Understanding the intricate assembly of your vehicle is crucial for both maintenance and repair. A detailed examination of each segment provides insights into the functionality and interconnectivity of various elements. Whether you are a seasoned mechanic or a novice enthusiast, having a visual reference can significantly enhance your knowledge and efficiency.

In the realm of automotive care, diagrams serve as invaluable resources. They not only illustrate the arrangement of components but also highlight their respective roles within the system. This clarity enables individuals to identify issues promptly and facilitates informed decision-making during restoration or enhancement processes.

Equipping yourself with a comprehensive visual guide can transform the way you approach repairs. By familiarizing yourself with the layout and design of critical assemblies, you can tackle challenges with confidence. This article aims to provide you with an essential overview of the schematic representation of these components, paving the way for effective vehicle management.

Understanding Lincoln 210 MP Components

When delving into the intricacies of a versatile welding machine, it is essential to grasp the various elements that contribute to its functionality. Each component plays a crucial role in ensuring efficient operation, and understanding these parts can greatly enhance the user experience and maintenance practices.

Key elements of this apparatus can be categorized into different functional groups. Below is a table highlighting these components along with their respective functions.

| Component | Function |

|---|---|

| Power Source | Provides the electrical energy needed for welding tasks. |

| Control Panel | Allows users to adjust settings such as voltage and current. |

| Wire Feeder | Delivers filler material to the welding arc consistently. |

| Cooling System | Prevents overheating by dissipating heat generated during operation. |

| Electrode Holder | Holds the electrode securely while providing an electrical connection. |

| Ground Clamp | Establishes a connection to the workpiece to complete the electrical circuit. |

By familiarizing oneself with these crucial components, operators can ensure optimal performance and longevity of the equipment, leading to more successful welding projects.

Overview of Lincoln 210 MP Features

This section provides a comprehensive look at the remarkable functionalities of a versatile welding machine designed for efficiency and ease of use. It combines advanced technology with user-friendly controls, catering to both novice and experienced welders. With a focus on performance and adaptability, this equipment stands out in various welding applications.

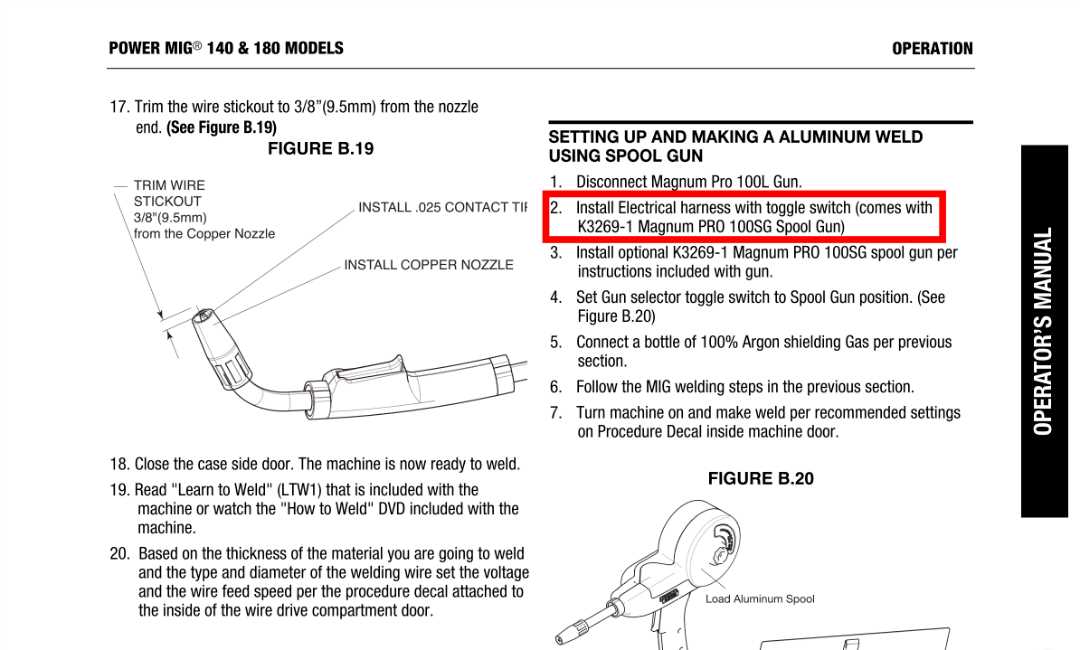

Key Specifications

| Feature | Description |

|---|---|

| Welding Process | Supports multiple welding methods, including MIG, TIG, and stick. |

| Input Voltage | Operates on both 120V and 240V power sources for flexibility. |

| Weight | Lightweight design for easy transport and maneuverability. |

| Digital Display | Offers real-time feedback and settings adjustments for precision. |

| Duty Cycle | High duty cycle rating for extended use without overheating. |

Usability and Performance

Designed with the user in mind, this machine features intuitive controls that simplify the setup process. The high-quality construction ensures durability and reliability in various environments. Its performance capabilities make it suitable for a wide range of welding tasks, from automotive repairs to industrial applications.

