Understanding the internal workings of a relaxation seat can greatly enhance its maintenance and longevity. These specialized seating systems are equipped with various mechanical and electrical elements, each playing a critical role in ensuring comfort and functionality. The focus here is to offer insight into the various interconnected elements that operate seamlessly to provide optimal support and ease of movement.

The functionality behind this type of seating is a combination of engineering and ergonomics. A motorized system, coupled with precision hardware, allows for smooth transitions between different positions. Each component is designed to interact with others, forming a cohesive mechanism that adjusts the angle and height of the seat, ensuring maximum comfort for the user.

In this guide, we will explore the essential features that contribute to the seamless operation of the reclining system. From electrical controls to the mechanical structures, understanding how each part works will empower you to address common issues, optimize performance, and appreciate the technology behind modern seating solutions.

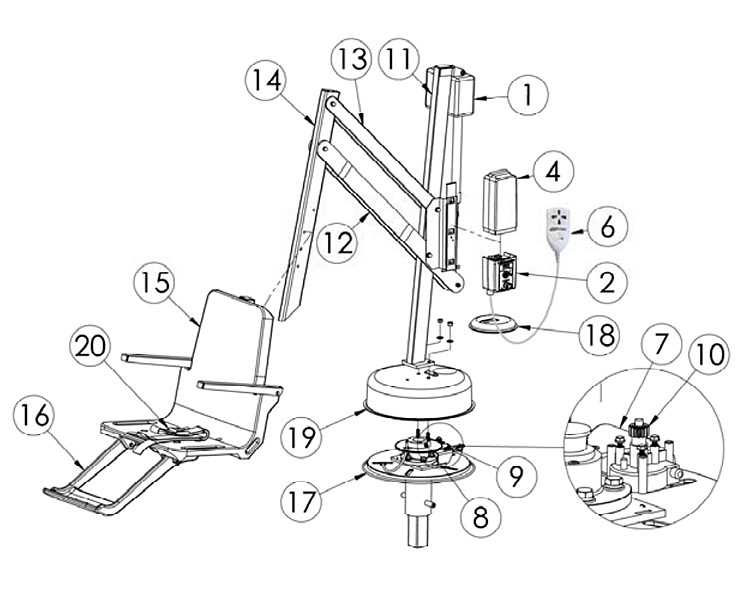

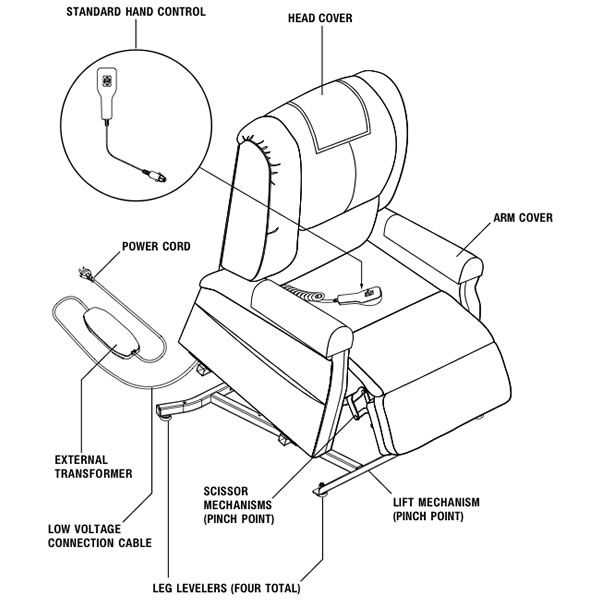

