In the realm of small engine maintenance, a comprehensive understanding of the various elements and their configurations is essential for optimal performance. Knowing how these components interact within the machinery can significantly enhance troubleshooting efforts and ensure efficient operation.

Each unit is designed with a specific arrangement of components that work together seamlessly. This arrangement allows for the effective functioning of the engine, making it crucial for users to familiarize themselves with each part’s role and placement. By grasping the intricacies of these mechanisms, one can better maintain and service their equipment.

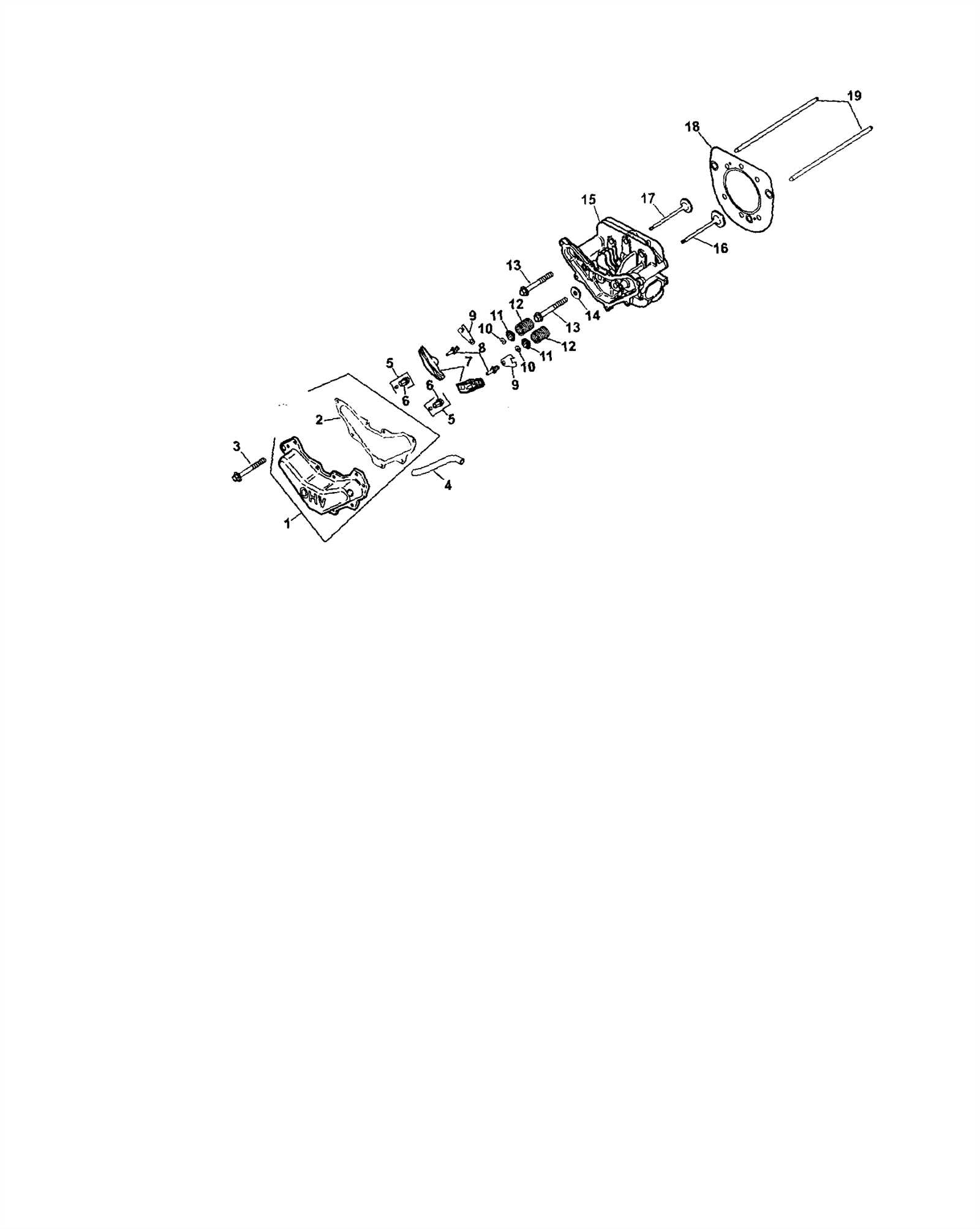

Whether for routine upkeep or extensive repairs, having a clear visual representation of the layout aids in identifying any issues that may arise. This knowledge empowers users to approach maintenance tasks with confidence, ensuring longevity and reliability in their engines.

Understanding the essential elements of a small engine system is crucial for effective maintenance and troubleshooting. Each component plays a specific role, contributing to the overall functionality and efficiency of the machinery. Here, we will explore several vital components and their respective functions within the system.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and is responsible for the combustion process, converting fuel into mechanical energy. |

| Piston | Moves up and down within the cylinder, creating the necessary pressure for combustion and driving the crankshaft. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion, powering the engine and connected systems. |

| Fuel System | Delivers the appropriate amount of fuel to the combustion chamber, ensuring optimal performance and efficiency. |

| Ignition System | Provides the spark needed to ignite the air-fuel mixture, initiating the combustion cycle. |

| Cooling System | Maintains an optimal operating temperature, preventing overheating and ensuring the longevity of the engine. |

| Oil System | Lubricates moving parts to reduce friction and wear, contributing to the smooth operation and durability of the engine. |

Exploring Engine Assembly Details

The internal structure of a small power unit is crucial for understanding its performance and maintenance. This section delves into the various components that comprise the assembly, highlighting their roles and interconnections.

