In the realm of automotive engineering, the intricate systems responsible for fuel delivery play a pivotal role in optimizing engine performance. A comprehensive understanding of these mechanisms is essential for effective maintenance and troubleshooting. This section aims to delve into the essential components that ensure efficient fuel flow and precision in combustion processes.

Exploring the individual elements of these systems reveals a complex interplay of functionality and design. Each component contributes to the overall efficiency, directly influencing how fuel is managed and utilized within the engine. By examining the structure and relationship of these elements, one can gain insights into both standard operations and potential issues that may arise over time.

Additionally, visual aids serve as valuable resources for grasping the configuration and interaction of various components. These illustrations not only clarify the intricate layout but also enhance the understanding of how each part works in harmony to deliver optimal performance. Whether for educational purposes or practical applications, a detailed exploration of these systems is crucial for any enthusiast or professional in the field.

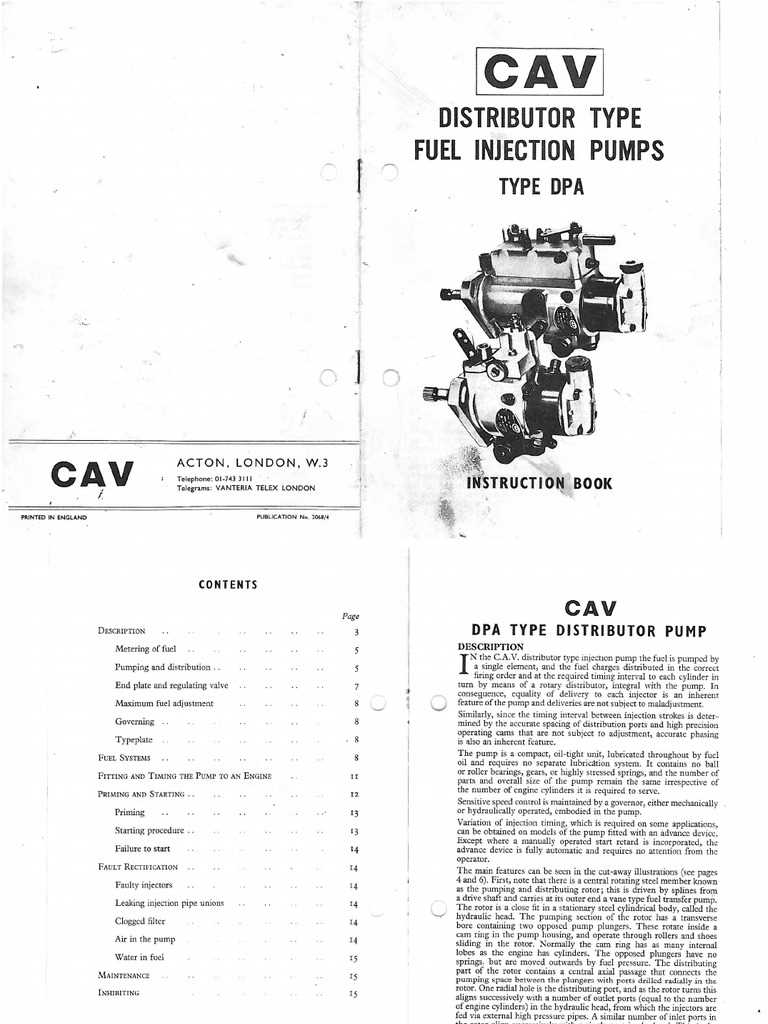

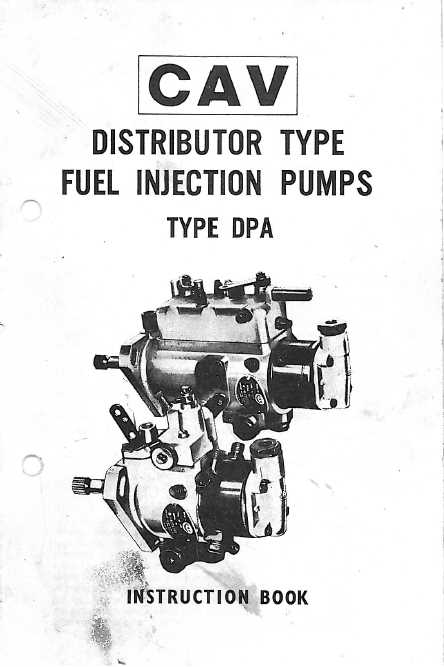

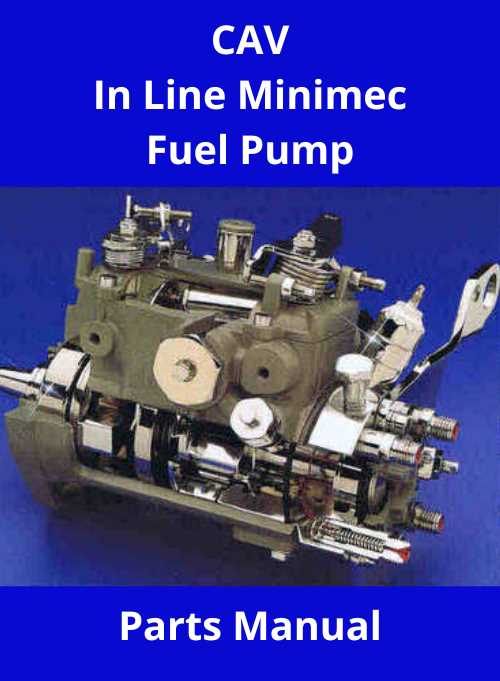

Understanding Lucas Cav Injection Pumps

This section delves into the mechanisms behind specific fuel delivery systems crucial for optimal engine performance. These systems ensure precise fuel management, contributing to efficiency and power in various vehicles. A clear comprehension of their components and functionality can significantly enhance maintenance and troubleshooting efforts.

