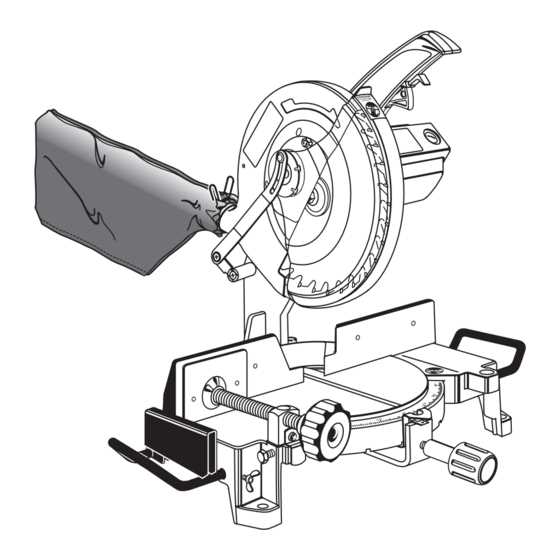

Understanding Mitre Saw Components

Exploring the essential elements of a cutting tool reveals a complex interplay of components that work in harmony to achieve precision and efficiency. Each segment plays a crucial role, contributing to the overall functionality and performance of the device.

- Base: Provides stability and support during operation.

- Blade: The primary tool for making cuts, varying in size and type.

- Motor: Powers the movement and rotation of the cutting edge.

- Arm: Facilitates the pivoting motion for angled cuts.

- Fence: Helps guide the material for accurate cutting.

Understanding these components allows users to delve deeper into the tool’s capabilities, ensuring optimal performance in various projects.

