Exploring the intricacies of marine engines reveals a wealth of knowledge that is essential for any enthusiast or professional. A particular focus on a specific 40 HP model unveils a myriad of components working in harmony to ensure optimal performance. Familiarity with these elements not only enhances maintenance but also deepens the appreciation for marine engineering.

Each section of the engine plays a critical role in its functionality, from the ignition system to the fuel delivery mechanisms. Understanding the layout and relationship between these elements is crucial for troubleshooting and repairs. By dissecting the structure, one gains insights into how each component contributes to the overall efficiency and reliability of the vessel.

For those involved in the upkeep or enhancement of their outboard engine, having a comprehensive visual reference is invaluable. It enables users to identify parts swiftly and understand their interactions. This knowledge empowers boat owners to tackle repairs with confidence and ensures that their watercraft remains in peak condition for countless adventures on the water.

Understanding Mercury 40 HP 2-Stroke Engines

The 40 HP outboard motors are renowned for their robust performance and reliability, making them a popular choice for various marine applications. These engines are designed to deliver impressive power-to-weight ratios, facilitating efficient navigation on the water. Their engineering combines simplicity with functionality, providing users with a dependable option for recreational boating and fishing.

Key Features

One of the defining characteristics of these engines is their compact design, which allows for easy installation and maneuverability. The lightweight construction ensures that vessels remain agile, while the potent power output enables quick acceleration and strong towing capabilities. Additionally, their straightforward maintenance requirements make them accessible for enthusiasts and casual users alike.

Performance and Efficiency

When it comes to performance, these engines are engineered to operate efficiently across a range of conditions. They offer smooth acceleration and consistent power delivery, which is essential for both leisurely outings and more demanding tasks. The design optimizes fuel consumption, providing users with a cost-effective solution for their maritime activities.

Applications

These motors are versatile and suitable for various applications, including fishing boats, small recreational crafts, and tenders. Their reliability makes them a favorite among fishermen who require dependable performance in various water conditions. Whether navigating calm lakes or choppy seas, these engines are engineered to meet the demands of diverse boating environments.