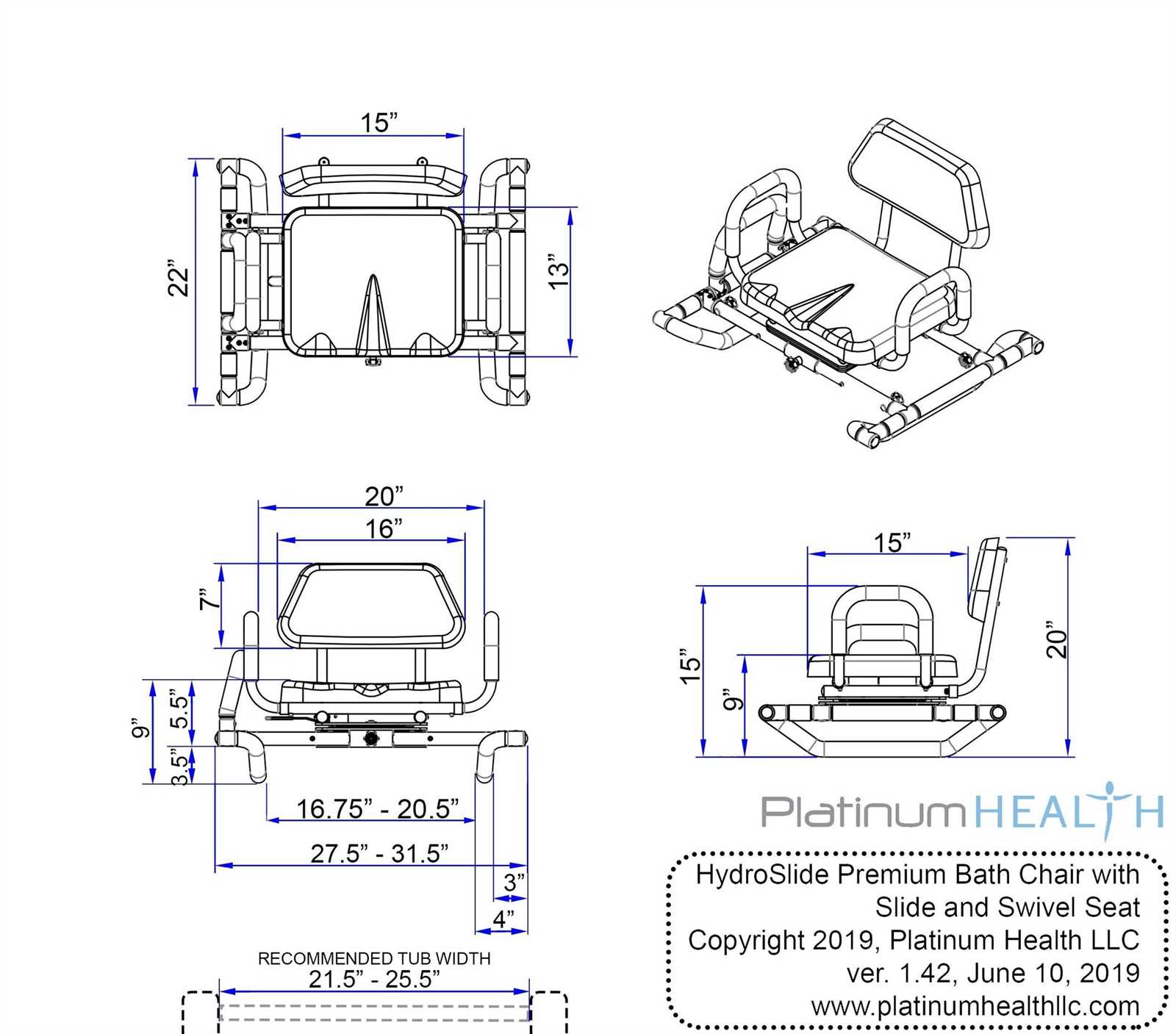

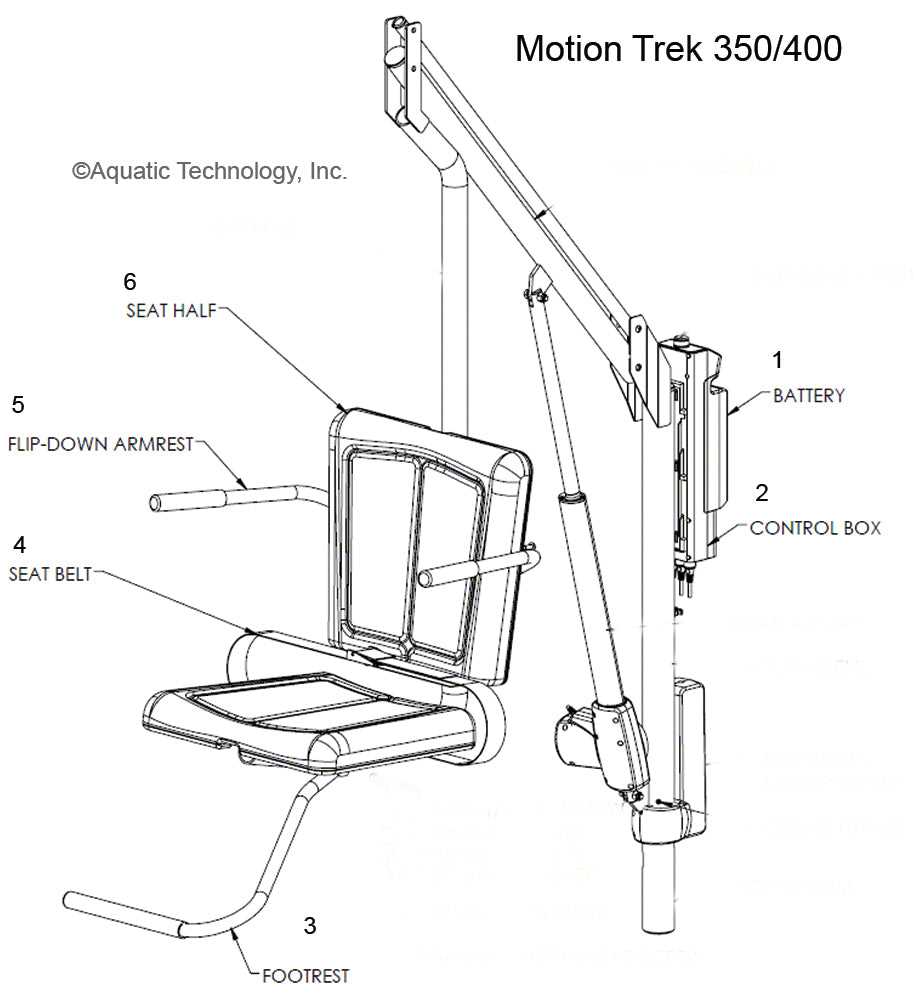

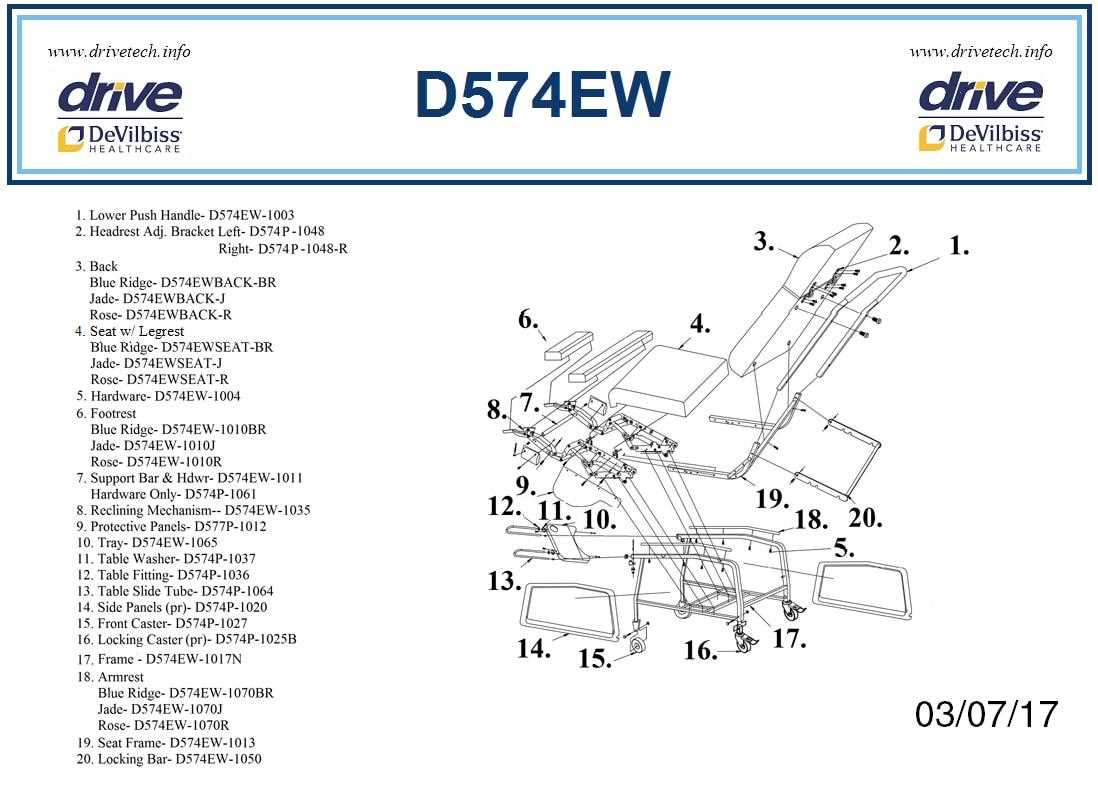

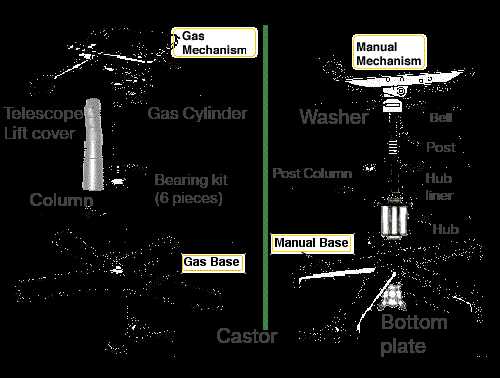

Understanding the Components of a Lift Chair

In this section, we will explore the key elements that make up a mobility-enhancing seating device. These elements work together to provide both comfort and support while assisting users in adjusting their seating position with ease.

- Base Structure – The foundation of the unit, designed to offer stability and durability, allowing it to withstand regular use.

