The intricate machinery that powers our trains is a marvel of engineering, consisting of a multitude of essential elements that work in harmony. Each segment plays a crucial role, contributing to the overall functionality and efficiency of these powerful machines. By delving into the various sections of this complex system, one can appreciate the sophistication involved in their design and operation.

Every unit within the assembly serves a specific purpose, from the systems responsible for propulsion to those that ensure safety and comfort. This comprehensive exploration will unveil the relationships between these individual elements, highlighting how they collectively facilitate smooth travel along vast networks of tracks.

By gaining insight into the structure and interplay of these components, enthusiasts and professionals alike can deepen their understanding of railway technology. Such knowledge not only enhances appreciation for these vehicles but also aids in maintenance and innovation within the industry. Join us as we navigate through the key elements that make modern rail travel possible.

Understanding Locomotive Components

In the realm of railway machinery, grasping the essential elements that contribute to functionality is crucial for enthusiasts and professionals alike. Each component plays a vital role in ensuring seamless operation and efficiency, forming a complex interplay that underpins the entire system.

The heart of this machinery consists of various assemblies designed to work together harmoniously. These structures include mechanical systems that facilitate movement, energy generation mechanisms that propel the vehicle, and safety features that safeguard both cargo and crew.

By delving into the specifics of these components, one can appreciate the intricate engineering that has evolved over time, leading to advancements in performance and reliability. Understanding these elements not only enhances operational knowledge but also contributes to the ultimate goal of optimizing performance and safety in rail transport.