Importance of Parts Diagrams

Understanding the intricate layout of components in machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools for technicians, providing clarity and facilitating effective troubleshooting. These illustrations not only enhance comprehension but also streamline the process of identifying specific elements within a complex system.

Enhanced Troubleshooting

Having a visual guide allows technicians to quickly locate faulty elements. This efficiency reduces downtime and ensures that repairs are executed swiftly. With a clear overview, even novice mechanics can gain confidence in diagnosing issues without extensive prior experience.

Streamlined Maintenance

Regular upkeep is vital for optimal performance. Visual references support scheduled checks and replacements by detailing the arrangement and connection of each unit. This proactive approach helps in preventing unexpected failures and extends the lifespan of the equipment.

| Benefit | Description |

|---|---|

| Clarity | Provides a clear view of component layout. |

| Efficiency | Speeds up the identification of issues. |

| Confidence | Assists less experienced technicians in understanding systems. |

| Preventive Care | Encourages regular checks to avoid breakdowns. |

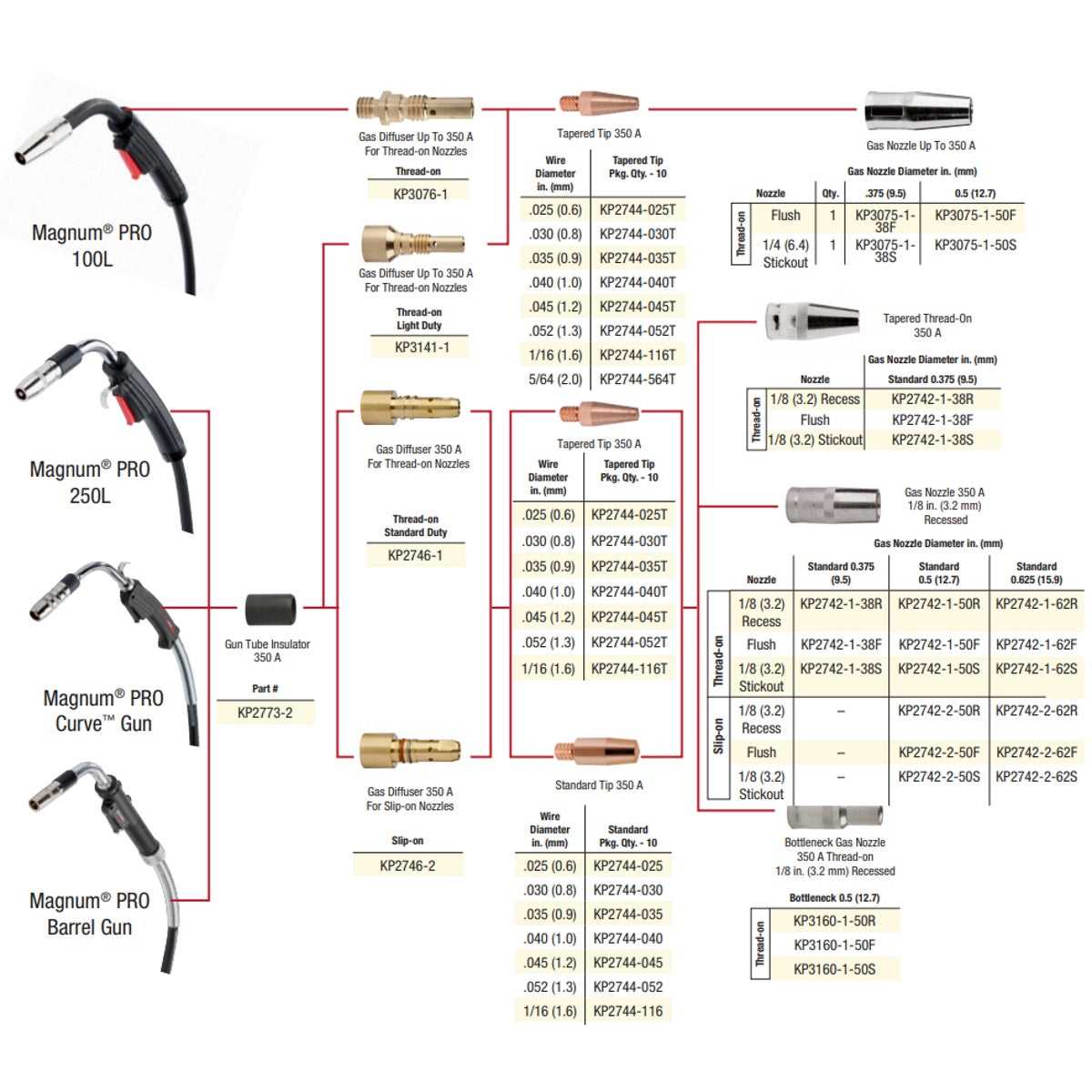

Common Replacement Parts for Lincoln 210 MP

When maintaining welding equipment, it’s essential to identify components that may need replacement over time. Regular wear and tear can affect performance, making it crucial to have a clear understanding of which items require attention. Below is a detailed overview of commonly needed replacements for optimal functionality.

| Component | Description | Signs of Wear |

|---|---|---|

| Contact Tip | Facilitates the transfer of electrical current to the filler material. | Excessive spatter, poor arc stability. |

| Gas Diffuser | Controls the flow of shielding gas to protect the weld area. | Inconsistent gas flow, increased contamination. |

| Nozzle | Directs the shielding gas and provides a pathway for the arc. | Burn-through, deformation, and discoloration. |

| Electrode | Serves as the source of the arc and can wear down with use. | Shorter arc length, difficulty in starting the arc. |

| Welding Cable | Transmits electrical current from the machine to the workpiece. | Fraying, exposed wire, reduced flexibility. |

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to assemble or repair machinery. These illustrations provide a clear layout of individual elements, their arrangement, and how they interact with each other. Grasping the conventions used in these visuals is essential for effective troubleshooting and maintenance.