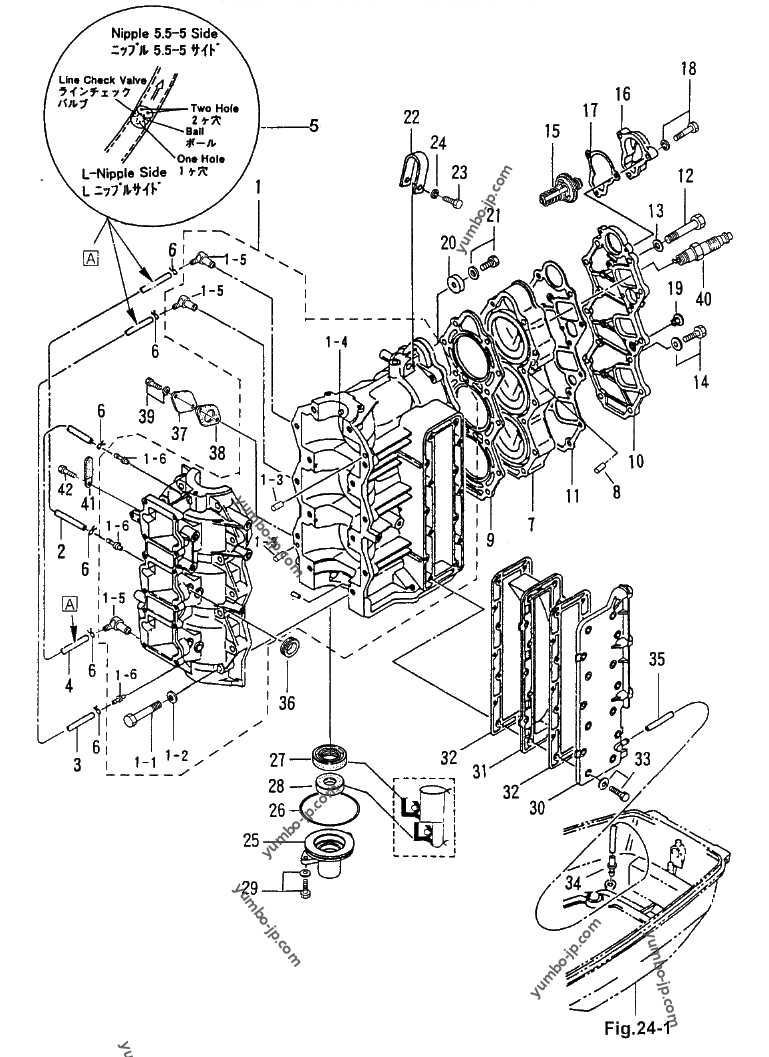

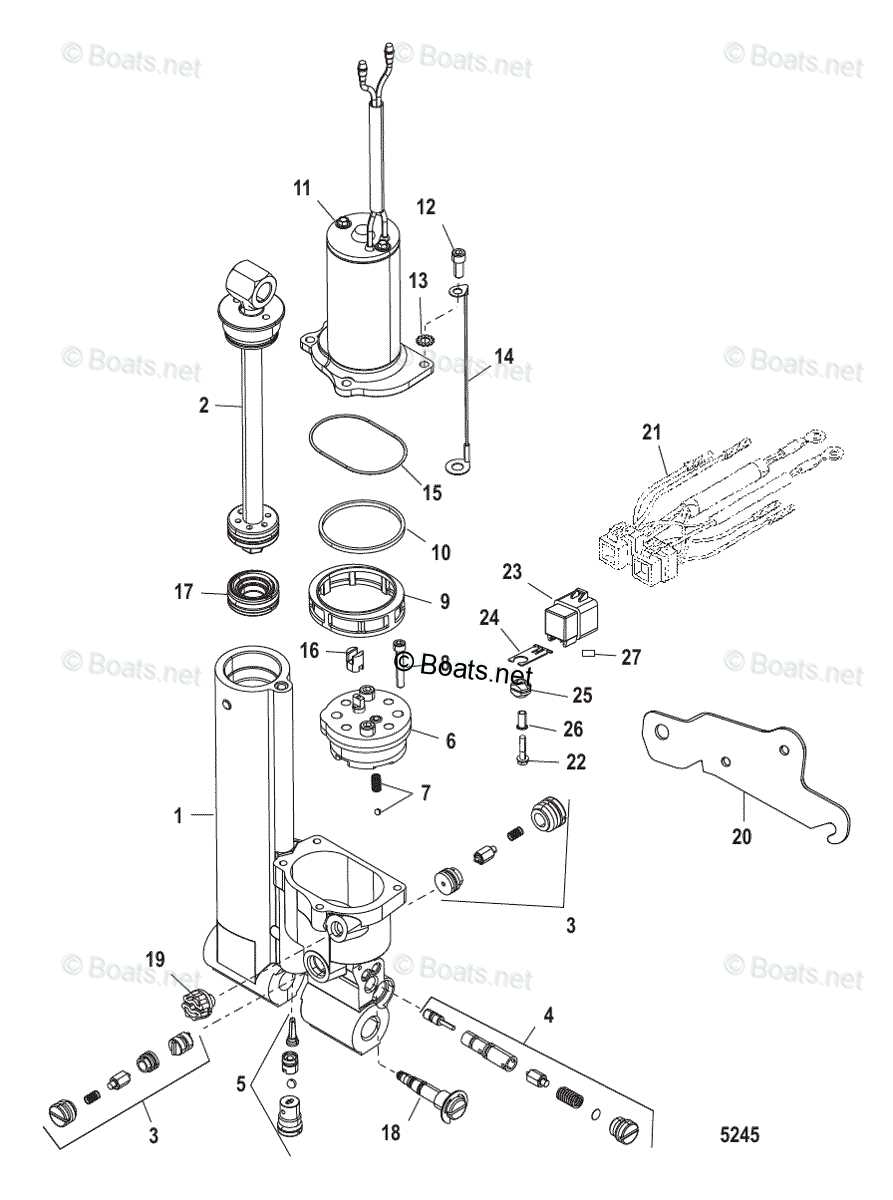

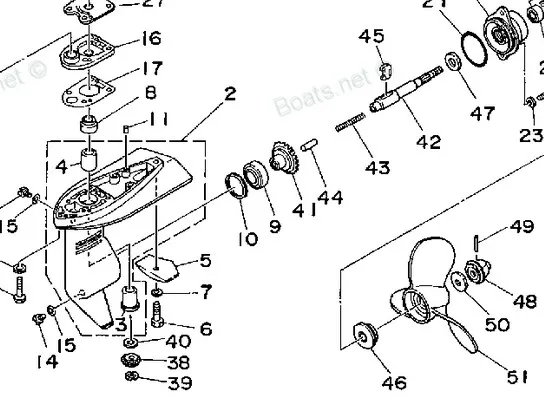

Key Components of Mercury 40 HP

This section explores the essential elements that contribute to the functionality and performance of the 40 HP outboard engine. Understanding these components is crucial for maintenance and troubleshooting, ensuring optimal operation on the water.