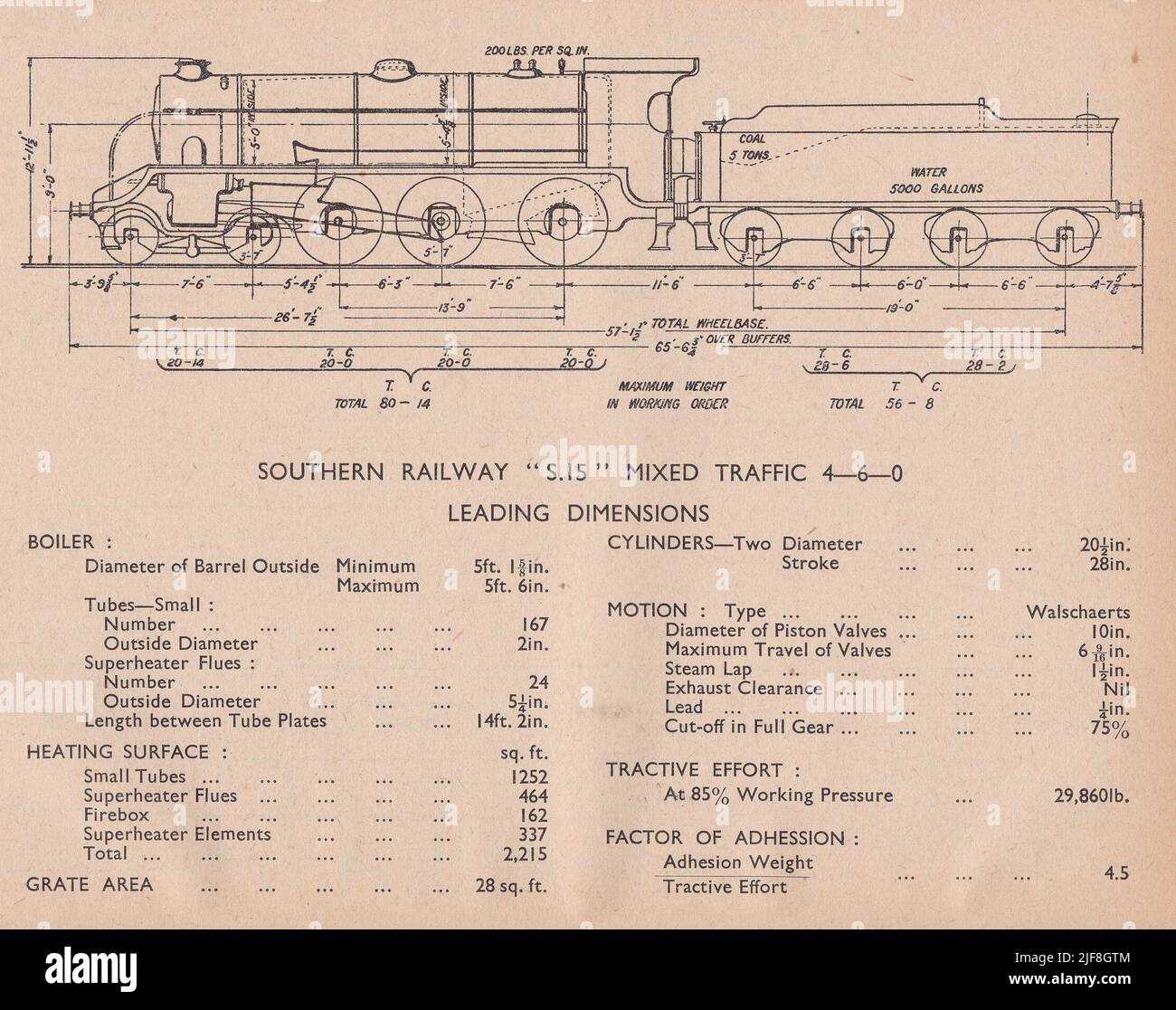

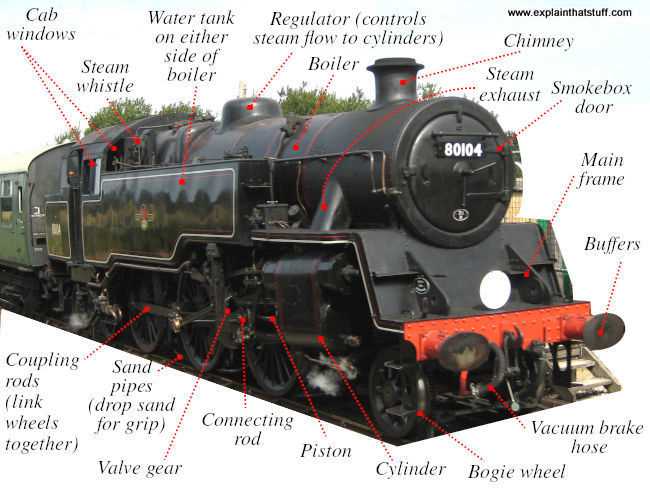

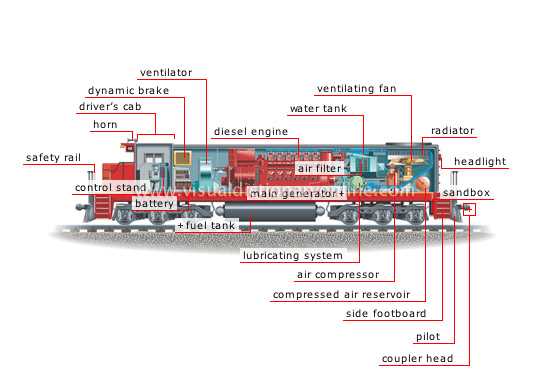

Key Parts of a Locomotive Engine

Understanding the essential components of an engine is crucial for grasping how these powerful machines operate. Each element plays a vital role in ensuring efficiency, reliability, and performance. From the heart of the system to the outer framework, these elements work in harmony to convert fuel into motion.

Core Components

At the center of any engine lies the cylinder, where the combustion process takes place. This is complemented by the piston, which moves within the cylinder, creating the necessary force to drive the mechanism. Additionally, the crankshaft transforms this linear motion into rotational energy, enabling movement.

Supporting Elements

To maintain optimal operation, various supporting structures are essential. The fuel injection system ensures that the right amount of fuel enters the combustion chamber, while the exhaust system manages the expulsion of gases produced during combustion. Furthermore, the cooling system prevents overheating, ensuring the longevity of the engine.

