Exploring the intricate structure of machinery is essential for maintaining efficiency and performance. Each unit comprises various elements that work harmoniously to ensure optimal functionality. Recognizing the interconnections between these components can significantly enhance repair and maintenance processes.

In this section, we will delve into the specifics of a particular engine model, examining its essential features. By breaking down the intricate relationships among these parts, one can gain insights into troubleshooting and upgrading the system.

The ultimate goal is to empower operators and technicians with the knowledge required to navigate the complexities of their equipment. A detailed overview will facilitate a deeper understanding and foster better decision-making regarding maintenance and repairs.

Kubota V2203 Overview

This section provides a comprehensive look at a specific engine model renowned for its performance and reliability in various applications. The machine is widely utilized across different industries, offering robust power output and efficiency. Understanding the intricacies of its components and functionalities is crucial for users who seek to maintain optimal performance.

Key Features

Engineered with advanced technology, this model boasts several noteworthy attributes that set it apart in its category:

| Feature | Description |

|---|---|

| Power Output | Provides impressive horsepower suitable for demanding tasks. |

| Fuel Efficiency | Designed to maximize fuel usage, reducing operational costs. |

| Durability | Built with high-quality materials ensuring long-lasting performance. |

| Compact Size | Ideal for tight spaces while maintaining powerful output. |

Applications

This engine variant is versatile, finding its place in numerous sectors such as agriculture, construction, and industrial machinery. Its adaptability allows it to perform effectively in diverse environments, making it a preferred choice among operators and equipment manufacturers.