- Mechanical System – A set of mechanisms responsible for smooth transitions between various seating angles. This often includes actuators or motors that drive movement.

- Cushioning Elements – Special padding and support

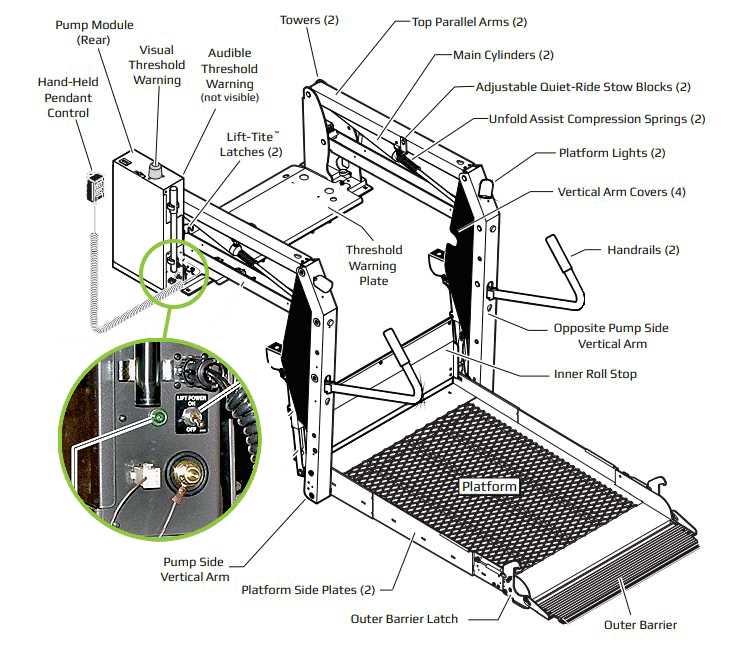

Key Mechanisms in a Lift Chair

Understanding the fundamental components of this mobility-enhancing furniture is essential for grasping how it operates. These pieces of equipment are designed with several interconnected elements that work together to provide smooth motion and optimal support. Each mechanism plays a crucial role in ensuring both comfort and functionality for the user.