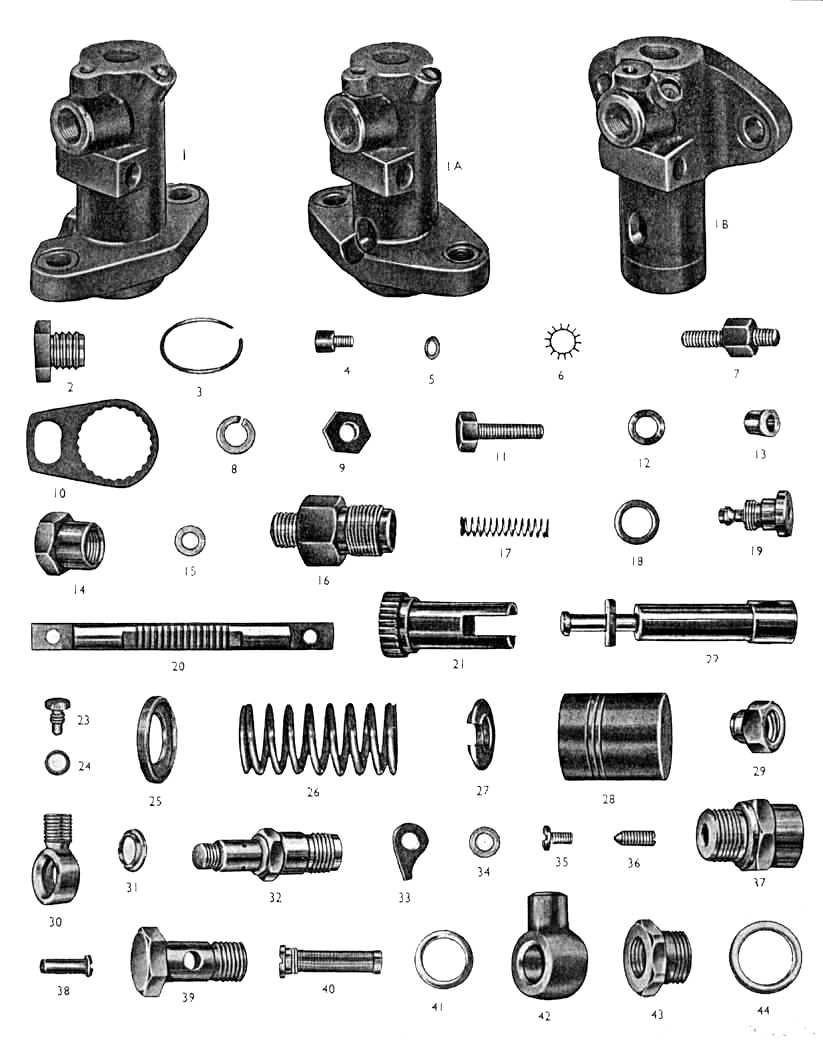

Key Components

- Fuel delivery mechanism

- Regulating valves

- Timing elements

- Governor systems

- Seals and gaskets

How They Operate

- Fuel is drawn from the tank into the system.

- The regulating elements manage the flow and pressure of the fuel.

- Timing components ensure that the fuel is delivered at the right moment.

- Governors adjust the output based on engine demands.

- Seals prevent leaks and maintain system integrity.

