In the world of machinery, comprehending the intricate relationships between various elements is crucial for optimal functionality. This knowledge empowers operators and technicians to maintain and troubleshoot equipment effectively.

Visual representations serve as invaluable tools for anyone seeking to grasp the layout and interaction of mechanical parts. By examining these illustrations, users can quickly identify specific sections and understand their roles within the system.

As we delve deeper into this topic, we will explore the ultimate guide to these essential schematics, ensuring that you have the resources necessary to enhance your operational knowledge and skills.

Kubota L3301 Overview

This section provides a comprehensive introduction to a robust and efficient utility vehicle designed for various agricultural and construction tasks. Known for its reliability and versatility, this machine has become a preferred choice among professionals and enthusiasts alike.

The model features an advanced engine that ensures optimal performance and fuel efficiency, allowing users to tackle demanding jobs with ease. Its compact size makes it suitable for both tight spaces and open fields, enhancing its usability across different terrains.

| Feature | Description |

|---|---|

| Engine Type | Powerful diesel engine with high torque output |

| Transmission | Seamless gear shifting for enhanced control |

| Hydraulic System | Efficient hydraulic lift capacity for various attachments |

| Operator Comfort | Ergonomic design with easy-to-use controls |

This vehicle stands out due to its durability and low maintenance requirements, making it an ideal investment for those seeking a reliable workhorse. Whether for farming, landscaping, or other heavy-duty applications, this model proves to be an indispensable asset.

