In the realm of farming, the intricate machinery that drives productivity plays a pivotal role. A comprehensive overview of the components within these machines reveals how each piece contributes to overall efficiency and performance. Recognizing the interplay between various elements allows operators to maintain their equipment effectively and ensure seamless operation.

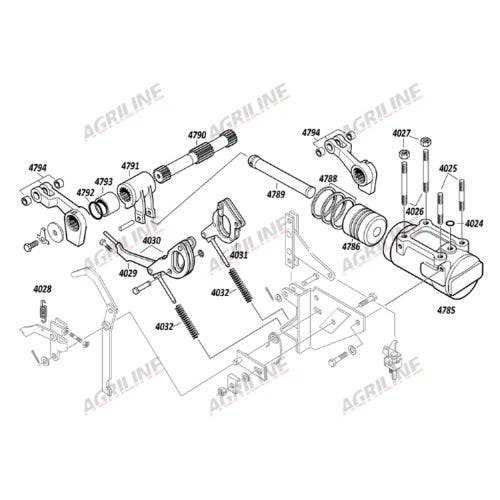

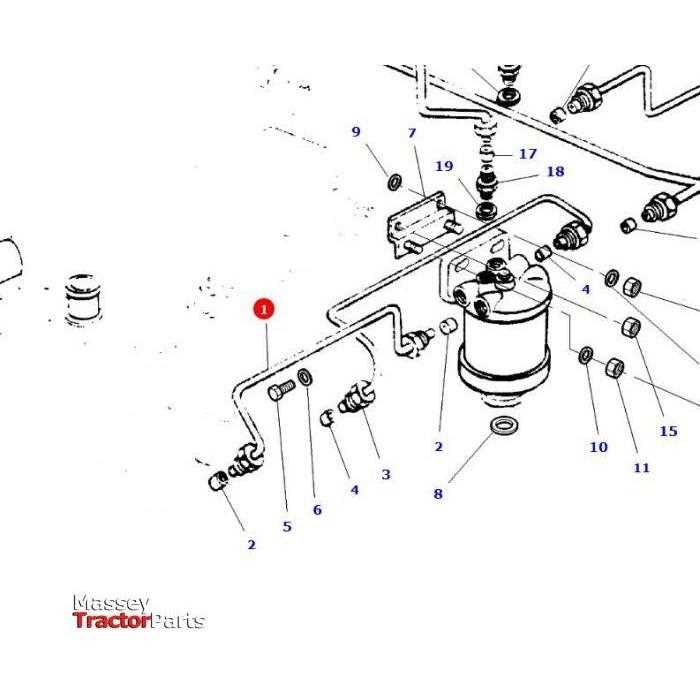

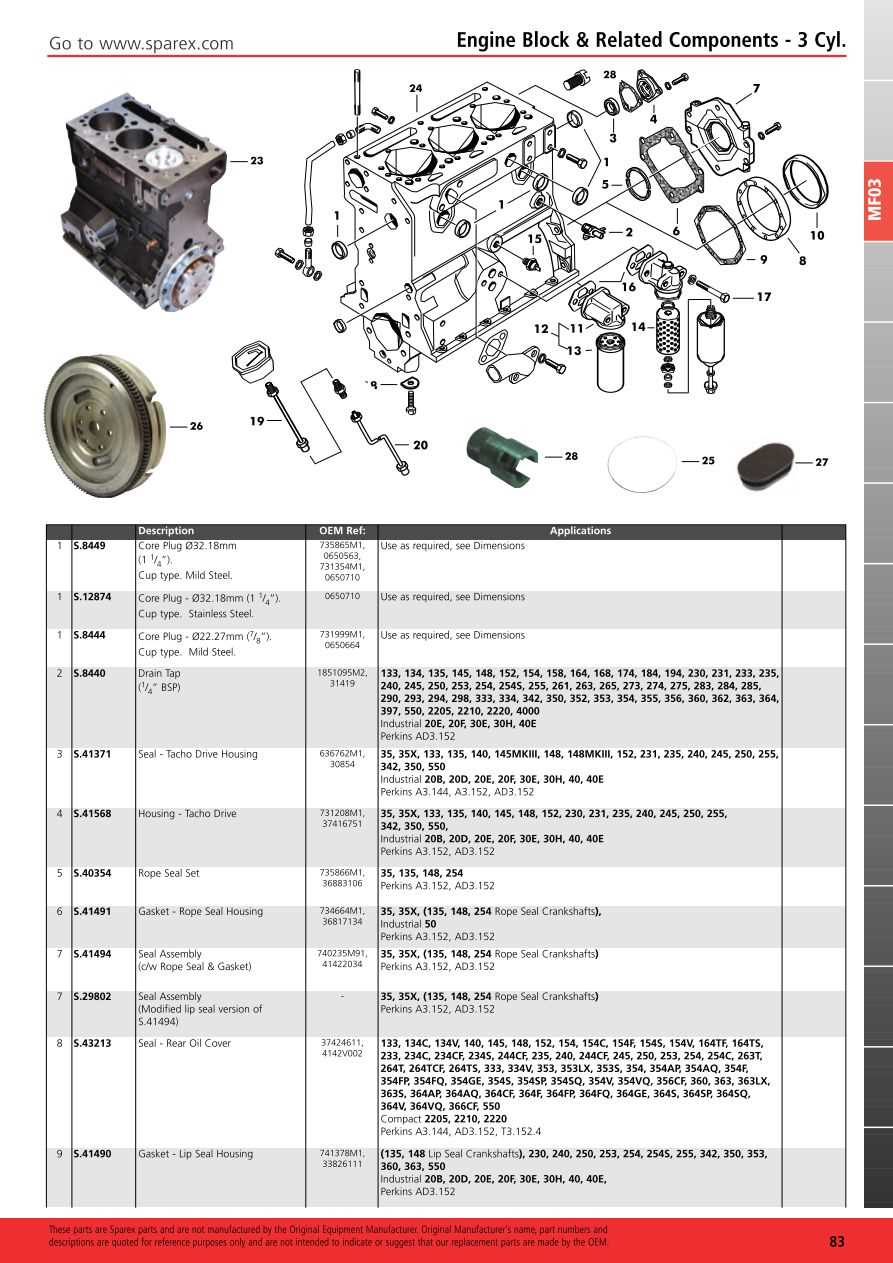

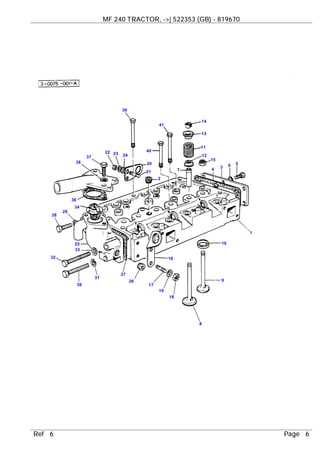

Visualization of machine assemblies can significantly enhance one’s understanding of their function and maintenance needs. By examining detailed illustrations, users can identify each component’s location and role, facilitating informed decision-making when repairs or replacements are necessary. This clarity is essential for both novice and experienced operators alike.

Furthermore, familiarity with the structure of agricultural equipment promotes better troubleshooting skills. When issues arise, a clear mental picture of the assembly can aid in swiftly diagnosing problems, thereby minimizing downtime and maximizing productivity. Engaging with these visual aids transforms the way users interact with their machinery, fostering a deeper connection and greater efficiency in their daily tasks.