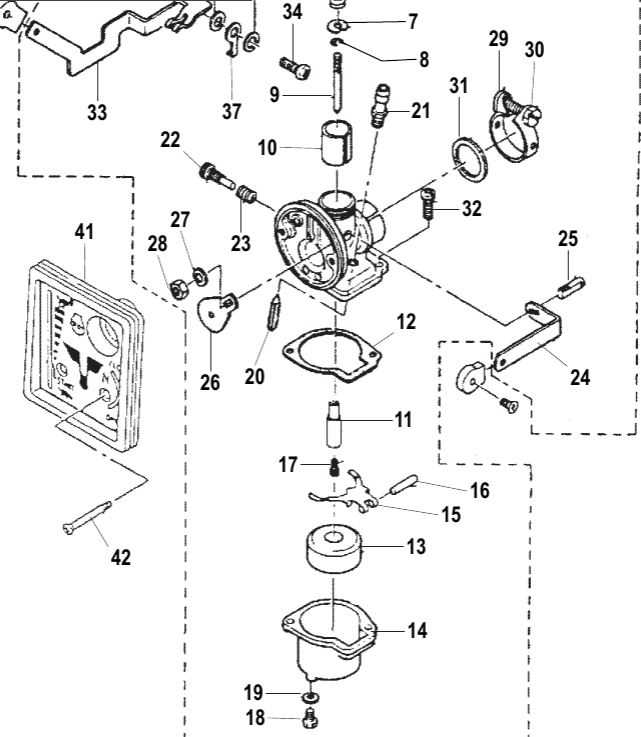

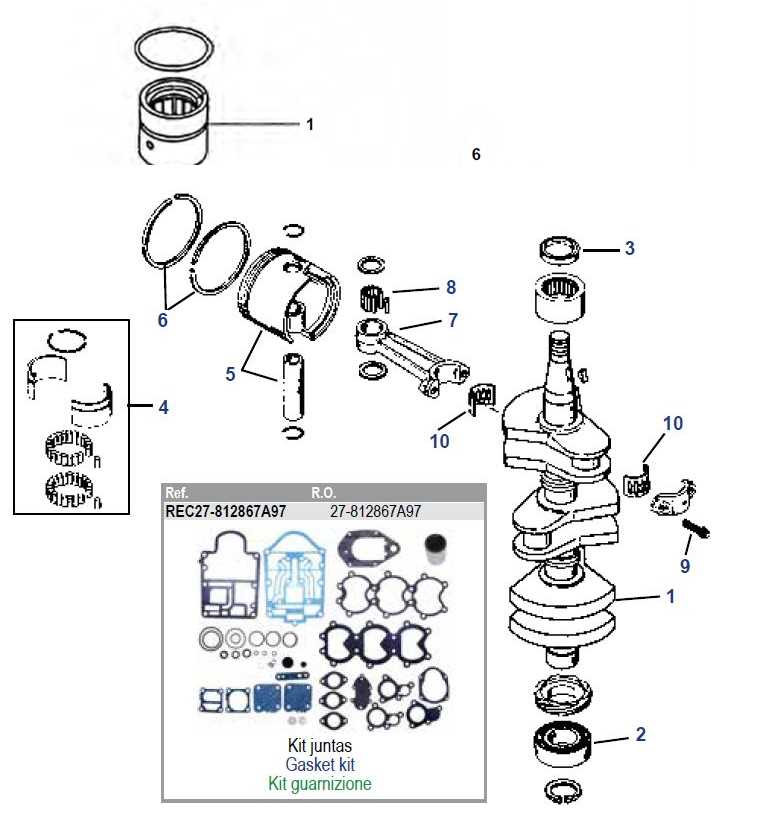

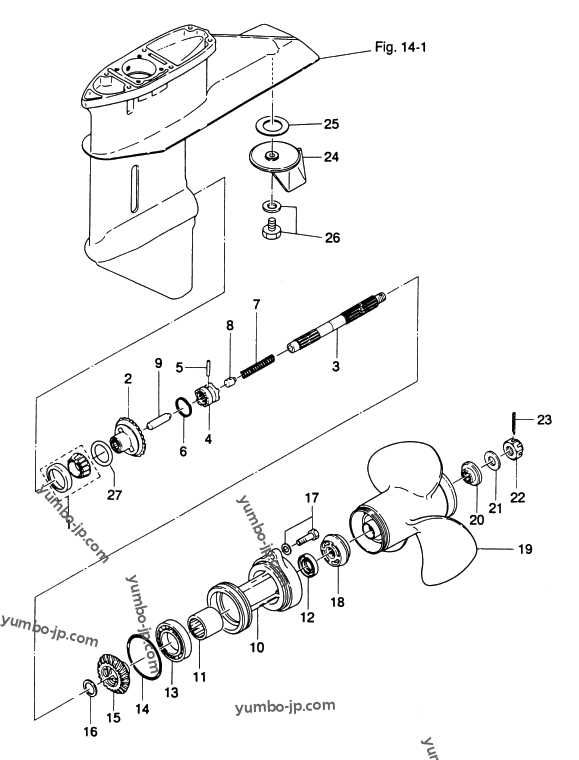

Essential Engine Parts

Each part plays a vital role in the engine’s overall performance. Key elements include the powerhead, fuel system, and ignition system, which work together to deliver reliable power and efficiency.

Component Overview

| Component | Description |

|---|---|

| Powerhead | Central unit where combustion occurs, generating power. |

| Fuel System | Manages the delivery and mixing of fuel and air. |

| Ignition System | Responsible for sparking combustion and initiating the power cycle. |

| Lower Unit | Houses the propeller and drives the engine’s output to the water. |

