Proper upkeep of machinery involves a clear understanding of its internal structure. By examining detailed illustrations, users can quickly identify key elements and understand how different sections connect. This approach simplifies repairs and replacements, ensuring that the equipment continues to function smoothly over time.

Having a visual reference helps in pinpointing specific areas that might require attention. It also aids in troubleshooting, as users can easily see the relationships between various elements, enabling faster diagnosis and resolution of issues.

Whether for routine upkeep or more complex adjustments, these visual guides are essential tools that support efficient and precise work. They provide a clear roadmap for anyone looking to ensure optimal performance and long-lasting durability.

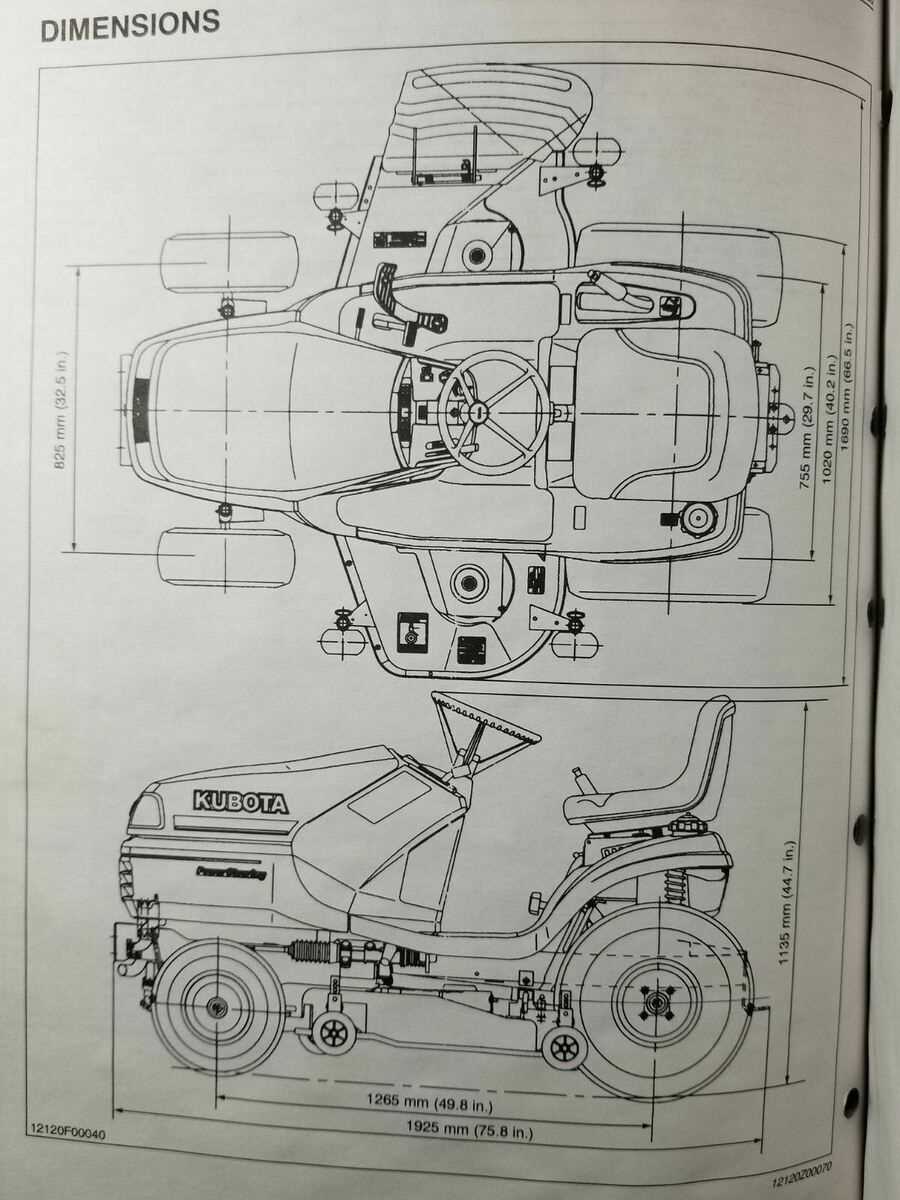

Essential Components of the Kubota TG1860

This machine is built with a series of vital mechanisms that work together to ensure its smooth operation and long-lasting performance. Each element plays a crucial role in maintaining overall efficiency, reliability, and user comfort.