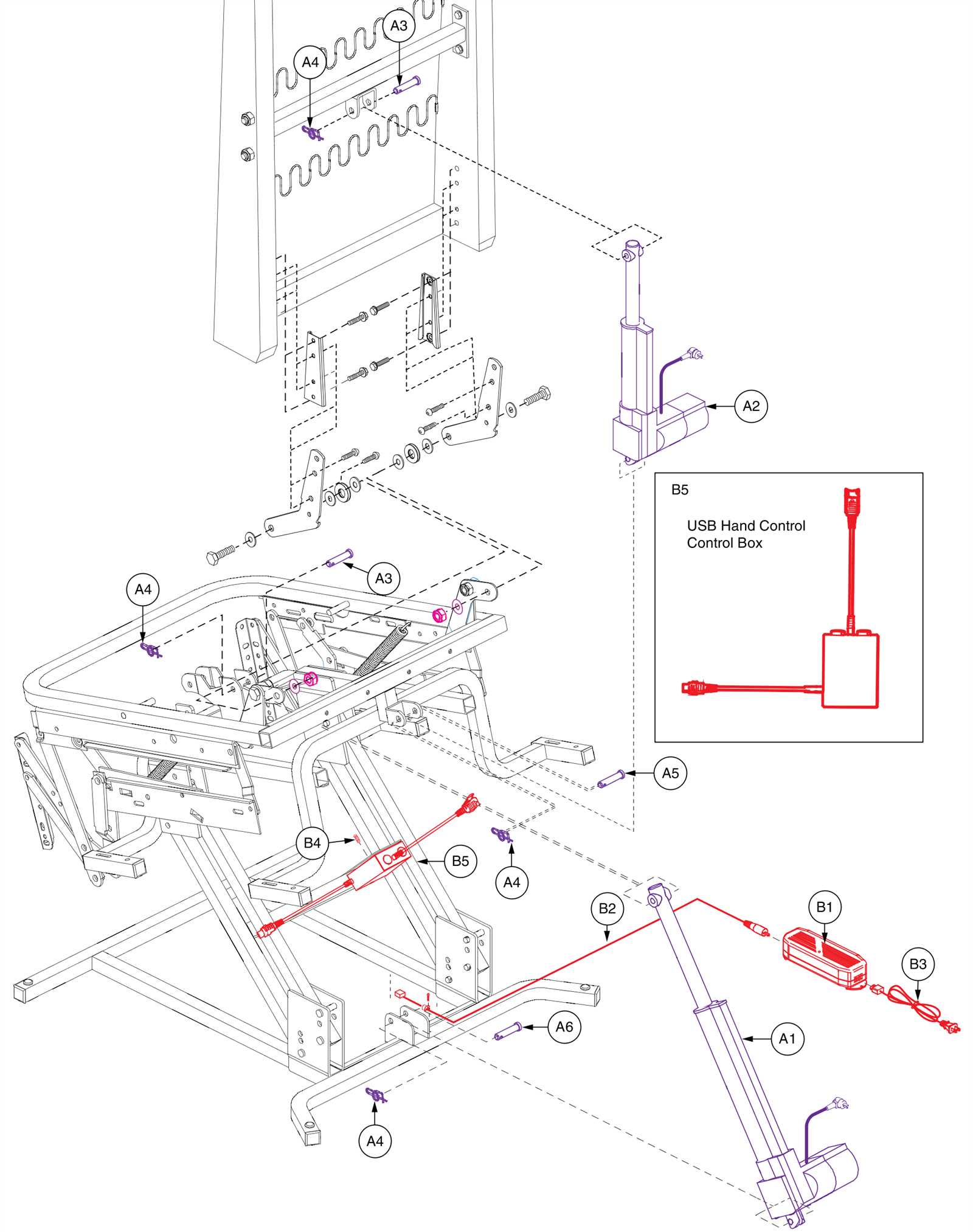

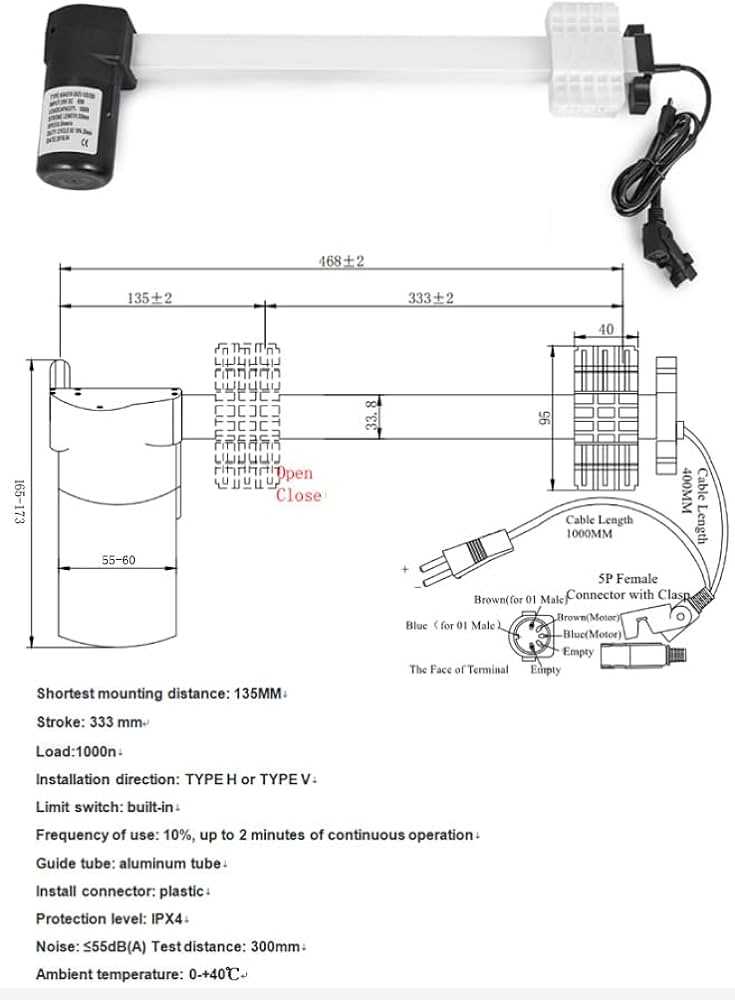

Motorized Systems

One of the primary components is the motorized system, which powers the movement. This system allows for controlled transitions, enabling various adjustments in positioning. The engine typically operates quietly and efficiently, ensuring seamless shifts in motion to enhance user experience.

Structural Frame and Cushioning

The framework supports the entire structure, providing stability and durability. Reinforced joints and sturdy materials ensure that the unit can handle frequent use. Meanwhile, the cushioning adds a layer of comfort, with padding materials designed to offer both softness and resilience, ensuring long-lasting comfort and reliability.

Identifying Common Electrical Connections

Understanding the basic wiring and electrical pathways is crucial for maintaining any mechanized seating solution. By familiarizing yourself with the typical connections, it becomes easier to troubleshoot electrical issues or replace faulty components. This section focuses on the most frequent electrical links you may encounter and how to recognize them efficiently.

Connection Type Description Common Indicators Power Connector Supplies energy to the system, typically through a DC or AC adapter. Thick cable, often leading to a transformer or power source. The Role of Motors in Chair Operation Mechanical systems designed to support movement and comfort rely heavily on the function of their internal engines. These devices enable smooth transitions between different positions, providing users with effortless adjustments. Understanding how these engines work is essential to grasp the broader functionality of the entire mechanism.

Powering Smooth Transitions

The motors are responsible for powering the various movements, ensuring a quiet and efficient operation. These components are often engineered to handle varying weight distributions and deliver consistent performance over time. Precision engineering allows for seamless adjustments, providing stability and control throughout each use.

Durability and Efficiency

Modern motors are designed to be both durable and energy-efficient. Long-lasting components ensure minimal maintenance, while energy-saving technologies contribute to lower power consumption. This balance between strength and efficiency is key to the system’s overall performance, ensuring reliability for years of usage.

Cushion and Frame Construction Details

The design of the seating system relies on the careful balance between comfort and durability. The structure and padding are thoughtfully crafted to provide optimal support while ensuring longevity. This section will explore how various components are integrated to create a seamless and functional experience.

