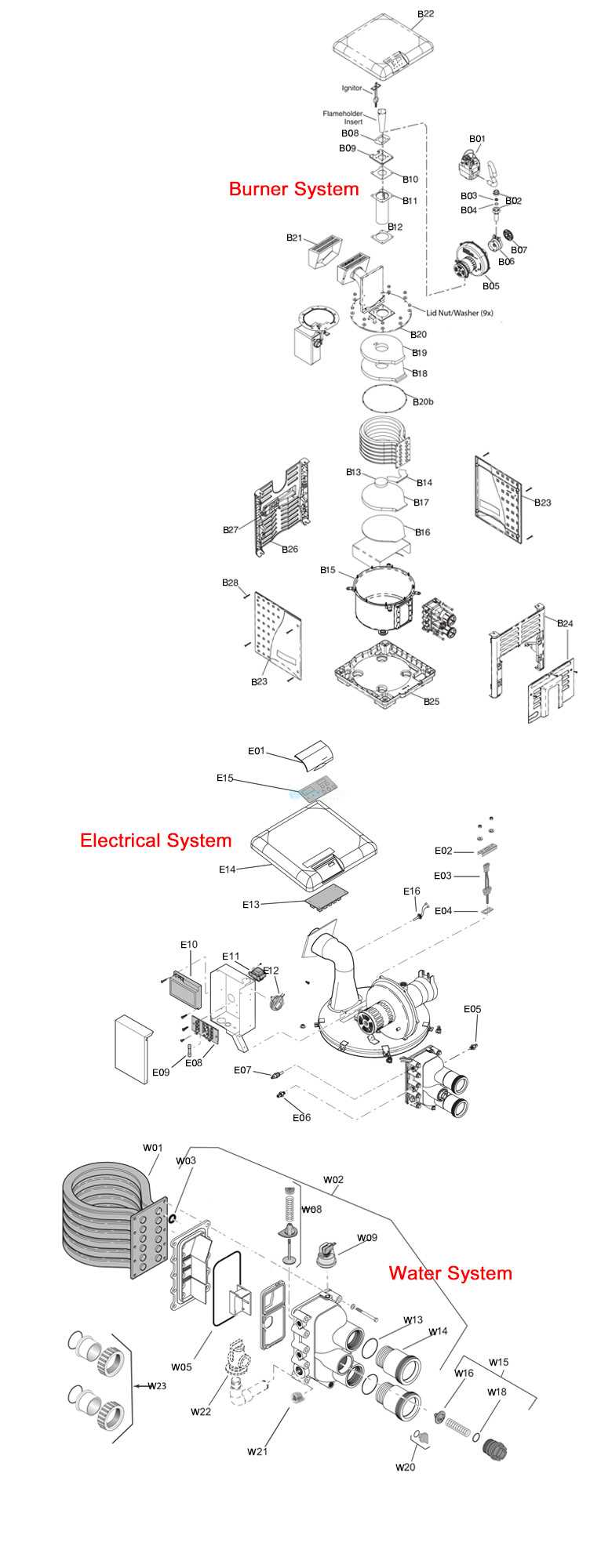

The functionality of a heating unit for aquatic environments hinges on its intricate assembly of elements. Recognizing how these components interact not only enhances maintenance efforts but also optimizes performance and longevity. A comprehensive understanding of the layout is essential for anyone involved in servicing or troubleshooting such equipment.