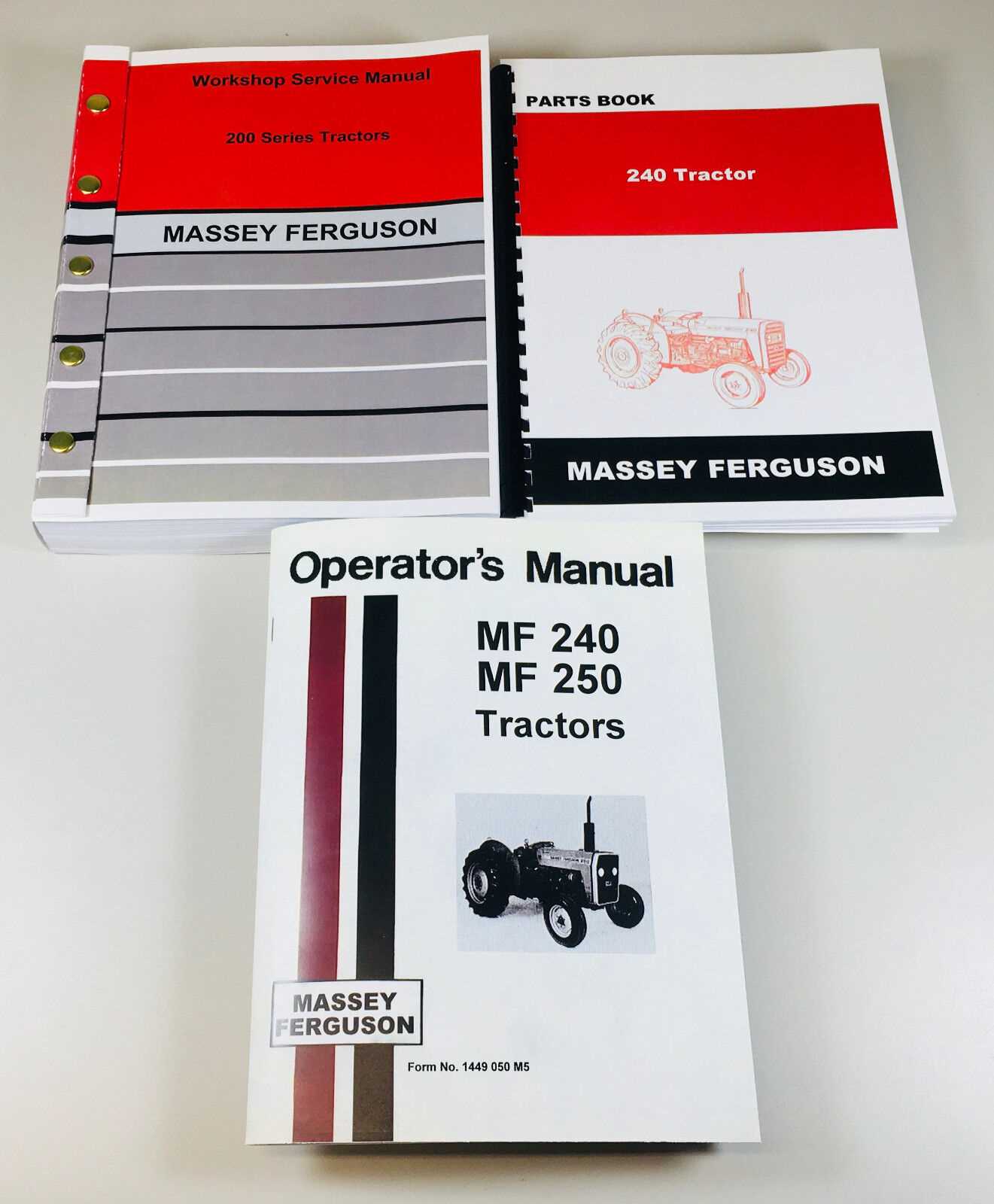

Massey Ferguson 240 Overview

This section provides a comprehensive look at a renowned agricultural machine that has become essential in modern farming practices. Understanding its features and functionalities can enhance operational efficiency and productivity.