A thorough understanding of these elements fosters effective maintenance practices, ensuring longevity and reliability in performance.

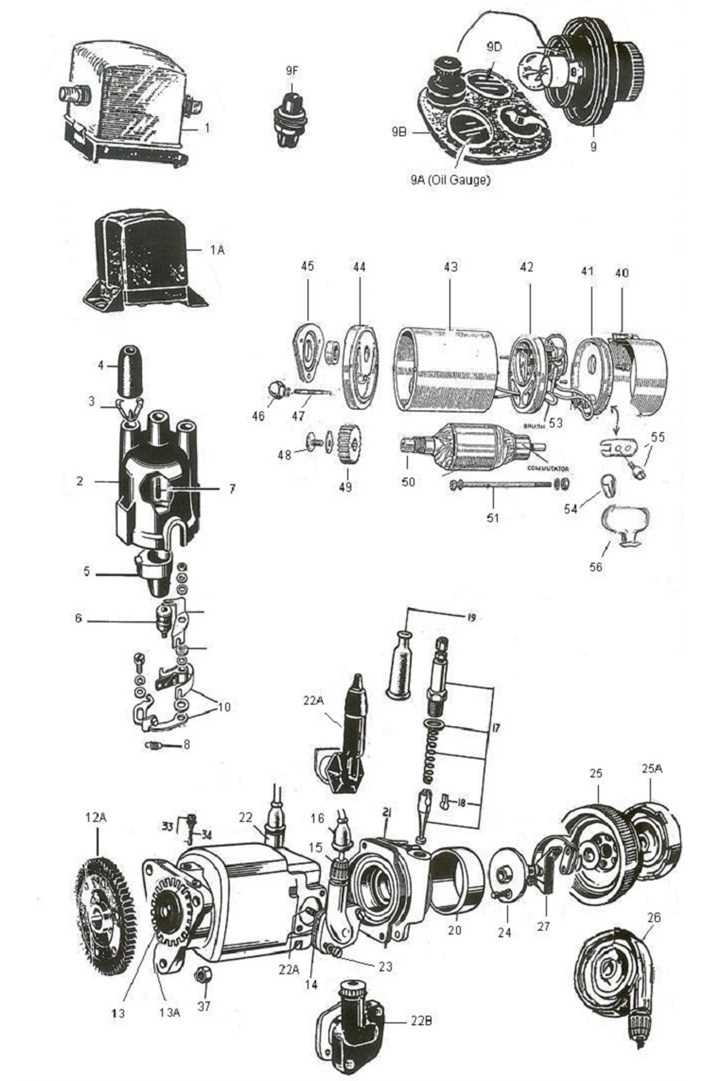

Components of Lucas Cav Systems

The functionality of these fuel delivery mechanisms relies on a variety of essential elements that work in harmony to ensure optimal performance. Each component plays a crucial role in regulating the flow and timing of fuel, thereby contributing to the overall efficiency of the system.