Key Mechanical Elements

- Engine System: The powerhouse of the equipment, delivering the energy needed for all functions, while optimizing fuel usage for sustained performance.

- Transmission: Responsible for seamless power distribution, ensuring a smooth drive and adapting to different speed requirements on various terrains.

- Cooling Mechanism: Keeps the core components at optimal temperature, preventing overheating during prolonged use.

- Steering Assembly: Provides precise control, enhancing maneuverability in both tight and open areas.

Structural and Operational Components

- Chassis: Offers a sturdy foundation, supporting all other systems and ensuring durability in various working conditions.

- Hydraulic Systems: Allow for smooth operation of key attachments and enhance overall functionality.

- Seat and Controls: Designed for operator comfort, these components ensure that the user can easily access and control the machine’s functions.

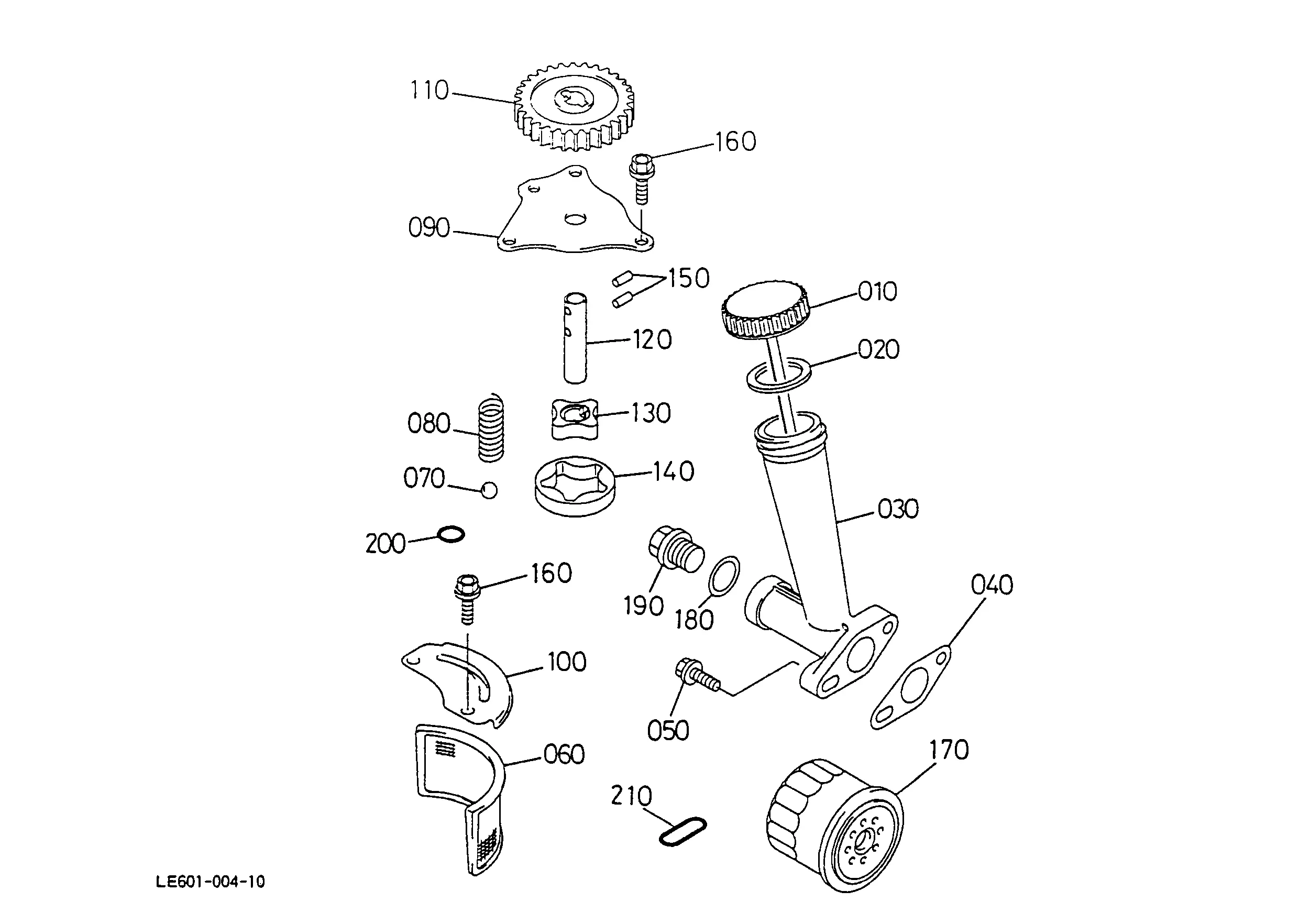

Understanding the Engine Layout

The configuration of the engine plays a crucial role in ensuring efficient performance and ease of maintenance. A clear understanding of its structure allows for better troubleshooting and long-term upkeep. This section explores the fundamental components and their arrangement within the engine, focusing on their relationship to one another.

Key Components of the Engine

Within the engine, several essential elements work in unison to provide power and functionality. The placement of each component is designed to maximize efficiency. These include the cylinders, which generate power through combustion, and the intake and exhaust systems, which regulate the flow of air and gases. Proper positioning of these parts ensures optimal performance.

Cooling and Lubrication Systems

Maintaining a stable operating temperature is vital to engine health, and this is achieved through the cooling system. The cooling mechanism circulates fluids to manage heat produced during operation. Equally important is the lubrication system, which reduces friction between moving parts, ensuring smooth functioning and preventing wear. Both systems are strategically located to maintain balance within the engine’s structure.