Key Features

- Powerful engine for enhanced performance

- User-friendly controls for ease of operation

- Robust build quality for longevity

- Versatile attachments for various tasks

Benefits of Use

- Improved productivity on the field

- Reduced labor costs with efficient machinery

- Reliable performance in diverse conditions

- Easy maintenance and availability of components

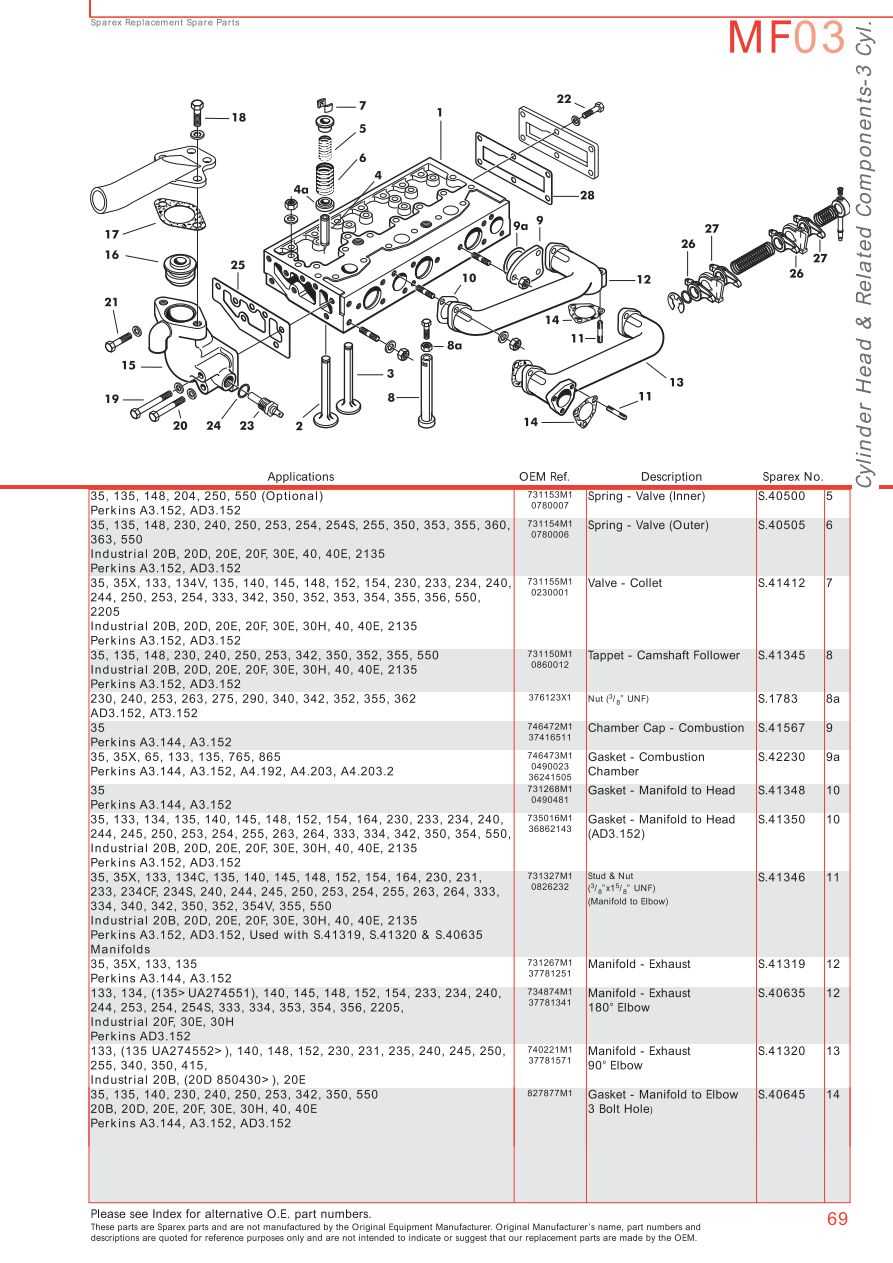

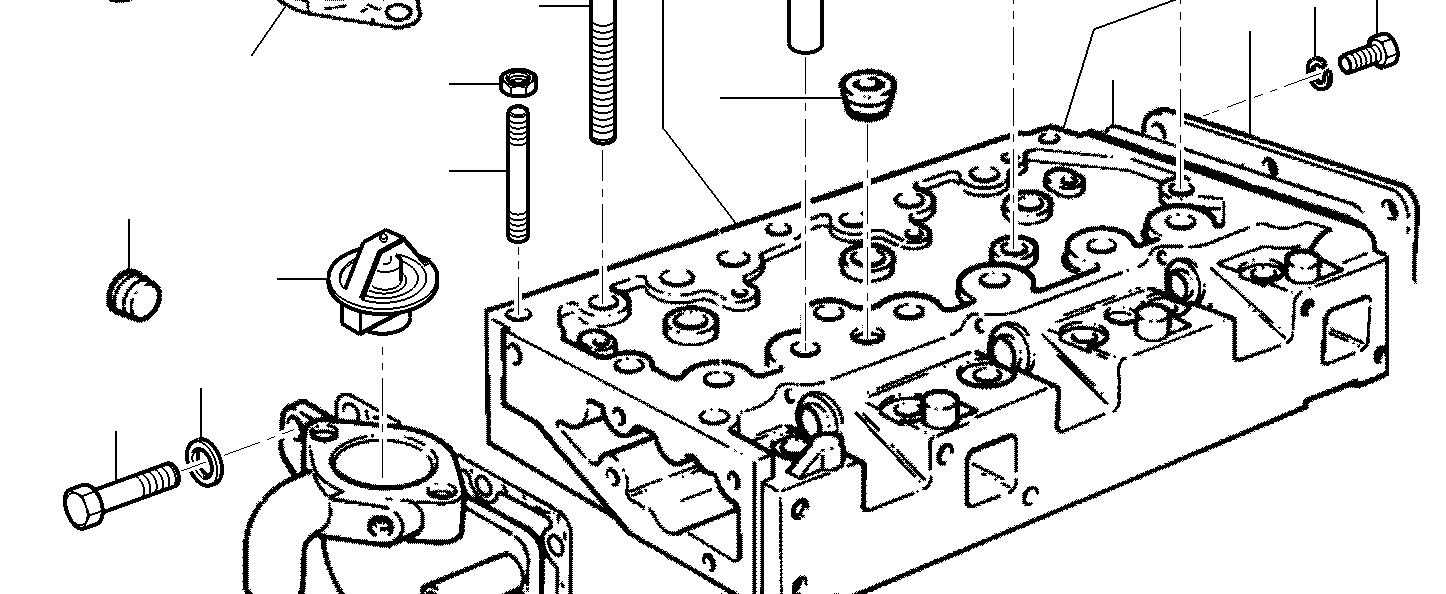

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. These illustrations provide an intuitive guide to identifying individual elements, facilitating maintenance, and ensuring proper assembly. By breaking down intricate systems into manageable sections, users can more effectively troubleshoot issues and perform repairs.

Enhanced Understanding

Having a visual reference allows operators and technicians to grasp the relationships between various parts. This clarity helps in recognizing potential problems before they escalate, ensuring the longevity of the equipment. Moreover, it aids in familiarizing new users with the assembly and disassembly processes, which is vital for safe and efficient operation.

Efficient Repair and Maintenance

Using visual aids significantly speeds up the repair process. Technicians can quickly locate specific components that need replacement or adjustment, minimizing downtime. This efficiency not only saves time but also reduces labor costs, ultimately leading to a more productive working environment.