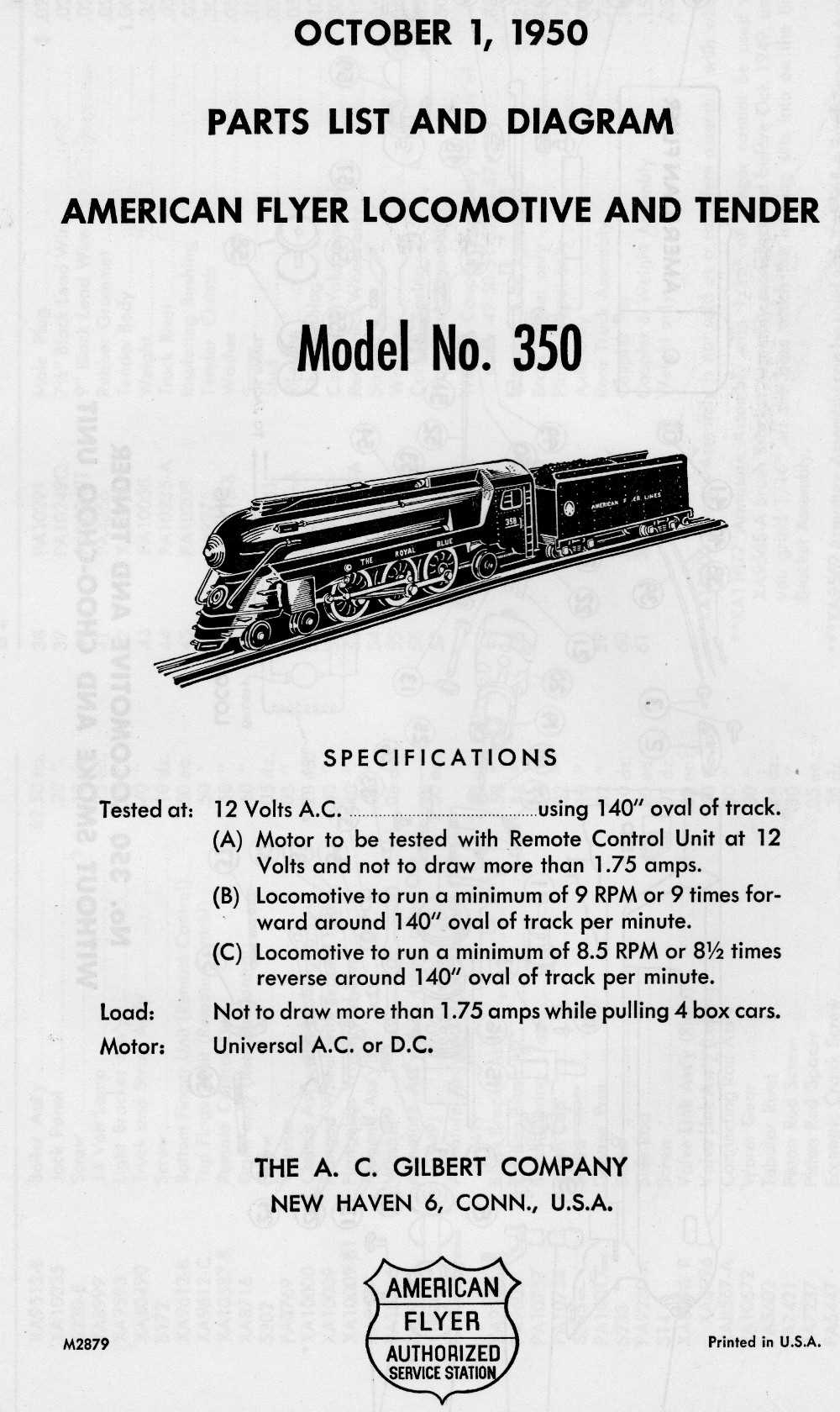

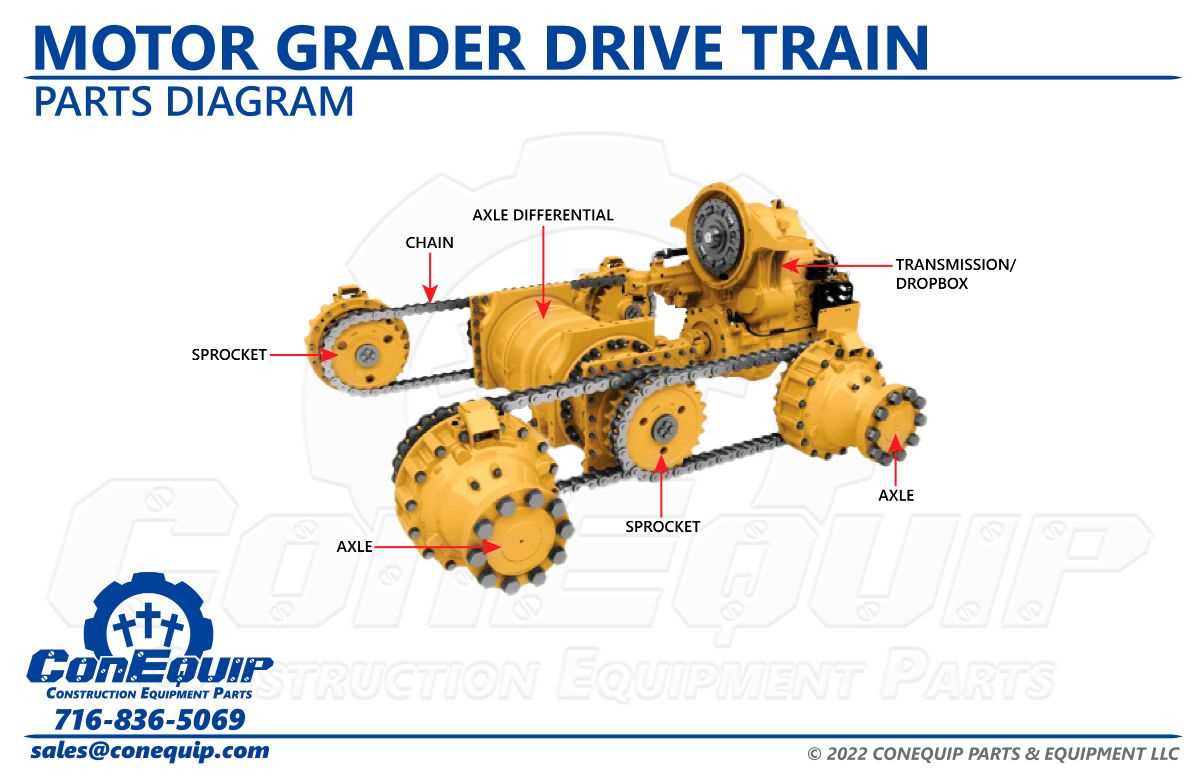

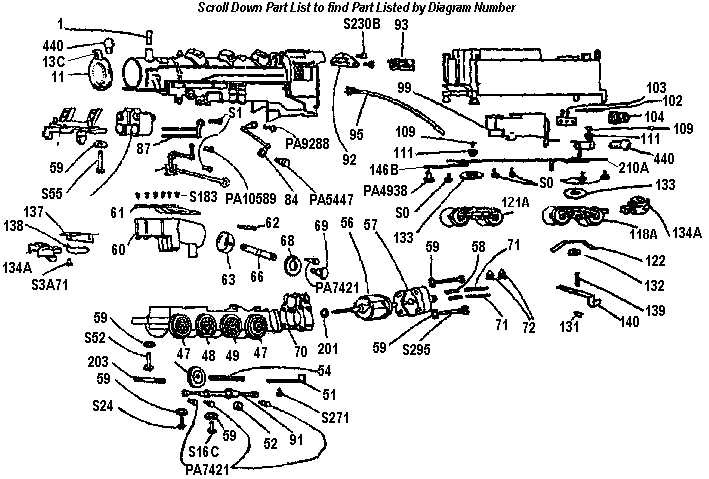

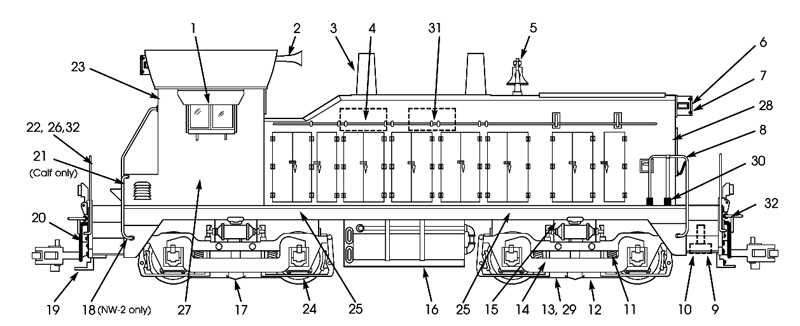

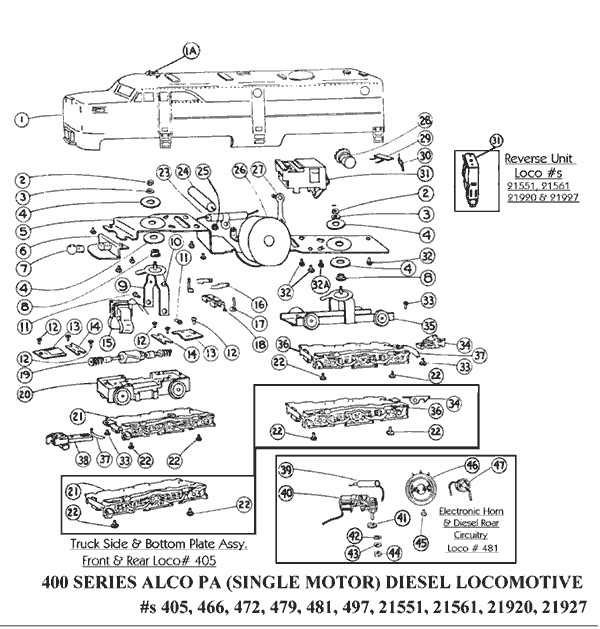

Importance of Accurate Diagrams

Precision in visual representations is crucial for understanding complex machinery. These illustrations serve as essential guides, facilitating maintenance, repairs, and assembly. A clear depiction can prevent misunderstandings that may lead to costly errors or safety hazards.

Clarity in these visuals ensures that technicians can easily identify components and their relationships. When details are presented accurately, the likelihood of mistakes diminishes significantly. This not only enhances the efficiency of work but also fosters a safer environment for all involved.

Furthermore, comprehensive illustrations support training efforts. New personnel benefit immensely from well-structured visuals that highlight critical aspects of machinery. As a result, they become proficient more quickly, minimizing downtime and enhancing overall productivity.

In summary, the significance of accurate representations cannot be overstated. They play a vital role in the effective operation and maintenance of machinery, directly impacting performance and safety.

Common Types of Locomotive Designs

This section explores various configurations of powerful rail vehicles, each engineered to meet specific operational needs and performance criteria. Understanding these designs helps in appreciating the diversity and innovation within the rail industry.

1. Diesel Electric

These models combine diesel engines with electric traction motors, providing efficiency and flexibility. They are widely used in freight and passenger services due to their reliability.

2. Steam-Powered

Although largely phased out, steam engines played a critical role in the history of rail transport. Their design involves burning fuel to produce steam that drives pistons, offering high power output.