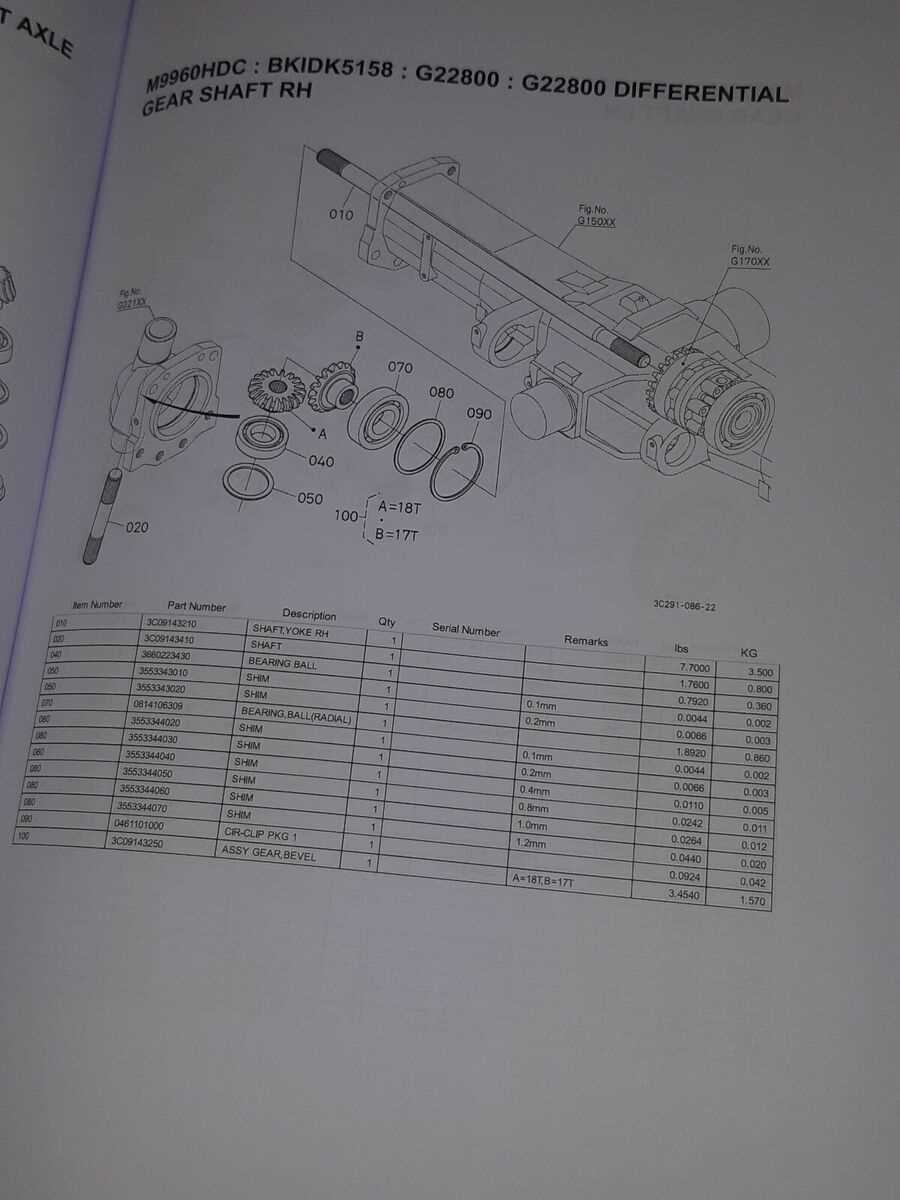

Transmission System Overview

The transmission system plays a crucial role in ensuring smooth and efficient power transfer from the engine to the wheels. By managing speed and torque, this system allows the vehicle to adapt to various terrains and operational demands, providing optimal performance under different conditions.

There are several key components that contribute to the functioning of the transmission system:

- Gear Mechanism: This component adjusts the speed and torque ratio, enabling the machine to move efficiently at various speeds.

- Hydraulic System: The hydraulic fluid helps in controlling the force applied to the gears, making gear shifts smoother and more responsive.

- Drive Shaft: This transfers the mechanical power from the engine to the wheels, ensuring consistent movement.

- Clutch Assembly: The clutch engages and disengages the power flow, allowing the machine to change gears seamlessly.

Understanding how these elements interact is essential for maintaining performance and prolonging the lifespan of the

Blade and Mower Deck Configuration

The arrangement of the cutting blade and the mowing deck is crucial for achieving an efficient and even cut. The deck not only houses the blade but also plays a role in directing the flow of clippings and ensuring proper grass disposal. To maximize performance, it’s essential to understand how these components interact and how their alignment affects the overall quality of the mowing process.

- Blade Positioning: The placement of the blade within the deck is designed to ensure uniform cutting height and minimize grass tearing. Proper alignment is key to avoiding uneven cuts and ensuring smooth operation.

- Deck Size: The dimensions of the deck influence the width of the cut and the ability to handle various terrains. Larger decks cover more ground, while smaller ones allow for greater maneuverability in tight spaces.

- Clipping Discharge: The deck typically features mechanisms for discharging or collecting grass clippings, which may include side or rear discharge options, or a collection bag for ease of disposal.

- Height Adjustment: Most systems allow for easy adjustment of the cutting height, offering versatility for different grass types and conditions. This ensures that the mower can adapt to varying lawn care needs.