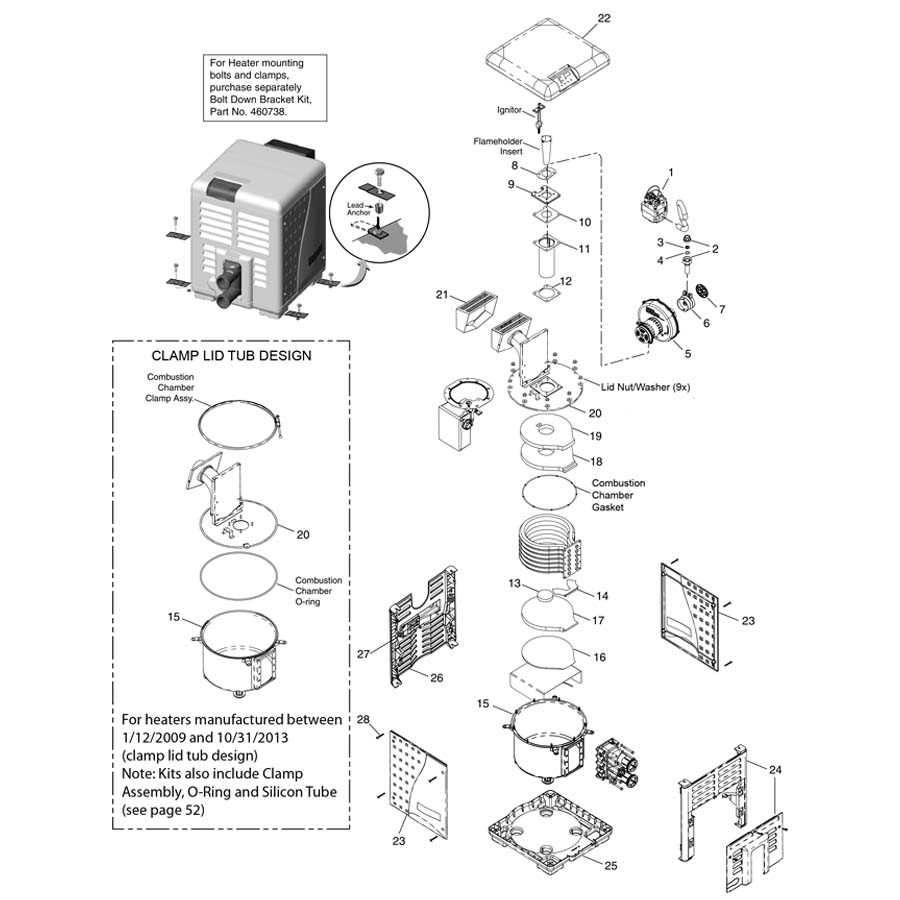

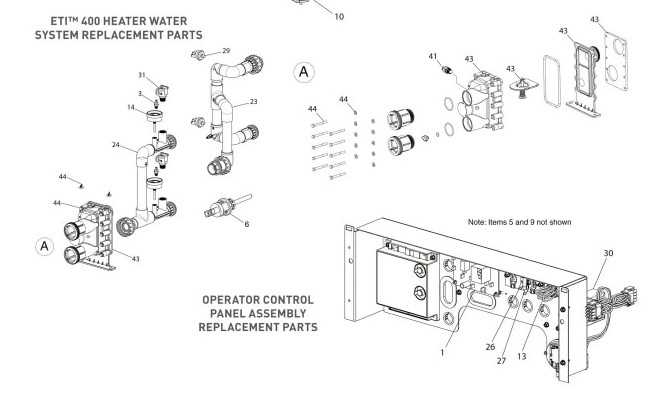

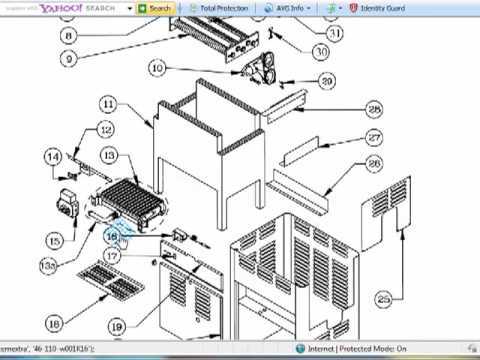

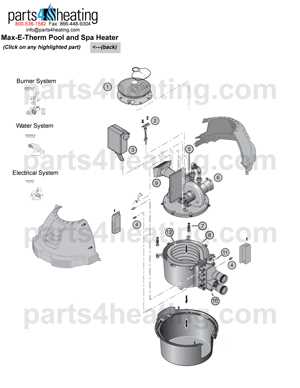

Detailed illustrations of the internal workings provide invaluable insights into each part’s role within the system. From circulation mechanisms to temperature regulation features, knowing what each component does can significantly streamline repair processes. Additionally, familiarizing oneself with the configuration allows for more informed decision-making regarding replacements and upgrades.