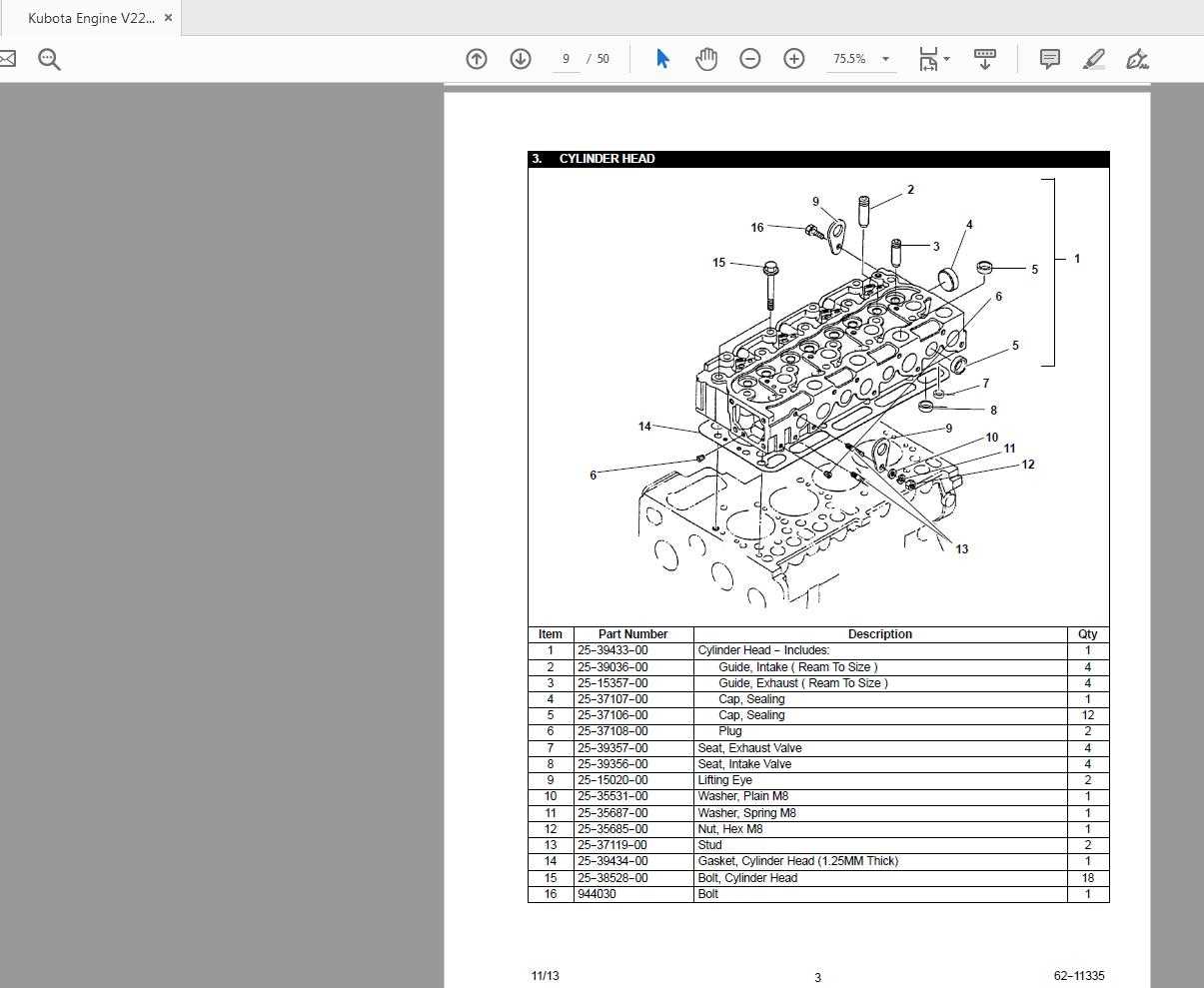

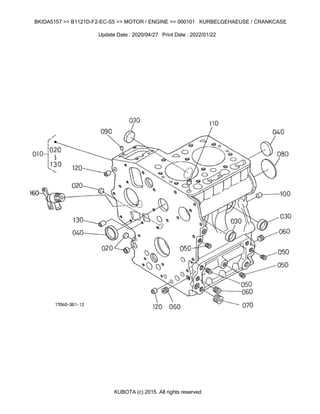

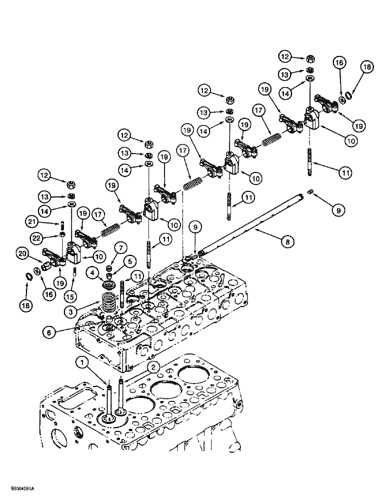

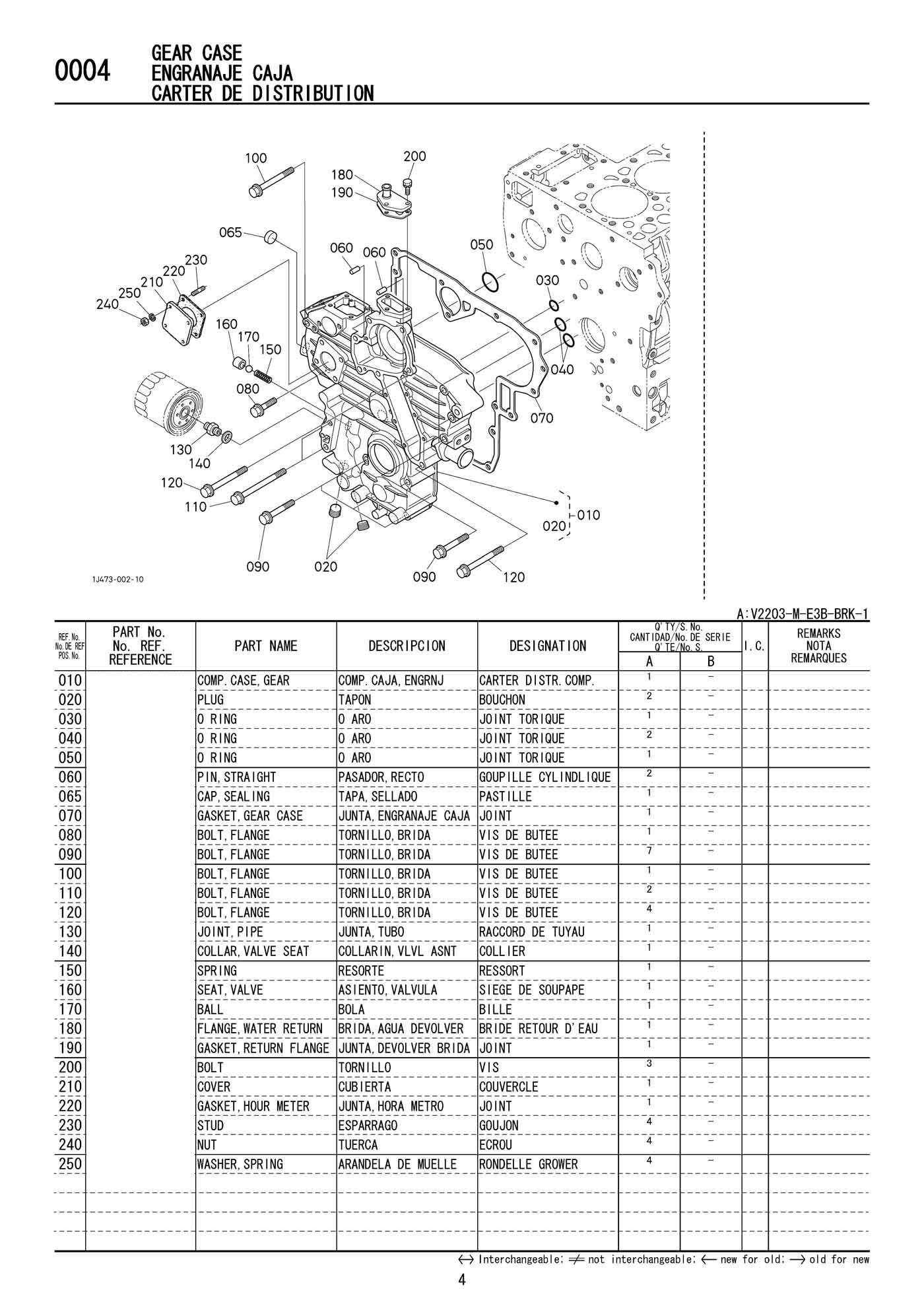

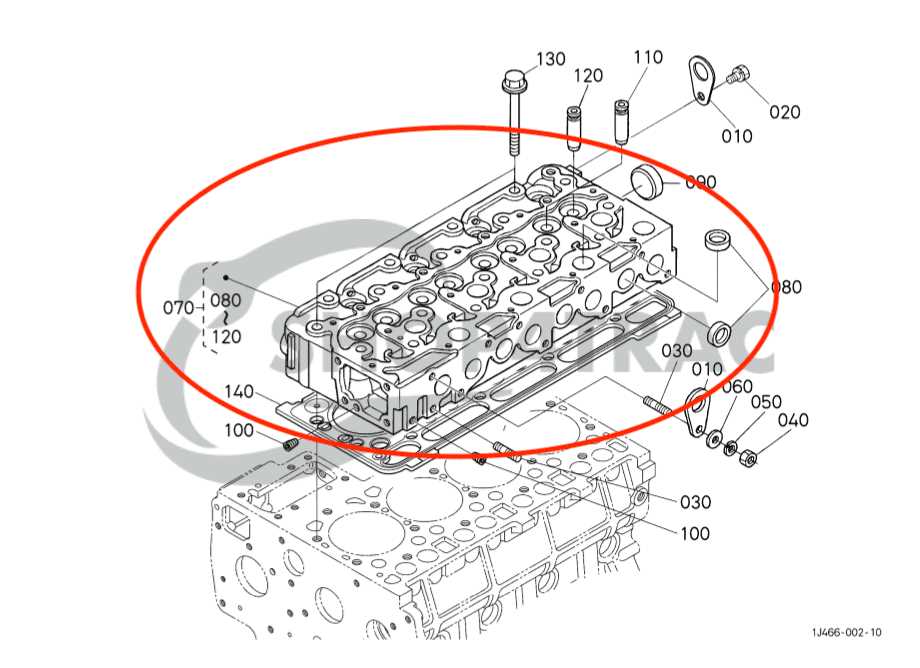

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for maintenance and repair tasks. Visual representations of elements not only enhance comprehension but also streamline the process of identifying and replacing components. A well-structured illustration serves as an invaluable reference, making it easier for technicians and operators to execute their work effectively.