Fuel Control Mechanism: This vital part governs the amount of fuel released into the engine, ensuring it receives the right quantity for effective combustion. Precision in this component directly affects engine power and emissions.

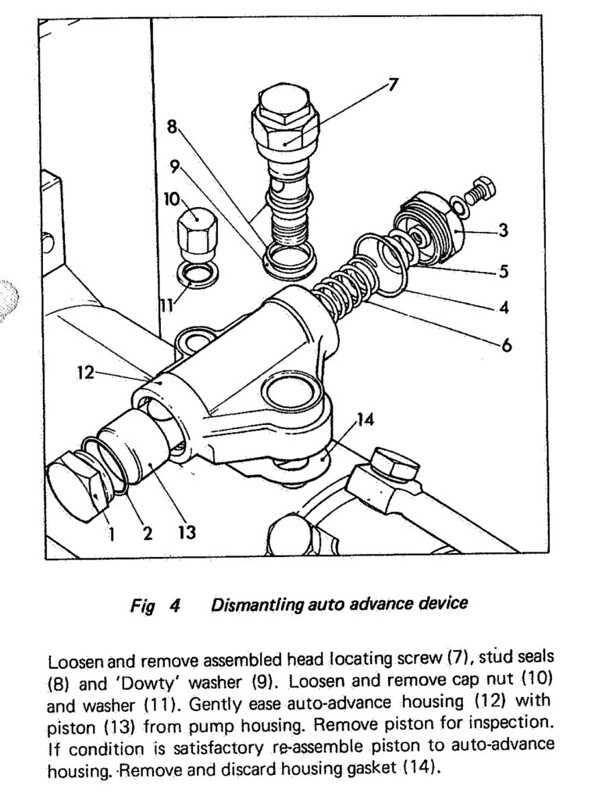

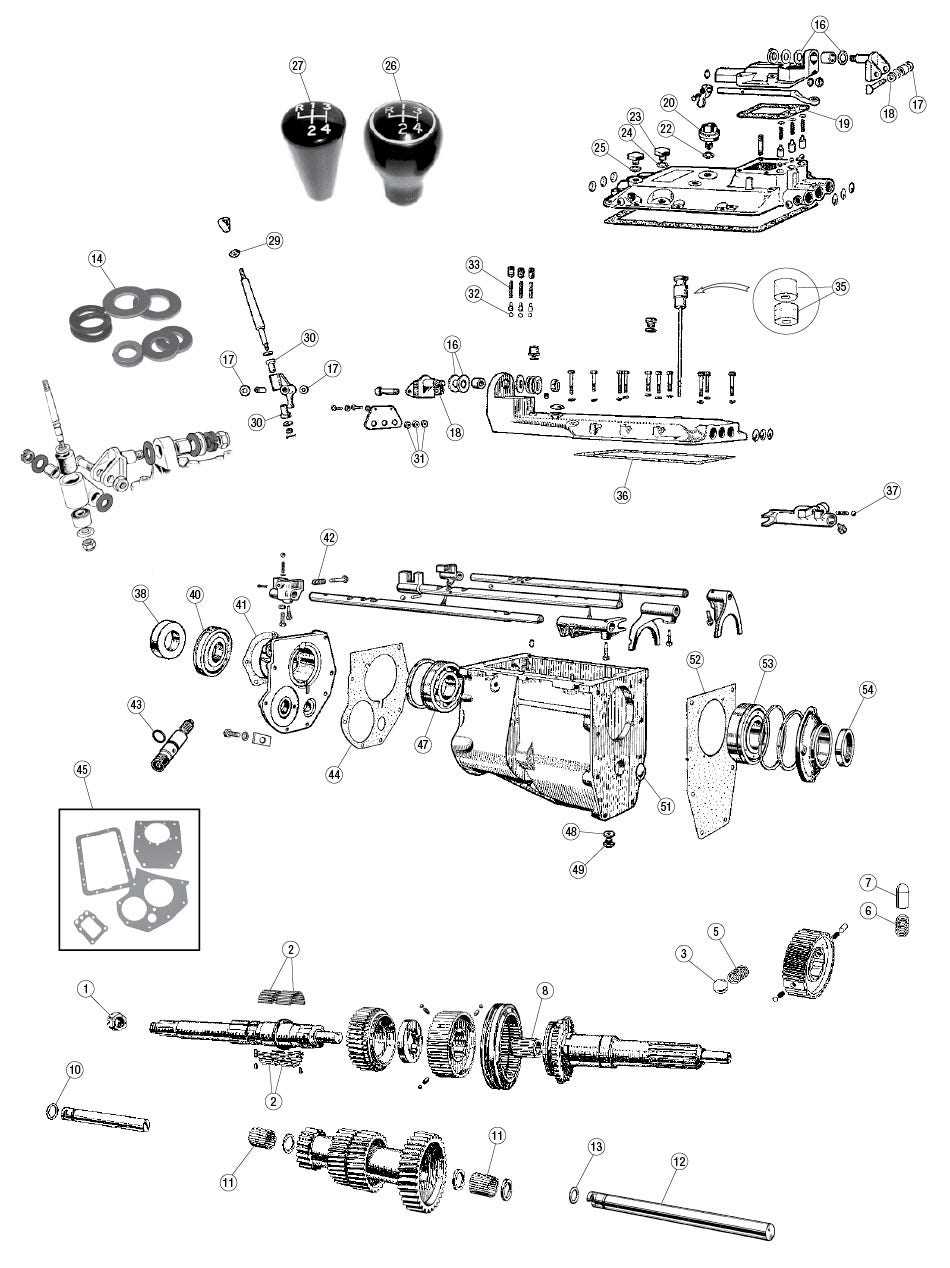

Timing Assembly: Accurate timing is essential for synchronizing fuel delivery with engine cycles. This assembly consists of various gears and linkages that help maintain proper coordination between fuel injection and engine operation.

Delivery Valve: Acting as a gatekeeper, this component regulates the fuel flow to the engine cylinders. It opens and closes at precise intervals, allowing for controlled injection that maximizes combustion efficiency.

Pressure Regulator: This element ensures that fuel is supplied at the appropriate pressure, which is crucial for maintaining consistent performance. It adjusts pressure levels in response to engine demands, preventing potential damage from fluctuations.

Spring Assembly: Springs within the system provide the necessary force for various components to function effectively. They help maintain tension and return components to their original positions after operation, ensuring reliability.

Understanding these components is essential for anyone involved in maintenance or troubleshooting. Each element contributes to the system’s overall functionality, making them integral to the effective operation of diesel engines.