For enthusiasts and professionals alike, a well-structured overview of the heater’s architecture serves as an essential reference. Whether aiming to resolve specific issues or simply seeking to deepen one’s knowledge, having access to a clear visual representation of the unit’s components can prove highly beneficial. Engaging with this material not only cultivates expertise but also instills confidence in handling various tasks related to the device.

Understanding Mastertemp 400 Components

Gaining insight into the various elements of a heating system is essential for efficient operation and maintenance. Each component plays a crucial role in ensuring optimal performance, enhancing longevity, and promoting safety. Familiarity with these elements helps users troubleshoot issues effectively and make informed decisions regarding repairs and replacements.

Key Elements and Their Functions

Within the heating unit, several key components work in unison. The heating element is responsible for generating warmth, while the circulation pump facilitates the movement of water throughout the system. Additionally, temperature sensors monitor the water temperature, ensuring that it remains within the desired range, thus preventing overheating or inefficiency.

Maintenance Considerations

Regular inspection of these components is vital for maintaining functionality. Checking for wear and tear, ensuring proper connections, and cleaning filters can significantly extend the lifespan of the system. Understanding the roles of each part enables users to identify potential issues before they escalate, ensuring a reliable and effective heating experience.

Overview of Mastertemp 400 Functionality

This section explores the operational principles and capabilities of a popular heating system designed for efficient water temperature management. Its design focuses on delivering reliable performance while ensuring energy efficiency and user-friendly features. Understanding the core functionalities allows for optimal usage and maintenance, enhancing overall satisfaction.

The heating system utilizes advanced technology to maintain consistent temperatures, making it ideal for various applications such as pools and spas. Its user interface provides easy access to controls, allowing users to set desired temperatures effortlessly. Furthermore, the device incorporates safety features that protect against overheating and other potential issues.

| Feature | Description |

|---|---|

| Temperature Control | Allows precise adjustments to meet specific heating needs. |

| Energy Efficiency | Designed to minimize energy consumption while maximizing performance. |

| Durability | Constructed with high-quality materials to ensure longevity and reliability. |

| Safety Mechanisms | Equipped with features to prevent overheating and ensure user protection. |

| User-Friendly Interface | Simple controls for easy operation and adjustments. |

By leveraging these features, users can enjoy a dependable and effective solution for maintaining their desired water temperatures, contributing to a more pleasant experience overall.