Benefits of Visual References

- Enhanced Clarity: Illustrations provide a clear view of how various components fit together, reducing the likelihood of errors during assembly or disassembly.

- Improved Efficiency: Quick access to visual guides can significantly speed up maintenance procedures, allowing for more time-efficient repairs.

- Better Training Tools: For new technicians, visual aids are essential in grasping complex systems, ensuring they become proficient more quickly.

Applications in Maintenance

- Identifying Components: Clear visual references help in pinpointing specific elements that may require attention.

- Streamlining Repairs: With a detailed illustration, repair processes can be executed in a systematic manner, minimizing the risk of overlooking parts.

- Facilitating Communication: These visuals enable easier discussions between team members regarding maintenance and repairs, fostering a collaborative environment.

Common Applications of V2203 Engine

The versatile engine in question is widely utilized across various industries due to its robust performance and reliability. Its design allows it to excel in multiple environments, making it a popular choice for numerous applications.

- Agricultural machinery: Ideal for tractors and harvesters, providing the necessary power for field operations.

- Construction equipment: Commonly found in excavators and loaders, delivering strong performance in demanding tasks.

- Industrial generators: Used in power generation units, ensuring consistent energy supply for various needs.

- Marine applications: Effective in small boats and vessels, contributing to smooth navigation and operation.

- Material handling: Employed in forklifts and other lifting equipment, enhancing productivity in warehouses.

These applications highlight the engine’s adaptability and effectiveness in diverse sectors, reinforcing its significance in the machinery landscape.