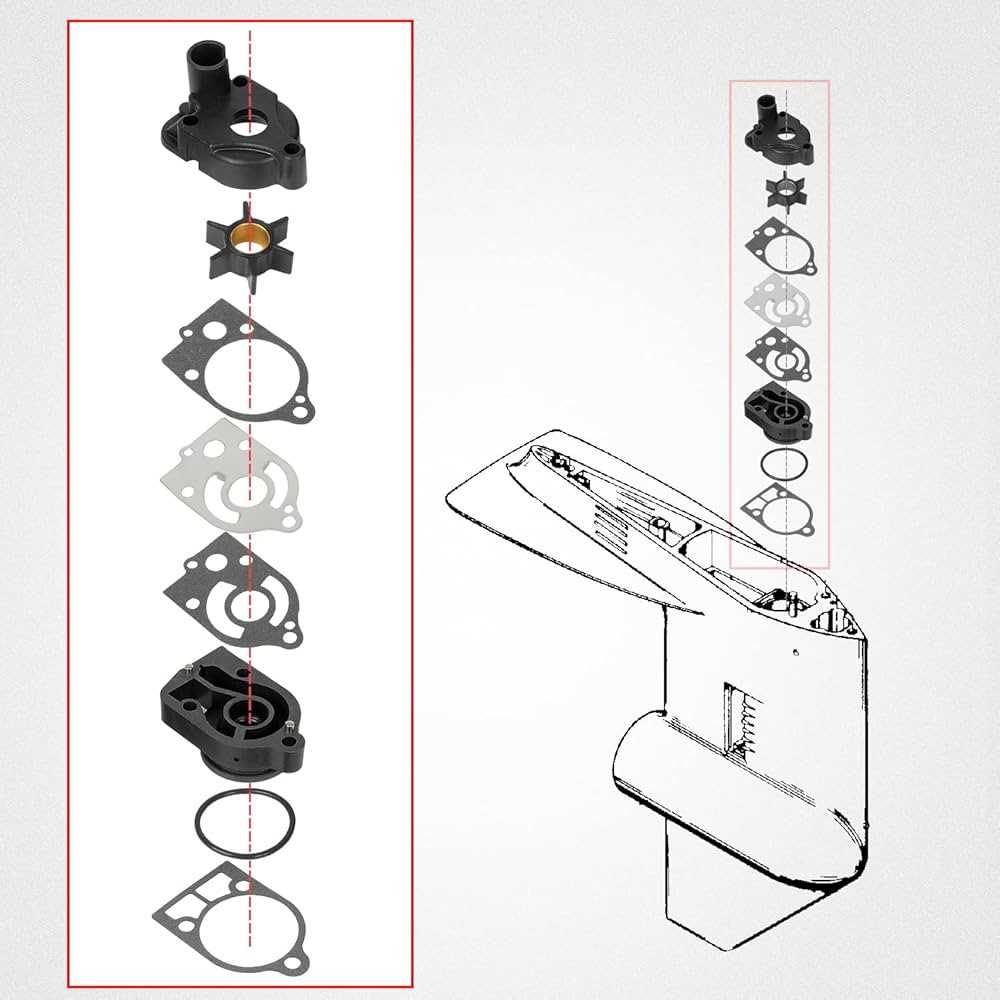

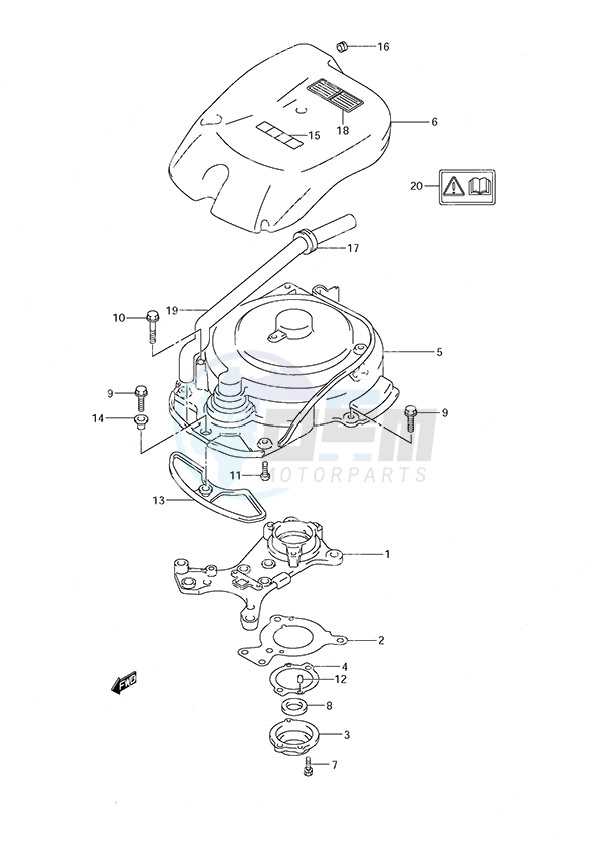

Importance of Parts Diagrams

Understanding the intricate components of any machinery is essential for effective maintenance and repair. Visual representations serve as crucial tools for both novice and experienced technicians, allowing them to grasp the arrangement and function of each element. This clarity can enhance efficiency and reduce the likelihood of errors during repairs.

Effective troubleshooting relies heavily on accurate visuals that depict the relationships between various components. By having a clear reference, individuals can quickly identify potential issues and implement appropriate solutions.

Moreover, these illustrations facilitate communication among team members, ensuring everyone is on the same page. When discussing repairs or upgrades, a shared visual aid can streamline conversations and enhance collaborative efforts.

Ultimately, leveraging these resources not only improves the repair process but also extends the lifespan of the equipment by promoting informed decision-making and timely maintenance.

Common Issues in 2-Stroke Engines

Two-cycle engines, while celebrated for their simplicity and power, often face a range of challenges that can affect performance and longevity. Understanding these common problems is crucial for maintenance and troubleshooting.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Poor Fuel Mix | Loss of power, excessive smoke | Adjust fuel-oil ratio |