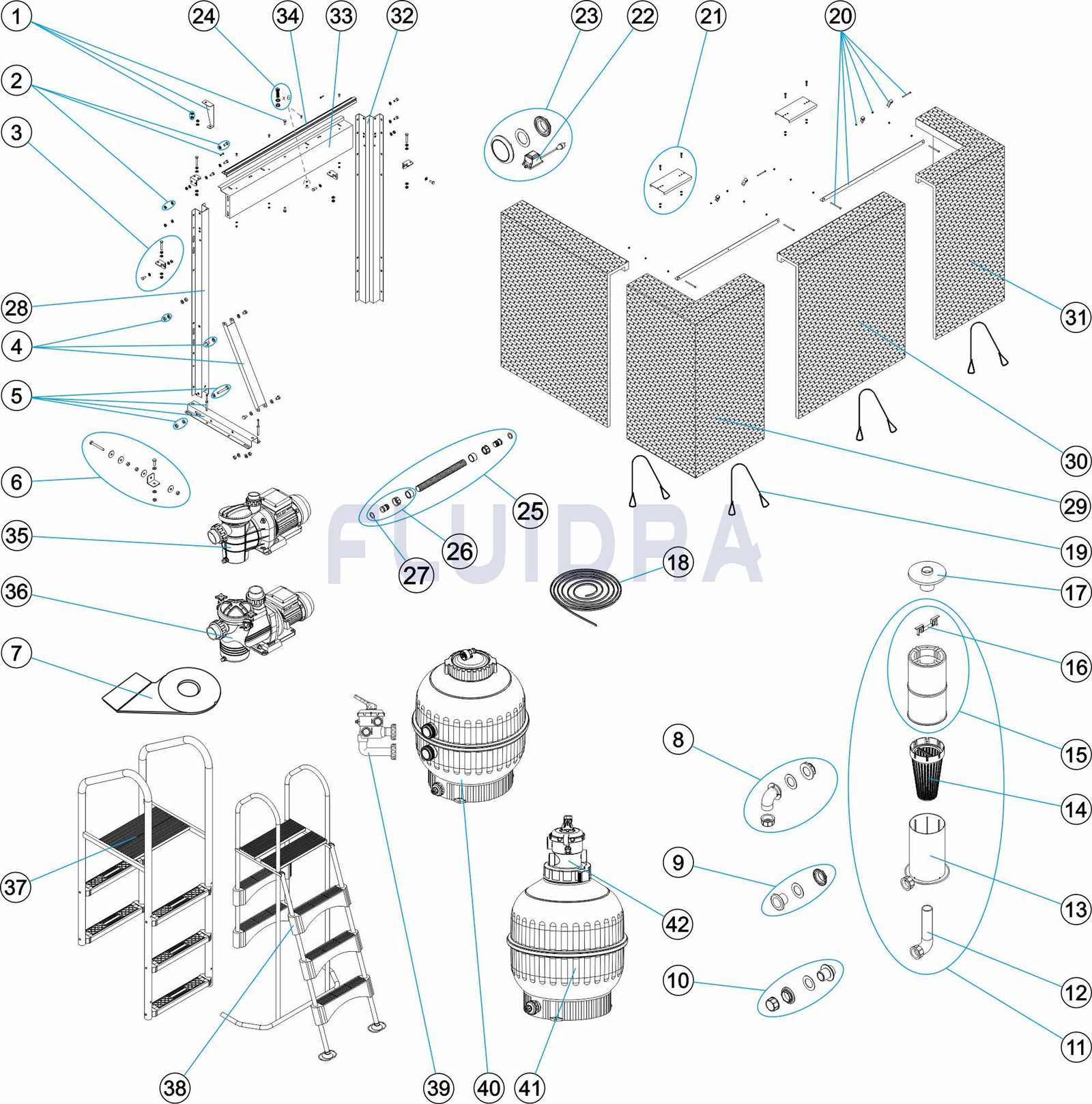

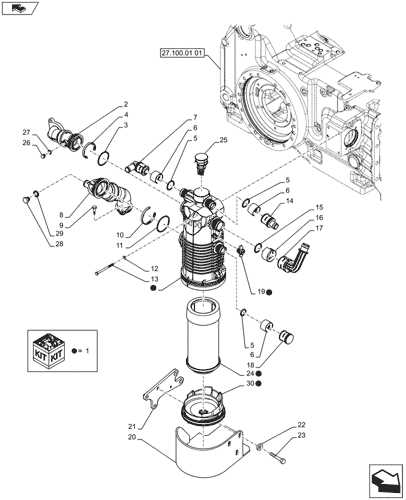

Identifying Key Parts in the Diagram

Understanding the essential components illustrated in a technical schematic is crucial for effective maintenance and troubleshooting. Each element plays a vital role in the overall functionality, and recognizing them can significantly enhance the efficiency of operations. By exploring these key elements, users can gain insights into their interactions and significance.

Components such as pumps, valves, and sensors are typically represented with specific symbols, making it easier to identify their function. Familiarity with these symbols enables quick diagnosis and repairs, ultimately leading to improved performance and longevity of the system. Proper identification is the first step in ensuring optimal operation and preventing potential issues.

Common Issues and Troubleshooting Tips

Understanding potential problems that may arise with your heating equipment can help you maintain optimal performance. This section highlights frequent concerns and offers practical solutions to address them effectively.

- Insufficient Heating:

- Check the thermostat settings to ensure they are properly adjusted.

- Inspect for any blockages in the water flow, such as debris or sediment.

- Ensure that the filter is clean and free of obstructions.

- Unusual Noises:

- Identify if the sounds come from the motor or the pump; loose components may need tightening.

- Examine for air bubbles in the system, which can cause cavitation.

- Check for any foreign objects that may have entered the unit.

- Leaking Water:

- Inspect all connections and fittings for signs of wear or damage.

- Examine seals and gaskets; replacing them may be necessary.

- Monitor for condensation, especially in cooler conditions.