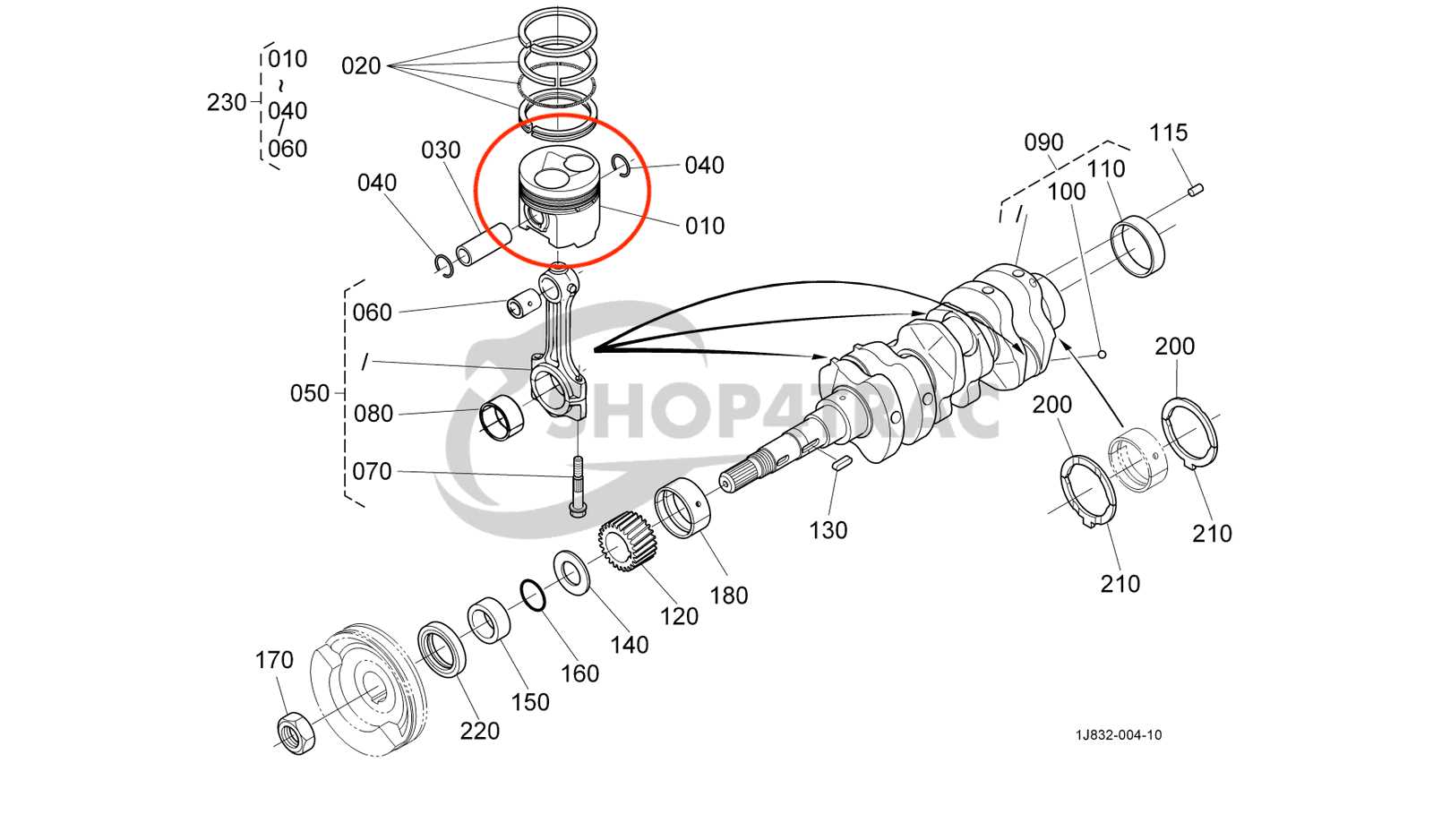

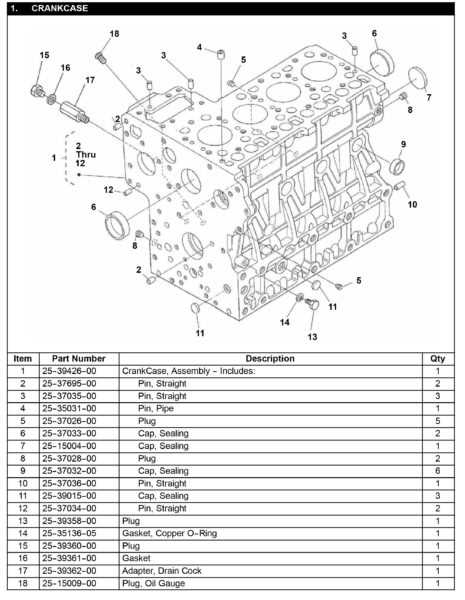

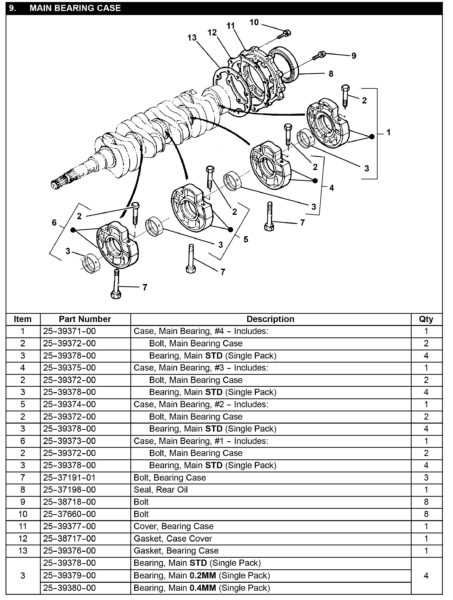

Understanding Engine Components

Grasping the intricacies of an engine requires familiarity with its various parts and how they interact to facilitate optimal performance. Each component plays a vital role in ensuring the engine operates smoothly, and understanding their functions can aid in diagnostics, maintenance, and enhancements.

