Maintaining the efficiency and longevity of any machinery requires a thorough understanding of its inner workings. A well-structured visual representation of various elements can greatly assist users in identifying parts and their specific functions. This guide will delve into the critical components that contribute to the overall performance of your equipment.

By exploring an organized layout of essential elements, users can enhance their knowledge about assembly and maintenance processes. This valuable insight not only aids in troubleshooting but also empowers operators to perform repairs and upgrades with confidence. Such familiarity ensures optimal operation and minimizes downtime, ultimately leading to improved productivity.

Equipped with this knowledge, users can approach their equipment with a newfound perspective. Recognizing each element’s role and interconnectivity can lead to more informed decision-making when it comes to repairs and enhancements. This resource is designed to provide clarity and support for anyone looking to deepen their understanding of the machinery they rely on.

Finding authentic components for machinery is crucial for maintaining optimal performance and longevity. When seeking replacements, it’s essential to explore reputable sources that guarantee quality and compatibility with your equipment.

Several options are available for acquiring original components:

| Source | Description |

|---|---|

| Authorized Dealers | These vendors are official representatives of the manufacturer and offer a wide range of genuine replacements. |

| Manufacturer’s Website | The official online platform often provides direct purchasing options, ensuring the authenticity of items. |

| Specialized Retailers | Stores focusing on machinery supplies may carry a selection of original components, often with expert advice available. |

| Online Marketplaces | Reputable e-commerce platforms can offer genuine items, but it’s vital to verify the seller’s credibility. |

| Local Repair Shops | Many repair facilities maintain connections with suppliers and can order authentic replacements as needed. |

Choosing the right source not only ensures the quality of replacements but also contributes to the longevity and efficiency of your equipment.

Wiring and Electrical Schematics

The organization and layout of electrical connections are vital for the efficient functioning of any machine. Understanding how these connections interact can significantly aid in troubleshooting and maintenance. A well-structured wiring setup ensures that all components work seamlessly, enhancing performance and reliability.

Key Components of Wiring Systems

- Connectors: Essential for joining different wires and ensuring a stable connection.

- Fuses: Protect electrical circuits from overloads and potential damage.

- Relays: Act as switches that control large currents with small signals.

- Grounding: Provides a safe path for excess current, preventing shocks and damage.

Electrical Circuit Layout

A clear and comprehensive electrical circuit layout allows for easier diagnostics and repairs. It often includes:

- Identification of all electrical components.

- Mapping out the flow of electricity through the system.

- Labeling connections for clarity.

By maintaining organized schematics, users can quickly locate issues and ensure the system operates efficiently.