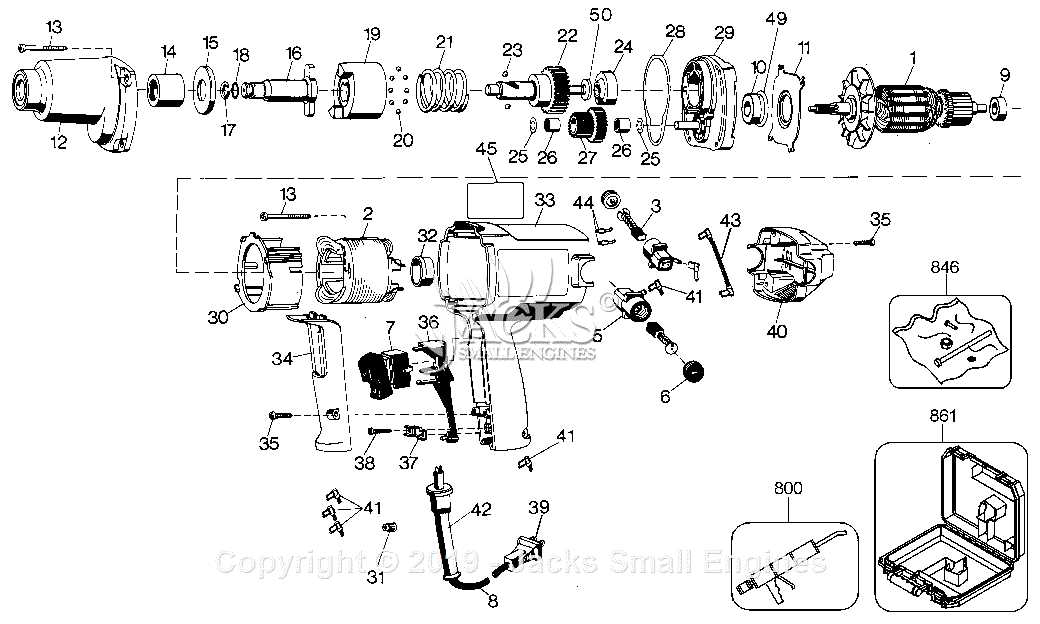

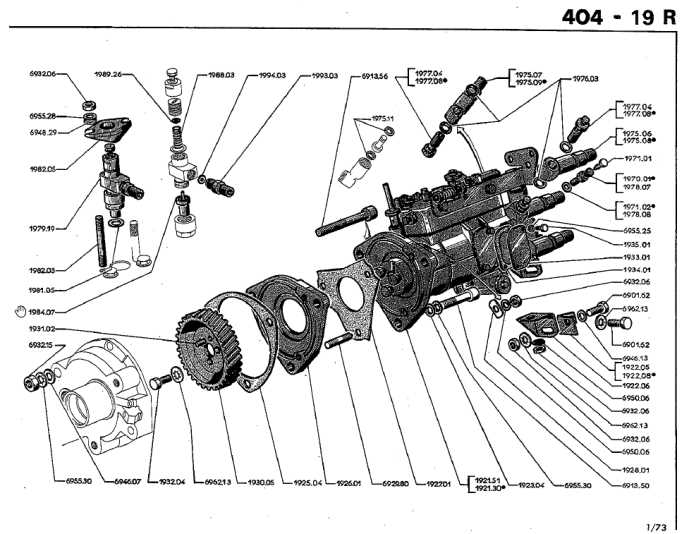

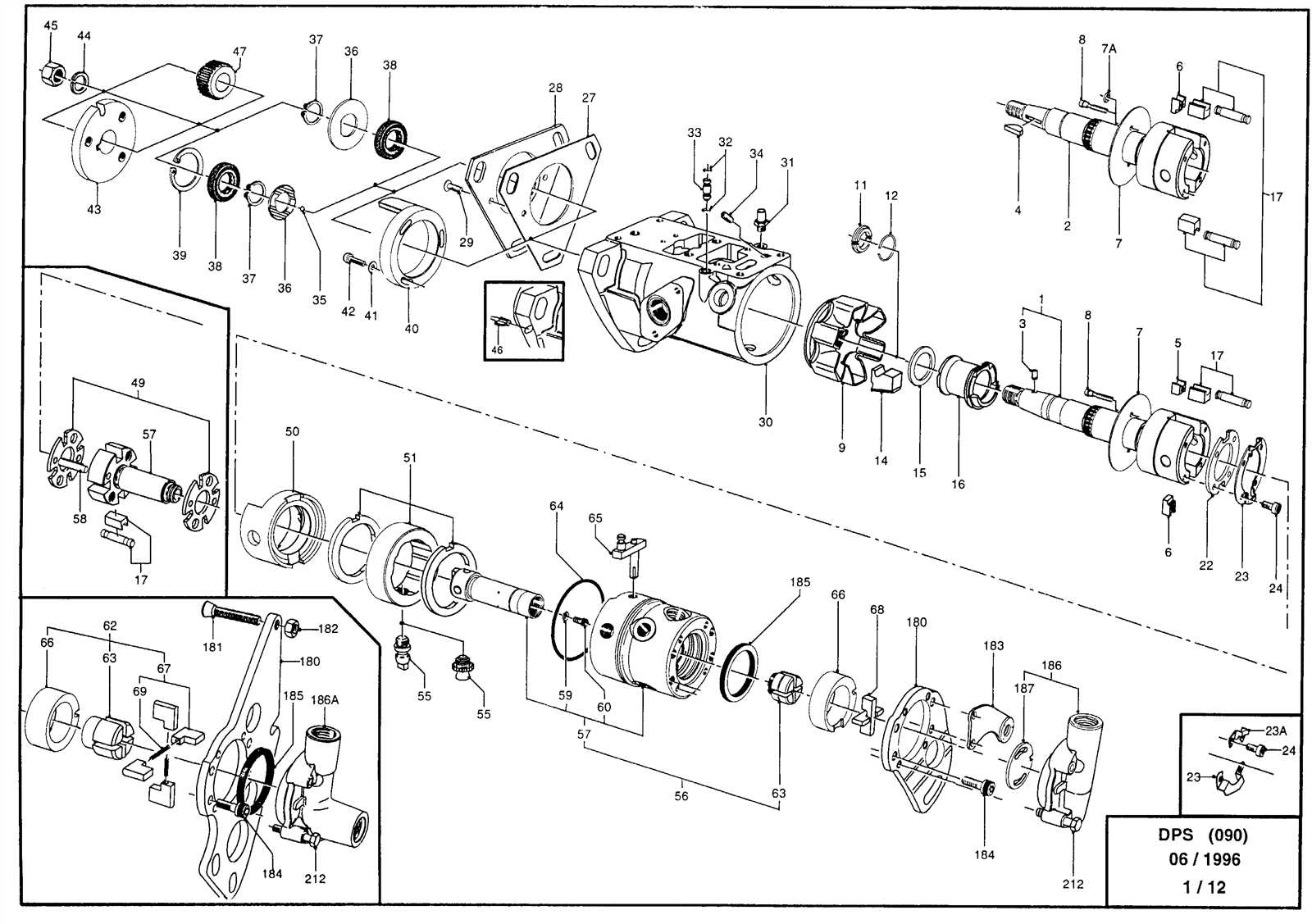

How to Read Pump Diagrams

Understanding technical illustrations is crucial for effective maintenance and troubleshooting. These visual representations offer insights into the components and their interrelations within a system, enabling users to grasp complex mechanisms with clarity.

Start by familiarizing yourself with the symbols used in these visuals. Each symbol typically represents a specific element or function, making it essential to reference the accompanying legend or key.

Next, observe the flow direction indicated in the illustration. Arrows often depict the movement of fluids or energy, providing vital information on how the system operates. Recognizing this flow helps in identifying potential bottlenecks or issues.

Finally, take note of the connections between different components. Understanding how these parts interact allows for more effective diagnostics and repairs. By delving into each section, you can uncover the ultimate functionality of the entire setup.

Common Issues with Injection Pumps

Understanding the frequent challenges faced by fuel delivery systems is essential for maintaining optimal performance. Various factors can contribute to malfunctions, often leading to inefficiencies in engine operation. Recognizing these issues early can prevent more severe problems down the line.

Fuel Contamination

One major concern is the presence of impurities in the fuel. Contaminated fuel can lead to clogged filters and reduced efficiency. Regular checks and maintaining fuel quality are critical for ensuring longevity.

Wear and Tear

Over time, mechanical components may experience wear and tear, resulting in decreased functionality. Regular maintenance and timely replacements can mitigate this risk, ensuring the system operates smoothly.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of fuel delivery systems requires regular care and attention. Implementing effective maintenance practices can significantly extend the lifespan of these essential components. Here are some key strategies to keep in mind for optimal performance.

Regular Inspections

Conducting frequent examinations helps identify potential issues before they escalate. Look for signs of wear, leaks, or any irregularities in operation. Regular checks can prevent costly repairs and ensure reliable functionality.

Proper Cleaning

Keeping the system clean is vital for smooth operation. Accumulation of debris or residue can hinder performance. Use appropriate cleaning agents and techniques to maintain optimal conditions.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect seals and connections | Monthly | Look for wear or damage |

| Clean filters | Every 500 hours | Replace if damaged |

| Check fluid levels | Weekly | Maintain within recommended range |

| Service components | Annually | Follow manufacturer guidelines |

By adhering to these maintenance tips, you can enhance the longevity of your fuel delivery system and ensure consistent performance over time.