| Type | Fuel Source | Usage |

|---|---|---|

| Diesel Electric | Diesel | Freight/Passenger |

| Steam-Powered | Coal/Wood | Historical/Heritage |

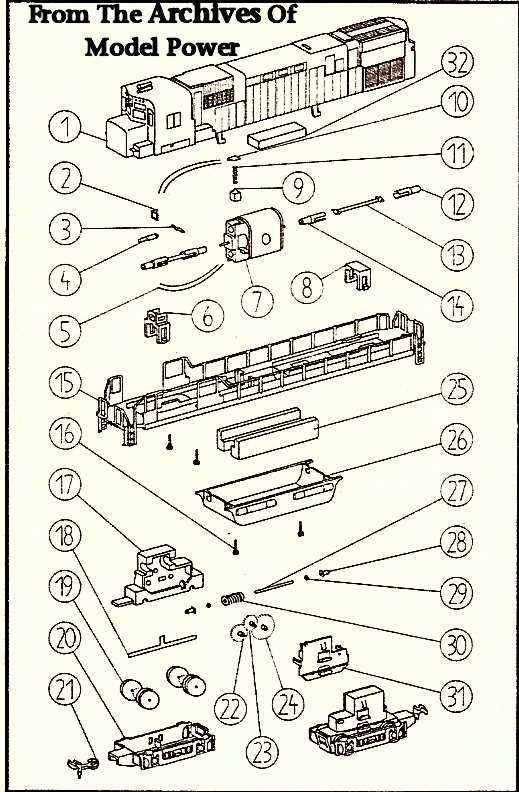

How Diagrams Aid Maintenance

Visual representations play a crucial role in enhancing the upkeep of complex machinery. They provide a clear, systematic overview, allowing technicians to quickly identify components and their interrelations. By simplifying the intricate details, these illustrations serve as invaluable tools for effective maintenance and troubleshooting.

One of the key benefits of utilizing such visual aids is the reduction of time spent on repairs. Technicians can efficiently locate issues and apply solutions without the need for extensive searching or guesswork. Additionally, these representations foster a deeper understanding of the machinery, promoting more informed decision-making during maintenance tasks.

| Benefits | Description |

|---|---|

| Efficiency | Reduces time spent on identifying issues. |

| Clarity | Simplifies complex relationships between components. |

| Training | Facilitates learning for new technicians. |

| Communication | Enhances collaboration among maintenance teams. |

In summary, visual tools are indispensable in the maintenance of sophisticated machinery. They not only streamline the repair process but also contribute to a more knowledgeable workforce, ultimately ensuring better performance and longevity of the equipment.

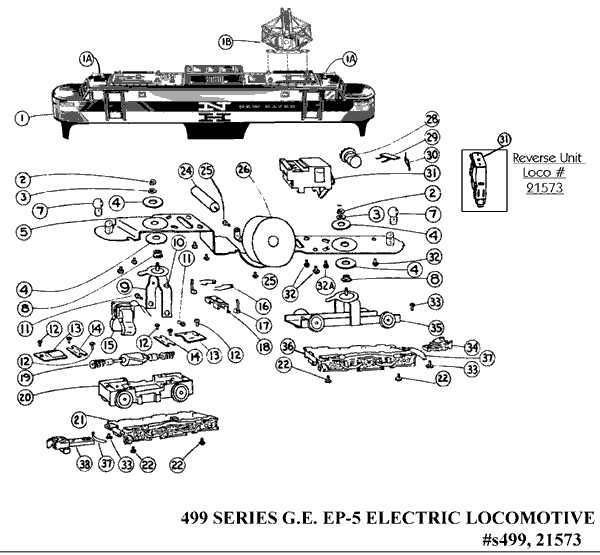

Components of Electric vs. Diesel Locomotives

Understanding the fundamental differences between two primary types of traction systems reveals how they are engineered to meet specific operational needs. Each system is composed of unique elements that influence performance, efficiency, and maintenance. This comparison sheds light on the distinctive characteristics that define electric and diesel models, emphasizing their respective advantages.

Electric Systems

Electric systems primarily rely on an array of components designed to convert electrical energy into mechanical power. Key features include powerful traction motors, which provide high acceleration and smooth operation. Additionally, transformers and converters play critical roles in managing power supply, ensuring optimal energy use. The absence of a combustion engine allows for reduced emissions and quieter operation, making these systems ideal for urban environments.

Diesel Systems

On the other hand, diesel configurations utilize internal combustion engines to generate power. These models incorporate various elements such as fuel tanks, exhaust systems, and generators that facilitate energy conversion. The ability to operate independently of external power sources grants them significant flexibility, making them suitable for long-distance travel and areas lacking electrification. However, they generally require more maintenance due to the complexity of their mechanical components.