- Indicator Lights:

- Refer to the user manual to decode warning signals or blinking lights.

- Reset the system to see if the issue persists.

- Look for any error codes displayed and consult troubleshooting resources.

By following these troubleshooting tips, users can often resolve common issues quickly and efficiently, ensuring their equipment runs smoothly and effectively.

Maintenance Practices for Optimal Performance

Ensuring peak functionality of heating systems requires a systematic approach to upkeep and regular inspections. By implementing consistent maintenance routines, users can enhance efficiency, extend the lifespan of their equipment, and reduce the likelihood of unexpected failures. This section outlines effective practices aimed at preserving optimal operational standards.

Routine Inspections

Conducting regular assessments is crucial for identifying wear and tear before they escalate into major issues. Checking for leaks, inspecting electrical connections, and evaluating pressure levels can prevent minor concerns from becoming costly repairs. Keeping a maintenance log can also help track performance trends over time.

Cleaning and Servicing

Regular cleaning of components, such as filters and heat exchangers, is essential for maintaining high efficiency. Dust and debris can obstruct airflow and heat transfer, leading to increased energy consumption. Scheduling professional servicing at least once a year can ensure that all parts function harmoniously and safely.

Replacing Parts: A Step-by-Step Guide

When maintaining your heating unit, knowing how to replace components efficiently can save you time and money. This guide provides a clear process for swapping out essential elements to ensure your system runs smoothly. Follow these steps to enhance your appliance’s performance and longevity.

Preparation Before Starting

- Gather necessary tools: screwdrivers, wrenches, and replacement components.

- Ensure the unit is turned off and disconnected from any power source.

- Consult the user manual for specific guidelines regarding your model.

Replacement Steps

- Identify the component that needs replacement and assess its condition.

- Carefully remove any coverings or panels to access the faulty part.

- Unscrew and detach the old component, taking note of how it is connected.

- Install the new part, ensuring it aligns correctly with the existing connections.

- Replace any panels or coverings and secure them tightly.

- Reconnect the power and test the unit to ensure proper functionality.

Following these steps will help you successfully replace components, ensuring your heating system remains efficient and effective.

Comparing Mastertemp 400 with Other Models

This section aims to explore the distinctions between a specific heating unit and its counterparts in the market. By examining various features, performance metrics, and overall efficiency, we can uncover which models offer superior benefits for different user needs.

Performance and Efficiency

When assessing heating units, efficiency plays a crucial role. Some models boast advanced technology that enhances energy consumption, while others may lag behind. Comparing these features allows users to select the most suitable option for their requirements.

Durability and Maintenance

Longevity is another vital aspect to consider. Some units are built with more robust materials, leading to lower maintenance needs over time. Understanding these differences can ultimately guide consumers towards making informed decisions that ensure long-term satisfaction.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is essential. Whether you’re looking to replace a worn-out item or enhance the performance of your system, knowing where to find reliable resources can save time and ensure optimal functionality.

Online marketplaces are a convenient starting point. Websites specializing in industrial supplies often carry a wide range of options. Be sure to check customer reviews and ratings to assess the reliability of both the parts and the seller.

Local distributors and authorized service centers can also be valuable resources. They not only provide authentic components but can also offer expert advice on installation and compatibility. Additionally, reaching out to local repair shops might yield useful leads on where to find specific items.

Forums and community groups dedicated to equipment maintenance can provide insights and recommendations from other users. Engaging with these communities allows you to learn from others’ experiences and discover hidden gems in the market.

Finally, always consider the manufacturer’s website. They often list approved vendors and may have an online store where you can find exactly what you need. This approach ensures that you’re obtaining genuine components designed for your specific model.

Expert Tips for Long-lasting Usage

Maintaining equipment effectively is crucial for ensuring its durability and optimal performance. By following a few essential practices, users can extend the life of their devices while minimizing the need for repairs.

Regular Maintenance

- Schedule routine check-ups to identify wear and tear.

- Clean components regularly to prevent buildup of debris.

- Replace worn parts promptly to avoid further damage.

Proper Usage

- Always follow manufacturer guidelines for operation.

- Avoid overloading the device to maintain functionality.

- Store the equipment in a dry, temperature-controlled environment.