Importance of Parts Diagrams

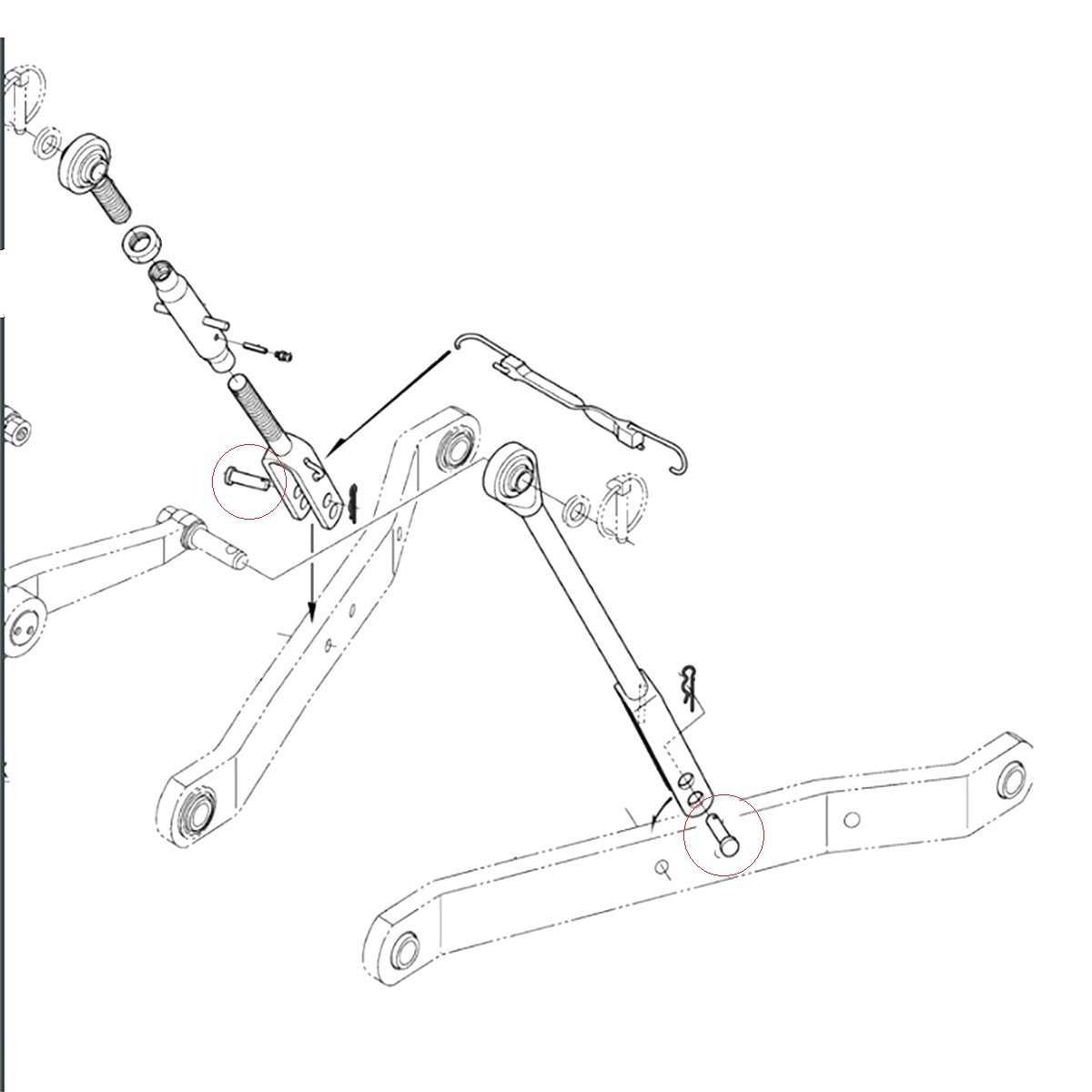

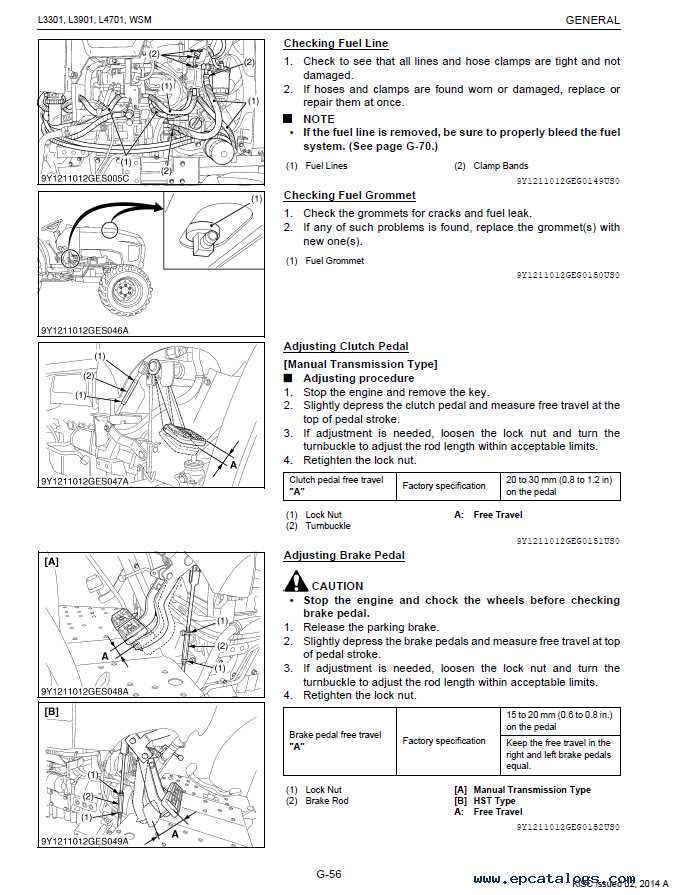

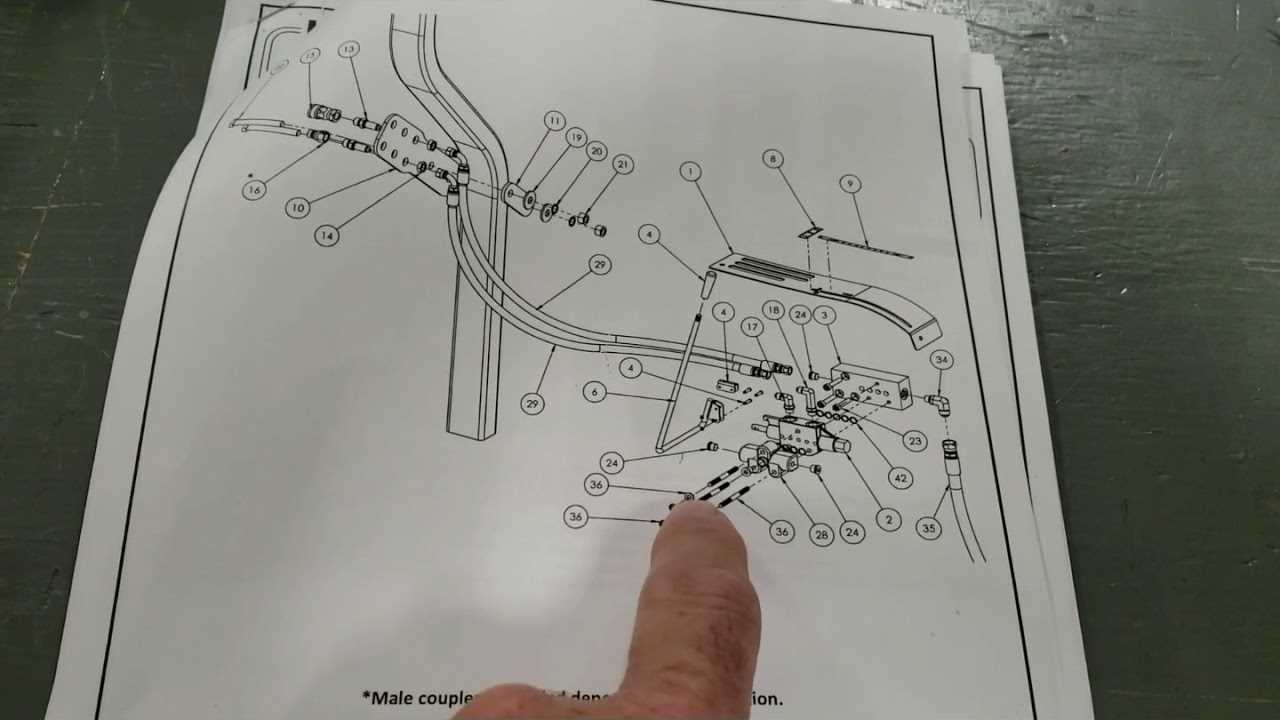

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations play a key role in facilitating this understanding, allowing users to quickly identify individual elements and their relationships within the system.

These visual aids offer several significant benefits:

- Enhanced Clarity: Diagrams provide a clear view of how different components fit together, reducing confusion during assembly or disassembly.

- Efficient Troubleshooting: By pinpointing specific areas, users can more easily diagnose issues and identify which parts may need replacement or repair.

- Streamlined Maintenance: Knowing the exact locations and functions of various components helps technicians perform routine checks and maintenance tasks effectively.

- Improved Communication: Visuals aid in discussions among team members, ensuring everyone is on the same page regarding repairs and upgrades.

In summary, leveraging these graphical representations not only simplifies the repair process but also enhances overall efficiency and accuracy in machinery upkeep.

Common Parts for Kubota L3301

This section highlights essential components commonly found in the machinery model discussed. Understanding these elements is crucial for maintenance and efficient operation, ensuring longevity and reliability in performance.

- Engine Assembly

- Transmission System

- Hydraulic Components

- Electrical Wiring

- Cooling System

Each of these components plays a vital role in the overall functionality of the equipment. Proper knowledge of their function and interconnections is important for troubleshooting and repairs.

- Engine Assembly: Vital for power generation, it includes key elements like the cylinder head and crankshaft.

- Transmission System: Facilitates movement and control, comprising gears and linkages.

- Hydraulic Components: Essential for lifting and tilting, involving pumps and cylinders.

- Electrical Wiring: Powers the ignition and various sensors, including batteries and alternators.

- Cooling System: Maintains optimal operating temperatures, featuring radiators and coolant hoses.

Having access to quality replacements for these parts ensures seamless operation and minimal downtime during use. Regular inspection and timely maintenance can prevent unexpected failures.