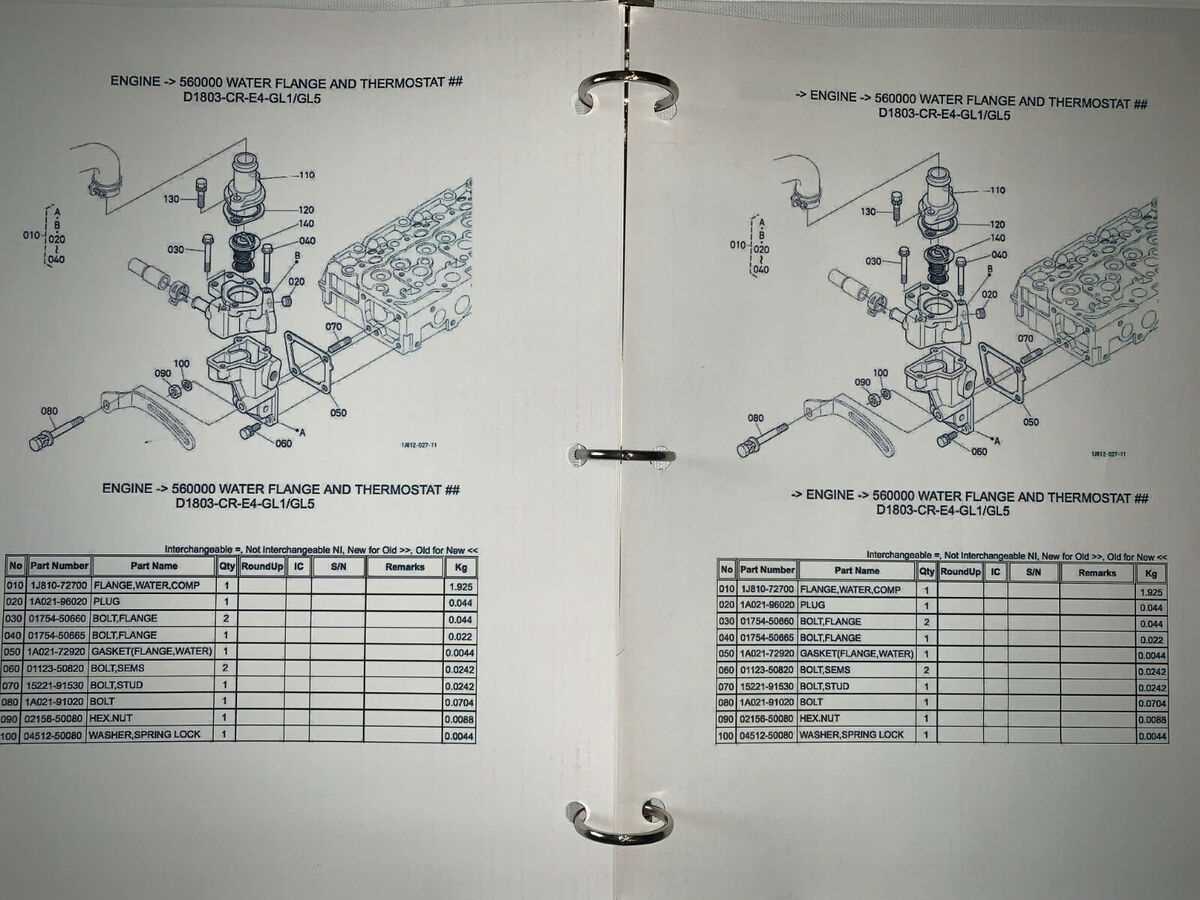

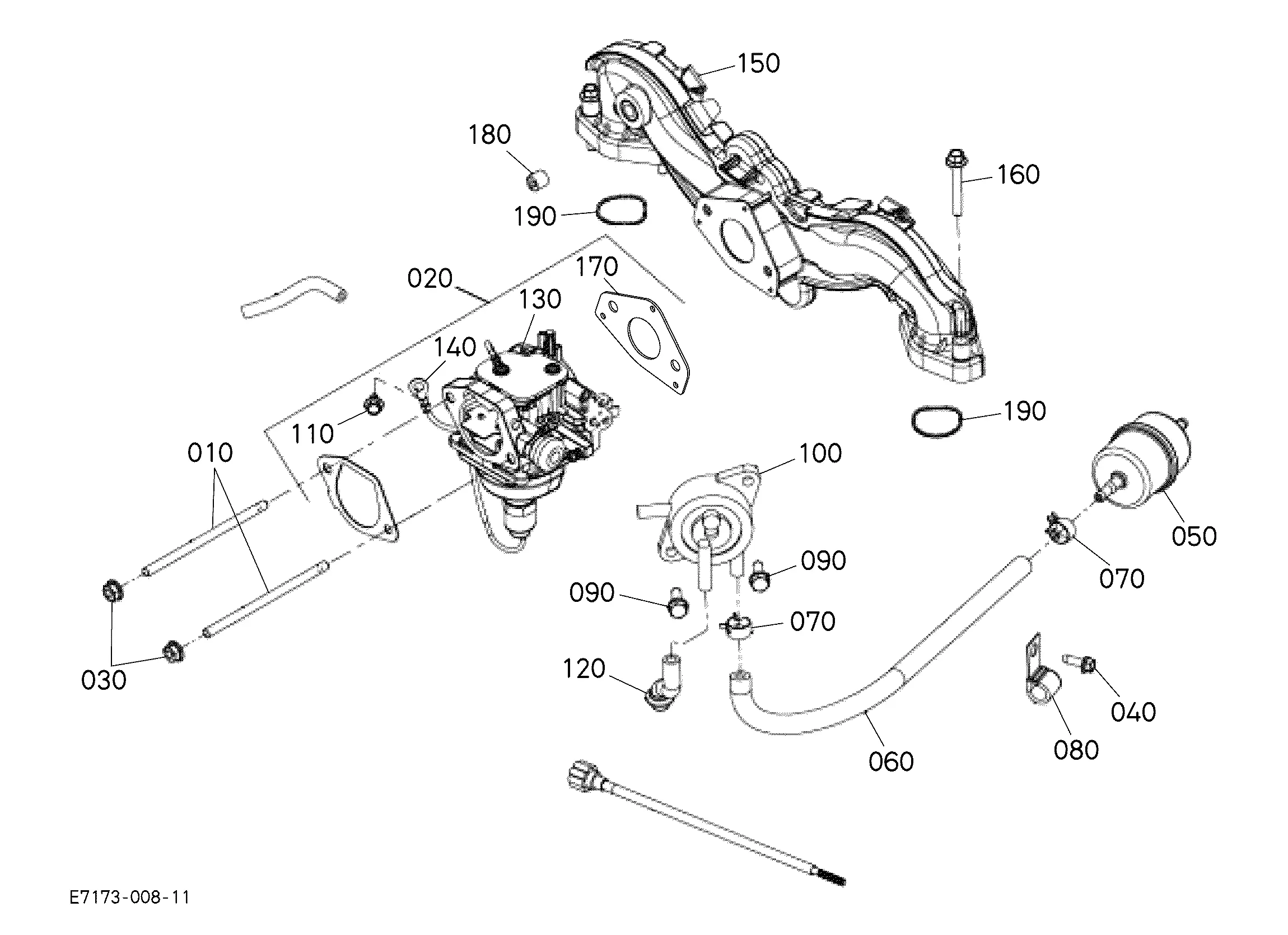

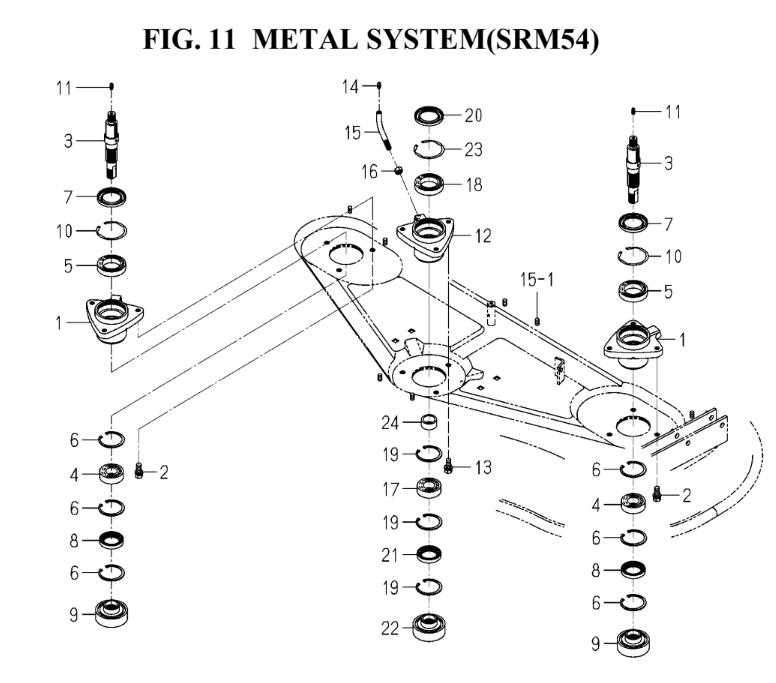

Assembly Process of Major Components

The assembly process of key elements is crucial for ensuring optimal performance and longevity in machinery. This procedure involves the careful integration of various parts, each playing a significant role in the overall functionality of the equipment. Proper alignment, secure fastening, and adherence to specifications are essential to achieving a reliable and efficient assembly.

Initially, it is vital to gather all necessary components and tools before beginning the assembly. Each part should be inspected for quality and compatibility to avoid any operational issues later on. Following a systematic approach allows for a more organized workflow and reduces the risk of errors.

During the assembly, components are typically connected in a specific sequence, often starting with the foundation elements that provide structural integrity. Assembling larger parts first helps in stabilizing the structure and allows for easier access to smaller components. Each connection should be made with precision, ensuring that fasteners are tightened to the specified torque to prevent loosening during operation.

Finally, once the major components are joined, a thorough inspection is necessary to verify that everything is in place and functioning correctly. Testing the assembly under load conditions can identify any potential weaknesses or areas for adjustment, ensuring that the equipment operates smoothly and reliably in the field.