Supportive Cushion Layers

The cushioning is typically composed of multiple layers, each serving a distinct purpose. High-density foam is often used as the core material, offering a balance between softness and resilience. Additionally, some designs incorporate memory foam for added comfort, ensuring the seat conforms to the user’s body while maintaining its shape over time.

Durable Framework Design

The underlying framework is constructed from robust materials such as reinforced metal or hardwood, providing a solid foundation. This structure is engineered to endure prolonged use, with joints

How Control Systems Manage Chair Movement

Control systems play a crucial role in the operation of seating mechanisms, ensuring smooth and precise adjustments to accommodate user preferences. These systems utilize a combination of sensors, actuators, and software to enable users to modify their seating position with ease and comfort. Understanding how these systems work can enhance user experience and functionality.

Components of Control Systems

- Sensors: These devices monitor the position and movement, providing real-time data to the control system.

- Actuators: Responsible for executing movement based on signals from the control system, actuators convert electrical energy into mechanical motion.

- Control Unit: This is the brain of the system, processing inputs from sensors and sending commands to actuators to perform desired actions.

Operational Mechanism

- The user inputs a command via a control interface, such as a remote or button panel.

- Sensors detect the current position of the mechanism and relay this information to the control unit.

- The control unit processes the information and determines the necessary movement.

- Actuators receive commands from the control unit and initiate the required adjustments.

- Continuous feedback from the sensors ensures that the adjustments are executed accurately, allowing for real-time monitoring of the seating position.

This integrated approach to managing movement not only enhances user convenience but also contributes to the overall safety and reliability of the seating mechanism.

Footrest and Recline Adjustments Overview

This section provides an understanding of the mechanisms that enable the adjustment of leg support and reclining positions for enhanced comfort and accessibility. Mastering these features is crucial for optimizing the overall experience and ensuring ease of use.

The following aspects are essential to comprehend when adjusting leg support and reclining features:

- Mechanism Types: Different models utilize various mechanisms to achieve adjustments. Familiarity with these systems can help users effectively operate their equipment.

- Control Options: Controls may be manual or electronic. Recognizing how to navigate these controls is vital for smooth operation.

- Positioning: Understanding the range of motion for both the leg support and recline function ensures that users can achieve their desired comfort level.

- Safety Features: Awareness of built-in safety features can prevent accidents during adjustments, particularly for individuals with limited mobility.

In summary, a comprehensive grasp of the functionalities associated with leg support and reclining adjustments significantly enhances the overall user experience. By familiarizing oneself with the mechanisms and controls, individuals can enjoy a more comfortable and accessible setting.

Common Issues with Lift Chair Parts

Understanding the typical challenges associated with mobility assistance furniture can help users maintain their equipment effectively. Many individuals rely on these devices for comfort and support, making it crucial to identify and address potential malfunctions promptly. Below are some frequent concerns that users might encounter.

Mechanical Failures

Mechanical failures can manifest in various forms, including issues with the reclining mechanism or the elevation function. Over time, wear and tear can lead to reduced efficiency, causing the equipment to operate inconsistently. Regular maintenance and timely repairs can extend the life of the device significantly.

Electrical Problems

Electrical problems are another common issue that can hinder functionality. Users may experience difficulties with the power supply, including interruptions or complete failures. Checking connections and replacing faulty wiring can often resolve these issues. It is essential to ensure that the equipment is plugged into a functioning outlet to prevent power-related malfunctions.

Maintenance Tips for Long-lasting Use

Proper upkeep is essential for ensuring the longevity and functionality of any seating device designed for comfort and assistance. Regular care can prevent wear and tear, enhance performance, and extend the overall lifespan of the product.

Regular Inspections

Conduct periodic checks to identify any signs of wear or damage. Look for frayed fabrics, loose components, or irregular movements. Addressing these issues promptly can help avoid more significant problems in the future.

Cleaning and Care

Keep the upholstery clean by following the manufacturer’s recommendations for cleaning products. Regularly dust and vacuum to prevent the buildup of dirt and debris. For mechanical elements, lubricate moving parts to maintain smooth operation and prevent rusting.

Emphasizing maintenance is vital for preserving the functionality and safety of your device. By implementing these simple practices, you can ensure a more reliable and enjoyable experience over time.