1. Familiarize Yourself with the Legend: Most illustrations include a legend or key that explains the symbols and numbers used. This guide is crucial for identifying different elements and their corresponding specifications.

2. Analyze the Layout: Pay attention to how components are positioned relative to each other. Often, the arrangement indicates the sequence of assembly or disassembly, making it easier to follow along during repairs.

3. Identify Groups: Components are often categorized into groups based on their functions. Recognizing these clusters can simplify the understanding of complex systems and allow for a more efficient workflow.

4. Reference Part Numbers: Each element typically has a unique identifier. These numbers are essential for sourcing replacements and ensuring compatibility, so take note of them for future reference.

5. Follow the Flow: In many cases, arrows or lines indicate the flow of materials or processes. Understanding this flow can provide insight into how systems operate and where potential issues may arise.

By mastering these techniques, you’ll improve your proficiency in interpreting visual guides, leading to more effective repairs and maintenance activities.

Identifying Compatible Accessories

When enhancing your equipment, it’s crucial to ensure that any additional items you consider will work seamlessly with your existing setup. This process involves understanding specifications, connection types, and overall functionality. Proper compatibility not only optimizes performance but also ensures safety and longevity of the equipment.

Research is key. Begin by reviewing manufacturer guidelines and user manuals to determine which accessories are recommended. This information often includes essential details about size, shape, and operational requirements.

Consulting online communities can also be beneficial. Forums and discussion groups are excellent resources for real-world experiences and insights. Engaging with fellow users can reveal which add-ons have proven successful and which ones to avoid.

Additionally, always consider quality and durability. Investing in well-made accessories can prevent future issues and enhance your overall experience. Prioritize products from reputable brands that are known for their reliability.

Maintenance Tips for Lincoln 210 MP

Proper upkeep is essential for maximizing the lifespan and performance of your welding equipment. Regular attention to maintenance can prevent costly repairs and ensure smooth operation. Here are some key practices to keep your machine running efficiently.

Regular Cleaning

Maintaining cleanliness is vital. Dust, debris, and spatter can accumulate and lead to malfunctions. Make it a habit to clean the exterior and interior components regularly. Use a soft brush or compressed air to remove particles, ensuring that all ventilation openings are clear. This will enhance airflow and prevent overheating.

Check Electrical Connections

Inspecting and tightening electrical connections should be part of your routine checks. Loose or corroded connections can cause erratic behavior or even failure. Always power down the equipment before performing inspections, and ensure all wiring is in good condition. Replacing damaged wires promptly will help maintain performance and safety.

Incorporating these practices into your maintenance routine will contribute significantly to the reliability and effectiveness of your welding apparatus.

Where to Find Replacement Parts

When it comes to maintaining and restoring machinery, sourcing the correct components is crucial for optimal performance. Whether you’re a hobbyist or a professional, knowing where to look can save time and ensure you get quality items.

Online Resources

The internet offers a wealth of options for finding the necessary components. Various websites specialize in selling equipment parts, ranging from original manufacturers to third-party suppliers. These platforms often feature search functions, allowing users to filter by model or specifications.

Local Retailers

Visiting local hardware stores or specialty shops can be beneficial as well. These establishments might stock a range of components or be able to order them for you. Building relationships with local suppliers can also provide insights into alternative solutions or recommendations.

| Resource Type | Examples |

|---|---|

| Online Stores | eBay, Amazon, Specialized Parts Websites |

| Local Shops | Hardware Stores, Specialty Equipment Suppliers |

| Forums and Community Groups | Online Discussion Boards, Social Media Groups |

FAQs about Lincoln 210 MP Parts

This section addresses common inquiries related to components for a specific welding machine, focusing on their functionality, compatibility, and maintenance. Understanding these aspects can significantly enhance the user experience and ensure optimal performance of the equipment.

| Question | Answer |

|---|---|

| What is the best way to find replacement components? | The most reliable method is to consult the manufacturer’s website or authorized dealers for specific recommendations. |

| Are all components interchangeable with other models? | No, compatibility varies, so it’s important to verify specifications for each model. |

| How often should I replace consumables? | It depends on usage; however, regular checks and timely replacements help maintain efficiency. |

| Where can I find a manual for maintenance? | A digital copy is usually available on the manufacturer’s site, providing detailed guidance. |

| What should I do if I encounter issues with a component? | Contact customer support or a qualified technician for troubleshooting assistance. |