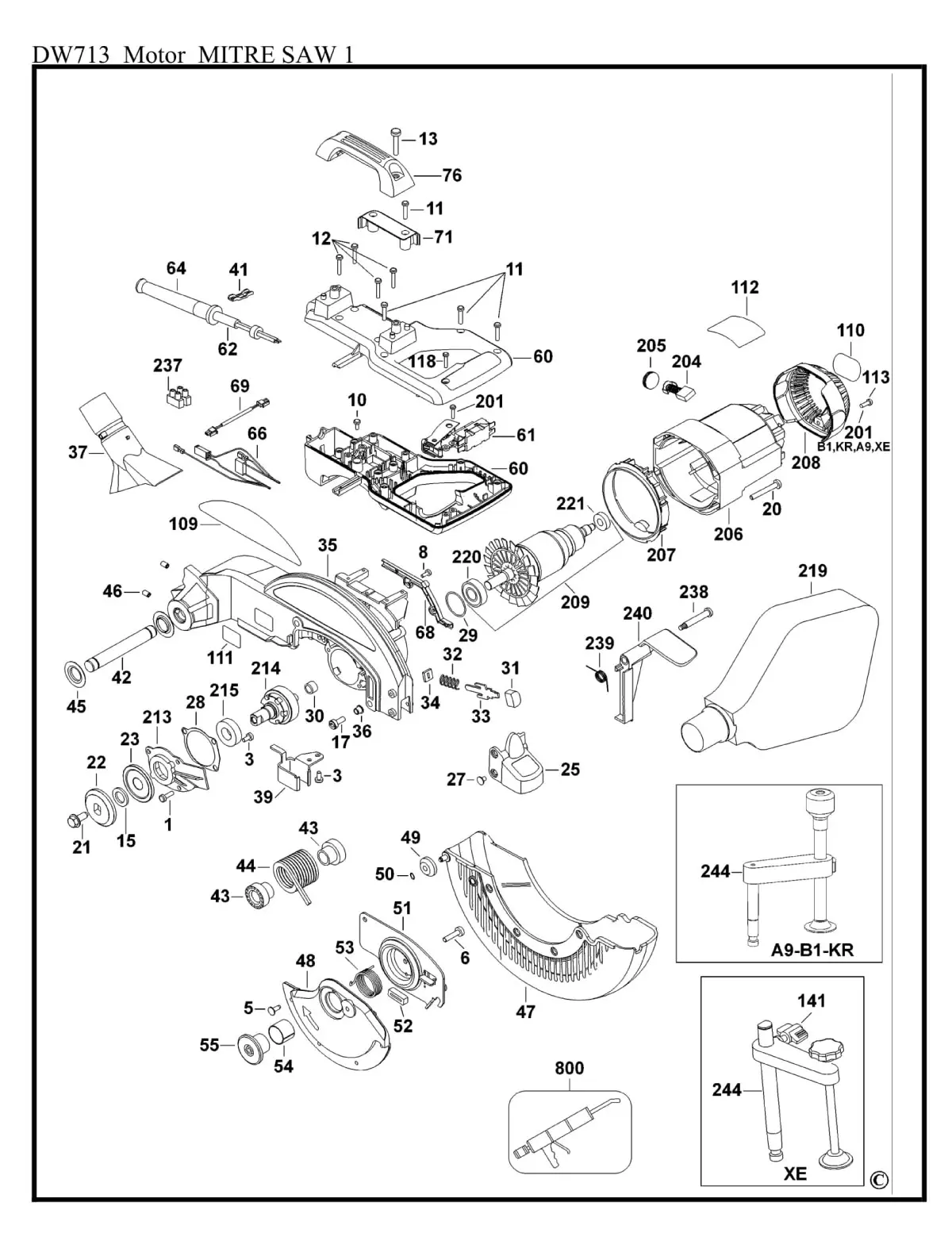

Main Functions of Each Part

Understanding the individual components of a cutting tool is essential for effective operation and maintenance. Each element plays a vital role in ensuring precision and safety during use. This section outlines the primary responsibilities associated with each component, highlighting their importance in the overall functionality of the equipment.

Base: The foundation provides stability and support, ensuring that the entire apparatus remains steady during operation. A robust base minimizes vibrations, enhancing accuracy.

Arm: This part facilitates the movement of the cutting mechanism, allowing for adjustable angles and positions. Its design enables smooth and controlled motions, essential for precise cuts.

Blade: The cutting edge is critical for performance, designed to slice through various materials effectively. The type of blade chosen significantly impacts the quality and efficiency of the work.

Handle: The grip is designed for comfort and control, enabling the user to operate the machine safely. An ergonomic handle reduces fatigue, allowing for longer working periods without discomfort.

Guard: Safety is paramount, and this protective covering shields users from potential hazards. It prevents accidental contact with the blade while allowing for visibility during operation.

Adjustment Mechanism: This feature allows users to modify settings for depth and angle of cuts. A reliable adjustment system enhances versatility, accommodating different project requirements.

Motor: The power source drives the blade, and its efficiency affects the overall performance of the tool. A high-quality motor ensures consistent speed and reduces the risk of overheating.