Key elements of the engine assembly include:

- Cylinder Block: The main body housing the internal components, providing strength and durability.

- Piston: A vital part that moves up and down within the cylinder, creating the necessary compression for ignition.

- Crankshaft: Transforms linear motion from the piston into rotational energy, driving the output shaft.

- Connecting Rod: Links the piston to the crankshaft, transferring motion between them.

- Valves: Regulate the intake of fuel and air as well as the expulsion of exhaust gases, crucial for the combustion cycle.

- Camshaft: Controls the timing of valve openings and closings, ensuring optimal engine function.

Understanding these components helps in diagnosing issues, performing repairs, and ensuring the longevity of the engine. Regular maintenance can prevent common problems and enhance performance.

For a comprehensive understanding of how these elements work together, it’s beneficial to consult detailed visual aids that illustrate their arrangement and functions.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular attention to key components ensures optimal performance and helps avoid premature failures. By following a few straightforward guidelines, you can significantly enhance durability and reliability.

First and foremost, routinely check and replace filters to maintain airflow and efficiency. Clogged filters can lead to overheating and reduce functionality. Additionally, ensure that fluids are at appropriate levels and replace them as recommended in the manual. Regular fluid changes help to keep internal mechanisms lubricated and operating smoothly.

Another vital aspect is to inspect and tighten any loose connections. Vibration during operation can lead to components loosening over time, which may result in operational issues. Additionally, keeping the exterior clean prevents debris accumulation, which can obstruct airflow and cooling.

Finally, adhering to a consistent schedule for inspections will help identify potential issues before they escalate. By dedicating time to maintenance, you can ensure that your machinery remains in excellent working condition for years to come.

Identifying Replacement Parts Easily

When it comes to maintaining outdoor machinery, recognizing the necessary components for repair can significantly streamline the process. Efficient identification of these elements ensures that your equipment operates smoothly, reducing downtime and enhancing productivity.

Begin by consulting the manufacturer’s guide, which typically includes illustrations and descriptions of each component. This resource is invaluable for understanding the layout and function of the various items. Furthermore, online resources, such as forums and product websites, can provide insights and recommendations from other users who have navigated similar repairs.

Another effective strategy is to take note of part numbers whenever possible. These unique identifiers facilitate quick searches in catalogs or online databases, helping you locate the right replacements efficiently. Visual aids like images and videos can also enhance comprehension, allowing you to verify that the components you select match your requirements.

In addition, connecting with local suppliers or service centers can offer personalized assistance. Experienced professionals can guide you in identifying and sourcing the correct items, ensuring you have everything needed for a successful repair. Utilizing these approaches will make the task of finding suitable components straightforward and effective.

Tools Needed for Disassembly

When undertaking the task of dismantling an engine component, having the right tools is essential for a smooth process. A well-equipped workspace allows for efficient handling of various parts, ensuring that the disassembly can be performed safely and effectively.

Essential Tools

To start, a set of standard wrenches and sockets is crucial for loosening bolts and nuts. Additionally, pliers and screwdrivers of varying sizes will aid in removing small fasteners and securing elements. A torque wrench may also be necessary to ensure that components are reassembled to the manufacturer’s specifications.

Specialty Tools

In some cases, specialized tools such as an impact wrench or a puller might be needed to tackle stubborn components. Investing in these tools can significantly reduce the time and effort required during disassembly, making the overall process more efficient.

Troubleshooting Common Issues

When working with small engines, various complications may arise that can hinder performance. Identifying and resolving these issues promptly is essential to maintain the efficiency and longevity of the machine. This section provides insights into typical problems and their potential solutions.

Engine Won’t Start

If the engine fails to start, consider the following possible causes:

- Check the fuel level and quality.

- Inspect the ignition system for any defects.

- Examine the air filter for blockages.

- Ensure that all safety switches are engaged.

Uneven Performance

Inconsistent operation can be frustrating. Here are steps to diagnose the problem:

- Look for any leaks in the fuel lines.

- Inspect the spark plug for wear or damage.

- Check the carburetor for clogs.

- Assess the overall engine condition for any visible issues.

Where to Find Genuine Parts

When it comes to maintaining outdoor power equipment, sourcing authentic components is crucial for optimal performance and longevity. Using reliable suppliers ensures that the replacements meet the necessary specifications and standards required for your machine.

One of the best avenues for locating these components is through authorized dealers. These establishments typically carry a comprehensive inventory of high-quality items, ensuring compatibility with your equipment. Additionally, many dealers offer expert advice and support to help you identify the exact component needed.

Another option is to explore manufacturer websites, where you can find official listings of genuine items tailored to your specific model. This can provide peace of mind, knowing you are purchasing the right part from a trusted source.

For those looking for convenience, online retailers can also be a valuable resource. Numerous websites specialize in selling authentic components, often with detailed descriptions and diagrams to assist in making the right choice. Just ensure you select reputable sellers to avoid counterfeit products.

In summary, whether through authorized dealers, manufacturer sites, or reliable online platforms, there are multiple avenues available for finding genuine components that will help maintain the performance of your equipment.