Historical Evolution of Locomotive Parts

The journey of mechanical transport has witnessed significant transformations in its essential components, reflecting advancements in technology and engineering. Each era has contributed unique innovations that enhanced efficiency, safety, and performance, shaping the very essence of rail travel.

Early Developments

The inception of steam-driven engines in the early 19th century marked a pivotal shift. Initial designs were rudimentary, relying on basic elements such as boilers and pistons. Over time, enhancements in metallurgy and design led to improved durability and power output, setting the foundation for future innovations.

Modern Innovations

Technological Advances in Locomotive Design

Recent innovations in engineering have significantly transformed the way heavy transport vehicles are designed and manufactured. These advancements not only enhance performance and efficiency but also improve safety and environmental impact. By integrating cutting-edge technologies, manufacturers are reshaping the future of rail transport.

One of the key areas of development has been in propulsion systems. The transition from traditional fuel-based engines to electric and hybrid alternatives is reducing carbon emissions and operational costs. Additionally, the adoption of advanced materials has led to lighter and stronger structures, enhancing overall durability and performance.

| Innovation | Description | Benefits |

|---|---|---|

| Electric Propulsion | Utilizes electric motors for drive. | Lower emissions, improved efficiency. |

| Hybrid Systems | Combines traditional and electric power sources. | Flexibility, reduced fuel consumption. |

| Lightweight Materials | Incorporation of composites and alloys. | Increased speed, better fuel economy. |

| Advanced Control Systems | Smart technology for real-time monitoring. | Enhanced safety, predictive maintenance. |

The integration of automation and data analytics further contributes to these advancements. Smart technologies allow for predictive maintenance, reducing downtime and operational costs. As the industry evolves, the focus on sustainability and efficiency will continue to drive innovation in vehicle design, ensuring a more reliable and eco-friendly future for transport systems.

Resources for Learning More

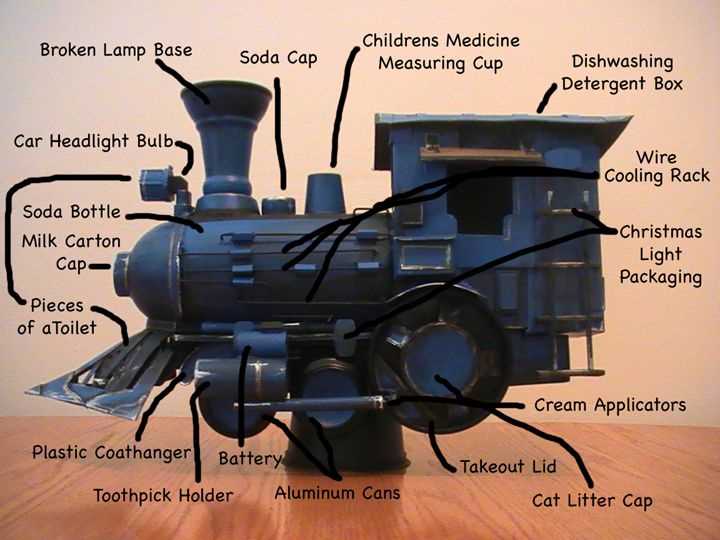

Understanding the intricate components of mechanical systems can greatly enhance one’s knowledge and skills in the field of engineering and design. This section provides a variety of resources that cater to different learning styles, whether you prefer reading, watching, or hands-on experience.

Books and Publications

- Technical Manuals: Look for specialized guides that delve into the engineering principles behind various mechanical systems.

- Textbooks: Academic resources often provide comprehensive insights into the design and functionality of machinery.

- Industry Journals: Subscribe to periodicals that feature the latest research and advancements in mechanical engineering.

Online Learning Platforms

- Coursera: Offers courses related to mechanical engineering fundamentals and advanced topics.

- edX: Provides access to lectures and materials from top universities around the world.

- YouTube: Search for educational channels that focus on engineering concepts and practical demonstrations.

By exploring these resources, you can build a solid foundation and deepen your understanding of mechanical structures and their functionalities.