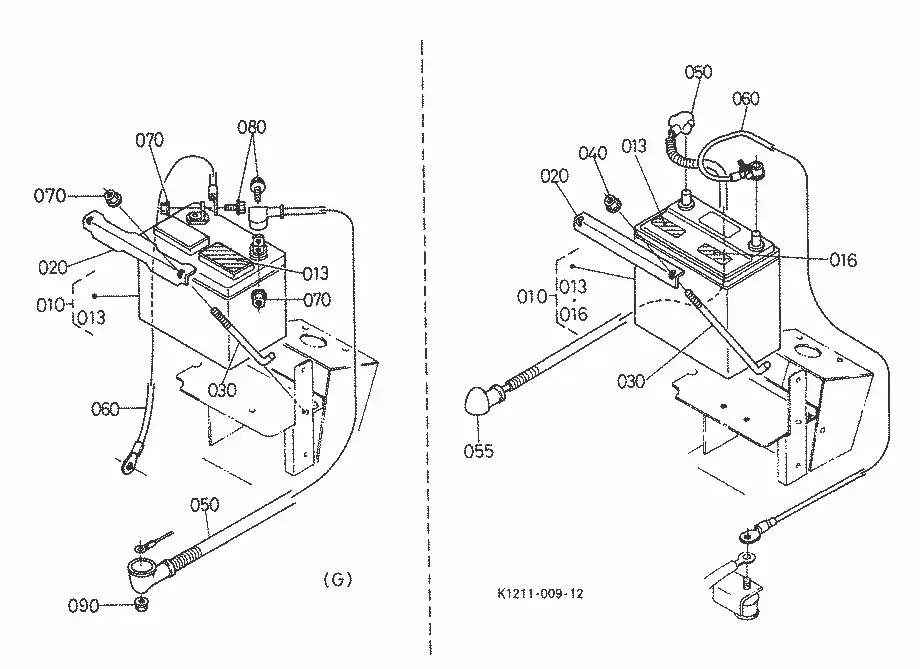

Electrical System Breakdown

The electrical system is a crucial aspect of the machine’s functionality, responsible for powering various components and ensuring seamless operation. Understanding the arrangement and connections of electrical elements helps in maintaining the system and troubleshooting potential issues.

- Battery and power distribution: The main source of energy, distributing current to key components like the ignition and lights.

- Wiring and connectors: These link different electrical components, providing the necessary pathways for power and signals.

- Fuses and relays: Protective elements that prevent overloads, ensuring the safety and durability of the system.

- Control switches: Allow the operator to manage functions like starting the engine or activating lights.

- Lighting and signaling: Responsible for visibility and communication, crucial for safe operation, especially in low-light conditions.

By carefully inspecting and maintaining these elements, the reliability of the machine’s electrical system can be preserved, preventing unexpected malfunctions and prolonging overall lifespan.

Fuel System and Filters

The fuel system plays a crucial role in ensuring optimal engine performance and longevity. It is responsible for delivering fuel to the combustion chamber, where it mixes with air and ignites to produce power. This section provides an overview of the essential components involved in fuel delivery, as well as the various filtration elements that help maintain the system’s efficiency.

Key Components of the Fuel System

At the heart of the fuel system is the fuel tank, which stores the necessary liquid for the engine’s operation. Fuel is then drawn through lines and delivered to the engine by a pump. Along this pathway, several critical components ensure that the fuel remains clean and free of impurities.

Filtration Elements

Filters are vital for protecting the engine from harmful contaminants that can damage components and reduce efficiency. Regular inspection and replacement of filters are essential maintenance tasks that should not be overlooked.

| Component | Description |

|---|---|

| Fuel Tank | Stores the fuel required for operation. |

| Fuel Pump | Transfers fuel from the tank to the engine. |

| Fuel Filter | Removes contaminants from the fuel before it reaches the engine. |