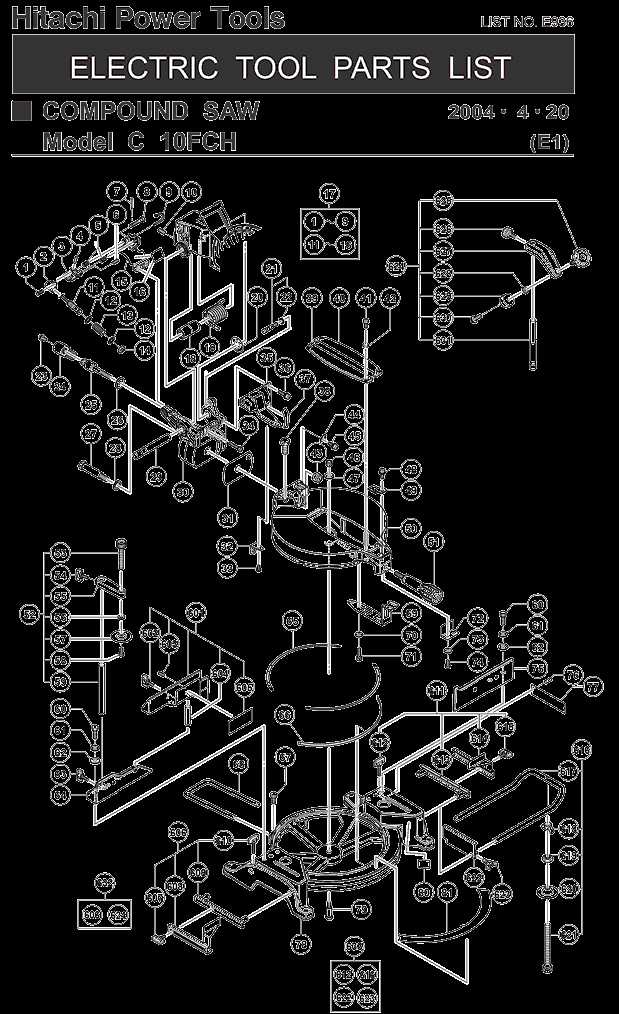

Common Types of Mitre Saws

When it comes to precision cutting tools, various designs cater to specific needs and tasks. Understanding the different types allows users to choose the right tool for their projects, enhancing both efficiency and accuracy.

Types Overview

Each design serves a unique purpose, from basic models for simple cuts to advanced versions that provide versatility and complex functionality. Here are the primary categories:

| Type | Description |

|---|---|

| Basic | Ideal for straightforward angled cuts, perfect for beginners. |

| Compound | Offers additional bevel capabilities, allowing for more complex angles. |

| Sliding | Features a sliding mechanism to extend cutting capacity, suitable for wider materials. |

| Laser-guided | Equipped with laser technology for enhanced cutting accuracy. |

Choosing the Right Tool

Identifying the most suitable type hinges on the intended use. Professionals and hobbyists alike benefit from selecting a model that aligns with their specific cutting requirements.

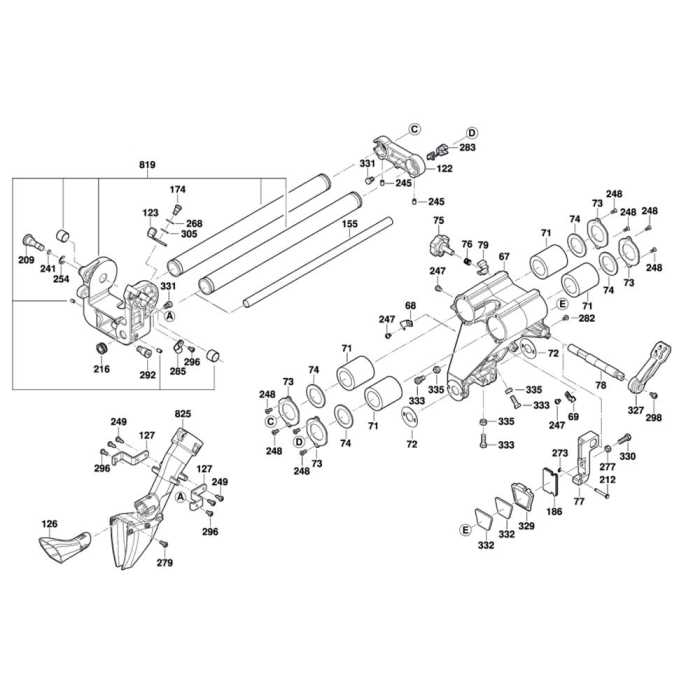

How to Identify Parts in Diagrams

Understanding how to recognize components in visual representations is crucial for effective interpretation and usage. These illustrations often serve as guides, providing insights into the structure and functionality of various tools. By familiarizing yourself with the common elements and their arrangements, you can enhance your ability to analyze and apply the information presented.

Familiarize Yourself with Common Symbols

Each visual representation typically employs a set of standardized symbols to denote specific elements. Becoming acquainted with these symbols will allow for quicker identification and comprehension. Many resources, including manuals and online platforms, offer glossaries or keys that explain these visual markers. Studying these references can significantly improve your understanding of how each component interacts within the larger system.

Practice Interpreting Illustrations

Regular practice in analyzing various illustrations can greatly enhance your skillset. Begin with simple examples before progressing to more complex representations. Try to outline the connections and functions of each component as you study. This method will help solidify your knowledge and make it easier to interpret more intricate visuals in the future.