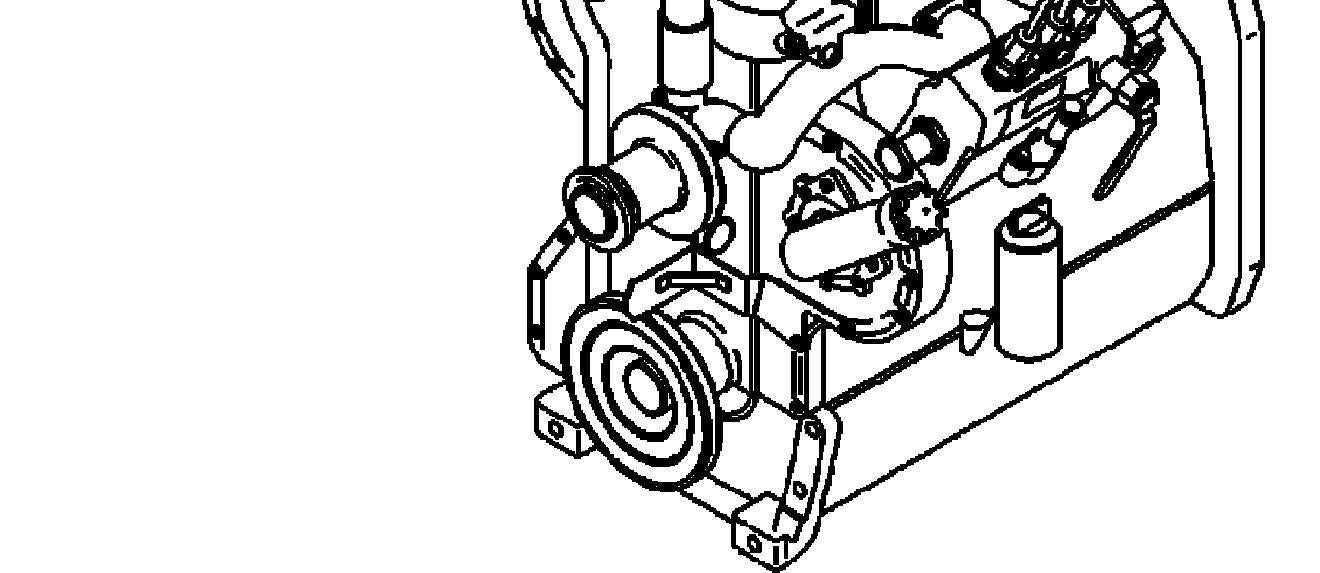

Key Components of the MF 240

The intricate machinery of agricultural vehicles encompasses various essential elements that contribute to their functionality and efficiency. Understanding these components is crucial for maintenance and operation, ensuring optimal performance in diverse farming tasks.

Main Systems

- Engine: The heart of the machine, providing power and reliability for all operations.

- Transmission: This system facilitates smooth shifting between gears, enabling effective speed control.

- Hydraulics: Vital for lifting and controlling attachments, ensuring versatility in various applications.

- Steering: Allows for precise maneuverability, crucial for navigating fields and tight spaces.

Supporting Components

- Fuel System: Responsible for delivering the necessary energy to the engine efficiently.

- Electrical System: Powers essential functions such as starting and lighting, ensuring operational readiness.

- Cooling System: Maintains optimal engine temperature, preventing overheating during extended use.

- Chassis: Provides structural integrity and support for all other systems, enhancing stability.

Finding Authentic Replacement Parts

When maintaining or repairing agricultural machinery, securing genuine components is crucial for ensuring optimal performance and longevity. Authentic replacements not only guarantee compatibility but also uphold the quality standards expected from original equipment. As users seek to prolong the life of their machinery, understanding where to source these elements becomes paramount.

Researching Authorized Dealers is a vital step. Authorized retailers often provide verified products with appropriate warranties, offering peace of mind to buyers. Additionally, exploring manufacturer websites can yield a comprehensive list of recommended suppliers.

Online marketplaces can also be beneficial, but caution is necessary. Ensuring that sellers have a reputation for providing genuine items will mitigate the risk of counterfeit goods. Always check customer reviews and product ratings to validate the authenticity of the components being considered.

Lastly, joining forums and communities dedicated to agricultural machinery can offer invaluable insights. Engaging with experienced users allows for the sharing of trusted sources and recommendations, ultimately aiding in the pursuit of quality replacements.