| Fuel Lines | Convey fuel between components of the system. |

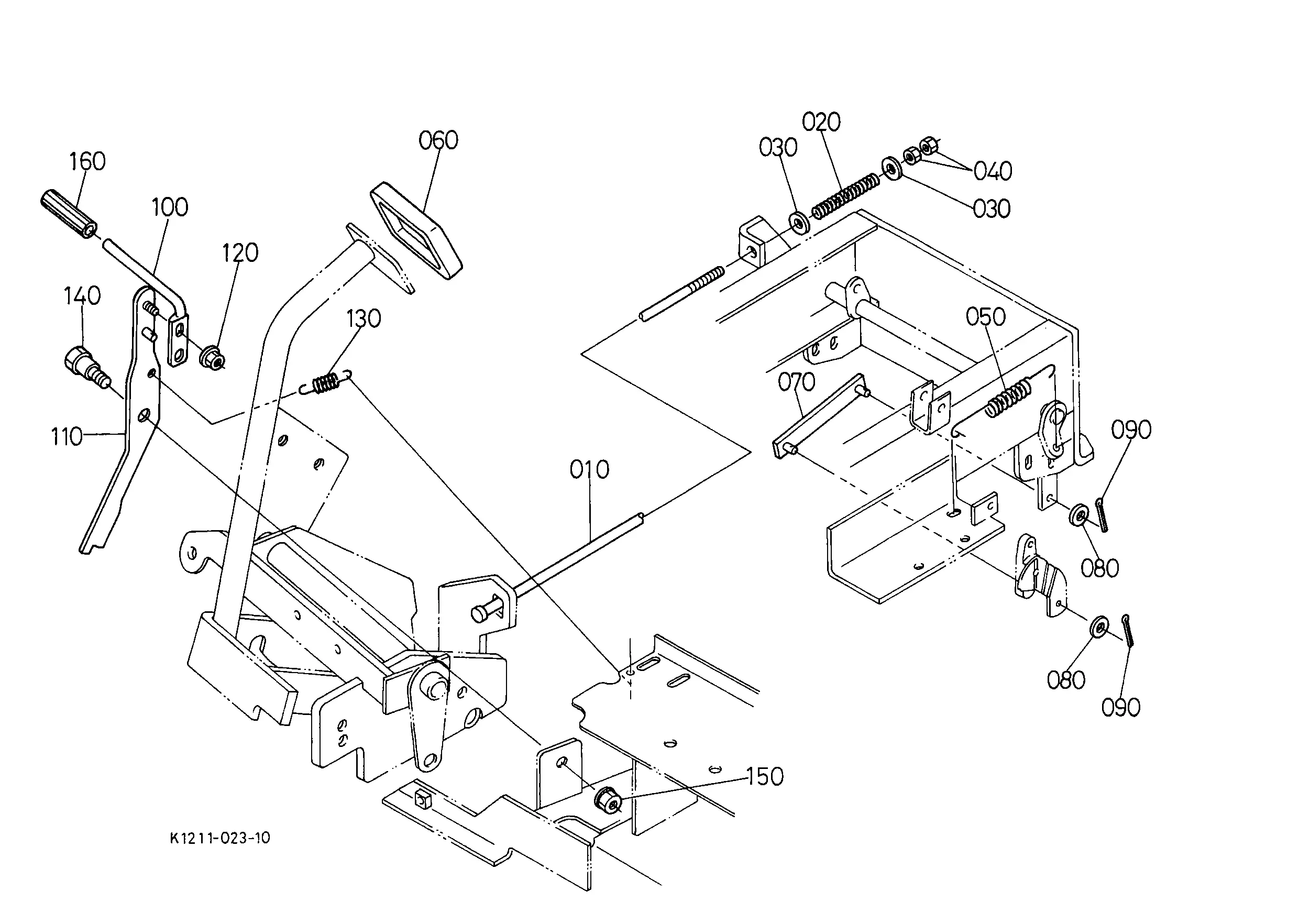

Hydraulic Controls and Linkages

The hydraulic control system is essential for managing various functions in agricultural machinery, ensuring efficient operation and precise movements. This system utilizes fluid pressure to transmit power and facilitate the movement of linkages and implements, allowing for enhanced control over tasks such as lifting and tilting.

Effective hydraulic controls consist of various components that work together seamlessly. Understanding these elements is crucial for maintaining optimal functionality and ensuring the longevity of the equipment.

| Component | Description |

|---|---|

| Hydraulic Cylinder | Converts hydraulic energy into mechanical force, allowing for lifting and lowering of implements. |

| Control Valve | Regulates the flow of hydraulic fluid, directing it to specific components as needed. |

| Hydraulic Lines | Transport hydraulic fluid between components, ensuring effective pressure delivery. |

| Reservoir | Stores hydraulic fluid, maintaining an adequate supply for the system’s operation. |

| Linkage Arms | Connect various components, facilitating movement and allowing for adjustments in positioning. |

Regular inspection and maintenance of hydraulic controls are vital for preventing leaks and ensuring consistent performance. Familiarity with the functions of each component enables operators to troubleshoot issues effectively and keep machinery in peak condition.