The key elements of an engine can be categorized into several groups, each with distinct responsibilities:

- Power Generation: These parts are crucial for converting fuel into usable energy. They include:

- Cylinders

- Pistons

- Crankshaft

- Air and Fuel Management: Efficient combustion is vital, and these components regulate the intake and delivery of air and fuel:

- Intake manifold

- Fuel injectors

- Carburetor

- Exhaust System: After combustion, it is essential to expel gases effectively. Key parts include:

- Exhaust manifold

- Catalytic converter

- Exhaust pipes

- Cooling and Lubrication: Maintaining optimal temperatures and reducing friction are critical for longevity:

- Radiator

- Oil pump

- Thermostat

- Electrical System: This includes components that control ignition and manage electrical functions:

- Ignition coil

- Battery

- Starter motor

lessCopy code

By comprehending these essential parts and their interactions, one can better appreciate the complexities of engine design and maintenance. This knowledge is invaluable for anyone involved in mechanical work, whether for personal projects or professional endeavors.

Locating Genuine Kubota Parts

Finding authentic components for machinery is crucial for maintaining performance and longevity. Using original parts ensures compatibility and reliability, reducing the risk of mechanical failures and extending the lifespan of equipment. This guide outlines effective methods to source these essential items.

Authorized Dealers and Service Centers

One of the most reliable sources for genuine components is through authorized distributors and service centers. These establishments often have direct access to the manufacturer’s inventory and can provide advice on the correct parts for your specific model. Additionally, they may offer warranties on their products, giving you peace of mind with your purchase.

Online Marketplaces and Manufacturer Websites

The internet has made it easier to locate original components. Reputable online platforms and official manufacturer websites typically feature catalogs with detailed descriptions and specifications. Always verify the authenticity of the seller and look for reviews from other customers to ensure a secure transaction. Utilizing these resources can save time and help you find the precise components you need.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires regular upkeep and attention. By adhering to a structured maintenance routine, you can significantly extend the lifespan of your equipment and enhance its performance. Below are some essential practices to consider.

- Regular Inspections: Conduct routine checks for wear and tear. Look for any signs of damage or irregularities that could indicate potential issues.

- Fluid Changes: Replace engine oil and other fluids at recommended intervals to ensure smooth operation and prevent corrosion.

- Filter Maintenance: Regularly clean or replace air, oil, and fuel filters to maintain optimal airflow and fuel efficiency.

- Belts and Hoses: Inspect belts and hoses for cracks or fraying. Replace any that show signs of deterioration to avoid breakdowns.

- Cleaning: Keep the exterior and engine compartment clean to prevent dirt accumulation, which can lead to overheating and other issues.

Implementing these strategies not only helps in avoiding costly repairs but also ensures that your machinery operates at peak efficiency. Consistent attention to detail will lead to improved performance and a longer service life.

Repair Techniques for V2203 Parts

Efficient restoration of engine components requires careful analysis and precise application of various techniques. Understanding the mechanical structure and knowing the right procedures can extend the lifespan of individual elements, reducing overall wear and tear.

Preparation Before Disassembly

Before starting the repair process, it’s crucial to ensure that the work area is clean and organized. This prevents contamination of sensitive parts and allows for a smoother workflow. Proper tools should be prepared and the component in question should be inspected thoroughly for any signs of external damage.

- Secure the machinery to prevent accidental movement.

- Identify key areas that may need lubrication or tightening.

- Use protective gear to avoid injury during disassembly.

Effective Reassembly Tips

Once the damaged areas have been repaired or replaced, it’s important to reassemble the components methodically. Tightening bolts and securing parts in the correct sequence ensures smooth operation and prevents future malfunctions.

- Follow the original order of assembly to avoid mistakes.

- Use torque specifications to avoid over-tightening.

- Test the system after assembly to check for proper alignment and function

Resources for Further Research

Exploring comprehensive materials can greatly enhance understanding and knowledge regarding machinery components. Various resources are available for enthusiasts and professionals alike, offering insights into maintenance, operation, and troubleshooting. Engaging with these materials can provide valuable information and aid in effective decision-making.

Online Platforms

Numerous websites and forums are dedicated to machinery enthusiasts, where individuals can exchange knowledge and experiences. These platforms often feature detailed guides, user-generated content, and community support, making them an excellent starting point for anyone seeking information.

Books and Manuals

Printed literature remains a reliable source of detailed information. Technical books and user manuals often include in-depth explanations of components, schematics, and maintenance procedures. Investing in such resources can facilitate a deeper understanding of mechanical systems and their functions.