Signs of Pump Failure to Watch

Recognizing the symptoms of malfunction in fuel delivery systems is crucial for maintaining optimal vehicle performance. Early detection can prevent costly repairs and ensure the longevity of the engine. Below are key indicators to monitor that suggest potential issues.

| Signs | Description |

|---|---|

| Inconsistent Performance | Unusual fluctuations in engine power can indicate delivery issues. |

| Difficulty Starting | Engines that struggle to ignite may be experiencing fuel supply problems. |

| Unusual Noises | Uncommon sounds such as knocking or whining can signal internal damage. |

| Excessive Smoke | Abnormal exhaust emissions may indicate improper fuel combustion. |

| Warning Lights | Dashboard alerts can indicate a malfunction in the fuel system. |

Replacement Parts Availability and Sources

Access to components necessary for maintaining and repairing fuel delivery systems is crucial for ensuring optimal performance. Various suppliers and manufacturers offer a range of alternatives to meet the demands of users. Understanding where to find these items can significantly impact the efficiency and longevity of your machinery.

Online Retailers and Marketplaces

Numerous online platforms provide a convenient way to source essential elements. These retailers often feature a wide selection, competitive pricing, and customer reviews that can aid in decision-making. Here are some popular options:

| Website | Description |

|---|---|

| eBay | A marketplace with both new and used options, often at varied price points. |

| Amazon | Offers a broad selection with fast shipping options and user ratings. |

| PartsDirect | Specializes in automotive and machinery components, providing detailed specifications. |

Local Distributors and Workshops

For those who prefer a more hands-on approach, local distributors and repair workshops can be invaluable. Establishing relationships with nearby suppliers not only fosters community support but can also provide immediate access to necessary items. Many local businesses offer personalized service and expert advice.

Comparing Different Injection Pump Types

In the world of fuel delivery systems, various mechanisms play crucial roles in ensuring optimal engine performance. Understanding the distinctions among these mechanisms is essential for anyone involved in maintenance or selection processes. Each type exhibits unique characteristics that cater to different operational requirements.

Types of Fuel Delivery Mechanisms

- Mechanical Systems

- Typically simpler in design.

- Relies on physical components to manage fuel flow.

- Often easier to repair and maintain.

- Electronic Systems

- Utilizes sensors and computer controls for precision.

- Can adapt to changing engine conditions dynamically.

- Often provides better fuel efficiency and performance.

Factors to Consider When Choosing

- Engine Compatibility

- Ensure the selected mechanism matches the engine specifications.

- Consider power requirements and performance goals.

- Maintenance Needs

- Evaluate how accessible the components are for servicing.

- Consider the frequency and cost of potential repairs.

- Fuel Efficiency

- Examine how each type influences overall fuel consumption.

- Look for mechanisms that offer better optimization strategies.

Choosing the right fuel delivery mechanism involves careful consideration of these aspects. Each type has its merits and limitations, making it vital to match the system to the specific needs of the vehicle and its intended use.

Best Practices for Installation and Adjustment

When it comes to the assembly and calibration of fuel delivery systems, meticulous attention to detail is crucial for optimal performance. Proper installation ensures reliability and efficiency, while accurate adjustments can significantly enhance engine functionality. Following a systematic approach is essential for achieving the best results.

Begin by thoroughly reviewing the manufacturer’s guidelines, as they provide invaluable insights into specifications and procedures. Ensure that all components are clean and free from debris before starting the installation. This helps prevent contamination, which can lead to premature wear or failure.

During assembly, use the appropriate tools and ensure that all connections are tight but not overly so, as excessive force may damage sensitive components. Pay close attention to alignment; misplacement can cause operational issues down the line.

Once the installation is complete, proceed with adjustments. Utilize calibrated measuring instruments to verify settings. Make incremental changes and test the system after each adjustment to monitor performance. This iterative process allows for fine-tuning and helps identify any potential issues early on.

Lastly, regular maintenance checks are essential to ensure continued efficiency. Monitoring performance metrics and addressing any anomalies promptly can extend the life of the system and maintain optimal operation.