| Clogged Exhaust | Overheating, reduced efficiency | Clean or replace muffler |

| Worn Piston Rings | Increased oil consumption, misfiring | Replace piston rings |

| Fuel Contamination | Starting issues, rough idling | Use fresh fuel, clean carburetor |

| Overheating | Engine seizing, loss of compression | Check cooling system, inspect for blockages |

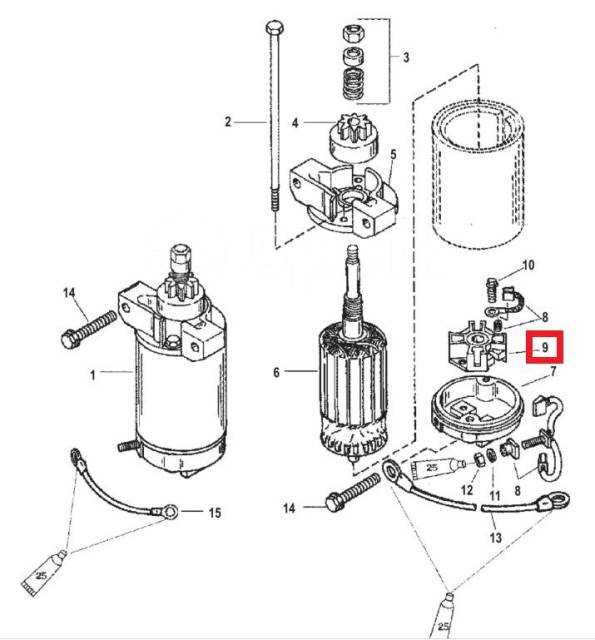

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair of machinery. These illustrations serve as a roadmap, guiding you through the various components and their relationships within the system. By familiarizing yourself with these visuals, you can enhance your ability to identify specific elements and comprehend their functions.

Familiarization with Symbols: Different icons and symbols represent various elements. It’s crucial to know what each symbol indicates to avoid confusion. Spend time reviewing the legend or key, as this will clarify any unfamiliar representations.

Component Relationships: Pay attention to how components are connected. Arrows and lines often indicate flow or movement, showing how parts interact with one another. This understanding can be vital when troubleshooting issues.

Numbering System: Many visuals employ a numbering system to correspond with a list of items. This list typically provides details like part names and specifications. Be sure to cross-reference this list for precise information about each component.