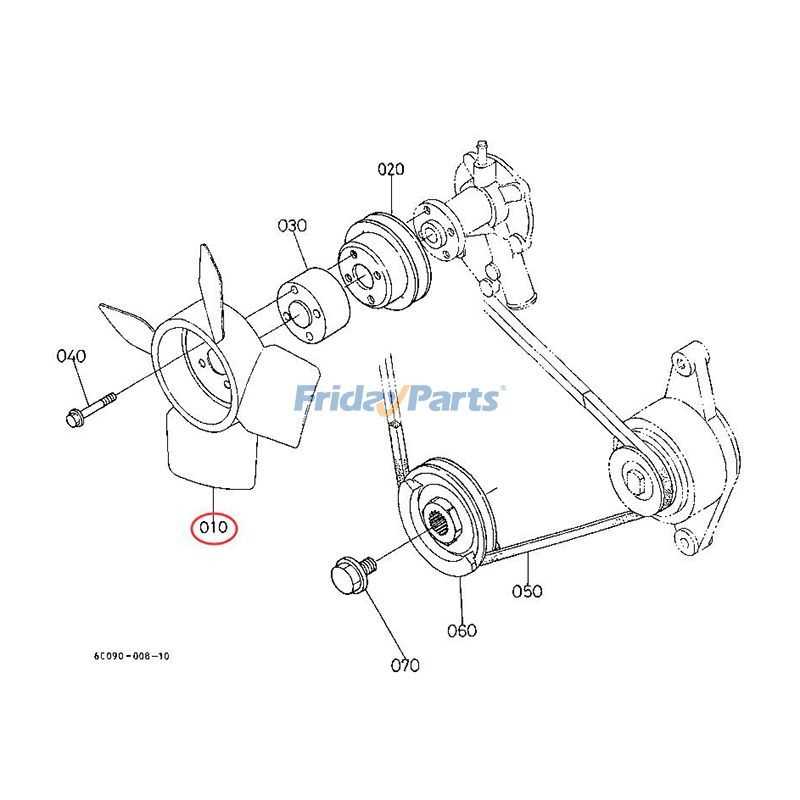

Cooling System Parts Diagram

The cooling mechanism within a machinery setup is crucial for maintaining optimal operating temperatures. Understanding the components involved can help ensure efficient performance and longevity. This section provides an overview of the essential elements found in the cooling arrangement, illustrating their functions and interconnections.

Key Components

At the heart of the cooling system lies the radiator, which dissipates heat from the fluid circulating through the engine. Additionally, the water pump plays a vital role in maintaining the flow of coolant, ensuring that all parts receive adequate thermal regulation. Hoses connect these key components, allowing for the seamless transfer of coolant throughout the system.

Additional Elements

Other notable components include the thermostat, which regulates the temperature by controlling coolant flow, and the expansion tank, which accommodates fluctuations in coolant volume. Proper maintenance and understanding of these parts are essential for the efficient functioning of the entire cooling arrangement.

Maintenance Tips for Key Parts

Regular upkeep of essential components is crucial for the longevity and efficiency of your equipment. Proper care not only enhances performance but also minimizes the risk of breakdowns. Here are some valuable practices to ensure that your machinery operates smoothly and reliably.

- Lubrication: Apply appropriate lubricants to moving parts regularly. This reduces friction and wear, promoting seamless operation.

- Inspection: Frequently check components for signs of wear or damage. Early detection of issues can prevent more extensive repairs later.

- Cleaning: Keep parts clean from dirt and debris. A clean environment helps maintain functionality and prevents blockages that could hinder performance.

- Adjustment: Ensure that all adjustable elements are properly calibrated. Regular adjustments help maintain optimal performance levels.

- Replacement: Stay vigilant about replacing worn or damaged parts. Timely replacements are vital to maintaining the equipment’s reliability.

By incorporating these maintenance practices into your routine, you can significantly extend the life of critical components and ensure consistent performance in your operations.