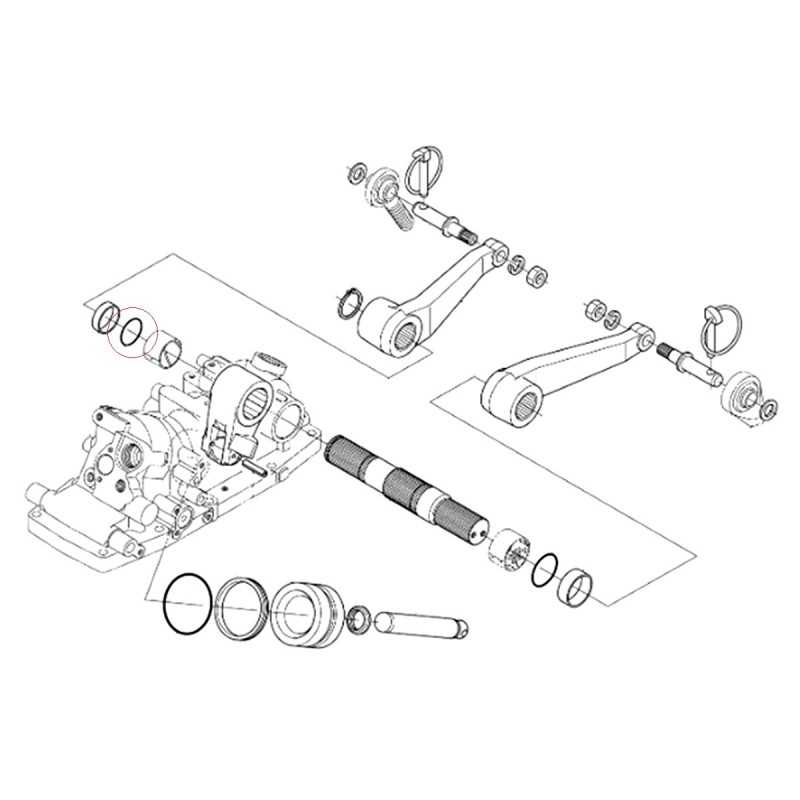

Understanding Hydraulic System Components

The hydraulic system plays a crucial role in the functionality of machinery, enabling efficient power transfer and control. By utilizing fluid pressure, these systems facilitate a variety of tasks, making them essential in numerous applications. This section explores the primary elements that constitute hydraulic systems and their respective functions.

| Component | Description |

|---|---|

| Hydraulic Pump | Converts mechanical energy into hydraulic energy by moving fluid through the system. |

| Hydraulic Cylinder | Transforms hydraulic energy back into mechanical energy, producing linear motion. |

| Hydraulic Fluid | Transmits power throughout the system while also providing lubrication and cooling. |

| Control Valve | Regulates the flow and direction of the hydraulic fluid, allowing for precise control of the system. |

| Reservoir | Stores excess hydraulic fluid, ensuring a constant supply and facilitating cooling. |

Each of these components works in concert to ensure the smooth operation of the hydraulic system, underscoring the importance of understanding their roles for effective maintenance and troubleshooting.

Engine Specifications and Parts

This section focuses on the key characteristics and components of the power unit used in agricultural machinery. Understanding these elements is crucial for optimal performance and maintenance, ensuring that the engine operates efficiently under various conditions.

Engine Characteristics

The engine typically features a four-cylinder design, providing a balance of power and efficiency. With a displacement of around 1.5 liters, it delivers robust torque and horsepower, making it suitable for a range of tasks. The cooling system generally employs liquid coolant, enhancing longevity and reliability.

Essential Components

Key components include the fuel injection system, which optimizes combustion, and the air filter, ensuring clean airflow to the engine. Additionally, the oil filter plays a vital role in maintaining engine health by preventing contaminants from causing wear. Regular inspection and replacement of these parts can significantly enhance the engine’s overall performance.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and efficient operation of machinery. Implementing a few simple practices can significantly enhance performance and extend the lifespan of your equipment.

Routine Checks

- Inspect fluid levels frequently, including oil and coolant.

- Examine filters and replace them as needed to maintain optimal function.

- Check tire pressure and tread condition for better traction and safety.

Proper Storage

- Keep machinery in a sheltered area to protect it from weather elements.

- Clean the equipment thoroughly before storage to prevent rust and corrosion.

- Disconnect batteries if storing for extended periods to avoid drainage.

Where to Find Replacement Parts

When it comes to maintaining machinery, sourcing quality components is crucial for optimal performance. Various avenues are available for those seeking to acquire necessary items, ensuring that equipment remains in excellent condition. Understanding where to look can save both time and money.

Online Retailers

The internet offers a vast marketplace where numerous vendors provide an extensive selection of components. Websites specializing in agricultural machinery often have detailed catalogs, making it easy to search for specific items. Customer reviews can also help gauge the reliability of sellers.

Local Dealerships

Visiting nearby dealerships can yield not only the components you need but also expert advice. Representatives can assist in identifying the correct items and may offer additional services such as installation. Building a relationship with local suppliers can be beneficial in the long run.

Benefits of Using Genuine Parts

When it comes to maintaining machinery, selecting authentic components is crucial for optimal performance and longevity. Genuine replacements are designed specifically for the equipment, ensuring a perfect fit and compatibility. This choice can lead to significant advantages in terms of efficiency and reliability.

Quality Assurance: Authentic components undergo rigorous testing and quality control measures. This ensures they meet the highest standards, reducing the likelihood of failures that can arise from inferior alternatives.

Enhanced Performance: Using original parts often leads to improved efficiency and functionality. These components are engineered to work seamlessly with the machinery, allowing it to operate at its best and maximizing productivity.

Long-term Cost Savings: While the initial investment in genuine items may be higher, the durability and reliability they offer can lead to lower maintenance costs over time. Avoiding frequent replacements and repairs ultimately saves money.

Warranty Protection: Many manufacturers provide warranties for their authentic components, offering peace of mind. Using non-genuine items can void warranties, leaving operators vulnerable to unforeseen expenses.

Support and Expertise: Purchasing genuine components often comes with access to knowledgeable support. Manufacturers can provide guidance on installation and maintenance, ensuring that users have the information they need for optimal operation.