Common Maintenance Practices

Regular upkeep is essential for ensuring the longevity and optimal performance of agricultural machinery. Implementing routine maintenance procedures helps prevent unexpected breakdowns and enhances the efficiency of equipment. This section outlines some key practices that every operator should follow to maintain their machinery effectively.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace old oil with fresh lubricant to ensure smooth operation and reduce engine wear. |

| Filter Inspection | Every 50 hours | Check air and fuel filters for clogs and replace them as necessary to maintain optimal airflow and fuel delivery. |

| Tire Pressure Check | Weekly | Ensure that tires are properly inflated to improve traction and prevent uneven wear. |

| Belt and Chain Tension | Every 100 hours | Inspect and adjust tension on belts and chains to avoid slippage and ensure efficient power transfer. |

| Battery Maintenance | Monthly | Check battery connections for corrosion and ensure terminals are clean and securely attached. |

By adhering to these maintenance tasks, operators can significantly enhance the reliability and functionality of their machinery, reducing downtime and increasing productivity on the farm.

Understanding the Parts Breakdown

Gaining insight into the components of machinery is essential for effective maintenance and repairs. A thorough comprehension of each element allows operators to identify issues quickly, ensuring optimal performance and longevity of the equipment. This section aims to clarify the structure and function of individual units, making troubleshooting and replacement more straightforward.

Importance of Component Identification

Recognizing each section of the machine plays a critical role in streamlining operational efficiency. By familiarizing oneself with the specific roles of various components, one can better anticipate potential malfunctions and execute timely interventions.

Key Components Overview

| Component Name | Function |

|---|---|

| Engine | Drives the entire machinery. |

| Transmission | Transfers power from the engine to the wheels. |

| Hydraulic System | Controls various attachments and implements. |

| Chassis | Provides structural support and stability. |

Troubleshooting Common Issues

When working with agricultural machinery, encountering problems is a common occurrence. Identifying and resolving these issues efficiently can significantly enhance productivity and minimize downtime. This section will explore typical complications, providing guidance on how to address them effectively.

Engine Overheating: One prevalent issue is engine overheating, often caused by low coolant levels or a malfunctioning thermostat. Regularly check fluid levels and inspect the cooling system for leaks. If overheating persists, consider examining the radiator for blockages or the fan operation.

Poor Engine Performance: If the engine exhibits sluggishness, it may indicate fuel supply problems or clogged filters. Ensure that fuel lines are clear and replace any dirty air or fuel filters. Additionally, inspect spark plugs for wear, as faulty plugs can hinder engine efficiency.

Hydraulic System Failures: Hydraulic issues can manifest as slow or unresponsive movements. Check for leaks in the hydraulic lines and ensure that fluid levels are adequate. If problems continue, inspect the hydraulic pump and cylinders for any signs of wear or damage.

Electrical Malfunctions: Electrical failures can lead to a variety of operational challenges. Start by examining the battery connections and ensuring that terminals are clean and tight. If the machine does not start, test the ignition system and fuses for continuity.

Transmission Difficulties: If shifting gears becomes problematic, it may indicate low transmission fluid or internal wear. Regularly inspect fluid levels and replace worn components as necessary. If issues persist, a thorough inspection of the transmission system may be required.

By systematically addressing these common issues, operators can maintain optimal performance and extend the life of their machinery.

Where to Purchase Parts Online

Finding components for agricultural machinery can be a straightforward process if you know where to look. The internet offers a plethora of options for sourcing essential items, whether you are seeking OEM replacements or aftermarket alternatives. This guide will help you navigate the online marketplace effectively.

Reliable Online Retailers

Several established online platforms specialize in machinery components. These retailers typically provide detailed descriptions and compatibility information, ensuring you make informed choices.

| Retailer | Website | Specialty |

|---|---|---|

| Tractor Supply Co. | tractorsupply.com | General farm equipment |

| Agri Supply | agrisupply.com | Agricultural supplies |

| eBay | ebay.com | New and used items |

Considerations When Buying

When purchasing online, always check for customer reviews and ratings. Ensure the seller offers a return policy and verify shipping costs to avoid unexpected expenses. By following these steps, you can efficiently find the components you need without hassle.