Scale and Orientation: Not all visuals are to scale, so be mindful of the proportions when interpreting sizes and distances. Additionally, ensure that you are viewing the illustration from the correct angle, as this can affect how you perceive the arrangement of parts.

By mastering these techniques, you can confidently navigate schematics and streamline your repair processes, ultimately leading to more efficient maintenance of your equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring that your engine remains in optimal condition for years to come. By following a consistent maintenance routine, you can prevent issues, enhance performance, and extend the lifespan of your machinery. Here are some key strategies to help you maintain your equipment effectively.

Routine Checks

- Inspect fuel levels and quality regularly to avoid performance issues.

- Check oil levels and replace it according to the manufacturer’s guidelines.

- Examine the cooling system to ensure it is functioning properly.

- Look for signs of wear on belts and hoses, replacing them as necessary.

Cleaning and Storage

- Clean the exterior to remove debris and prevent corrosion.

- Store the unit in a dry, sheltered area when not in use.

- Flush the system with fresh water after use in saltwater environments.

- Cover the equipment to protect it from dust and moisture.

By adhering to these practices, you can ensure that your engine operates smoothly and lasts longer, ultimately saving you time and money on repairs.

Where to Find Replacement Parts

Finding suitable components for your outboard motor can be a challenging task, but with the right approach, it can become a seamless process. Various resources are available to ensure you have access to the necessary items to keep your engine running smoothly.

Online Retailers

Numerous online platforms specialize in marine equipment and components. Here are some popular options:

- Specialized Marine Websites: Look for retailers that focus solely on boating supplies, as they often carry a wide range of components.

- Marketplace Platforms: Websites like eBay and Amazon can provide both new and used items from various sellers.

- Manufacturer Websites: Directly visit the official site for your motor’s manufacturer, which often has a dedicated section for replacements.

Local Dealers and Repair Shops

Don’t overlook the benefits of local resources. Here’s where you can check:

- Authorized Dealers: Find local dealers who specialize in your motor brand for genuine items.

- Marine Repair Shops: Many repair shops can order components directly for you or may have a selection in stock.

- Boating Supply Stores: Check local boating stores, which often carry essential items for maintenance.

Cost Considerations for Repairs

When it comes to maintenance and restoration of outboard motors, evaluating expenses is crucial. Understanding the financial implications helps in making informed decisions, ensuring that the investment in repairs aligns with both performance needs and budget constraints.

Factors Influencing Repair Costs

Several elements impact the overall expenses of restoration efforts. These include the type of damage, availability of replacement components, and labor rates charged by professionals. Labor costs can vary significantly depending on the expertise required for specific repairs. Additionally, if certain components are rare or outdated, their market value may increase, leading to higher overall expenditures.

Long-Term Financial Impact

Considering the long-term effects of repair choices is equally important. Sometimes, opting for higher-quality components may result in greater upfront costs but can enhance durability and reduce the likelihood of future issues. Investing wisely today can save substantial amounts in potential repairs and maintenance down the line, emphasizing the importance of thorough planning.

Enhancing Performance with Upgrades

Improving the efficiency and output of your marine engine can significantly elevate your boating experience. By implementing targeted enhancements, you can optimize speed, fuel consumption, and overall reliability. Various modifications are available, allowing enthusiasts to tailor their vessel to meet specific performance goals.

One key area for improvement is the exhaust system. Upgrading to a high-performance exhaust can enhance airflow, reducing back pressure and boosting horsepower. This modification often leads to a more aggressive sound, which many boaters find appealing.

Another effective approach is adjusting the fuel delivery system. By installing a performance carburetor or fuel injector, you can achieve a more efficient air-fuel mixture. This change can result in better throttle response and increased torque, making your engine more responsive during acceleration.

Finally, considering weight reduction can greatly impact performance. Removing unnecessary components or replacing heavy materials with lightweight alternatives can improve handling and speed. Every pound counts when it comes to maximizing your vessel’s potential on the water.