Safety Features in Mitre Saws

When working with precision cutting tools, ensuring user safety is paramount. Various mechanisms and enhancements are integrated into these machines to minimize risks and protect operators during use. Understanding these features is essential for anyone looking to utilize them effectively and securely.

Guarding Mechanisms

One of the primary safety components includes guarding systems that prevent accidental contact with the blade. These shields automatically retract when in use and return to position when not engaged, significantly reducing the chance of injuries.

Electronic Safety Systems

Advanced tools often incorporate electronic features that enhance safety. For instance, soft start technology minimizes kickback, while blade brake systems rapidly halt rotation, ensuring the utmost control and safety during operation.

Maintaining Your Mitre Saw

Proper upkeep of your cutting tool is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances the precision of your equipment but also promotes safety during operation. Implementing a systematic approach to care can significantly extend its lifespan, reduce the likelihood of malfunctions, and maintain cutting accuracy.

Routine Care Steps

To keep your device in top condition, follow these key maintenance steps:

| Task | Frequency | Description |

|---|---|---|

| Clean the surface | After each use | Remove sawdust and debris from the table and blade to prevent buildup. |

| Inspect the blade | Monthly | Check for damage or dullness; replace if necessary for optimal cutting. |

| Lubricate moving parts | Quarterly | Apply lubricant to pivot points and sliding mechanisms to ensure smooth operation. |

| Check alignment | Every six months | Verify that the alignment is correct to maintain accurate cuts and prevent wear. |

Storing Your Equipment

Proper storage is equally important. Always keep your device in a dry and stable environment. Use a protective cover to shield it from dust and moisture, which can lead to rust and degradation. Additionally, storing the tool away from extreme temperatures will help preserve its components.

Choosing the Right Blade Type

Selecting the appropriate cutting tool is essential for achieving optimal results in various woodworking tasks. The right blade can significantly enhance efficiency, precision, and the quality of the finished product. Understanding the different types available and their specific applications will help users make informed choices based on their project requirements.

When evaluating cutting instruments, consider the material being worked with. Blades designed for softwoods differ from those made for hardwoods or composite materials. The number of teeth on the blade also plays a crucial role; a higher tooth count typically provides a smoother finish, while fewer teeth can facilitate quicker cuts. Additionally, the blade’s thickness and design influence the depth of cut and potential for splintering.

Another factor to consider is the type of cut desired. Crosscuts, rip cuts, and angled cuts each require distinct blade characteristics to perform effectively. Specialized blades, such as those with alternate top bevel (ATB) or flat top grind (FTG) designs, can provide enhanced performance for specific tasks.

Ultimately, selecting the right cutting tool is about aligning the blade’s attributes with the intended application, ensuring both efficiency and high-quality results in every project.

Upgrading Mitre Saw Accessories

Enhancing the functionality of your cutting tool can significantly improve your efficiency and precision in various projects. By investing in high-quality add-ons, you can achieve cleaner cuts, better safety measures, and an overall more enjoyable experience. This section will explore the benefits of upgrading your equipment and highlight key accessories that can take your cutting capabilities to the next level.

Essential Accessories for Enhanced Performance

When it comes to optimizing your tool, several components can make a considerable difference. Here are some of the most beneficial accessories that you might consider adding to your arsenal:

| Accessory | Benefits | Compatibility |

|---|---|---|

| Laser Guide | Improves accuracy and alignment, making precise cuts easier. | Most standard models |

| Dust Collection System | Minimizes cleanup time and improves visibility while working. | Varies by manufacturer |

| Replacement Blades | Different tooth configurations for specific materials provide cleaner cuts. | Compatible with various brands |

| Clamping System | Secures workpieces, enhancing safety and stability during operation. | Universal fit |

Choosing the Right Upgrades

Before making any purchases, consider your specific needs and the types of projects you frequently undertake. Not all enhancements will suit every user, so it’s essential to assess compatibility and functionality. Researching and selecting the right tools will not only elevate your performance but also enhance your overall experience.